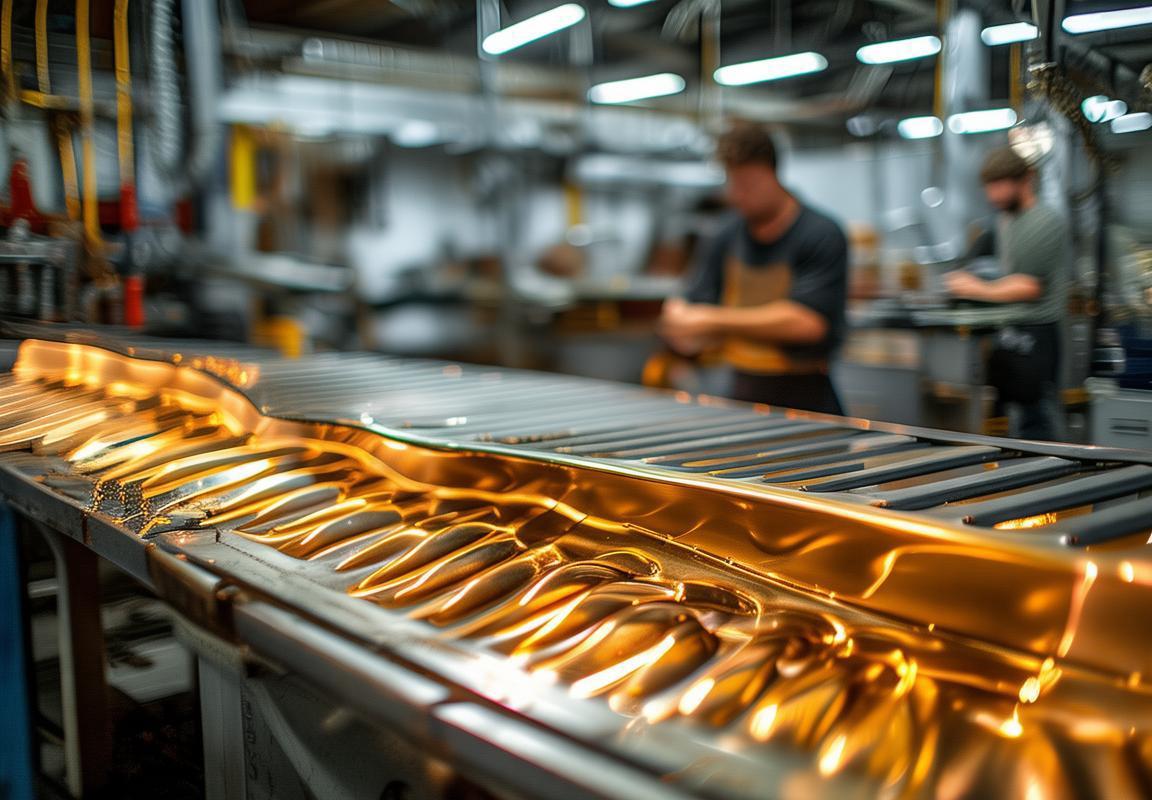

In-House Mold Making for Grills: Enhancing Efficiency and Benefits for Manufacturers

In-house mold making for grill production has revolutionized the industry, significantly enhancing efficiency and offering a multitude of benefits. By producing molds internally, manufacturers gain complete control over the design and quality of grill components, leading to more precise, durable, and aesthetically pleasing products. This approach not only speeds up production and reduces lead times but also allows for greater customization and cost savings. With the ability to iterate and refine molds quickly, manufacturers can respond swiftly to market demands and customer preferences, ensuring they stay competitive in the dynamic grill market. Overall, in-house mold making has become a game-changer for companies looking to optimize their production processes and deliver high-quality grills.