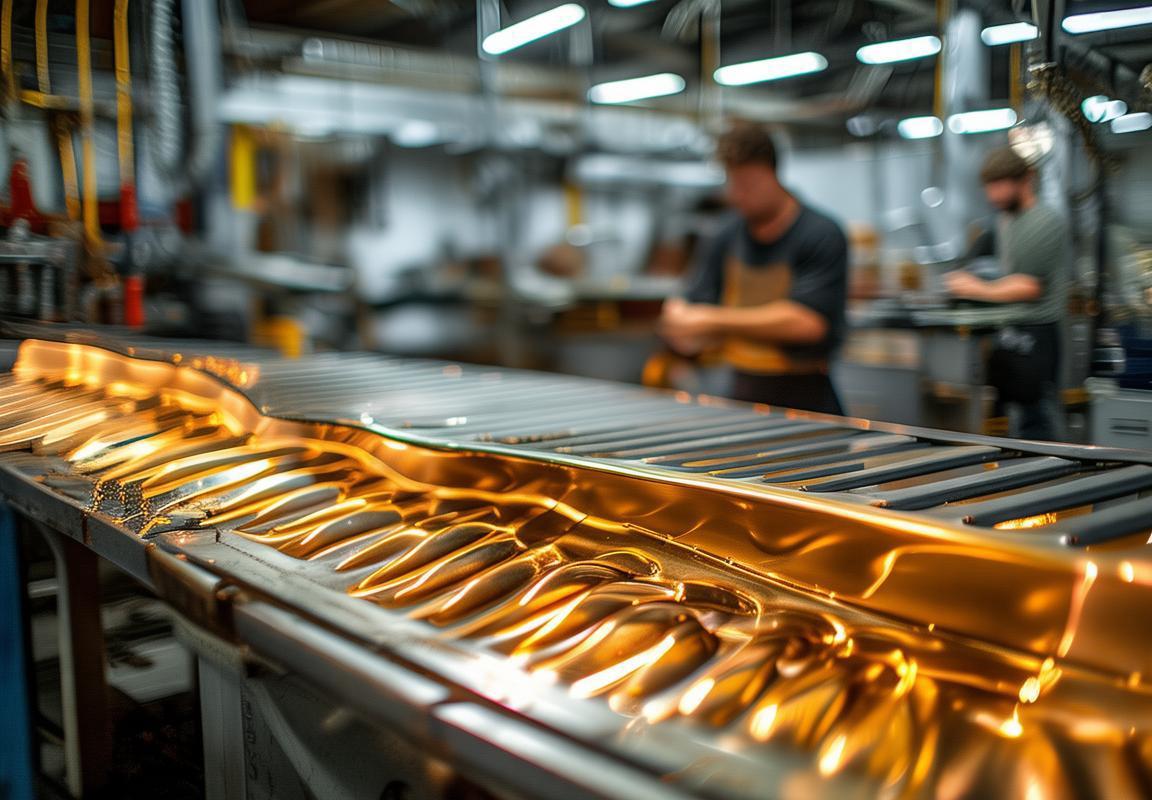

Continuous Operation Sandwich Grill Plant: Efficiency, Technology, and Modern Cooking Solutions

In the food industry, the continuous operation sandwich grill plant stands as a beacon of efficiency, leveraging advanced technology to ensure seamless, high-speed cooking. These plants represent a leap forward in production, churning out quality sandwiches with precision, meeting the growing demand for fast, fresh meals. Their non-stop operation, enhanced by cutting-edge automation and real-time monitoring, guarantees both speed and consistency, setting a new standard for foodservice excellence.