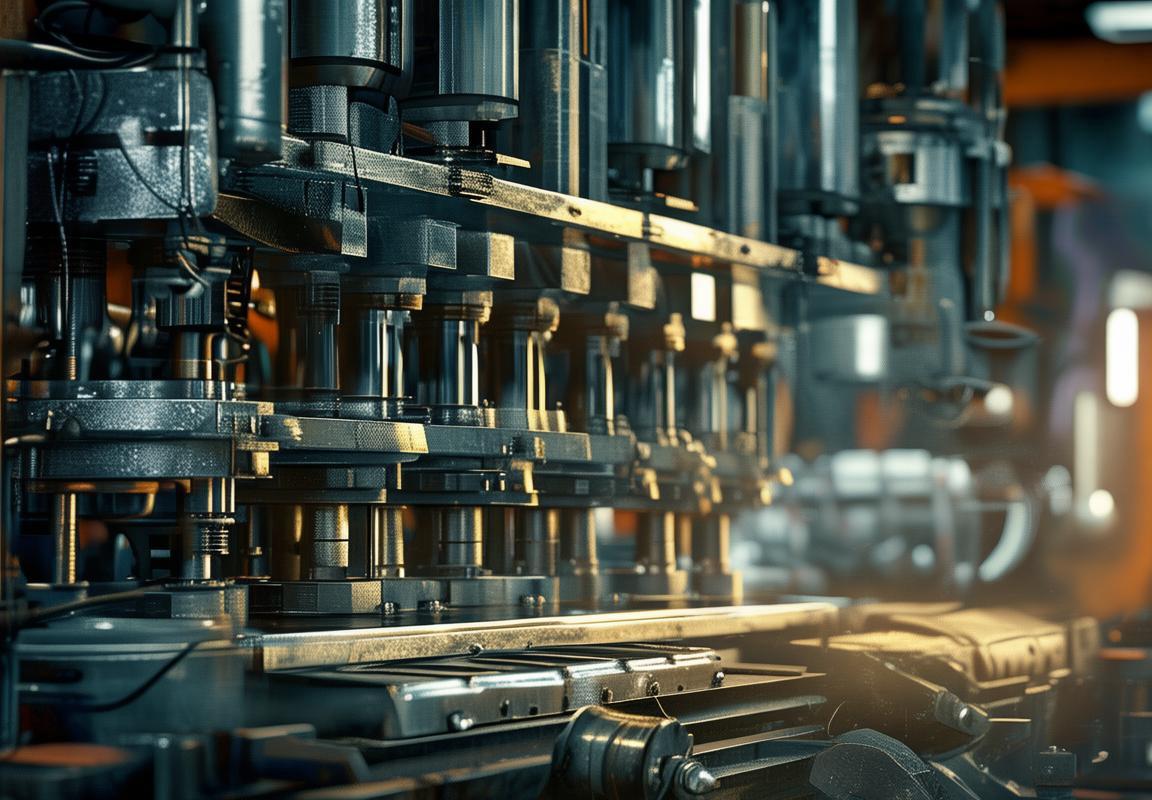

Sandwich Press Manufacturers: Ensuring Efficiency with Advanced Technology and Features

In the dynamic industrie, sandwich press manufacturers are crucial in ensuring efficiency through their cutting-edge technology and features. These manufacturers are pivotal in driving innovation, producing presses that not only enhance productivity but also cater to a range of industries from food processing to electronics. Their focus on advanced technology guarantees precision and reliability, with features like variable temperature controls, non-stick surfaces, and even Bluetooth connectivity. By prioritizing efficiency and quality, these manufacturers are pivotal in meeting the diverse needs of the market.