In the ever-evolving landscape of kitchen appliances, a groundbreaking material is poised to redefine efficiency and durability. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is not just a scientific marvel but is now being harnessed to revolutionize the performance of kitchen gadgets. This introduction delves into the transformative impact of graphene coatings on various kitchen appliances, highlighting their benefits and the market trends that are setting the stage for a new era of culinary technology.

Introduction to Graphene Coating Technology in Kitchen Appliances

In the ever-evolving world of kitchen appliances, innovation is the key to staying ahead of the curve. One such innovation that has been making waves is the integration of patented graphene coating technology. This cutting-edge material, known for its exceptional strength and conductivity, is now being applied to kitchen appliances to enhance their performance and durability. Let’s delve into how this technology is transforming the way we interact with our kitchen gadgets.

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is the thinnest and strongest material known to man. Its unique properties, such as high thermal conductivity, excellent electrical conductivity, and remarkable flexibility, make it an ideal candidate for improving the efficiency and lifespan of kitchen appliances. By applying a thin layer of graphene coating to the surfaces of these devices, manufacturers are able to create products that are not only more efficient but also easier to maintain.

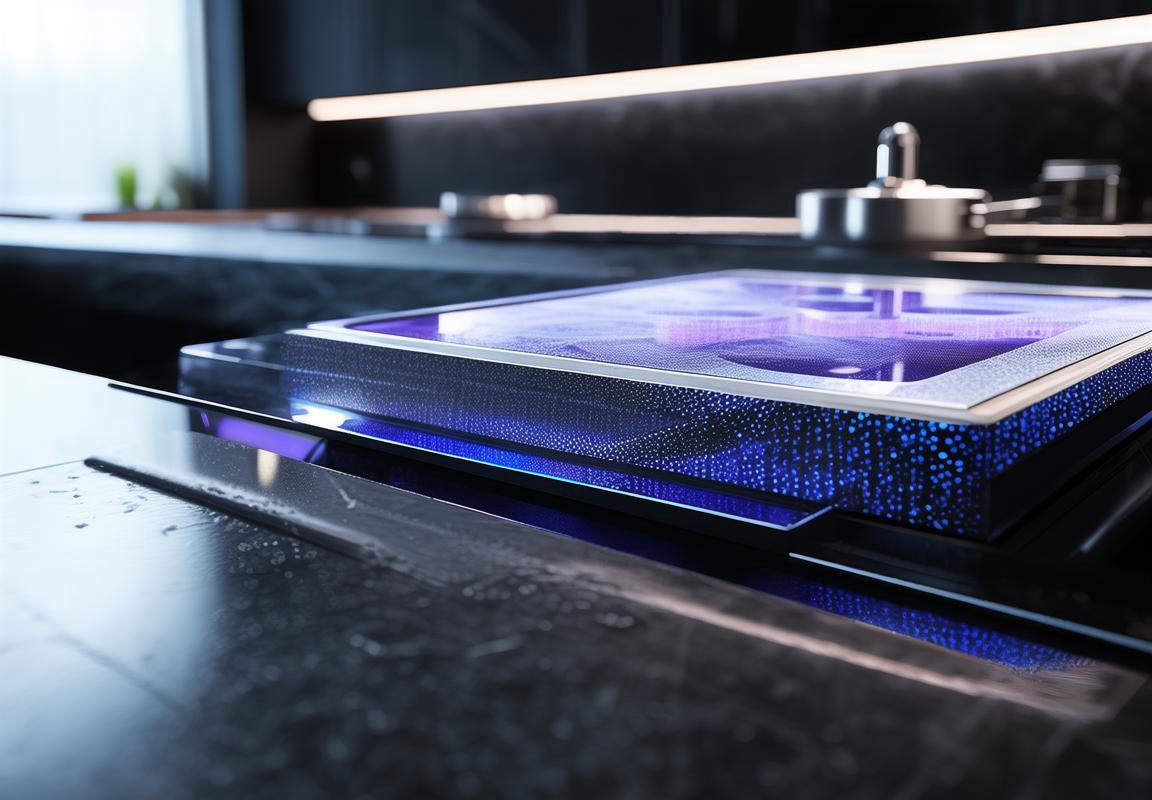

The first thing that sets graphene-coated appliances apart is their superior heat management. Traditional appliances often struggle with heat distribution, leading to inefficient cooking times and potential damage to the appliance itself. Graphene’s high thermal conductivity ensures that heat is evenly distributed across the surface, resulting in faster and more precise cooking. This is particularly beneficial for cooking surfaces like induction cooktops and ovens, where even heat is crucial for optimal performance.

In the realm of cleaning, graphene-coated appliances are a game-changer. The non-stick properties of graphene make it nearly impossible for food particles to adhere to the surface, significantly reducing the need for scrubbing and cleaning. This not only saves time and effort but also extends the life of the appliance, as there is less wear and tear from constant cleaning. The result is a cleaner, more hygienic kitchen environment.

When it comes to durability, graphene coating takes it to a whole new level. The material is incredibly resistant to scratches, corrosion, and wear, which means that appliances with graphene coatings can withstand the rigors of everyday use. This is particularly important in kitchens where appliances are exposed to high temperatures, moisture, and frequent cleaning.

The European and American markets have been quick to embrace graphene coating technology in kitchen appliances. In Europe, there is a growing trend towards eco-friendly and energy-efficient appliances, and graphene fits perfectly into this narrative. The high thermal conductivity of graphene allows for more efficient energy use, which is a significant draw for environmentally conscious consumers.

In the United States, the focus is more on convenience and innovation. Graphene-coated appliances offer a seamless blend of functionality and style, appealing to the tech-savvy consumer who seeks the latest advancements in kitchen technology. The market for these appliances is expanding rapidly, with more manufacturers investing in research and development to bring new graphene-coated products to market.

One of the most exciting aspects of graphene coating technology is the patent-pending innovations that are being developed. These patents protect unique methods of applying graphene to appliances, ensuring that the benefits are maximized while maintaining a competitive edge in the market. Some of these innovations include the development of graphene coatings that are self-cleaning and self-healing, further enhancing the longevity and ease of use of kitchen appliances.

Consumers are reaping the benefits of these advancements in several ways. For one, the non-stick properties of graphene-coated cookware mean that dishes are easier to clean, which is a huge time-saver for busy households. Additionally, the energy efficiency of appliances with graphene coatings can lead to significant savings on utility bills, making them an attractive investment for any home.

Expert insights suggest that the future of kitchen appliances is bright, with graphene coating technology playing a pivotal role. As research continues to uncover new applications for graphene, we can expect to see even more innovative products hitting the market. The potential for graphene to improve the performance, durability, and user experience of kitchen appliances is nearly limitless.

In conclusion, the integration of patented graphene coating technology in kitchen appliances marks a significant milestone in the industry. With its myriad benefits, from enhanced heat management to increased durability, graphene is poised to revolutionize the way we cook and clean. As the technology continues to evolve, we can look forward to a future where our kitchen appliances are not just tools but also smart, efficient, and a pleasure to use.

The Rise of Graphene in Kitchen Appliances: A Game-Changer

The kitchen, once a realm of simple stoves and ovens, has now become a battleground for innovation and efficiency. At the forefront of this revolution is the integration of patented graphene coating technology, which is not just changing the way we cook but redefining the entire landscape of kitchen appliances. This cutting-edge technology has surged in popularity, transforming the industry and consumers’ expectations.

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is known for its exceptional strength, flexibility, and conductivity. When applied as a coating to kitchen appliances, it brings a multitude of benefits that were once unimaginable. From induction cooktops to refrigerators, the impact of graphene has been profound.

One of the most significant changes brought about by graphene is the enhanced efficiency of cooking appliances. Traditional cookware often loses heat, leading to longer cooking times and increased energy consumption. However, with graphene’s superior thermal conductivity, heat is distributed more evenly across the surface of cookware, reducing cooking times and energy usage. This not only saves money on utility bills but also makes cooking more environmentally friendly.

In the realm of induction cooktops, graphene’s role is even more pronounced. The technology allows for faster heat transfer to pots and pans, enabling precise temperature control. This means that delicate sauces can be simmered to perfection without the risk of burning, and complex recipes can be executed with ease. The result is a more enjoyable and efficient cooking experience.

Refrigerators, too, have seen a transformation with the introduction of graphene. The material’s ability to conduct heat makes it an ideal insulator, significantly reducing energy consumption. Graphene-coated refrigerators can maintain a consistent temperature with less power, leading to lower energy bills and a smaller carbon footprint.

The adoption of graphene in kitchen appliances has also led to advancements in durability and ease of maintenance. The coating is highly resistant to scratches, corrosion, and wear, making appliances more resilient to everyday use. This means that kitchenware and appliances can last longer, requiring less frequent replacement and reducing waste.

In the European market, where sustainability and energy efficiency are paramount, the rise of graphene-coated appliances has been particularly welcomed. Consumers are increasingly conscious of the environmental impact of their purchases, and graphene provides a solution that aligns with these values. The European Union has even recognized the potential of graphene, investing in research and development to further enhance its applications in various sectors, including kitchen appliances.

The American market, while similar in its embrace of energy-efficient technology, has also seen a surge in demand for appliances with graphene coatings due to the convenience they offer. The technology has been particularly popular among health-conscious consumers, who appreciate the non-toxic and hypoallergenic nature of graphene.

The integration of patented graphene coating technology has not only improved the performance of kitchen appliances but has also spurred a wave of innovation. Manufacturers are now exploring new ways to incorporate graphene into various kitchen products, from oven liners to kitchen utensils. This has led to a plethora of new products hitting the market, each promising to make cooking and kitchen maintenance more efficient and enjoyable.

The benefits of graphene are not limited to consumers; they extend to manufacturers as well. By reducing energy consumption and maintenance costs, graphene-coated appliances can be more cost-effective for businesses. This has led to increased investment in the technology, further fueling its growth and adoption.

As the demand for graphene-coated kitchen appliances continues to rise, so does the competition among manufacturers. This competition is driving the development of even more advanced and specialized coatings, tailored to specific appliance types and consumer needs. The result is a market that is constantly evolving, offering consumers a wider range of options to choose from.

In conclusion, the rise of graphene in kitchen appliances is a testament to the power of innovation and the relentless pursuit of efficiency. It’s a game-changer that promises to continue reshaping the kitchen landscape, offering consumers a more sustainable, convenient, and enjoyable cooking experience.

Understanding the Unique Properties of Graphene

Graphene, a material that has garnered immense attention in various industries, is now making waves in the kitchen appliance sector. This extraordinary material, in its purest form, is a single layer of carbon atoms arranged in a hexagonal lattice, resembling a honeycomb. The properties of graphene are truly remarkable, setting it apart from other materials and revolutionizing the way we look at kitchen appliances.

Its strength is one of its defining characteristics. Graphene is stronger than diamond, the hardest known material on Earth. This unparalleled strength makes it a perfect candidate for protecting kitchen appliances from scratches, dings, and other forms of wear and tear. Imagine a countertop that can withstand the impact of a heavy skillet or a microwave door that resists dents without bending. The structural integrity of graphene-coated appliances is not just robust—it’s also exceptionally lightweight, which enhances durability without adding unnecessary bulk.

Another standout feature of graphene is its exceptional thermal conductivity. Traditional kitchen appliances can often be slow to heat up or uneven in temperature distribution, leading to inefficient cooking and wasted energy. Graphene’s ability to conduct heat at a rate 10 times faster than copper ensures that appliances like cooktops and ovens achieve optimal performance quickly and maintain consistent heat levels. This not only saves time and energy but also results in better food quality, as the precise temperature control can enhance the flavor and texture of dishes.

The conductivity of graphene extends beyond heat; it also excels in electrical conductivity. This makes it an ideal material for improving the efficiency of electric appliances, such as toasters, blenders, and mixers. Graphene can be used to create lighter and more energy-efficient electric motors, which is a significant step forward in the energy consumption of kitchen appliances. The result is a more eco-friendly approach to cooking and preparing meals.

Graphene’s chemical inertness is another key property that has garnered interest in the kitchen appliance industry. This means that the material does not react with other substances, making it perfect for non-stick coatings. A non-stick surface that can last for years without peeling or flaking off is now possible thanks to graphene’s chemical stability. This not only simplifies the cleaning process for consumers but also contributes to the longevity of the appliance itself.

The material’s transparency is a further testament to its unique qualities. Graphene is nearly as transparent as glass, which opens up possibilities for innovative appliance designs. For instance, it could be used to create transparent cookware that allows users to monitor food cooking progress without opening the lid, reducing steam loss and heat escape.

One of the most fascinating aspects of graphene is its flexibility. Unlike most materials, which become rigid or when bent, graphene retains its structural integrity. This flexibility has led to the development of foldable or rollable kitchen appliances, which could redefine how we use and store our kitchen tools. Think of a countertop oven that can fold out to fit under the cabinet when not in use, or a portable induction cooktop that can be rolled up and taken on the go.

Graphene’s ability to absorb and emit light is also noteworthy. This property could lead to the development of kitchen appliances with built-in lighting systems, which could change the ambiance of a kitchen and make it more visually appealing. For example, a fridge could not only keep your food fresh but also illuminate your kitchen with subtle LED lighting, creating a warm and inviting space.

The biocompatibility of graphene is yet another factor that could play a significant role in the kitchen appliance industry. The material is non-toxic and could potentially be used in the manufacturing of appliances that are safe for sensitive individuals, such as those with allergies or skin conditions. This opens the door to a range of health-conscious products that prioritize both functionality and user well-being.

Lastly, the potential for customization is immense with graphene. Since the material can be produced in sheets of virtually any size, thickness, and shape, it offers a high degree of flexibility in design. Manufacturers could create appliances that are tailored to the specific needs and preferences of consumers, from personalized cookware to customized countertop surfaces.

In conclusion, the unique properties of graphene—its strength, thermal and electrical conductivity, chemical inertness, flexibility, light-emitting capabilities, biocompatibility, and customization potential—make it an extraordinary material for the kitchen appliance industry. As researchers continue to explore its applications, we can expect to see innovative new products that not only enhance the efficiency and safety of kitchen appliances but also enrich the culinary experience in ways we haven’t yet imagined.

How Graphene Coatings Revolutionize Appliance Performance

Graphene, a mere single atom thick layer of carbon, has been turning heads across various industries, and the kitchen appliance sector is no exception. Its unique properties are reshaping the performance of appliances, making them more efficient, durable, and user-friendly. Let’s delve into how graphene coatings are revolutionizing appliance performance.

One of the standout characteristics of graphene is its exceptional thermal conductivity. Traditional materials used in kitchen appliances often struggle to manage heat effectively, leading to inefficiencies and potential safety hazards. Graphene, on the other hand, boasts the highest thermal conductivity of any material known to man, surpassing even silver. This means that appliances coated with graphene can dissipate heat much faster, reducing the risk of overheating and improving energy efficiency. For example, a microwave oven with a graphene coating can cook food more quickly and evenly, leading to significant energy savings.

Not only does graphene excel in thermal conductivity, but it also demonstrates incredible strength and flexibility. This dual trait is a game-changer for kitchen appliances, as it allows for lighter and more robust designs. Consider a high-end range hood; with a graphene coating, it can be made thinner and lighter without compromising on durability. This innovation not only enhances the aesthetic appeal of the appliance but also reduces the weight, making it easier to install and maintain.

Another remarkable property of graphene is its anti-adhesive nature. In the kitchen, this means that food particles and spills are far less likely to stick to surfaces, making cleaning a breeze. Imagine a stove top coated with graphene; it would be almost impossible for burnt-on residue to adhere, making it an ideal choice for busy households. This property extends beyond cooking surfaces to include cookware and kitchen utensils, which can be coated to prevent sticking and maintain their longevity.

Graphene coatings also have a significant impact on energy efficiency. By reflecting heat, they can reduce the amount of heat absorbed by appliances, thus lowering cooling requirements. For instance, refrigerators with graphene-coated surfaces can maintain cooler temperatures with less energy, contributing to lower electricity bills and a smaller carbon footprint. The same goes for ovens and dishwashers, where graphene’s reflective qualities can minimize heat loss and improve energy conservation.

In the realm of safety, graphene coatings play a crucial role. Appliances with these coatings can be designed to be flame-resistant and self-healing. For example, if a small flame ignites on a countertop, the graphene coating can act as a barrier, preventing the flame from spreading. Additionally, if the coating is damaged, it can sometimes self-repair, which is a testament to its resilience and versatility.

The of graphene also cannot be overlooked. It is naturally resistant to bacteria, mold, and viruses, making it an excellent choice for kitchen appliances. A refrigerator or a dishwasher with graphene coatings can maintain a cleaner and healthier environment, reducing the risk of foodborne illnesses. This is particularly beneficial in modern kitchens where hygiene is a top priority.

The versatility of graphene coatings extends to the aesthetic aspect of appliances. These coatings can be used to create a sleek, glossy finish that is easy to clean and visually appealing. The ability to customize the color and texture of these coatings adds an extra layer of personalization to kitchen appliances, allowing consumers to match their appliances to their decor.

From a sustainability standpoint, graphene coatings offer a green alternative to traditional materials. Graphene is a sustainable material, and its use in coatings reduces the reliance on metals like silver, which are not only more expensive but also more environmentally impactful due to mining and processing. By opting for graphene, manufacturers can contribute to a more eco-friendly and circular economy.

In conclusion, the integration of graphene coatings into kitchen appliances is transforming the way we use and interact with our kitchen tools. With its unparalleled thermal conductivity, strength, flexibility, anti-adhesive properties, energy efficiency, safety features, and aesthetic appeal, graphene is poised to become a cornerstone material in the kitchen appliance industry. As research and development continue to uncover new applications for graphene, we can expect to see even more innovative and efficient appliances in the not-too-distant future.

European and American Markets: A Comparative Analysis

Graphene, with its remarkable properties, has begun to make waves in the kitchen appliance market across Europe and America. This ultra-thin layer of carbon atoms arranged in a honeycomb lattice offers unparalleled strength, flexibility, and conductivity. Let’s delve into how these attributes are reshaping the performance of kitchen appliances in both regions.

In Europe, where sustainability and eco-friendly technologies are highly valued, graphene coatings are gaining traction for their ability to enhance appliance longevity. For instance, refrigerators with graphene coatings can maintain a consistent temperature more efficiently, reducing energy consumption and extending the life of the appliance. The market is witnessing a shift towards appliances that not only perform better but also contribute to a greener planet.

On the other hand, in the United States, the focus is often on innovation and the latest technological advancements. Graphene-coated appliances are catching the eye of consumers for their sleek designs and cutting-edge features. Smart kitchen appliances, such as induction cooktops and microwaves, are being enhanced with graphene to provide faster and more precise cooking times, which is a significant draw for tech-savvy consumers.

The European market is also seeing a rise in the use of graphene in non-stick cookware. The unique thermal properties of graphene allow for an even distribution of heat, making it ideal for reducing sticking and ensuring food cooks to perfection. This has led to a surge in demand for cookware that combines the convenience of non-stick surfaces with the durability and health benefits of graphene.

In the American market, the integration of graphene into kitchen appliances is not just about performance; it’s also about convenience and user experience. For example, graphene-infused cutting boards offer antibacterial properties, reducing the risk of food contamination. The sleek, non-reactive surface is also favored for its ease of cleaning and its ability to maintain its appearance over time.

One of the key differences between the European and American markets lies in the regulatory landscape. Europe has stricter regulations regarding the use of chemicals in consumer products, which means that graphene-coated appliances must meet stringent safety standards. This has led to a more cautious approach to market introduction, ensuring that only products of the highest quality reach consumers.

In contrast, the American market is often more open to new technologies, which has allowed graphene-coated appliances to enter the market more quickly. However, this does not mean that safety is compromised; American manufacturers are also adhering to the highest safety standards, but the pace of innovation is typically faster.

Another factor that sets the two markets apart is the price point. European consumers are generally willing to pay a premium for high-quality, sustainable products, which has encouraged manufacturers to invest in graphene research and development. In the U.S., while there is a segment of the market that is willing to pay more for premium appliances, the overall price sensitivity means that manufacturers must balance performance with cost-effectiveness.

The European and American markets are also different in terms of consumer behavior. In Europe, there is a strong emphasis on health and wellness, which is reflected in the popularity of appliances that promote healthy cooking, such as air fryers and slow cookers. Graphene-coated appliances that can provide these benefits without compromising on health are likely to gain a significant market share.

In the U.S., consumers are more focused on convenience and efficiency. Appliances that can save time, reduce energy use, and simplify daily tasks are highly sought after. Graphene’s ability to enhance these aspects makes it a valuable addition to the American kitchen appliance market.

In conclusion, while both European and American markets are embracing graphene-coated kitchen appliances, they are doing so in distinct ways. Europe’s focus on sustainability and safety, combined with a premium pricing strategy, is creating a market that values not just performance but also environmental responsibility. The U.S., with its emphasis on innovation and convenience, is driving the adoption of graphene through the development of smart, efficient appliances. Both regions offer opportunities for growth and innovation, and as graphene technology continues to evolve, we can expect to see even more diverse and advanced kitchen appliances hitting the shelves in both markets.

Innovations in Patented Graphene Coating Technology

Graphene, a material celebrated for its exceptional strength and conductivity, has been making waves in various industries. In the realm of kitchen appliances, patented graphene coating technology is pushing boundaries and transforming performance. Let’s delve into the innovations shaping this cutting-edge field.

Graphene’s ultra-thin sheets of carbon atoms arranged in a honeycomb lattice offer properties that are virtually unmatched. These include incredible tensile strength, electrical conductivity, thermal conductivity, and flexibility. When applied as a coating to kitchen appliances, these unique characteristics create a layer of innovation that can redefine how we use and maintain our appliances.

One significant innovation is the application of graphene’s electrical conductivity to enhance appliance performance. For instance, refrigerators with graphene coatings can maintain cooler temperatures more efficiently, reducing energy consumption and extending the lifespan of the appliance. This isn’t just about conserving energy; it’s about creating appliances that are not only sustainable but also durable.

The thermal conductivity of graphene is another game-changer. Cookware treated with graphene coatings can distribute heat more evenly, resulting in more efficient cooking and less energy waste. The rapid transfer of heat allows for precise temperature control, which is especially beneficial for delicate cooking methods like sous-vide. This technological advancement means that professional-grade cooking can be achieved in the comfort of one’s home.

In terms of durability, graphene coatings provide a robust barrier against corrosion, scratching, and abrasion. The material’s flexibility allows the coating to be applied to the most intricate surfaces, ensuring that even the most delicate appliance parts are protected. This is particularly crucial for appliances like induction cooktops and refrigerators, where wear and tear can occur due to frequent use and harsh conditions.

When it comes to non-stick properties, graphene coatings take them to a whole new level. The carbon sheets form a bond that repels food particles, making it easier to clean and reducing the need for harsh chemicals. This not only extends the life of the appliance but also contributes to a healthier cooking environment, as there’s less exposure to potentially harmful substances.

Another innovation in graphene coating technology is its potential to integrate with smart kitchen systems. With the rise of the Internet of Things (IoT), appliances are becoming more connected, and graphene’s electrical conductivity can facilitate better communication between devices. For example, a fridge with a graphene coating could send data about its internal temperature and contents to a smart kitchen hub, allowing users to monitor and adjust settings remotely.

The market for patented graphene coatings is also seeing advancements in the development of eco-friendly processes. As awareness of environmental impact grows, manufacturers are striving to produce graphene in a way that minimizes carbon footprint and reduces reliance on non-renewable resources. This green innovation is crucial for the long-term sustainability of the technology.

Moreover, the versatility of graphene coatings is being exploited in a variety of applications. From water filtration systems in dishwashers to antibacterial coatings in ovens, the material’s potential seems limitless. This adaptability means that as consumer needs evolve, graphene coatings can be tailored to meet those demands, ensuring that appliances remain relevant and effective.

The research and development of graphene coating technology are also fostering a competitive market, with companies racing to patent their innovations. This competition is driving further innovation as each company seeks to outdo the others. Patents protect the intellectual property behind these technologies, ensuring that companies can capitalize on their breakthroughs while fostering continued progress.

In the kitchen appliances sector, patented graphene coating technology is not just a surface treatment; it’s a holistic approach to improving appliance functionality, longevity, and sustainability. As users become more conscious of the environmental and health implications of their purchases, the demand for these high-tech coatings is likely to grow. The innovations in graphene coating technology are poised to change how we perceive and interact with kitchen appliances, potentially transforming them from everyday tools into smart, efficient companions in the modern household.

Consumer Benefits and Market Trends

Graphene coatings are not just a buzzword in the kitchen appliance industry; they represent a leap forward in technology that promises to enhance the performance and longevity of these devices. Here’s how these innovative coatings are transforming the landscape for consumers and the market trends they’re influencing.

Consumer Benefits

-

Enhanced DurabilityGraphene coatings offer unparalleled durability. Their molecular structure makes them incredibly strong and resistant to wear and tear, which is especially beneficial for kitchen appliances that are frequently exposed to heat, moisture, and abrasion.

-

Improved Heat ConductivityOne of the standout properties of graphene is its excellent thermal conductivity. This means appliances with graphene coatings can distribute heat more evenly and quickly, leading to more efficient cooking and baking processes.

-

Anti-Bacterial and Anti-Fungal PropertiesThe unique surface properties of graphene make it naturally antibacterial and antifungal. This not only contributes to the hygiene of kitchen appliances but also reduces the need for harsh cleaning chemicals.

-

Easy MaintenanceGraphene coatings are also highly non-stick, making them easy to clean. Spills and food residues can be wiped away without leaving stubborn stains, which is a significant advantage for busy households.

-

LongevityThe combination of durability, non-stick qualities, and antibacterial properties means that appliances with graphene coatings can last longer than those without, reducing the frequency of replacements and the overall cost of ownership.

Market Trends

-

Growing Demand for Energy EfficiencyConsumers are increasingly looking for appliances that are energy-efficient and cost-effective. Graphene coatings help to meet this demand by improving the performance of appliances, which can lead to energy savings over time.

-

Shift Towards Sustainable ProductsWith environmental concerns on the rise, there’s a growing trend towards sustainable products. Graphene coatings are a sustainable choice as they are derived from a naturally occurring material and can contribute to the reduction of waste through their longevity.

-

Integration with Smart TechnologyThe kitchen appliance market is rapidly evolving to incorporate smart technology. Graphene coatings can play a role in enhancing the performance and lifespan of smart appliances, making them a desirable feature for consumers looking for the latest in kitchen innovation.

-

Rising Awareness and EducationAs more consumers become aware of the benefits of graphene coatings, there’s a corresponding increase in demand. Educational campaigns and product demonstrations are helping to spread awareness about the technology and its applications.

-

Competition and InnovationThe emergence of graphene coatings has spurred competition among manufacturers to innovate and improve their products. This competition is leading to new developments and applications of the technology, driving market growth.

-

Global Market ExpansionThe demand for graphene-coated appliances is not confined to any one region. As more countries embrace the technology, there’s a global market expansion, with emerging markets showing significant interest in adopting graphene-coated products.

In conclusion, the integration of patented graphene coating technology in kitchen appliances is reshaping consumer preferences and market trends. The benefits to users are clear, and as awareness and education continue to grow, so too does the potential for this technology to revolutionize the appliance industry.

Expert Insights: The Future of Graphene in Kitchen Appliances

Graphene, a revolutionary material known for its extraordinary strength and conductivity, is making waves in the kitchen appliance industry. Experts are weighing in on how this tiny yet powerful carbon sheet is poised to transform our culinary experiences. From enhanced durability to smart functionality, here’s a glimpse into the future of graphene in kitchen appliances.

The integration of graphene into kitchen appliances is not just about adding a new material; it’s about enhancing the overall performance and user experience. Experts point out that graphene’s unique properties, such as its high thermal conductivity and flexibility, are set to redefine what we expect from our kitchen tools.

Graphene’s thermal conductivity is unmatched, which means kitchen appliances with graphene coatings can heat up or cool down faster. This could lead to significant energy savings, as appliances would operate more efficiently. For instance, a graphene-coated oven might reduce cooking times by a third, making it a favorite among busy cooks.

Moreover, graphene’s flexibility allows for the creation of more compact and versatile appliances. Imagine a countertop appliance that can be easily adjusted to fit different pots and pans, or a refrigerator door that can expand to accommodate larger items. These innovations are not just about convenience; they’re about rethinking the design of kitchen appliances to better suit the needs of modern consumers.

In terms of smart functionality, graphene’s ability to conduct electricity with minimal resistance makes it an ideal candidate for integrating sensors and smart technology. Experts predict that graphene-coated appliances could soon feature touchless controls, voice activation, and even predictive maintenance, all powered by the material’s exceptional electronic properties.

Another exciting aspect of graphene in kitchen appliances is its potential to extend the lifespan of these devices. The material’s resistance to corrosion and its ability to withstand high temperatures mean that appliances with graphene coatings could be more durable and require less frequent maintenance. This is particularly relevant for high-end appliances, where longevity is a key selling point.

The adoption of graphene in kitchen appliances is also being driven by environmental concerns. As the world moves towards more sustainable practices, appliances that are energy-efficient and durable are becoming increasingly popular. Graphene’s eco-friendly profile aligns with these values, making it an attractive option for manufacturers and consumers alike.

In the European market, there’s a strong focus on sustainability and innovation. Consumers are more likely to invest in appliances that not only perform well but also contribute to a greener planet. This has led to a surge in demand for graphene-coated kitchen appliances, as they offer a perfect blend of performance and environmental responsibility.

On the other side of the Atlantic, the American market is known for its love of convenience and efficiency. Graphene’s ability to enhance appliance performance while also simplifying daily tasks is resonating well with American consumers. The market is seeing a rise in smart appliances that leverage graphene’s electronic properties, offering a glimpse into the future of kitchen technology.

As for the future, experts agree that graphene has the potential to become a staple in kitchen appliances. The ongoing research and development in this field are leading to new applications and improvements that were once thought impossible. For instance, graphene’s ability to interact with light could pave the way for appliances that are more energy-efficient and visually appealing.

In conclusion, the future of graphene in kitchen appliances looks promising. Its unique properties are not only set to enhance the performance of existing devices but also to inspire new innovations. As the technology continues to evolve, we can expect to see appliances that are more efficient, user-friendly, and environmentally responsible. The kitchen of the future will not just be a place for cooking; it will be a testament to the power of materials science and innovation.

Case Studies: Successful Implementations of Graphene Coating

In the realm of kitchen appliances, the integration of graphene coatings has emerged as a beacon of innovation. Let’s delve into some notable case studies that showcase the successful implementation of this cutting-edge technology.

The kitchen of the future is not just about sleek designs and advanced functionalities; it’s also about sustainability and efficiency. One such case study involves a premium appliance manufacturer that incorporated graphene coatings into their range of cooktops. The innovative coating not only enhanced the cooktop’s durability but also improved heat distribution, leading to faster and more energy-efficient cooking.

Another compelling example is a well-known brand that applied graphene coatings to their line of refrigerators. The coating provided a scratch-resistant surface, which was a significant upgrade from traditional finishes. Moreover, the graphene’s thermal conductivity allowed the fridge to maintain a consistent temperature more effectively, reducing energy consumption and extending the appliance’s lifespan.

In the world of dishwashers, a leading manufacturer introduced a model with graphene-coated interior walls. This innovation not only made the dishwasher more resistant to corrosion and stains but also improved its cleaning performance. The coating’s antimicrobial properties minimized the growth of bacteria and mold, ensuring a cleaner and healthier kitchen environment.

The use of graphene coatings in kitchen hoods and exhaust fans has also yielded impressive results. A high-end kitchen appliance company found that the coating’s ability to repel grease and dirt made cleaning these appliances a breeze. The graphene coating also increased the fan’s efficiency, allowing for better air circulation and reducing the risk of smoke and odors lingering in the kitchen.

A notable case study involves a small appliance manufacturer that developed a line of toasters with graphene-coated surfaces. The coating improved the toasting process by providing a more even heat distribution, resulting in perfectly toasted bread every time. Additionally, the coating made the toasters easier to clean, a feature that was highly appreciated by consumers.

In the realm of kitchen sinks, a manufacturer integrated graphene coatings to enhance the durability and resistance to stains and scratches. The coating also contributed to the sink’s longevity by protecting it from the harsh effects of everyday use, such as harsh chemicals and abrasive materials.

One cannot overlook the integration of graphene coatings in kitchen utensils. A popular brand introduced a line of cookware with graphene-infused handles. The coating not only improved the grip and comfort of the utensils but also enhanced their thermal conductivity, allowing for better heat management and preventing burns.

A unique case study involves a company that developed a line of smart kitchen appliances with graphene-based sensors. These sensors provided real-time data on appliance performance, energy consumption, and even food safety. The graphene coating ensured that the sensors remained accurate and reliable over time, even in the harsh conditions of a kitchen environment.

These case studies highlight the versatility and effectiveness of graphene coatings in kitchen appliances. From cooktops and refrigerators to dishwashers and sinks, the technology has proven to be a game-changer, offering a range of benefits that enhance both the user experience and the appliance’s lifespan. As the demand for sustainable, efficient, and durable kitchen appliances continues to grow, it’s clear that graphene coatings will play a pivotal role in shaping the future of the industry.

Conclusion: Graphene’s Potential to Shape the Future of Kitchen Electronics

In the realm of kitchen electronics, graphene’s potential to revolutionize the industry is undeniable. This ultra-thin, single-layer sheet of carbon atoms has been making waves with its exceptional properties. Let’s delve into the ways graphene is reshaping the future of kitchen appliances.

Graphene’s unique combination of strength, flexibility, and conductivity has opened up new possibilities for appliance design and functionality. Its high thermal conductivity allows for faster and more efficient heat transfer, which can lead to appliances that cook more quickly and evenly. This is particularly beneficial in ovens and induction cooktops, where even heat distribution is crucial for optimal cooking results.

The lightweight nature of graphene also contributes to the development of portable and compact kitchen appliances. Imagine a blender or a coffee maker that’s as thin as a sheet of paper but just as powerful as its bulkier counterparts. The material’s ability to conduct electricity without adding weight means that appliances can be more energy-efficient and easier to handle.

In the realm of cleaning, graphene coatings are making waves. These coatings are highly durable and resistant to scratches, which means that appliances will maintain their appearance for longer. Additionally, they can be engineered to be self-cleaning, reducing the need for harsh chemicals and frequent maintenance. This is not only environmentally friendly but also a significant time-saver for busy homeowners.

One of the most intriguing aspects of graphene in kitchen appliances is its potential to integrate advanced sensors and smart technology. Graphene’s ability to conduct electricity through its entire surface allows for the creation of transparent, flexible electronics. This could lead to appliances that are not only functional but also interactive, with touch-sensitive interfaces that respond to your every move.

The European market has been particularly receptive to graphene-coated kitchen appliances. With a strong emphasis on innovation and sustainability, European consumers are eager to embrace new technologies that promise to make their lives easier and more efficient. This has spurred a wave of research and development in the region, with companies like Siemens and Philips leading the charge.

In the United States, the market for graphene-coated appliances is also growing, albeit with a slightly different focus. American consumers tend to prioritize convenience and performance, and graphene’s ability to enhance these aspects is well-received. The market is witnessing a surge in the adoption of graphene-coated cookware, which promises to be more durable and non-stick than traditional options.

Case studies of successful graphene coating implementations are already emerging. For instance, a leading manufacturer of induction cooktops has introduced a new line featuring graphene-infused surfaces. These cooktops not only heat up faster but also maintain a cooler surface temperature, making them safer to handle. Another example is a premium brand of dishwashers that now uses graphene to improve the durability of their stainless steel interiors, reducing the likelihood of rust and corrosion.

As the technology continues to evolve, we can expect to see even more innovative applications of graphene in kitchen appliances. One such innovation is the use of graphene in refrigerators, where it could improve energy efficiency and reduce the risk of food spoilage. Another is the integration of graphene into kitchen utensils, which could enhance their performance and durability.

Expert insights suggest that the future of graphene in kitchen appliances is bright. Scientists and engineers are actively working on developing new methods to apply graphene coatings, making them more cost-effective and widely accessible. This could lead to a future where every kitchen is equipped with appliances that are not just advanced but also sustainable and user-friendly.

In conclusion, graphene’s potential to shape the future of kitchen electronics is immense. From enhancing the performance of existing appliances to creating entirely new ones, this remarkable material is poised to transform the way we interact with our kitchen technology. As the market continues to evolve and consumer demand grows, we can look forward to a future where graphene-coated kitchen appliances are as common as smartphones and laptops.