CE-EMC Compliant 2200W Devices: Key Features, Efficiency, and Manufacturer Insights

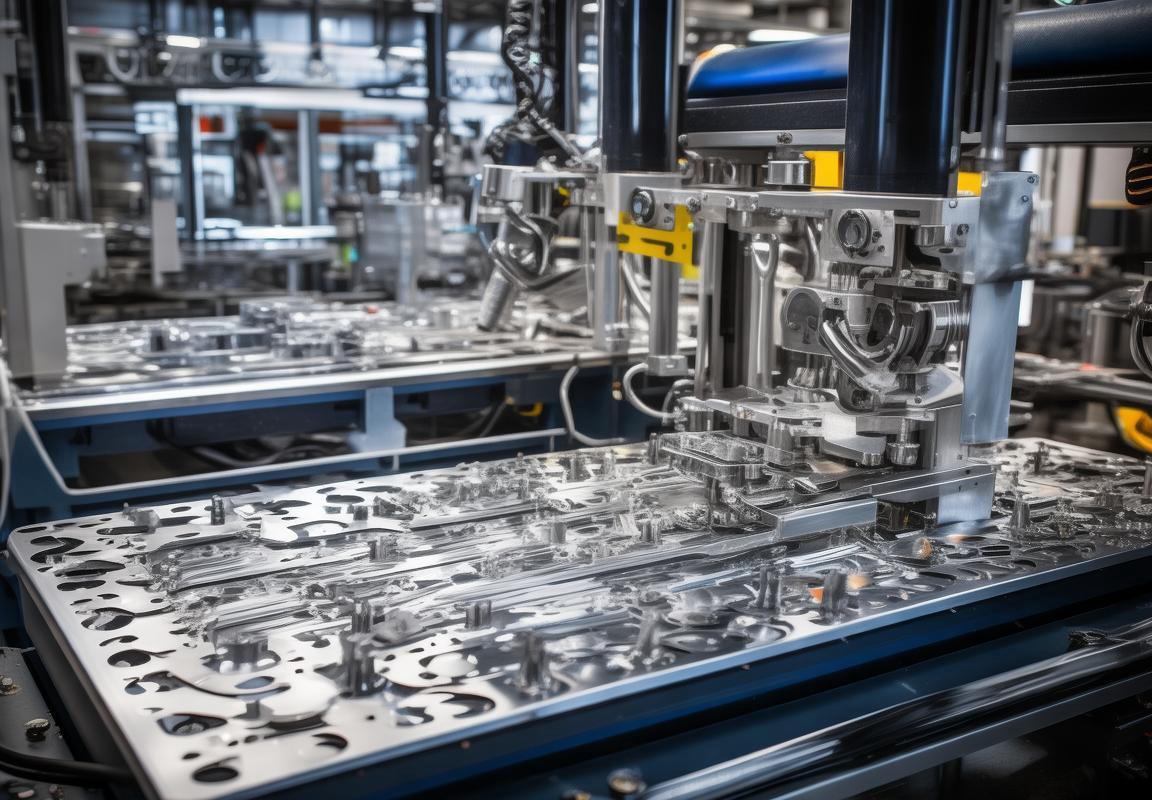

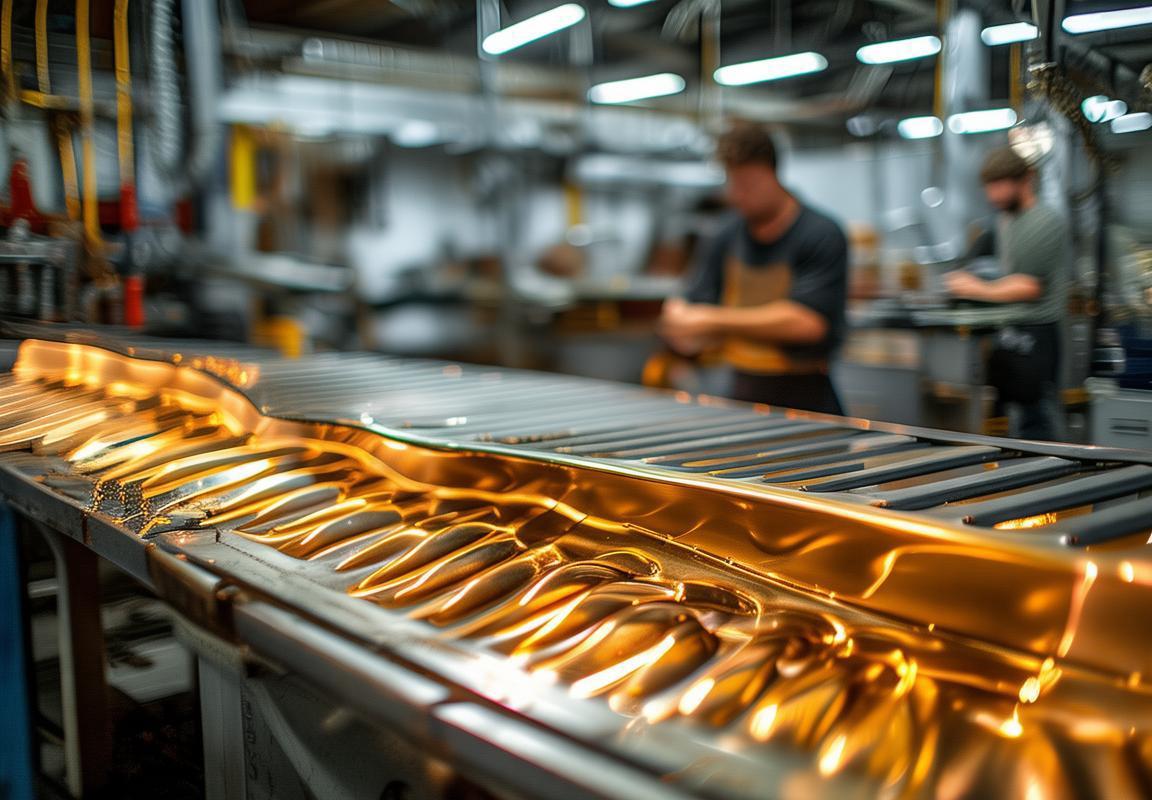

In today’s tech-driven world, CE-EMC compliant 2200W devices are integral for enhanced daily living. These high-power gadgets, like powerful computers and appliances, are essential, yet their safety and efficiency are paramount. Manufacturers must ensure these devices not only meet the demanding power needs but also incorporate key features such as robust EMI filters and efficient heat dissipation. These features, along with compliance to stringent CE-EMC standards, guarantee safety, reliability, and optimal performance. Users benefit from devices that deliver on their promise without compromising on safety or efficiency, all while adhering to international quality and environmental standards.