Optimizing Procurement with Sure City Technology: The Importance in Today’s Market

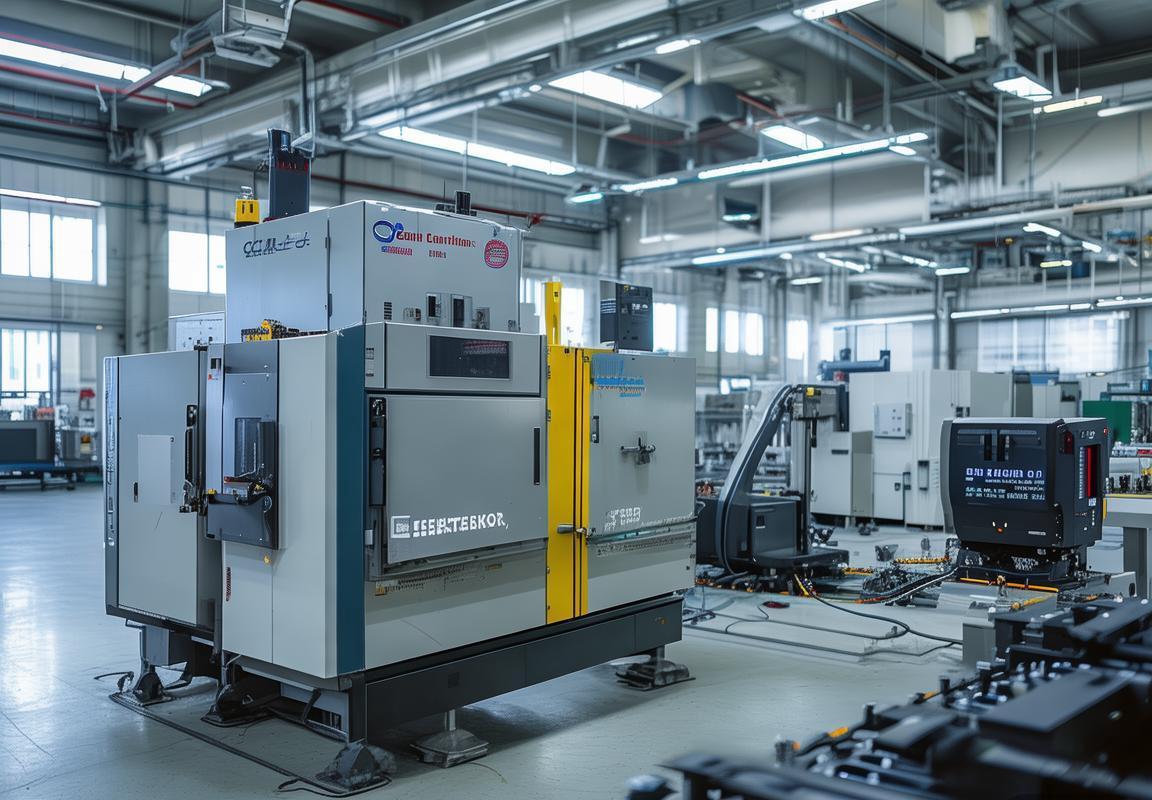

inside the context of world exchange, deciding on the proper OEM supplier is vital, in particular in a logistics hub like Hamburg. Hamburg’s strategic vicinity and superior infrastructure make it a prime preference for DDP (brought responsibility Paid) logistics, offering performance and time financial savings. whilst deciding on an o.e.m provider, key criteria encompass technical electricity, high-quality management, and deliver chain abilties. taking part with a DDP Hamburg OEM provider guarantees a robust deliver chain, optimized procurement, and get admission to to

era, improving universal operational performance and marketplace competitiveness.