In the ever-evolving landscape of industrial manufacturing, the role of specialized equipment is paramount. Among these tools, the sandwich press stands out as a critical component in various industries, from food processing to electronics. This article delves into the intricacies of sandwich press manufacturing, exploring the innovations, technologies, and the significance of choosing the right manufacturer for these versatile machines. As we peek into the future of sandwich press manufacturing, we’ll also highlight some notable players in the industrie and what trends and predictions lie ahead.

The World of Sandwich Press Manufacturers: A Closer Look

The world of sandwich press manufacturers is a bustling hub of innovation and precision, where the art of crafting high-quality sandwich presses meets the demands of a diverse range of industries. These manufacturers are the backbone of the sandwich press industry, ensuring that the products they produce cater to the needs of bakeries, restaurants, and even home kitchens around the globe. Let’s take a closer look at this fascinating world.

Sandwich presses, often referred to as panini makers or pressos, have become a staple in the culinary world. They allow for the perfect grilling of sandwiches, burgers, and even desserts, sealing in flavors and creating a delicious, golden-brown exterior. The manufacturers behind these appliances are not just producing tools for cooking; they are creating experiences.

One of the first things that come to mind when thinking about sandwich press manufacturers is the level of craftsmanship involved. These companies often start with high-quality materials that can withstand the heat and pressure required to make a perfect sandwich. Stainless steel is a common choice for its durability and ability to distribute heat evenly. The design of the press is also crucial, with many manufacturers focusing on ergonomics and ease of use.

The technology used in sandwich presses has evolved significantly over the years. Early models were simple, with a single heating element and a flat surface. Today, sandwich press manufacturers are pushing the boundaries with features like variable temperature controls, non-stick surfaces, and even Bluetooth connectivity for remote temperature adjustments. These innovations not only enhance the cooking experience but also cater to the demands of professional chefs and home enthusiasts alike.

In the realm of sandwich press manufacturing, there’s a clear emphasis on versatility. Manufacturers understand that one size does not fit all, which is why they offer a wide range of models to suit different applications. From compact, countertop models perfect for home use to large, commercial-grade presses capable of handling high-volume orders in restaurants and cafes, the variety is impressive.

Quality control is another critical aspect of sandwich press manufacturing. These presses are often subjected to rigorous testing to ensure they meet safety standards and deliver consistent performance. Manufacturers invest in quality assurance processes to prevent defects and ensure that every unit that leaves the factory is reliable and long-lasting.

The industry is also highly competitive, with manufacturers constantly striving to outdo each other in terms of design, functionality, and customer satisfaction. This competition drives innovation and leads to the development of unique features that can set one brand apart from another. For example, some sandwich presses come with adjustable pressure settings, allowing users to customize the cooking experience to their preference.

When it comes to marketing and distribution, sandwich press manufacturers have a wide array of channels at their disposal. They sell directly to consumers through online marketplaces and retail stores, and they also supply to wholesalers and distributors who then distribute to restaurants, cafes, and hotels. The global nature of the market means that these presses are not just a local phenomenon; they are a part of the international foodservice industry.

Another interesting aspect of the sandwich press manufacturing world is the customization options available. Many manufacturers offer bespoke solutions for specific needs, such as creating presses with unique shapes or sizes to cater to particular menu items. This level of customization highlights the flexibility and adaptability of the industry.

The environmental impact is also a growing concern for sandwich press manufacturers. As sustainability becomes more important, these companies are looking for ways to reduce their carbon footprint. This includes using eco-friendly materials, improving energy efficiency, and finding ways to recycle or repurpose parts of the presses at the end of their life cycle.

In conclusion, the world of sandwich press manufacturers is a dynamic and innovative space. From the materials used to the features offered, these manufacturers are dedicated to providing the best tools for creating delicious sandwiches. Whether it’s for a busy kitchen or a cozy home, the variety and quality of sandwich presses available reflect the industry’s commitment to excellence.

What is a Sandwich Press? An Overview of Its Functionality

A sandwich press, often affectionately referred to as a panini press or a press grill, is a kitchen appliance designed to cook food by pressing it between two heated plates. These plates, which are typically flat and round, come together to seal the food in a “sandwich” shape, hence the name. Here’s a closer look at how these devices work and the variety of functionalities they offer.

The core functionality of a sandwich press is to apply even pressure to the ingredients placed between the plates. This pressure, combined with heat, helps to cook the food thoroughly and ensures that the flavors meld together. The process is quite simple: you place your chosen ingredients, such as bread, cheese, vegetables, and meats, in between the plates, close them, and wait for the desired level of cooking.

Modern sandwich presses come in various shapes and sizes, each tailored to specific cooking needs. For instance, there are flat sandwich presses that are perfect for making traditional paninis or grilled cheese sandwiches. These are often compact and designed to fit on a countertop, making them a convenient addition to any kitchen.

On the other hand, there are square or rectangle-shaped sandwich presses that are better suited for larger portions or for making open-faced sandwiches. These models might also feature a non-stick surface, which makes it easier to release the cooked sandwich from the appliance.

One of the standout features of many sandwich presses is the adjustable temperature control. This allows users to set the heat to the perfect level for their preferred type of sandwich. For instance, a warm setting is ideal for melting cheese without cooking the bread, while a high heat setting can quickly toast the bread and brown the cheese.

Beyond the classic sandwich, sandwich presses are versatile appliances that can be used to cook a wide array of foods. You can use them to grill vegetables, sear meats, or even make mini pizzas. The key to using a sandwich press effectively lies in understanding the cooking times and temperatures for different ingredients.

The plates themselves are often made of non-stick materials, which not only make them easier to clean but also ensure that the food doesn’t stick and burn. Some models come with removable plates for easy cleaning, while others have a dishwasher-safe design.

Another interesting aspect of sandwich presses is their ability to create different textures and finishes. For example, some presses have a ridged surface that creates a grill-like pattern on the sandwich, while others have a smooth surface that provides a more traditional toast-like appearance. This texture variation is not just for aesthetic purposes; it can also enhance the overall taste and texture of the food.

In terms of convenience, many sandwich presses come with features like a locking mechanism to prevent the plates from coming apart while cooking and a safety lock to prevent accidental opening. Some models even have a window to watch the cooking process without the need to open the press, which is particularly useful for those who like to see their food being cooked to perfection.

One of the most innovative features found in some sandwich presses is the ability to cook multiple sandwiches at once. These models often have multiple sets of plates, allowing for a batch cooking experience. This is great for families or for hosting a gathering where you want to serve a variety of sandwiches quickly.

The functionality of sandwich presses doesn’t end with cooking. Some models are designed with a flip-up top that doubles as a cutting board or a serving tray. This feature is especially handy for those who like to present their sandwiches with a flourish or for those who want to make a quick snack on the go.

In conclusion, the sandwich press is an incredibly versatile kitchen appliance that offers a wide range of functionalities. From the ability to cook a variety of foods to the convenience of adjustable temperatures and innovative design features, these presses are more than just a tool for making sandwiches. They are a testament to the evolution of kitchen technology and the endless possibilities for culinary creativity.

The Role of Sandwich Press Manufacturers in the Industrie

Sandwich presses, a staple in the food industry, play a pivotal role in shaping the way products are processed and served. These presses are not just tools; they are integral to the functionality and efficiency of the manufacturing process. The role of sandwich press manufacturers in the industrie is multifaceted, encompassing innovation, quality control, and the drive for efficiency.

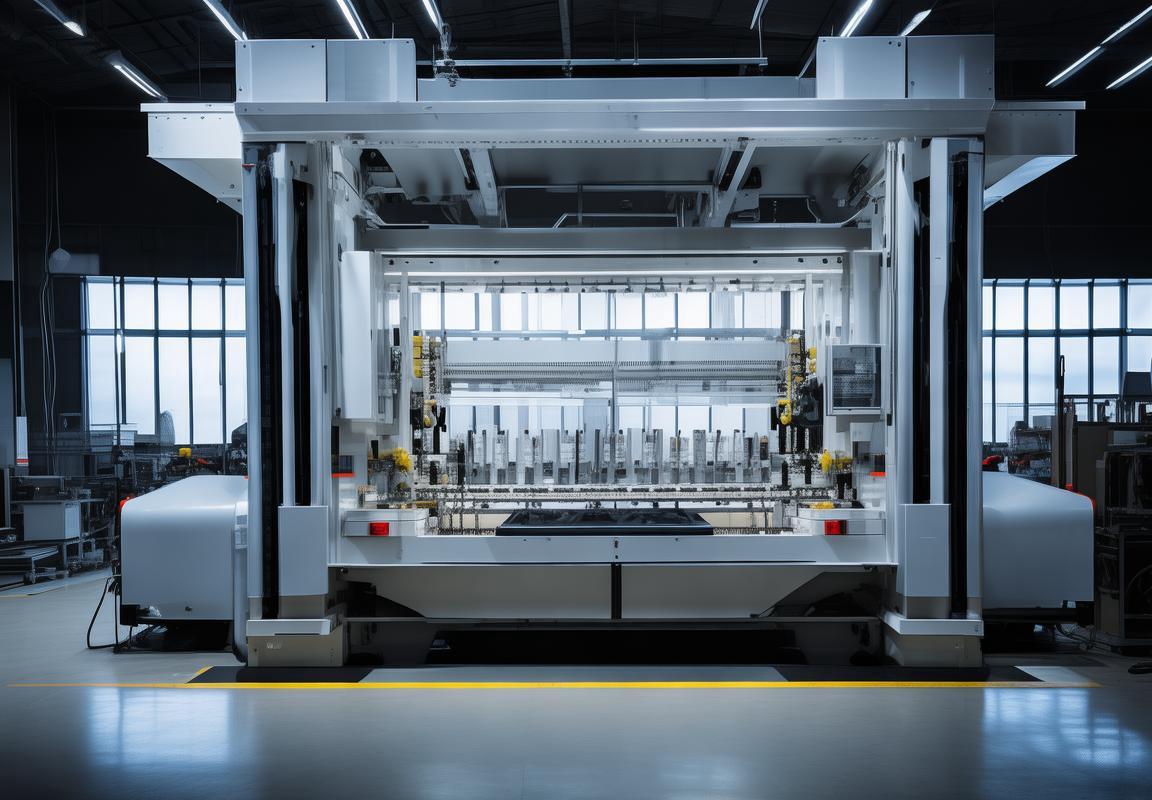

Manufacturers of sandwich presses are at the forefront of technological advancements. They design and develop machines that not only cater to the current needs of the market but also anticipate future trends. From the early days of simple mechanical presses to the sophisticated hydraulic and pneumatic models of today, these manufacturers have continually pushed the boundaries of what is possible. Their innovations have led to faster production times, reduced waste, and improved product consistency.

In terms of quality control, sandwich press manufacturers are meticulous. They understand that the integrity of the final product depends on the precision and reliability of the pressing process. Whether it’s ensuring even pressure distribution across the entire surface of a sandwich or maintaining consistent temperatures during the cooking process, these manufacturers focus on details that others might overlook. This dedication to quality is what sets high-end sandwich presses apart from their competitors.

Efficiency is another cornerstone of the role played by sandwich press manufacturers. In the fast-paced industrie, time is money, and these presses are engineered to maximize output while minimizing downtime. The ability to process a high volume of products in a short period is critical, especially in industries like bakery, fast food, and snack manufacturing. Manufacturers achieve this by creating machines that are easy to operate, maintain, and clean, thereby reducing the need for skilled labor and frequent service interventions.

The versatility of sandwich presses is a testament to the ingenuity of their manufacturers. These presses are not limited to just sandwiches; they are used to produce a wide array of food products, including pizzas, wraps, and even non-food items like insulation materials. The ability to customize these presses to meet specific production needs is a key factor in their widespread adoption. Manufacturers offer a range of options, from manual to fully automated systems, each designed to cater to different scales of production.

Safety is also a top priority for sandwich press manufacturers. They incorporate safety features that prevent accidents and ensure a secure working environment. These features can include emergency stop mechanisms, safety guards, and clear instructions for operation. By prioritizing safety, manufacturers not only protect their customers but also contribute to the overall health and well-being of the workforce.

Another crucial aspect of the role of sandwich press manufacturers is their contribution to sustainability. As the world becomes more environmentally conscious, these manufacturers are increasingly focusing on creating energy-efficient machines. By reducing energy consumption and minimizing waste, they help businesses operate more sustainably. This shift towards eco-friendly practices is not just a moral imperative but also a smart business strategy, as it resonates with consumers who are increasingly looking for products made with the environment in mind.

Collaboration with research institutions and food scientists is also a vital part of the sandwich press manufacturing process. Manufacturers often work closely with these experts to develop new materials and processes that enhance the quality and safety of food products. This partnership leads to the creation of presses that can handle new and emerging food trends, such as gluten-free or plant-based products.

Lastly, the global reach of sandwich press manufacturers is significant. They supply machines to businesses all over the world, from small local bakeries to large multinational corporations. This international presence not only expands their market but also exposes them to a variety of challenges and opportunities. It forces them to adapt to different regulatory standards, cultural preferences, and market demands, making them more versatile and adaptable as a result.

In conclusion, sandwich press manufacturers are not just suppliers of machinery; they are key players in the industrie, driving innovation, ensuring quality, and enhancing efficiency. Their contributions extend beyond the physical product to the overall production process, safety, sustainability, and global market trends. Without their expertise and dedication, the industrie would struggle to meet the demands of an ever-evolving food landscape.

Innovations and Technologies from Sandwich Press Manufacturers

In the ever-evolving landscape of manufacturing, sandwich press manufacturers have played a pivotal role in driving innovations and advancing technologies. These specialized presses are not just tools of the trade; they are the heartbeat of numerous industries, from automotive to aerospace, from food processing to electronics. Let’s delve into some of the groundbreaking developments and technologies that have emerged from the world of sandwich press manufacturers.

The advent of multi-axis technology has revolutionized the way sandwich presses are used. Once limited to simple two-axis operations, these presses now offer precise control over multiple axes, allowing for complex and intricate shaping processes. This advancement has opened up new possibilities for creating lightweight yet strong components that are essential in high-performance industries.

One of the most significant innovations is the integration of computer numerical control (CNC) into sandwich presses. This integration has turned these machines into precision tools that can execute highly detailed and customized tasks. CNC systems enable operators to program complex patterns and shapes with ease, resulting in products that meet the exacting standards required in modern manufacturing.

The development of high-pressure hydraulic systems has been another game-changer. These systems provide the necessary force to compress materials with precision, ensuring that the sandwich structure achieves the desired thickness and density. This technology is particularly crucial in the production of composite materials, where the consistency of the sandwich layers is paramount for the final product’s performance.

Energy efficiency has also become a focal point for sandwich press manufacturers. With the rise of environmental concerns and the need to reduce carbon footprints, these manufacturers have developed energy-saving features that not only lower operational costs but also contribute to a greener planet. Advanced insulation, optimized hydraulic circuits, and the use of regenerative braking systems are just a few examples of how these presses are becoming more eco-friendly.

The introduction of smart sensors and real-time monitoring systems has enhanced the safety and efficiency of sandwich presses. These sensors can detect anomalies in the manufacturing process, such as overheating or pressure imbalances, and alert operators to potential issues before they lead to costly errors. The data collected by these systems can also be analyzed to improve processes and reduce downtime.

In the realm of materials, sandwich press manufacturers have explored new frontiers. The ability to bond dissimilar materials, such as combining metals with plastics or ceramics, has expanded the range of applications for sandwich structures. This material innovation has enabled the creation of lightweight, durable, and thermally efficient components that are essential in industries like aerospace and automotive.

Another key innovation is the development of modular sandwich press designs. These presses can be configured to handle a variety of materials and processes, making them versatile and adaptable to changing manufacturing needs. The modular approach also simplifies maintenance and allows for quick upgrades to keep pace with technological advancements.

The use of advanced software and simulation tools has allowed sandwich press manufacturers to optimize the design and operation of their machines. By simulating the manufacturing process, engineers can predict and mitigate potential issues, leading to higher quality products and reduced waste.

In the food industry, sandwich press manufacturers have contributed to the creation of healthier and more sustainable food products. The ability to compress and form a variety of ingredients into compact, nutrient-rich sandwiches has opened up new avenues for food innovation. These presses are also used in the production of energy bars and other snack foods, where the consistency and texture are crucial.

As sandwich press manufacturers continue to innovate, they are also focusing on the integration of Internet of Things (IoT) capabilities. This means that these presses can be connected to a network, allowing for remote monitoring, predictive maintenance, and real-time data analysis. The IoT integration is expected to further enhance the efficiency and productivity of sandwich presses in the industrie.

In conclusion, the role of sandwich press manufacturers in driving innovations and technologies is undeniable. From multi-axis control and CNC integration to energy-efficient systems and IoT connectivity, these manufacturers are at the forefront of creating the tools that shape the future of manufacturing. Their continuous pursuit of excellence ensures that sandwich structures remain a cornerstone in the industrie, providing solutions for a wide range of complex challenges.

Choosing the Right Sandwich Press Manufacturer: Key Factors to Consider

When it comes to selecting the right sandwich press manufacturer, the decision can significantly impact the quality and efficiency of your production process. Here are some key factors to consider:

Quality Assurance: The cornerstone of any reputable sandwich press manufacturer is their commitment to quality. Look for manufacturers that have rigorous quality control measures in place, ensuring that every press they produce meets the highest standards. This might include certifications like ISO or CE, which demonstrate compliance with international quality and safety regulations.

Technical Expertise: The technical capabilities of a sandwich press manufacturer are crucial. They should be adept at understanding the specific needs of your industry and designing presses that cater to those requirements. This expertise often translates into a deep understanding of materials, heat distribution, and pressure regulation, which are all critical in achieving uniform and high-quality sandwiches.

Customization Options: Every business has unique needs, and the ability to customize your sandwich press is a significant advantage. A good manufacturer should offer a range of configurations, from size and shape to features like adjustable heat settings and non-stick surfaces. This flexibility allows for a tailored solution that fits your specific production demands.

Warranty and Support: A reliable sandwich press manufacturer will stand behind their products with a robust warranty and exceptional customer support. This means being available for maintenance, repairs, and technical assistance as needed. It’s also important to consider how quickly they can respond to issues and whether they provide training or documentation to help you get the most out of your equipment.

Durability and Longevity: The lifespan of your sandwich press is a critical consideration. Look for manufacturers that use high-quality materials and construction techniques that result in durable, long-lasting machines. A well-made sandwich press can withstand the rigors of continuous use and reduce the frequency of repairs and replacements.

Cost-Effectiveness: While investing in a high-quality sandwich press is important, it’s equally crucial to consider the cost-effectiveness of the manufacturer’s offerings. This includes not just the initial purchase price but also the long-term costs such as maintenance, energy consumption, and potential downtime due to equipment failure. A cost-effective solution is one that offers the best value for your money over time.

Industry Reputation: The reputation of a sandwich press manufacturer in your industry can speak volumes about their reliability and performance. Look for companies with a strong track record, positive reviews from other businesses, and a history of innovation. A manufacturer with a good reputation is more likely to provide you with a reliable and efficient press.

Regulatory Compliance: Depending on the industry you’re in, there may be specific regulations and standards that your sandwich press must adhere to. A reputable manufacturer will be well-versed in these requirements and will ensure that their products are compliant, saving you from potential legal issues or recalls.

Service and Training: The level of service and training provided by the manufacturer can greatly influence the success of your operation. Consider whether they offer comprehensive training for your staff on how to operate and maintain the sandwich press effectively. Good manufacturers will have a support team that is readily available to address any questions or concerns you may have.

Market Responsiveness: The ability of a sandwich press manufacturer to respond to market trends and customer feedback is important. A company that is proactive in adapting to new technologies and customer needs is more likely to provide you with a press that is future-proof and adaptable to any changes in your business.

After-Sales Service: Finally, consider the after-sales service offered by the manufacturer. This includes the availability of spare parts, the ease of obtaining repairs, and the overall support provided after the sale. A manufacturer that invests in a strong after-sales service network demonstrates a commitment to customer satisfaction and ongoing support.

Case Studies: Notable Sandwich Press Manufacturers in the Industrie

In the world of sandwich presses, there are several manufacturers that have made a significant mark in the industrie. Let’s delve into a few notable case studies that highlight the contributions of these manufacturers.

One such manufacturer is German-based Hesse Maschinenbau, known for its precision engineering and state-of-the-art sandwich press technology. Their presses are widely used in the automotive, aerospace, and construction industries, where high-quality sandwich panels are essential. Hesse’s commitment to innovation is evident in their ability to produce presses that can handle materials like carbon fiber and honeycomb cores, offering unparalleled performance and durability.

Another standout manufacturer is Italian firm Foseco, which has a reputation for producing high-speed sandwich presses that are both efficient and cost-effective. Their presses are often equipped with advanced control systems that ensure precise and repeatable production processes. Foseco’s case studies often showcase how their machinery has helped customers reduce production times and improve overall productivity.

In the United States, Aker Finnyards has made a name for itself in the marine industry with its specialized sandwich press solutions. Their presses are designed to produce lightweight, strong panels for shipbuilding, which are crucial for fuel efficiency and environmental sustainability. Aker Finnyards’ case studies often highlight the energy savings and reduced carbon footprint achieved by their customers, thanks to the lightweight sandwich panels produced on their machinery.

Swedish manufacturer Sandvik has also made significant strides in the sandwich press industrie. Known for their expertise in materials technology, Sandvik has developed presses that can handle a wide range of materials, including metals, plastics, and ceramics. Their case studies often feature the development of custom solutions for unique applications, such as creating sandwich panels for high-performance racing cars or aerospace components.

Japanese company Nippon Sheet Glass has a strong presence in the architectural and transportation sectors with their sandwich press technology. Their presses are capable of producing panels with excellent thermal insulation properties, which are vital for energy efficiency in buildings and vehicles. Case studies from Nippon Sheet Glass often highlight the aesthetic appeal and structural integrity of the sandwich panels they produce, as well as the environmental benefits of using their products.

In the realm of renewable energy, Chinese manufacturer Zhejiang Jinfeng has made a notable impact with their sandwich presses designed for solar panel production. Their technology ensures the precise alignment and bonding of solar cells to substrates, which is critical for the efficiency of solar panels. Jinfeng’s case studies often showcase how their presses have helped solar panel manufacturers achieve higher yields and lower production costs.

Another example is the British company MTC, which has developed sandwich presses specifically for the aerospace industry. Their presses are designed to handle the complex geometries and high-precision requirements of aerospace components. Case studies from MTC often reveal how their presses have contributed to the production of lightweight, strong, and reliable structures for aircraft, ultimately enhancing fuel efficiency and reducing emissions.

The French firm Saint-Gobain has also made significant contributions to the sandwich press industrie, particularly in the construction sector. Their presses are used to produce insulation panels that offer excellent thermal and acoustic properties. Case studies from Saint-Gobain often demonstrate how their sandwich panels have been integrated into green building projects, helping to achieve energy-efficient and sustainable structures.

These case studies from various sandwich press manufacturers in the industrie illustrate the diverse applications and innovative solutions that these companies offer. From automotive to aerospace, construction to renewable energy, the role of sandwich press manufacturers is pivotal in driving technological advancements and meeting the evolving demands of various industries.

The Future of Sandwich Press Manufacturing: Trends and Predictions

In the ever-evolving landscape of manufacturing, sandwich press technology has become a cornerstone in various industries. The future of sandwich press manufacturing is poised to be shaped by a blend of technological advancements, market demands, and environmental considerations. Here’s a glimpse into the trends and predictions that could define the next chapter in this field.

The integration of automation is a trend that’s gaining momentum. With the rise of Industry 4.0, sandwich press manufacturers are increasingly focusing on creating systems that can be integrated into larger automated production lines. This not only enhances efficiency but also reduces the need for manual labor, leading to cost savings and improved precision.

Energy efficiency is another critical area of innovation. As the world becomes more conscious of its environmental footprint, manufacturers are exploring ways to make sandwich presses more energy-efficient. This includes the development of new materials that can reduce energy consumption during the pressing process, as well as the implementation of smart systems that optimize energy usage in real-time.

Customization is becoming more accessible and tailored to specific industry needs. Modern sandwich press manufacturers are offering a range of options that cater to different applications, from food processing to composite materials. The ability to customize the size, pressure, and temperature settings of a sandwich press ensures that it can be optimized for the unique requirements of each project.

The rise of additive manufacturing, or 3D printing, is also influencing the sandwich press industry. While 3D printing is not yet a direct replacement for traditional sandwich press methods, it is being used to create custom molds and tools that can then be used with sandwich presses. This hybrid approach allows for more complex and intricate designs that were previously unattainable.

Sustainability is a driving force in the manufacturing sector, and sandwich press manufacturers are responding by exploring eco-friendly materials and processes. Recyclable materials, biodegradable components, and energy-saving technologies are becoming standard features in new sandwich press models. The goal is to reduce the carbon footprint and support a more sustainable production cycle.

Smart sensors and IoT (Internet of Things) technology are being integrated into sandwich presses to provide real-time data and predictive maintenance. These smart presses can monitor their own performance, alerting operators to potential issues before they become major problems. This not only increases uptime but also reduces the risk of downtime and costly repairs.

In terms of market trends, the demand for lightweight and high-strength materials is on the rise. Sandwich panels, which are created using sandwich press technology, are increasingly being used in the aerospace, automotive, and construction industries. As these industries continue to grow, so too will the demand for efficient and reliable sandwich press solutions.

Regulatory compliance is another area that is shaping the future of sandwich press manufacturing. As standards and regulations become more stringent, manufacturers must ensure that their products meet the latest safety and quality requirements. This often involves investing in new testing equipment and quality control measures.

The global nature of the market is also a factor. Sandwich press manufacturers are looking beyond their domestic markets to expand into new regions. This requires a deep understanding of local regulations, cultural preferences, and market dynamics. It also means adapting their products to meet the specific needs of different markets.

Innovation in software and control systems is another trend. Advanced software is being developed to optimize the pressing process, ensuring that each panel is produced to the highest standards. This includes the ability to simulate the pressing process before it occurs, allowing for adjustments to be made without the need for physical prototyping.

The future of sandwich press manufacturing also hinges on the availability of skilled labor. As the technology becomes more complex, the need for skilled technicians and engineers who can operate and maintain these advanced systems grows. Investing in training and education is therefore a priority for many manufacturers.

Lastly, the rise of remote monitoring and control systems is expected to become more prevalent. These systems allow operators to manage and monitor sandwich press operations from anywhere in the world, providing flexibility and convenience. This trend is likely to continue as the industry becomes more globalized and interconnected.

In conclusion, the future of sandwich press manufacturing is bright, with a host of trends and predictions pointing to a future of innovation, efficiency, and sustainability. As manufacturers continue to adapt to the changing demands of the market, the sandwich press industry is poised to play a crucial role in shaping the future of manufacturing across various sectors.

Conclusion: Why Sandwich Press Manufacturers Are Essential in the Industrie

In the ever-evolving landscape of manufacturing, sandwich press manufacturers play a pivotal role. These companies are the architects of precision, crafting machines that are integral to various industries. The importance of these manufacturers cannot be overstated, as their contributions extend far beyond the production line. They are the driving force behind innovation, efficiency, and the quality of products that we rely on daily. Let’s delve into why sandwich press manufacturers are essential in the industrie.

Their expertise lies in the ability to design and produce presses that cater to specific needs, ensuring that the sandwiching process is not just efficient but also reliable. From the automotive industry to food processing, these presses are the backbone of numerous applications. The precision and consistency they deliver are critical for the quality of the final product.

The quality of materials used in the construction of sandwich presses is paramount. Manufacturers must select high-grade materials that can withstand the demands of continuous use and the rigors of different manufacturing environments. Whether it’s stainless steel for food-grade applications or specialized alloys for high-temperature processes, the choice of materials directly impacts the lifespan and performance of the press.

Innovation is at the heart of what sandwich press manufacturers do. They are constantly pushing the boundaries of technology to create more efficient, durable, and user-friendly machines. Features like automated controls, advanced safety systems, and energy-saving mechanisms are just a few examples of how these manufacturers are leading the way in technological advancements.

When it comes to customization, sandwich press manufacturers excel. Each industry has unique requirements, and these manufacturers are adept at tailoring their presses to meet those specific needs. This level of customization ensures that the end product is not only of high quality but also optimized for the particular application.

The reliability of a sandwich press is non-negotiable. These machines are expected to run for extended periods without failure, which is why rigorous testing and quality control are integral parts of the manufacturing process. Manufacturers invest in state-of-the-art testing facilities to ensure that their products meet the highest standards of performance and safety.

Safety is another critical aspect that sandwich press manufacturers prioritize. They understand the importance of creating machines that minimize the risk of accidents and protect the well-being of operators. From ergonomic designs to fail-safe mechanisms, these manufacturers go the extra mile to ensure that their presses are as safe as possible.

In the food industry, where hygiene is paramount, sandwich press manufacturers must adhere to strict regulations. They produce presses that are easy to clean and maintain, reducing the risk of contamination and ensuring compliance with health standards. This dedication to cleanliness and safety is what sets them apart in the industrie.

The sustainability aspect cannot be ignored. As the world becomes more environmentally conscious, sandwich press manufacturers are responding by developing machines that are energy-efficient and eco-friendly. From using recycled materials to designing presses with longer lifespans, these companies are taking steps to reduce their ecological footprint.

The global reach of sandwich press manufacturers is impressive. They supply to markets all over the world, adapting their products to meet regional standards and preferences. This international presence allows them to stay ahead of trends and incorporate global best practices into their manufacturing processes.

When considering the impact of sandwich press manufacturers on the industrie, one must also look at the economic angle. They create jobs, support local economies, and contribute to the overall growth of the manufacturing sector. Their contributions are not just in the physical products they produce but also in the knowledge and expertise they share with customers and the industry at large.

In the realm of research and development, sandwich press manufacturers are at the forefront. They invest in R&D to explore new materials, improve existing technologies, and create solutions that address the evolving needs of their customers. This commitment to innovation ensures that they remain competitive and at the cutting edge of their field.

The partnerships that sandwich press manufacturers form with raw material suppliers, component manufacturers, and end-users are crucial. These collaborations lead to the development of integrated solutions that enhance the overall efficiency and effectiveness of the manufacturing process.

The importance of after-sales service cannot be overstated. Sandwich press manufacturers understand that the relationship doesn’t end when the machine is delivered. They offer comprehensive support, including training, maintenance, and technical assistance, to ensure that their customers can maximize the value of their investment.

In conclusion, sandwich press manufacturers are indispensable in the industrie. Their role in driving innovation, ensuring quality, and supporting the economic growth of manufacturing cannot be underestimated. From the precision of their machines to the reliability of their service, these manufacturers are the backbone of modern production, and their contributions are vital to the success of countless industries worldwide.