In contemporary exceptionally competitive market environment, lowering manufacturing lead instances has come to be a key component for businesses to enhance efficiency and increase market responsiveness. this newsletter will discuss the elements that influence production lead times, endorse optimization strategies, and exhibit successful practices in shortening lead instances through case studies.

Production Cycle Overview

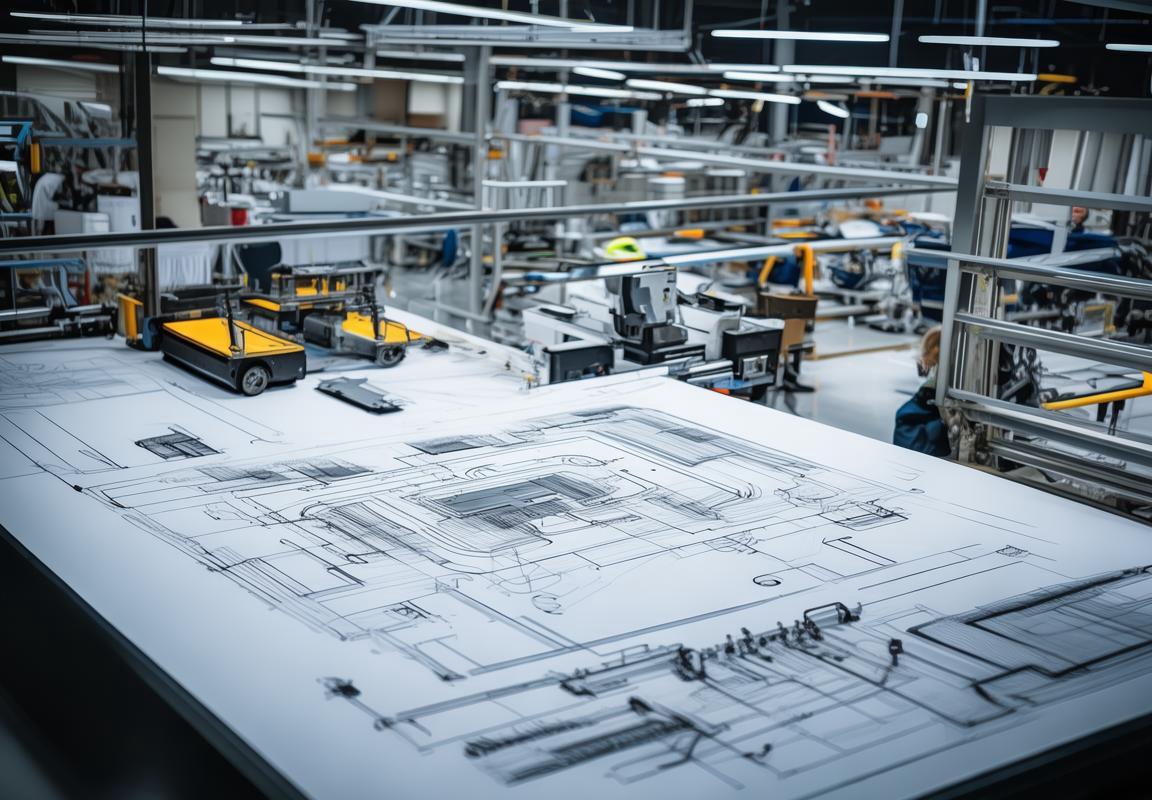

within the manufacturing manner, the manufacturing cycle refers back to the whole method from the procurement of raw materials to the of entirety of the product and preparation for cargo. This cycle entails more than one tiers, which includes order processing, uncooked cloth education, manufacturing manufacturing, satisfactory inspection and packaging, as well as logistics distribution. distinctive styles of products and manufacturing fashions have various production cycle lengths. as an instance, customized merchandise may additionally require longer customization and processing instances, even as standardized batch manufacturing merchandise may additionally have shorter manufacturing cycles.

within the production industry, shortening the production cycle is vital for enhancing performance and decreasing charges. A compact manufacturing cycle means that a business enterprise can respond extra speedy to market adjustments, beautify patron satisfaction, and keep a aggressive side within the marketplace. but, reaching this aim requires considering elements which includes production efficiency, fabric management, system protection, and supply chain collaboration. under is a short description of numerous key tiers inside the production cycle:

-

Order Processing: This level consists of order reception, order affirmation, and patron communique. speedy and correct order processing can lessen order delays and save time for subsequent manufacturing levels.

-

uncooked fabric practise: ensuring the fine and enough supply of raw materials is critical to making sure the manufacturing cycle. stock management and supply chain control are essential for well timed acquisition of uncooked materials.

-

production manufacturing: The manufacturing production degree is the core of the manufacturing cycle. production performance, device performance, and employee abilties all affect the time required for this level.

four. first-rate Inspection and Packaging: After the product is manufactured, it wishes to undergo strict exceptional inspection to make sure it meets requirements. The packaging technique additionally desires to be efficient to minimize garage time of finished products.

- Logistics Distribution: ultimately, the product desires to be disbursed via the logistics device, and the efficiency of this level at once affects the arrival time of the product and consumer satisfaction.

The production cycle is a complex process related to multiple stages and factors. To optimize this cycle, it is vital to begin from the supply and improve the performance of all levels.

The importance of a 15-day production lead time.

The 15-day manufacturing lead time is a important node in employer deliver chain control, and its significance can not be overstated. first off, it immediately influences the delivery performance of consumer orders and impacts the speed at which the enterprise responds to marketplace call for. unexpectedly responding to marketplace call for can beautify the employer’s competitiveness and enhance purchaser delight.

a 15-day manufacturing lead time facilitates organizations to arrange manufacturing plans extra correctly. inside this time body, the agency can meticulously plan for uncooked material procurement, production strategies, and satisfactory control, making sure a excessive and solid manufacturing technique.

affordable production lead instances also can help reduce stock fees. immoderate manufacturing lead instances can lead to inventory buildup, whereas production lead times can assist reduce stock and enhance capital turnover quotes.

The 15-day production lead time aids establishments in better responding to marketplace modifications. In a fiercely aggressive marketplace environment, quickly adjusting manufacturing plans to satisfy the various needs of customers is fundamental to the agency’s survival and improvement.

Shortening the manufacturing lead time can also beautify the agency’s brand photograph. efficient manufacturing tactics and brief product deliveries can set up a positive image of the corporation within the minds of clients, strengthening logo loyalty. therefore, the significance of a fifteen-day manufacturing lead time is self-evident and is a cornerstone for the organisation’s sustained development.

Analysis of Factors Affecting Production Lead Time

The manufacturing lead time from order popularity to of entirety includes multiple stages, with the performance and high-quality of every degree impacting the overall production lead time. the following are numerous key elements:

-

design and research and development phase: The complexity of the layout and the duration of the research and improvement procedure immediately affect the production training time. complicated drawings and a lengthy studies and development process might also lead to repeated design modifications, extending the production education time.

-

deliver Chain management: The responsiveness of providers, the best and balance of uncooked substances, and the deliver chain’s reliability substantially have an effect on manufacturing lead time. Any delays inside the deliver chain can result in production schedule delays.

three. device and production lines: The overall performance of production gadget, preservation conditions, and the extent of automation within the production strains all impact manufacturing efficiency. outdated or poorly maintained system can cause decreased manufacturing pace.

four. employee skills and training: The operational skills, production knowledge, and familiarity with the process go with the flow of employees without delay have an effect on manufacturing efficiency. loss of training or insufficient competencies among employees can lead to manufacturing mistakes and inefficiencies.

five. production planning and Scheduling: The rationality of production plans, the effectiveness of scheduling strategies, and the flexibility to handle sudden events are all crucial elements affecting manufacturing lead time. Unreasonable plans can lead to resource waste and manufacturing delays.

-

nice control: Strict best manage approaches can lessen the fee of transform and defective merchandise, thereby shortening manufacturing lead time. insufficient quality manipulate can bring about merchandise not assembly standards, growing the manufacturing cycle.

-

outside factors: consisting of weather, transportation delays, policy adjustments, and different external elements can also effect manufacturing lead time. those uncontrollable factors may additionally motive deliver chain disruptions, main to production halt.

eight. modifications in market call for: Fluctuations in customer demand also can have an effect on production lead time. An growth in call for can also require the organization to accelerate manufacturing, at the same time as a decrease in demand can result in production modifications and inventory buildup.

In summary, the length of the production lead time is at once associated with a company’s price control, marketplace responsiveness, and client delight. therefore, agencies want to don’t forget those factors comprehensively and take measures to optimize production methods with a purpose to shorten manufacturing lead time and decorate marketplace competitiveness.

Optimize the 15-day production lead time strategy

-:thru specific demand forecasting and order control, lessen inventory build-up and manufacturing line halt caused by call for fluctuations, and make sure the rational allocation of materials and sources.-:give a boost to provider control to ensure timely supply of uncooked substances and additives, lessen ready times, and optimize logistics strategies to shorten transportation cycles.-:put in force computerized equipment and technology to decorate the extent of automation on production strains, reduce human operation errors, and enhance manufacturing performance and stability.-:fortify go-departmental conversation and collaboration to make sure clean statistics drift, quick reply to troubles within the manufacturing manner, and enhance standard operational performance.-:regularly check out and hold manufacturing equipment and techniques, right away replace and optimize them, reduce downtime due to malfunctions, and ensure the continuity of manufacturing.

Case Study: Successful Practice in Reducing Production Lead Times

through enforcing the subsequent measures, a sure electronic product producer successfully decreased the manufacturing lead time from 20 days to fifteen days:

-

supply Chain Collaboration Optimization: with the aid of setting up close partnerships with providers, reaching instantaneous shipping of uncooked substances and components, reducing stock congestion, and ensuring the continuity of the production line.

-

production technique Reengineering: Streamlining the manufacturing process, removing unnecessary steps, and adopting lean manufacturing methods to decorate manufacturing efficiency.

-

Automation upgrade: Introducing automated device along with robots and sensible production strains to reduce guide operation time and increase manufacturing speed.

four. fine manipulate ahead: enforcing strict great manipulate at an early level of product production to decrease rework and delays resulting from exceptional troubles.

five. employee schooling and Incentives: presenting professional skill education for personnel to enhance their operational proficiency, and implementing incentive rules to decorate worker paintings enthusiasm and performance.

-

facts control machine production: organising a complete records management device for real-time tracking and analysis of manufacturing statistics, bearing in mind rapid response to issues in the production method.

-

flexible manufacturing Plan Adjustment: Adjusting manufacturing plans flexibly in reaction to modifications in market demand, avoiding overcapacity or undercapacity because of order fluctuations.

via the implementation of those strategies, the producer effectively decreased the manufacturing lead time to fifteen days, which no longer most effective progressed consumer delight but also strengthened the business enterprise’s market competitiveness. unique achievements include:

- A 30% growth in manufacturing efficiency;

- A 25% reduction in inventory costs;

- A 50% shorter customer order transport cycle;

- A 20% increase in worker pleasure;

- a fifteen% increase in market percentage for the employer.