25°C Cold Resistant Model: CIP Moscow Commercial Factory’s Innovation in Kitchen Appliances Technology Efficiency

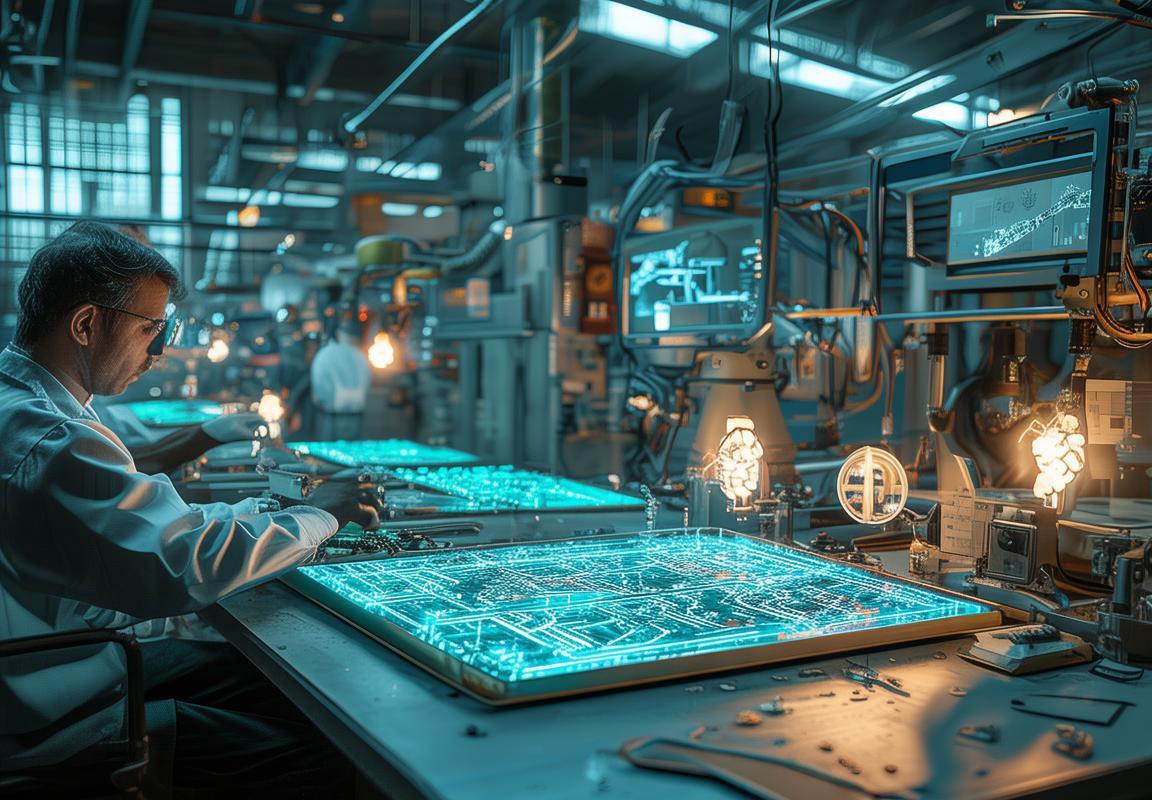

The -25°C cold-resistant model has revolutionized the kitchen appliance industry, offering resilience and efficiency in extreme climates. Developed by the innovative CIP Moscow commercial factory, these advanced appliances are engineered to withstand freezing temperatures, ensuring peak performance even in sub-zero environments. This technological breakthrough, combining robust construction with energy-efficient designs, has been warmly received by consumers seeking reliable kitchen solutions. As climate change reshapes landscapes, the demand for such cold-resistant kitchen appliances continues to grow, driven by their ability to adapt to challenging conditions while maintaining efficiency and performance, much like the cutting-edge technology and skilled craftsmanship at CIP Moscow.