The world of culinary delights is vast, and one of the most cherished breakfast treats is the waffle. The texture, the taste, and the intricate patterns make waffles a favorite among many. At the heart of these delicious waffles lie the waffle plates—often overlooked yet crucial to the final product. In this article, we delve into the realm of OEM cast aluminum waffle plates, exploring their significance, benefits, and how they can elevate your waffle game to new heights.

Introduction to Cast Aluminum Mold Waffle Plates

Cast aluminum mold waffle plates have become a staple in the world of culinary art, offering a delightful twist to the classic waffle experience. These specialized molds, crafted from durable cast aluminum, are designed to create those iconic ridged patterns that we all know and love. In this exploration, we’ll delve into the intricacies of these waffle plates, their origins, and why they continue to be a favorite among bakers and chefs alike.

The process of creating waffle plates is an art form in itself, requiring precision and skill. Cast aluminum mold waffle plates are made by pouring molten aluminum into a mold, which is then cooled and solidified to form the desired shape. This method ensures that each plate is not only durable but also has the perfect texture for producing those crispy, golden waffles.

One of the standout features of cast aluminum waffle plates is their heat retention. The material’s high thermal conductivity allows for even heat distribution, ensuring that every section of the waffle is cooked to perfection. Whether you’re a fan of fluffy Belgian waffles or the dense, syrup-absorbent American style, these molds are up to the task.

The history of waffle making dates back centuries, with its origins tracing back to the Middle Ages. Over the years, the process has evolved, with various materials being used to create waffle molds. Cast aluminum, however, has emerged as a preferred choice due to its unique combination of properties.

One of the primary reasons for the popularity of cast aluminum molds is their longevity. These molds are designed to withstand the rigors of frequent use, making them a cost-effective investment for both professional kitchens and home cooks. Unlike some other materials, cast aluminum does not warp or degrade over time, ensuring that your waffles will continue to come out beautifully, year after year.

The design of a waffle plate is not just about aesthetics; it’s also about functionality. The intricate ridges on these molds are not just for show—they serve a purpose. They help to trap steam and create the perfect pockets for the waffle’s texture. The grooves also ensure that the waffles are easy to remove from the mold without sticking, making the cooking process smoother and less frustrating.

In the realm of waffle making, customization is key. Cast aluminum mold waffle plates offer a level of customization that is unmatched. From classic patterns to whimsical designs, you can find molds to suit any preference. For those who prefer a more personalized touch, there are also options for engraving or adding unique designs to the plates themselves.

The versatility of cast aluminum waffle plates is another reason for their enduring popularity. They are not limited to just waffles; these molds can be used to create a variety of other baked goods. From bread to cake, the possibilities are endless. This versatility makes cast aluminum molds a valuable addition to any kitchen.

When it comes to the food industry, the quality and consistency of the product are paramount. Cast aluminum mold waffle plates are produced with strict quality control measures in place. This ensures that each mold meets the highest standards of performance and durability. Whether you’re producing waffles for a small café or a large-scale commercial kitchen, you can rely on these molds to deliver consistent results.

For those looking to purchase cast aluminum mold waffle plates, there are several factors to consider. The reputation of the manufacturer, the quality of the material, and the design of the mold are all crucial. It’s important to choose a manufacturer that has a track record of producing high-quality, reliable products. This will not only ensure that your waffles turn out great but also that you’ll have a long-lasting investment.

In conclusion, cast aluminum mold waffle plates are a testament to the art of waffle making. With their enduring popularity, it’s clear that these molds have earned their place in the hearts of waffle enthusiasts everywhere. Whether you’re a seasoned baker or just starting out, these molds offer a combination of quality, durability, and versatility that is hard to match. So, why not elevate your waffle game with a cast aluminum mold waffle plate today?

The Unique Charm of Waffle Plates

Waffle plates have a certain je ne sais quoi that sets them apart from the ordinary. Their intricate patterns and distinct texture offer a visual appeal that’s hard to resist. The unique charm of these plates lies in their ability to transform the simplest of foods into something special.

The intricate patterns that adorn waffle plates are not just for show; they serve a practical purpose. These grooves and ridges trap heat, creating a crispy outer layer while keeping the inside tender and juicy. It’s this contrast in texture that makes waffles so irresistible, and the charm of the plate itself becomes a part of the dining experience.

The aesthetic appeal of waffle plates is undeniable. Whether you’re serving up classic Belgian waffles or experimenting with sweet and savory variations, the plate’s design adds a touch of whimsy to the meal. The variety of patterns available—from classic diamond shapes to more modern, abstract designs—allows for personalization and a sense of individuality in your kitchen.

The history of waffle plates is rich and varied. They have been a staple in European cuisine for centuries, with origins that can be traced back to Belgium and France. Over time, waffle plates have evolved, adopting new designs and becoming a symbol of culinary sophistication. Today, they are not just a tool for cooking but also a decorative element that can enhance the look of any kitchen.

The versatility of waffle plates is another reason for their charm. They are not limited to waffles; you can use them to serve a variety of dishes. From pancakes to bread, the ridges on the plate can add a unique texture to your food. This versatility makes waffle plates a must-have for any foodie or anyone looking to add a bit of flair to their dining table.

The tactile experience of a waffle plate is also something to be cherished. The ridges are not just for looks; they provide a satisfying grip that makes handling your food a pleasure. The grooves catch the food, preventing it from sliding off the plate, and the overall design encourages a more interactive dining experience.

In the realm of entertaining, waffle plates can be a conversation starter. They are not a common sight on most dinner tables, and their unique appearance can spark curiosity and conversation among guests. It’s a subtle way to introduce a touch of novelty to your gatherings.

The charm of waffle plates also extends to their durability. Made from high-quality materials, these plates are designed to withstand the rigors of everyday use. They are often dishwasher safe, making cleanup a breeze. This durability ensures that your waffle plate will be a cherished item for years to come.

The culinary possibilities with waffle plates are endless. From traditional recipes to creative twists, you can get creative with your cooking. The ridges can help lock in flavors, and the unique texture can elevate even the most basic ingredients to new heights.

In a world where homogeneity is often the norm, the unique charm of waffle plates offers a breath of fresh air. They remind us that sometimes, it’s the little things that can make a big difference in our lives. Whether it’s the joy of cooking, the satisfaction of eating, or the pleasure of entertaining, waffle plates have a way of bringing a smile to our faces.

The charm of waffle plates is not just in their functionality or design; it’s in the memories they create. Whether you’re making waffles with your family on a Sunday morning or entertaining friends with a waffle bar, these plates have a way of making every moment feel a bit more special. It’s this intangible quality that keeps waffle plates cherished and continues to draw us to their unique charm.

Why Cast Aluminum for Waffle Molds?

Cast aluminum has emerged as a favored material for waffle molds, and there are several compelling reasons behind this choice:

The lightweight nature of cast aluminum is a significant advantage when it comes to waffle molds. Unlike heavier metals like steel or iron, aluminum is much lighter, making it easier to handle and maneuver during the waffle-making process. This ease of use is particularly beneficial for commercial kitchens where efficiency is key, as operators can move the molds more swiftly and with less exertion, reducing the risk of strain and improving productivity.

Aluminum’s thermal conductivity is another standout quality. It’s known for its ability to quickly and evenly distribute heat, which is crucial for the perfect waffle. With cast aluminum molds, the heat is transferred more rapidly from the heat source to the waffle batter, ensuring a consistent and even cooking process. This results in waffles that are golden brown on the outside and perfectly cooked through on the inside, every time.

Durability is a hallmark of cast aluminum, and this material stands up well to the rigors of regular use. The molds are designed to withstand countless batches of waffles without showing signs of wear. This longevity means that businesses and home chefs alike can rely on their molds for years, making it a cost-effective choice in the long run.

When it comes to the aesthetic appeal of waffle molds, cast aluminum shines. The smooth, non-stick surface of these molds is not only functional but also visually appealing. The lustrous finish of cast aluminum adds a touch of sophistication to kitchen counters and waffle irons, making them not just a practical tool but also a decorative element.

The versatility of cast aluminum in waffle mold production cannot be overstated. It can be cast into a wide variety of shapes and sizes, allowing for endless design possibilities. From traditional Belgian waffles to whimsical novelty shapes, cast aluminum molds can accommodate a myriad of waffle designs. This adaptability makes it a popular choice for businesses looking to offer a unique product or for individuals who enjoy experimenting with their waffle-making.

Another key factor is the cost-effectiveness of cast aluminum. While it may be more expensive than some other materials initially, the low maintenance and extended lifespan of cast aluminum molds often offset the higher upfront cost. This affordability makes it accessible to both large-scale commercial operations and home enthusiasts alike.

Moreover, the eco-friendly aspect of cast aluminum should not be overlooked. Aluminum is a highly recyclable material, and the fact that cast aluminum molds can be reused over and over again means that they contribute to a reduced carbon footprint. In an era where sustainability is increasingly important, choosing cast aluminum for waffle molds is a responsible decision.

The moldability of aluminum is also a significant factor. It can be easily manipulated into intricate patterns and designs, which is not as feasible with other materials. This means that even the most detailed and artistic waffle patterns can be achieved with cast aluminum molds, giving chefs and bakers the freedom to express their creativity.

Lastly, the ease of cleaning is a practical consideration. Cast aluminum molds are generally non-stick and easy to clean, which is essential for maintaining hygiene in commercial settings. The non-reactive nature of aluminum means that it won’t impart any unwanted flavors or odors into the waffles, ensuring that the taste and quality of the final product remain consistent.

In conclusion, the choice of cast aluminum for waffle molds is a multifaceted decision influenced by its lightweight, thermal conductivity, durability, aesthetic appeal, versatility, cost-effectiveness, eco-friendliness, moldability, and ease of cleaning. These qualities make cast aluminum an excellent choice for anyone looking to create the perfect waffle time and time again.

The Benefits of OEM Cast Aluminum Waffle Plates

OEM cast aluminum waffle plates offer a host of advantages that make them a preferred choice in various industries. Here’s a closer look at some of the key benefits:

Their lightweight nature is a standout feature. Aluminum is one of the lightest metals, which means that waffle plates made from this material are significantly lighter than their steel or cast iron counterparts. This weight reduction can be particularly beneficial in applications where the plates are used to cook large volumes of food, as it makes them easier to handle and maneuver.

The thermal conductivity of cast aluminum is another advantage. Aluminum is known for its excellent heat transfer properties, allowing waffle plates to distribute heat more evenly and quickly. This even heating ensures that each waffle is perfectly cooked, with a crispy exterior and a tender interior. Whether you’re running a commercial bakery or a home kitchen, the efficiency of aluminum waffle plates can lead to faster cooking times and improved productivity.

Durability is a hallmark of cast aluminum. These waffle plates are designed to withstand the rigors of frequent use and high temperatures. Unlike some other materials, aluminum is resistant to warping and cracking, even after prolonged exposure to heat. This longevity means that your waffle plates will maintain their quality and performance over time, reducing the need for frequent replacements.

Customization is a breeze with OEM cast aluminum waffle plates. Whether you’re looking for a specific design, size, or finish, the versatility of aluminum allows for endless possibilities. This level of customization can be crucial for businesses that want to offer unique products or match their branding. From intricate patterns to sleek finishes, the options are virtually limitless.

Maintaining these waffle plates is a straightforward process. Aluminum is naturally corrosion-resistant, which means that it’s less prone to rust and tarnish compared to other metals. This resistance to corrosion not only extends the life of the waffle plates but also makes them easier to clean and maintain. A simple wipe with a damp cloth is often all that’s needed to keep them looking like new.

Energy efficiency is a key concern for many businesses, and cast aluminum waffle plates can contribute to this goal. Their superior heat retention properties mean that once they’re hot, they stay hot. This feature reduces the amount of energy required to maintain cooking temperatures, which can lead to significant savings on utility bills.

Safety is paramount in any cooking environment, and aluminum waffle plates do not require the use of harmful coatings or chemicals to prevent sticking. This means you can enjoy the delicious taste of freshly cooked waffles without the risk of consuming potentially harmful substances. The natural non-stick surface of aluminum also makes cleanup a lot easier and safer.

Lastly, the aesthetic appeal of cast aluminum waffle plates should not be overlooked. The smooth, sleek finish of these plates adds a touch of sophistication to any kitchen. They can be a great addition to commercial kitchens looking to enhance the overall look of their workspace, or for home chefs who want to elevate their cooking experience with high-quality equipment.

In summary, the benefits of choosing OEM cast aluminum waffle plates are clear. From their lightweight design and excellent heat transfer properties to their durability and customization options, these plates offer a compelling package for both commercial and domestic use. Their ease of maintenance, energy efficiency, safety, and aesthetic value make them a wise investment for anyone looking to improve their waffle-making experience.

The Process of Manufacturing OEM Waffle Plates

The process of manufacturing OEM cast aluminum waffle plates is a blend of precision, creativity, and technical expertise. Here’s a detailed look at the steps involved:

-

Design and Prototyping: The journey begins with the design phase, where engineers and designers create detailed blueprints for the waffle plates. This is where the dimensions, patterns, and specifications are finalized. Once the design is approved, a prototype is made to ensure the design is functional and meets the required standards.

-

Material Selection: Cast aluminum is chosen for its durability, strength, and heat conductivity. The raw aluminum is typically an alloy, often 6061 or 7075, which is known for its excellent casting properties and resistance to corrosion.

-

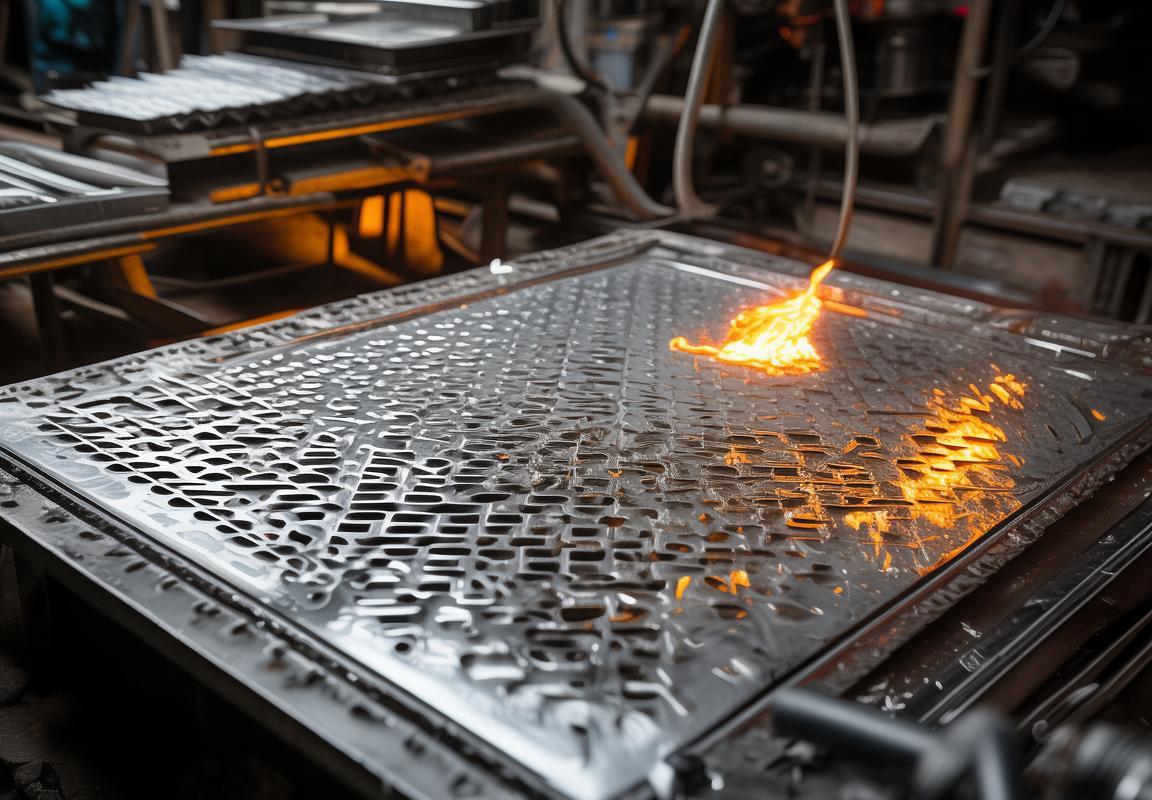

Machining the Molds: The molds used for casting are precision-machined from high-quality steel. These molds are critical as they determine the shape and quality of the final product. The mold-making process involves cutting, grinding, and polishing to achieve the intricate waffle patterns.

-

Melting the Aluminum: In a foundry, the selected aluminum alloy is melted in a furnace. The melting process must be carefully controlled to prevent oxidation and ensure that the aluminum is pure and ready for casting.

-

Pouring the Molten Aluminum: Once the aluminum is melted and reaches the correct temperature, it is poured into the molds. The molten metal fills the cavities of the mold, taking the shape of the waffle pattern. It’s crucial to pour the metal at the right temperature and flow rate to achieve a uniform thickness and avoid defects.

-

Cooling and Solidification: After pouring, the molds are allowed to cool slowly. This slow cooling process, known as quenching, helps in reducing internal stresses and improves the mechanical properties of the aluminum. The cooling time can vary depending on the size and complexity of the waffle plates.

-

Removal from Molds: Once the aluminum has solidified, it is removed from the molds. This step requires care to avoid damaging the waffle pattern. The plates are then set aside to continue cooling to room temperature.

-

Finishing Processes: The cast waffle plates are then subjected to various finishing processes. This includes de-gating to remove any excess material left from the casting process, trimming to the final dimensions, and surface treatment to enhance the appearance and durability.

-

Quality Control: Throughout the manufacturing process, quality control checks are conducted at various stages. This ensures that the waffle plates meet the specified tolerances and are free from defects. Inspections may include dimensional checks, visual inspections, and material testing.

-

Packaging and Shipping: After the quality control process is complete, the OEM waffle plates are packaged in protective materials to prevent damage during transportation. They are then shipped to the customer, ready for use in their intended application.

-

Customer Feedback and Iteration: In the world of OEM manufacturing, customer satisfaction is key. After the waffle plates are delivered, the manufacturer often seeks feedback to make any necessary adjustments or improvements to the design or production process.

This intricate process combines the art of design with the science of engineering to produce OEM cast aluminum waffle plates that are not only visually appealing but also robust and reliable for a wide range of uses, from cooking to industrial applications.

Customization and Versatility in OEM Waffle Plates

OEM waffle plates, crafted with precision and tailored to meet specific requirements, offer a world of customization and versatility. From the design phase to the final product, these plates are engineered to stand out in their uniqueness and practicality.

The design of OEM waffle plates is a testament to creativity. They can be crafted in a myriad of shapes and sizes, catering to a wide range of preferences. Whether it’s the classic waffle pattern or a more intricate design, the possibilities are endless. The ability to customize the pattern and size allows for a personalized touch, making these plates not just functional but also a statement piece in any kitchen.

Material selection is another area where OEM waffle plates shine. The use of high-quality materials ensures that the plates are not only durable but also heat-resistant. This means that they can withstand high temperatures without warping or losing their shape, making them ideal for both traditional and modern cooking methods.

One of the most striking aspects of OEM waffle plates is their versatility. They can be used for a variety of dishes, from sweet treats like Belgian waffles to savory options like hash browns or even as a unique serving dish for desserts. The non-stick surface ensures that food releases easily, making the cooking process a breeze.

Customization extends beyond just the pattern and size. OEM waffle plates can be coated with different materials to enhance their performance. For instance, a ceramic coating can add a glossy finish and improve the non-stick properties, while a titanium-infused coating can offer superior heat retention and durability.

Moreover, the handles and overall design can be tailored to user preferences. Some customers may prefer a sleek, modern look with minimalistic handles, while others might opt for a more traditional design with ergonomic handles for a secure grip. This level of customization allows the end-user to have a product that not only performs well but also fits seamlessly into their kitchen decor.

The versatility of OEM waffle plates also extends to the materials used in their construction. They can be made from various metals, such as stainless steel or aluminum, each offering its own set of benefits. For example, aluminum is lightweight and conducts heat efficiently, making it a popular choice for those who enjoy cooking with precision and speed.

In terms of maintenance, OEM waffle plates are designed with ease of cleaning in mind. The non-stick surface reduces the likelihood of food particles sticking to the plate, and many are also dishwasher-safe, saving time and effort in the kitchen. This feature, combined with their durability, ensures that these plates can be a staple in the kitchen for years to come.

Another aspect of versatility is the ability to stack these plates when not in use. This space-saving feature is perfect for those who have limited storage in their kitchen cabinets. The ability to stack multiple waffle plates on top of each other means that you can maximize your storage without sacrificing functionality.

Furthermore, OEM waffle plates can be tailored to specific dietary needs. For instance, plates made from materials that are free from harmful chemicals or with coatings that are safe for those with allergies or sensitivities can be produced. This customization allows for a product that is not only visually appealing but also health-conscious.

Lastly, the branding aspect of OEM waffle plates cannot be overlooked. With the ability to add custom logos or designs, these plates can become a marketing tool for businesses looking to promote their brand or offer a unique product to their customers. This level of branding versatility makes OEM waffle plates an excellent choice for commercial kitchens, food trucks, or even as a gift item for culinary enthusiasts.

In summary, the customization and versatility of OEM waffle plates make them a standout choice in the kitchenware market. From the design and materials used to the practical features and branding opportunities, these plates are crafted to cater to the diverse needs and preferences of users worldwide.

Industry Applications of Cast Aluminum Waffle Plates

Cast aluminum waffle plates have found their way into a myriad of industries, each harnessing their unique properties to enhance their operations. From culinary delights to industrial processes, these versatile waffle plates have become an indispensable component in many sectors.

In the foodservice industry, waffle plates are a staple for creating those delightful Belgian waffles. Their intricate patterns not only add a visual appeal to the final product but also provide a textured surface that holds toppings and syrups. The ability to customize the waffle patterns allows for a variety of designs, catering to specific brand identities or seasonal themes.

Manufacturers in the aerospace industry use cast aluminum waffle plates for their structural integrity and lightweight nature. These plates can be found in aircraft components, such as heat sinks and other thermal management systems, where their ability to dissipate heat efficiently is crucial. The uniformity of the waffle pattern also aids in maintaining consistent performance over time.

In the automotive sector, cast aluminum waffle plates serve a dual purpose. They are used in the production of heat exchangers and radiators, where the waffle design helps in maximizing surface area for heat transfer. Moreover, the lightweight material contributes to the overall weight reduction of the vehicle, improving fuel efficiency.

The construction industry has also embraced cast aluminum waffle plates for their durability and resistance to corrosion. They are employed in the creation of panels and cladding, providing an aesthetically pleasing finish that can withstand harsh environmental conditions. The waffle texture can also offer sound absorption properties, making them suitable for interior applications.

In the medical field, waffle plates have a more specialized role. They are used in the production of surgical instruments and implants, where the intricate patterns can create specific surfaces for grip or to mimic natural tissue textures. The precision of casting ensures that the plates meet the strict quality standards required in medical device manufacturing.

The agricultural industry finds utility in cast aluminum waffle plates for a range of applications, from irrigation systems to storage solutions. The waffle design can enhance the flow of water or air, optimizing the efficiency of agricultural equipment. Additionally, the plates are durable enough to withstand the rigors of outdoor use, making them a reliable choice for farm implements.

The sports and leisure industry utilizes waffle plates for their innovative uses, such as in the construction of sports equipment and playground surfaces. The texture of the waffle pattern can improve traction, safety, and comfort, whether it’s on a soccer field, a basketball court, or a playground.

In the electronics sector, waffle plates play a role in heat sinks and thermal management solutions. The unique design of the waffle pattern allows for increased airflow, which is essential for dissipating heat from electronic components. This ensures that devices remain cool and functional, even under heavy use.

The energy industry also benefits from cast aluminum waffle plates, particularly in the design of solar panels and wind turbine components. The waffle texture can help in the efficient collection and transfer of heat or wind, enhancing the overall performance of renewable energy systems.

Lastly, the transportation industry uses waffle plates for a variety of applications, from creating lightweight but strong components for trains and buses to providing a stable base for cargo containers. The versatility of these plates means they can be tailored to fit specific requirements, whether it’s for structural support or thermal management.

In summary, the cast aluminum waffle plates’ industry applications are as diverse as they are innovative, reflecting their ability to blend aesthetics with functionality across multiple sectors. Whether it’s in the kitchen, on the factory floor, or in the great outdoors, these waffle plates continue to prove their worth in enhancing the efficiency and performance of various products and systems.

Quality Assurance in OEM Cast Aluminum Waffle Plate Production

The meticulous attention to quality in the production of OEM cast aluminum waffle plates is a cornerstone of excellence in this industry. From the selection of raw materials to the final inspection, every step is carefully monitored to ensure that each waffle plate meets the highest standards of craftsmanship and durability. Here’s a closer look at the quality assurance process:

Materials and Design ApprovalThe journey begins with the selection of the right materials. Premium-grade aluminum is chosen for its strength and ability to withstand high temperatures. The design of the waffle plates is also crucial, and it undergoes a thorough approval process to ensure it aligns with the intended specifications and industry standards. This includes evaluating the waffle pattern, size, and thickness to guarantee optimal performance.

Molding PrecisionOnce the design is approved, the actual molding process is initiated. The use of advanced casting techniques ensures that the waffle plates are free from imperfections. The mold is meticulously crafted to replicate the intricate waffle design with precision. During this stage, any inconsistencies in the mold’s surface or shape can lead to uneven waffle patterns or weak spots, so every detail is scrutinized.

Casting ProcessThe casting process itself is a delicate balance of science and art. Molten aluminum is poured into the mold at the appropriate temperature to avoid any thermal shock or distortion. The aluminum must cool uniformly to prevent warping or cracking. The casting process is also monitored for consistency in thickness, ensuring that the waffle plates are neither too thin nor too thick, which can affect their performance and lifespan.

Finishing and Surface TreatmentAfter the aluminum has solidified and the waffle pattern is formed, the plates are subjected to various finishing processes. These include sandblasting to achieve a smooth surface, which not only enhances the aesthetic appeal but also reduces the risk of food sticking. followed by washing to remove any residual casting materials. Depending on the application, additional surface treatments such as anodizing or powder coating may be applied to increase resistance to corrosion and enhance the plate’s longevity.

Inspection and TestingQuality assurance doesn’t end with the finishing stage. Each waffle plate is inspected for any visible defects such as cracks, pits, or uneven waffle patterns. Beyond visual inspection, the plates are tested for their mechanical properties. This includes hardness tests to ensure the aluminum is within the desired range and durability tests to simulate real-world use. Each plate must meet or exceed the required specifications to pass the quality control.

Documentation and TraceabilityIn the world of OEM cast aluminum waffle plates, documentation is king. Every stage of the production process is documented, from the original design to the final product. This ensures traceability, meaning that if there’s an issue with a batch of plates, the exact point of origin and cause can be identified quickly. This level of documentation is not just for quality control but also for compliance with industry regulations and customer requirements.

Continuous ImprovementQuality assurance is an ongoing process. Manufacturers of OEM cast aluminum waffle plates continuously seek feedback from customers and conduct internal audits to identify areas for improvement. This could involve tweaking the casting process, updating machinery, or revising design specifications. The goal is to deliver not just a product that meets current standards but one that exceeds expectations and evolves with the market.

Customer SatisfactionUltimately, the quality assurance process is about ensuring customer satisfaction. By providing OEM cast aluminum waffle plates that are free from defects, durable, and meet the exact specifications, manufacturers build a reputation for reliability. Satisfied customers are more likely to return for future orders and recommend the product to others, creating a positive cycle of repeat business and brand loyalty.

In summary, the quality assurance in the production of OEM cast aluminum waffle plates is a comprehensive and meticulous process. It involves careful material selection, precise molding, meticulous finishing, rigorous testing, thorough documentation, and a commitment to continuous improvement. This dedication to excellence ensures that each waffle plate that leaves the factory is a testament to the manufacturer’s pursuit of perfection.

How to Choose the Right OEM Cast Aluminum Waffle Plate Manufacturer

When selecting the right OEM cast aluminum waffle plate manufacturer, it’s crucial to consider several factors that can ensure you get a product that meets your specific needs and expectations. Here’s a detailed look at what to look for:

Understanding Your RequirementsBefore diving into the search for a manufacturer, it’s essential to have a clear understanding of what you need. Consider the size, thickness, and design of the waffle plates, as well as the quantity you require. Knowing these details will help you communicate effectively with potential manufacturers.

Experience and ReputationLook for manufacturers with a proven track record in the industry. An experienced manufacturer will have a better grasp of the casting process, quality control, and the ability to handle complex designs. Check their reputation through online reviews, testimonials, and industry awards to gauge their standing.

Quality Control MeasuresA reliable manufacturer will have stringent quality control measures in place. This includes regular inspections at various stages of production, ensuring that each waffle plate meets the required specifications. Ask about their quality assurance protocols and certifications, such as ISO standards, which indicate a commitment to quality.

Customization OptionsOEM cast aluminum waffle plates are often customized to meet specific client needs. The right manufacturer should offer a range of customization options, from altering the size and shape of the waffle pattern to modifying the surface finish. Ensure that the manufacturer can provide the level of customization you require without compromising on quality.

Production CapacityConsider the manufacturer’s production capacity to ensure they can meet your delivery timelines. A manufacturer with high capacity may be able to handle larger orders or rush orders, which is particularly important if you have tight deadlines or a high demand for your products.

Pricing StructureWhile cost is a significant factor, it shouldn’t be the sole determinant of your choice. Compare quotes from different manufacturers to find a balance between affordability and quality. Be wary of unusually low prices, as they may indicate subpar materials or workmanship.

Communication and Customer ServiceEffective communication is key in the manufacturing process. Choose a manufacturer that is responsive to your inquiries and provides clear, concise information. Good customer service can also help resolve any issues that arise during production or after the delivery of your waffle plates.

After-Sales SupportInquire about the manufacturer’s after-sales support. This includes warranty coverage, technical assistance, and the availability of replacement parts. A manufacturer that stands behind its products demonstrates a commitment to customer satisfaction.

Sustainability PracticesIn today’s market, sustainability is a growing concern. Look for manufacturers that practice environmentally friendly production methods, such as using recycled materials or reducing energy consumption. This not only benefits the environment but can also be a selling point for your products.

Technical ExpertiseThe technical expertise of the manufacturer’s team is vital for producing high-quality waffle plates. Ensure that they have skilled engineers and technicians who are well-versed in the casting process and can provide innovative solutions if needed.

Supply Chain ReliabilityA robust supply chain is essential for maintaining production schedules and ensuring a steady supply of raw materials. A manufacturer with a reliable supply chain can prevent delays and ensure consistency in the quality of the cast aluminum waffle plates.

Technology and EquipmentModern manufacturing processes and advanced equipment can significantly impact the quality and efficiency of the waffle plates. Ask about the technology and equipment used by the manufacturer to ensure they are up-to-date and capable of producing precision-cast products.

Collaboration and InnovationThe right manufacturer should be open to collaboration and innovation. They should be willing to work with you to develop new designs or improve existing ones, ensuring that your waffle plates stand out in the market.

Legal ComplianceEnsure that the manufacturer complies with all relevant legal regulations and standards. This includes adherence to labor laws, environmental regulations, and intellectual property rights.

By carefully considering these factors, you can select the right OEM cast aluminum waffle plate manufacturer that will not only meet your current needs but also support your long-term business goals.

Conclusion: Elevate Your Waffle Game with Cast Aluminum Molds

In wrapping up, the use of cast aluminum molds for waffle plates isn’t just a trend; it’s a game-changer for both culinary enthusiasts and professionals. These molds offer a unique blend of durability, ease of use, and the ability to create a myriad of waffle designs. As we reflect on the journey of waffle plates from simple kitchen gadgets to sophisticated tools in the culinary world, it’s clear that cast aluminum molds have become an indispensable part of the process. From the precision of the molds to the endless possibilities of customization, the decision to use cast aluminum for waffle plates is one that enhances the quality and consistency of the final product. Whether you’re a baker looking to expand your repertoire or a food service provider aiming to offer a unique experience to your customers, investing in high-quality cast aluminum molds can elevate your waffle game to new heights. As we continue to innovate and improve, the future of waffle making looks bright, with cast aluminum molds leading the way in both form and function.