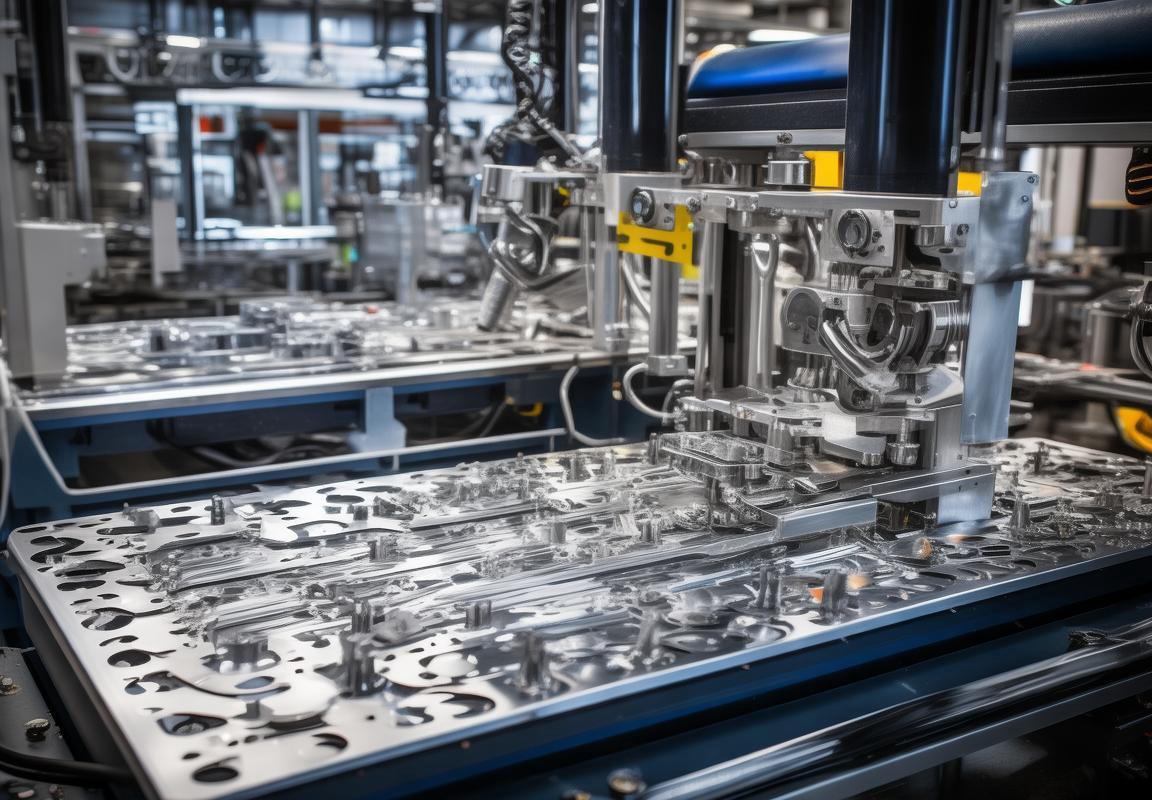

Efficiency and Versatility: Integrated Metal Stamping Technology for Lightweight Sandwich Plates

Integrated metal stamping has revolutionized the production of sandwich plates, offering unparalleled efficiency and versatility. This technology ensures precision in forming lightweight, strong panels, ideal for diverse applications. By optimizing material usage and streamlining the manufacturing process, integrated metal stamping reduces waste and production times, making it a cost-effective choice. Its adaptability to various materials and complex designs has propelled the technology forward, reinforcing its pivotal role in the advancement of sandwich plate technology.