In the world of medical equipment, the right components can mean the difference between successful treatment and potential harm. One such component that often goes unnoticed but plays a crucial role is the medical grade stainless steel basket. These baskets are not just tools; they are the backbone of many medical devices, ensuring precision, durability, and safety. In this article, we delve into the intricacies of these baskets, exploring their significance, the meticulous process behind their creation, and the wide array of applications that rely on their exceptional quality.

Introduction to Medical Grade Stainless Steel Baskets

Medical grade stainless steel baskets are an essential component in various industries, particularly in healthcare where they serve as the backbone for numerous medical devices and instruments. These baskets are meticulously crafted to meet the stringent requirements of medical environments, ensuring safety, durability, and precision. Let’s dive into the world of medical grade stainless steel baskets and understand their importance.

In the realm of medical devices, the basket is often the unsung hero. It’s the foundation that holds everything together, from delicate surgical instruments to complex medical devices. The choice of material for these baskets is crucial, and that’s where medical grade stainless steel steps in.

Medical grade stainless steel is not just any stainless steel; it’s a specialized grade designed to withstand the harsh conditions of a medical facility. It’s resistant to corrosion, has a high melting point, and maintains its strength and shape even when exposed to extreme temperatures. This makes it the ideal material for creating baskets that will be used in critical medical applications.

When it comes to the construction of these baskets, every detail is carefully considered. The design must be both functional and safe, allowing for easy handling and sterilization. The edges need to be smooth to prevent any damage to the instruments or injury to the medical staff. The manufacturing process involves precision engineering to ensure that each basket is uniform in size and shape, fitting perfectly into the devices they are intended for.

The manufacturing of medical grade stainless steel baskets begins with the selection of the right material. The stainless steel used is of the highest grade, often referred to as 316L or 316Ti, known for its exceptional resistance to corrosion, especially in chloride environments. This is crucial in medical settings where instruments are frequently exposed to chemicals and bodily fluids.

Once the material is chosen, it undergoes a series of processes to transform it into a functional basket. The steel is first shaped into the desired form, often through deep drawing or stamping, which allows for the creation of intricate designs and shapes. The process must be precise to ensure that the basket will not only fit but also perform its intended function without fail.

After shaping, the basket is subject to heat treatment, which is essential for achieving the required strength and hardness. This step is critical as it determines the basket’s resistance to bending, scratching, and other forms of wear. The heat treatment process must be carefully controlled to avoid any potential defects that could compromise the basket’s integrity.

Next comes the finishing process, which is as important as the material and manufacturing processes. The surface of the basket is polished to a mirror-like finish, which not only enhances its appearance but also aids in maintaining a sterile environment. The polished surface is less likely to harbor bacteria and other pathogens, which is vital in a medical setting.

Quality control is a non-negotiable aspect of producing medical grade stainless steel baskets. Each basket is inspected for any defects, from cracks and dents to inconsistencies in size and shape. Advanced testing methods, such as x-ray inspection and ultrasonic testing, are employed to ensure that the baskets meet the highest standards of quality.

The applications of medical grade stainless steel baskets are vast. They are found in everything from laboratory equipment to surgical instruments, and even in the construction of some medical devices. The versatility of these baskets is unmatched, as they can be customized to fit a wide range of medical equipment and instruments.

In conclusion, medical grade stainless steel baskets are more than just metal containers; they are a cornerstone of modern healthcare. Their ability to withstand harsh conditions, maintain precision, and provide a sterile environment makes them indispensable in medical settings. As technology advances and the demand for high-quality medical devices continues to grow, the importance of these baskets will only increase.

Understanding the Significance of Stainless Steel in Healthcare

Stainless steel has long been a staple in the healthcare industry, serving as a cornerstone material due to its exceptional properties and benefits. Its significance in medical applications is undeniable, as it offers a myriad of advantages that are crucial for patient care and safety.

One of the primary reasons stainless steel is favored in healthcare is its inherent antimicrobial properties. Unlike many other metals, stainless steel naturally resists the growth of bacteria, fungi, and algae, making it ideal for surfaces that come into contact with bodily fluids and medical instruments. This resistance is a result of the alloy’s composition, which includes iron, chromium, nickel, and molybdenum, creating a passive oxide layer that prevents the adhesion of pathogens.

In addition to its antimicrobial qualities, stainless steel boasts excellent durability. It can withstand harsh chemicals, high temperatures, and extreme pressure, which are common in medical environments. This durability means that stainless steel instruments and devices can endure rigorous use without degrading, ensuring that they remain effective throughout their lifespan.

The corrosion resistance of stainless steel is another key factor in its popularity in healthcare. In environments where moisture and humidity are prevalent, such as operating rooms and surgical theaters, the risk of metal corrosion is high. Stainless steel’s resistance to corrosion ensures that medical equipment remains functional and safe for use, even after prolonged exposure to these challenging conditions.

Stainless steel’s non-reactive nature is also a significant advantage. It does not interact with bodily fluids or medications, which is critical in maintaining the integrity of treatments and reducing the risk of adverse reactions. This non-reactivity is particularly important in the case of implantable medical devices, where compatibility with the body is paramount.

The clarity and transparency of stainless steel are also beneficial in medical applications. Its polished finish allows for easy visibility, which is essential for surgeons and medical professionals who need to monitor their instruments and procedures closely. This clarity extends to the material’s ability to maintain its appearance over time, minimizing the need for frequent cleaning and maintenance.

Moreover, stainless steel is highly recyclable, making it an environmentally friendly choice. In an industry that is increasingly focused on sustainability, the ability to reuse and recycle materials is a compelling factor. By choosing stainless steel, healthcare facilities can contribute to a reduction in waste and environmental impact.

In the realm of medical equipment, stainless steel is the go-to material for a variety of reasons. Its strength and malleability allow for the creation of complex shapes and structures that are required for surgical instruments and medical devices. The material can be easily fabricated into thin sheets for delicate tools or formed into sturdy components for more robust equipment.

The aesthetic appeal of stainless steel cannot be overlooked. Its sleek and modern look is often associated with cleanliness and precision, qualities that are highly valued in medical settings. This visual appeal contributes to a positive impression among patients and staff, enhancing the overall experience of healthcare facilities.

The versatility of stainless steel is also a major factor in its widespread use. It can be used in everything from simple hand tools to intricate mechanical devices, such as heart valves and catheters. The material’s ability to be heat-treated and alloyed with other elements ensures that it can be tailored to meet the specific requirements of different medical applications.

In terms of cost-effectiveness, stainless steel stands out. While it may have a higher upfront cost compared to some other materials, its long lifespan and reduced maintenance requirements often result in lower overall costs over time. This economic advantage is particularly important for healthcare providers who must manage budgets while delivering quality care.

The ease of cleaning and disinfecting stainless steel is also a significant benefit. In healthcare settings, the cleanliness of equipment is paramount to prevent the spread of infections. Stainless steel surfaces can be quickly and effectively sanitized, reducing the risk of contamination and improving patient outcomes.

In conclusion, the significance of stainless steel in healthcare is multifaceted. Its antimicrobial, durable, corrosion-resistant, non-reactive, and recyclable properties make it an indispensable material. Whether it’s for surgical instruments, medical devices, or structural components, stainless steel’s unique qualities ensure that it will continue to play a vital role in the healthcare industry for years to come.

The Role of Baskets in Medical Equipment

In the intricate tapestry of medical equipment, baskets play a pivotal role, often overlooked yet crucial in the precision and efficiency of healthcare operations. These simple yet robust structures are found in a variety of medical devices, each contributing to the overall functionality and safety of the equipment they are a part of.

Medical baskets are commonly seen in surgical instruments, where they serve as organizers for delicate tools. They are designed to hold scalpels, forceps, and other small implements securely, ensuring they are easily accessible to the surgeon during an operation. The basket’s grid-like design allows for optimal spacing between items, reducing the risk of tools becoming entangled or damaged during use.

In diagnostic equipment, baskets are integral to the functionality of devices like MRI machines and CT scanners. These baskets are used to hold and secure patients’ limbs or body parts, ensuring they remain still during the scanning process. The design of these baskets is such that it minimizes any discomfort or restriction felt by the patient, while also providing the necessary stability for accurate imaging.

Dental care is another field where baskets are indispensable. Dental trays, often equipped with various-sized baskets, are used to organize dental instruments and materials. The baskets help keep the instruments clean and readily available, streamlining the workflow for dental professionals. The use of baskets in dental care also helps prevent cross-contamination, a critical aspect of infection control.

In laboratory settings, baskets are used for a range of tasks, from sorting and organizing samples to transporting them between workstations. The durability and hygienic properties of stainless steel make these baskets ideal for handling potentially hazardous materials. The baskets can be designed with features like drain holes, which are essential for the safe handling of liquids, and they are easy to sterilize, ensuring that they do not compromise the integrity of the experiments or tests being conducted.

The role of baskets in medical waste management is equally significant. They are used to collect and contain medical waste, including sharps and infectious materials, in a manner that is safe for both healthcare workers and the environment. The sturdy construction of these baskets ensures that they can withstand the rigors of waste handling and disposal processes, while their design allows for efficient waste segregation and disposal.

In the realm of rehabilitation and physical therapy, baskets are used to organize equipment such as therapy balls, resistance bands, and other tools. These baskets help patients maintain a clutter-free environment, which can be particularly beneficial for those with limited mobility or cognitive impairments. The baskets also make it easier for therapists to locate and retrieve the necessary equipment during sessions.

Baskets are not just limited to the physical realm of medical equipment; they also play a role in digital medical devices. In devices like insulin pumps and infusion pumps, baskets are used to organize and secure the small components, such as batteries and tubing, ensuring they remain in place and functioning correctly.

The versatility of baskets is not just confined to their physical applications. They also serve a symbolic purpose in medical equipment, representing organization, efficiency, and safety. In a world where precision and cleanliness are paramount, the basket stands as a silent guardian, ensuring that every piece of equipment operates at its best.

In summary, the role of baskets in medical equipment is multifaceted, encompassing organization, stability, safety, and hygiene. From the operating room to the laboratory, from the dental office to the patient’s recovery room, these unassuming structures play a crucial role in the delivery of quality healthcare. Their presence may go unnoticed, but their absence would leave a significant gap in the functionality and effectiveness of medical devices worldwide.

Why Medical Grade Stainless Steel is Superior

In the world of medical equipment, the choice of materials is paramount for both functionality and safety. One material that stands out in this regard is medical grade stainless steel. Its superiority lies in several key attributes that make it a preferred choice in healthcare applications.

Its corrosion resistance is unmatched. Medical environments are often fraught with harsh chemicals and substances that can be detrimental to the longevity of materials. Medical grade stainless steel is designed to withstand these elements, ensuring that it remains durable and reliable over time. This resistance to corrosion is especially crucial in devices like IV stands and surgical instrument trays, where contact with bodily fluids is a daily occurrence.

The material’s biocompatibility is another major advantage. In medical settings, the interaction between patients and equipment must be seamless and safe. Medical grade stainless steel is non-reactive, meaning it doesn’t cause any adverse reactions within the body. This is particularly important in devices that come into direct contact with blood or tissue, as it reduces the risk of infection and allergic reactions.

Strength and durability are two more qualities that set medical grade stainless steel apart. The material can withstand heavy loads and frequent use without losing its structural integrity. This is essential for items such as surgical trays, which must be able to support the weight of various instruments and tools without bending or breaking. The robustness of medical grade stainless steel also ensures that medical equipment can endure the rigors of cleaning and sterilization processes.

Hygiene is a cornerstone of healthcare, and medical grade stainless steel excels in this area. The smooth, non-porous surface of the material makes it highly resistant to bacterial growth. This is a vital feature for surgical instruments and medical devices, where the risk of contamination is high. The ease of cleaning and the material’s resistance to stains contribute to maintaining a clean and sterile environment, which is critical in preventing hospital-acquired infections.

The thermal properties of medical grade stainless steel are also noteworthy. It has excellent heat resistance, which is essential for instruments that may need to be sterilized using heat. The material can maintain its integrity even at high temperatures, ensuring that it won’t warp or deform, which could compromise its functionality.

In addition to its physical properties, medical grade stainless steel is also versatile. It can be easily shaped and formed into complex designs, making it suitable for a wide range of medical equipment. Whether it’s the frame of a hospital bed, the handle of a surgical tool, or the components of a diagnostic machine, stainless steel’s versatility allows for customization to meet the specific needs of healthcare applications.

The material’s aesthetic appeal is often overlooked but is an important aspect of its value. Aesthetics play a role in the usability and comfort of medical equipment. The sleek, modern look of stainless steel can contribute to a more positive patient experience and a more efficient healthcare environment.

Lastly, the cost-effectiveness of medical grade stainless steel cannot be underestimated. While it may be a premium material, its long lifespan and reduced maintenance needs can lead to significant cost savings over the life of the product. This is particularly significant in a healthcare industry where budgets are tight and efficiency is key.

In summary, medical grade stainless steel’s corrosion resistance, biocompatibility, strength, hygiene, thermal properties, versatility, aesthetic appeal, and cost-effectiveness make it the superior choice for medical equipment. Its ability to meet the rigorous demands of healthcare settings is why it continues to be a staple in the industry.

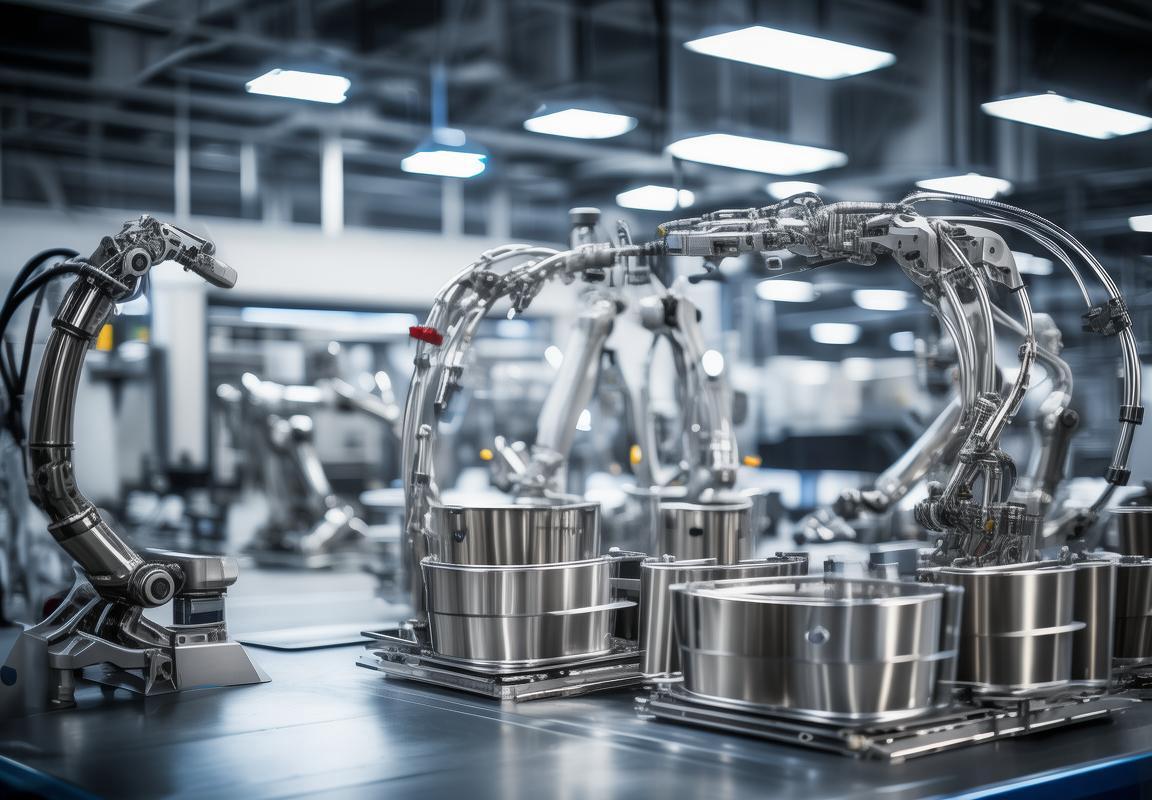

The Process at Our Medical Grade Stainless Steel Basket Factory

Our medical grade stainless steel basket factory is a hub of precision and innovation, where every step in the process is meticulously designed to ensure the highest quality products. Here’s an inside look at the journey our baskets take from raw materials to finished goods.

We start with the selection of materials, choosing only the finest grade stainless steel, known for its exceptional strength and corrosion resistance. This material is not just any stainless steel; it’s specifically designed to meet stringent medical standards, ensuring that our baskets are not just durable but also safe for use in critical healthcare applications.

The first phase in the manufacturing process is cutting. Advanced cutting technology is employed to shape the stainless steel sheets into the initial basket frames. This process requires precision to ensure that each piece will fit perfectly into the assembly. The cutting machines are calibrated with extreme accuracy to prevent any jagged edges or misalignments.

Once the frames are cut, they move on to the welding stage. Our skilled welders use a combination of manual and automated techniques to join the pieces together. The welding process is crucial, as it not only holds the basket together but also affects its structural integrity. We use only the highest quality welding procedures to ensure that each basket is leak-proof and strong.

After welding, the baskets undergo a series of forming operations. These include bending, rolling, and pressing, which shape the steel into the characteristic basket weave pattern. Each step is carefully monitored to maintain the integrity of the design, ensuring that the baskets are both functional and aesthetically pleasing.

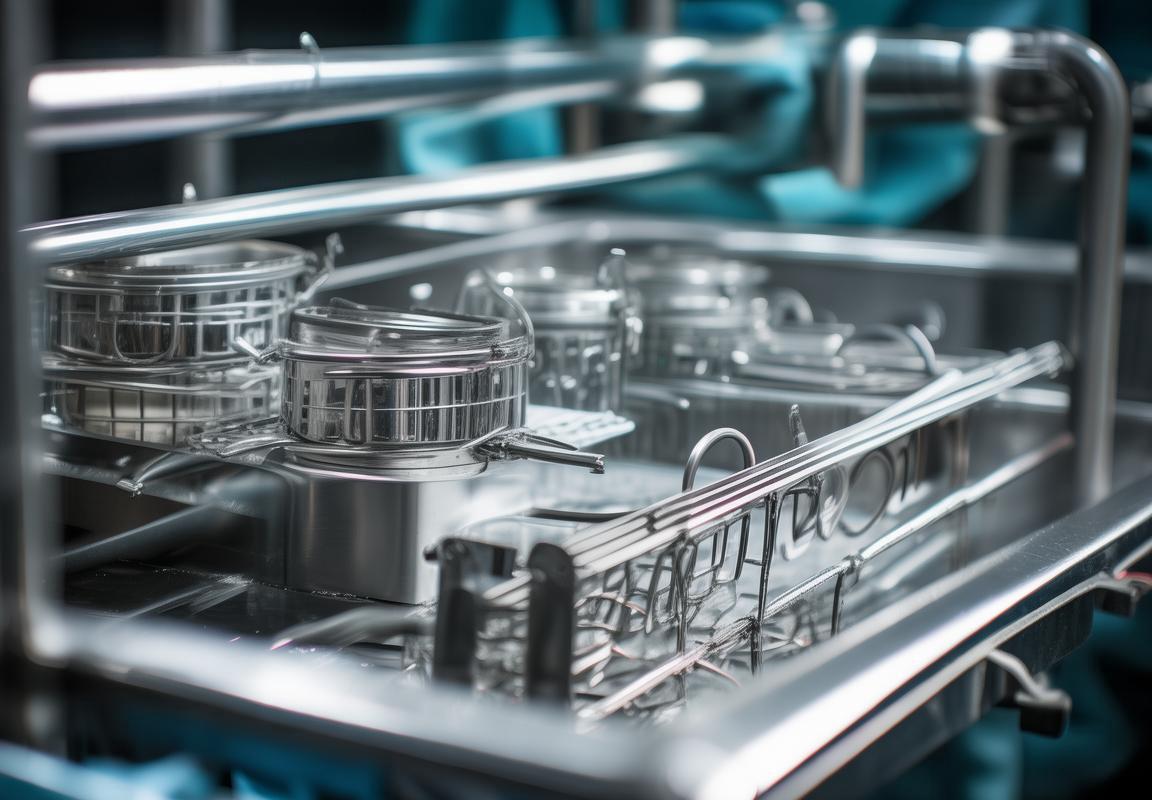

Next comes the cleaning process. Stainless steel baskets are subject to a rigorous cleaning regimen to remove any residual oils, welding slag, or impurities. This is essential for maintaining the hygiene standards required in medical environments. We use a combination of mechanical and chemical cleaning methods to achieve a pristine finish.

Once the baskets are clean, they move through the heat treatment phase. This process involves heating the steel to a specific temperature and then cooling it at a controlled rate. This treatment improves the material’s hardness and reduces its susceptibility to deformation, ensuring that the baskets maintain their shape and strength over time.

The next critical step is the surface finishing. We apply a series of coatings and platings to protect the stainless steel from corrosion and to enhance its aesthetic appeal. These finishes are designed to withstand repeated sterilization cycles, a common requirement in medical settings.

Quality control is woven into every stage of our manufacturing process. We conduct numerous inspections to ensure that each basket meets our exacting standards. This includes dimensional checks, material analysis, and functional testing. Our quality assurance team is dedicated to detecting any deviations from perfection, ensuring that only the best products leave our factory.

Once the baskets pass all quality checks, they are packaged. We use protective materials to safeguard the baskets during shipping, ensuring that they arrive at their destination in pristine condition. The packaging also includes detailed specifications and certifications, providing customers with the assurance that they are receiving a product that meets the highest medical standards.

Our medical grade stainless steel basket factory is a testament to the dedication and innovation that goes into creating products that are not just made to last but also to save lives. From the selection of materials to the final packaging, every aspect of our process is designed to deliver a superior product that healthcare professionals can trust.

Innovations in Manufacturing

In the ever-evolving landscape of manufacturing, innovation is the driving force behind progress. Within the realm of medical grade stainless steel basket production, advancements have not only improved efficiency but also enhanced the quality and reliability of these critical components. Here’s a closer look at some of the innovative manufacturing techniques shaping the industry:

The integration of automation has been a game-changer. Robots and computerized systems are now adept at handling tasks that were once manual, such as welding, cutting, and forming. This not only increases speed but also ensures precision, reducing the likelihood of human error.

Precision cutting technologies have seen remarkable developments. Lasers and water jet cutting methods have replaced traditional methods like sawing or shearing. These technologies offer cleaner cuts with minimal material waste, which is not only cost-effective but also environmentally friendly.

The use of advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software has revolutionized the design and production process. Engineers can create intricate designs with ease, and these digital models can be directly translated into machine instructions, minimizing the need for physical prototypes.

Quality control has been bolstered by the introduction of AI-driven inspection systems. These systems can analyze the surfaces of stainless steel baskets for defects at a rate much faster than human inspectors, ensuring that only the highest quality products leave the factory.

The adoption of modular manufacturing processes has allowed for greater flexibility. Different sections of the basket can be produced independently and then assembled, which means that if a design change is required, it can be implemented without disrupting the entire production line.

Energy efficiency is a growing concern, and manufacturers are responding with innovative solutions. LED lighting, energy-saving motors, and smart heating systems are just a few examples of how factories are cutting down on their energy consumption while maintaining productivity.

The development of eco-friendly materials and processes is another area of innovation. Recycled stainless steel, for instance, can be used to produce new baskets, reducing the industry’s carbon footprint and promoting sustainability.

The implementation of 3D printing technology is also making waves. While it’s not yet the norm for large-scale production of medical grade stainless steel baskets, it’s being used for prototyping and for creating complex geometries that would be difficult to produce with traditional methods.

Innovation in the field of surface treatment has led to the development of new coatings and finishes that not only enhance the appearance of the baskets but also improve their resistance to corrosion and wear.

The integration of IoT (Internet of Things) sensors into the production line has provided real-time data on the performance of machines and the quality of products. This data-driven approach allows for predictive maintenance, reducing downtime and improving overall reliability.

Lastly, the emphasis on continuous improvement and lean manufacturing principles has led to more streamlined operations. By eliminating waste and optimizing processes, manufacturers are able to produce high-quality medical grade stainless steel baskets more efficiently than ever before.

Quality Control and Standards

In the world of medical-grade stainless steel basket production, the commitment to quality is paramount. Ensuring that each basket meets the highest standards is not just a process; it’s a philosophy that drives our factory. Here’s an insight into how we maintain such stringent quality control and adhere to industry standards.

The meticulous inspection process begins at the very start of our manufacturing cycle. Each piece of raw material, whether it’s stainless steel or any other component, is thoroughly examined for quality and purity. We rely on advanced testing equipment to detect any impurities or defects that could compromise the integrity of the final product.

Our factory is equipped with state-of-the-art technology that allows us to monitor the entire production process. From cutting and bending to welding and polishing, every step is closely watched. This ensures that the stainless steel baskets we produce are not just structurally sound but also meet the exact specifications required for medical applications.

One key aspect of our quality control is the use of standardized procedures. We follow a strict set of guidelines that have been developed over years of experience and are in line with international medical device regulations. These procedures cover everything from material handling to the final packaging of the baskets.

Every basket undergoes a series of tests to validate its performance. These include tensile strength tests to ensure that the baskets can withstand the stresses of medical use, non-destructive testing to detect any hidden cracks or weaknesses, and surface finish assessments to guarantee that the baskets are smooth and free from any sharp edges or blemishes.

We also place a strong emphasis on environmental standards. Our factory is designed to minimize waste and maximize efficiency, reducing the environmental impact of our operations. This not only aligns with global sustainability goals but also ensures that the materials used in our baskets are as pure and clean as possible.

Certification is another critical aspect of our quality control efforts. We hold numerous certifications, including ISO 13485, which specifically addresses the quality management systems for medical devices. This certification requires us to undergo regular audits by independent bodies to confirm that we are maintaining the highest standards of quality and safety.

Our team of inspectors is trained to spot even the most subtle defects. They are adept at identifying inconsistencies in size, shape, and finish that could affect the functionality of the baskets in a medical setting. The fact that our inspectors are also medical professionals adds a unique perspective to the quality control process, ensuring that our baskets are not just up to industry standards but also meet the specific needs of healthcare providers.

In the realm of quality control, we understand the importance of traceability. Every basket produced in our factory is marked with a unique identification number that can be tracked throughout its lifecycle. This allows us to quickly and accurately identify any issues and take immediate corrective action if necessary.

Our approach to quality also involves continuous improvement. We regularly review our processes and are always looking for ways to enhance our efficiency and the quality of our products. This can mean adopting new technologies, refining our manufacturing techniques, or even reevaluating our supply chain to ensure we are working with the best suppliers.

In summary, our commitment to quality is unwavering. From the moment raw materials enter our factory to the time they leave as finished medical-grade stainless steel baskets, every aspect of our manufacturing process is subject to rigorous scrutiny. This dedication to excellence is what sets us apart and ensures that our products are reliable, safe, and effective for their intended medical applications.

Applications of Our Stainless Steel Baskets

In the healthcare industry, stainless steel baskets play a pivotal role in a wide range of applications. From surgical instruments to laboratory equipment, these baskets are designed to ensure precision, durability, and sterility. Let’s delve into the various uses of our medical grade stainless steel baskets.

Our baskets are a staple in operating rooms, where they securely hold surgical instruments during procedures. The fine mesh design allows for easy access and visualization of tools, while the smooth surfaces prevent any potential damage to the instruments. This not only enhances the efficiency of surgical operations but also contributes to the overall safety of the patient.

In dental practices, our stainless steel baskets are used for organizing and sterilizing dental instruments. The baskets’ ability to maintain a high level of cleanliness is crucial in preventing cross-contamination and infection. The baskets are designed to be stackable, saving valuable counter space in dental clinics.

Pharmacies rely on our baskets for storing medications and other healthcare products. The clear visibility provided by the baskets’ construction ensures that pharmacists can quickly locate the items they need. Moreover, the baskets are designed to be resistant to corrosion and chemicals, making them ideal for long-term storage.

Microbiology and pathology laboratories utilize our stainless steel baskets for handling and transporting samples. The baskets’ durability and resistance to chemicals are essential in maintaining the integrity of these critical materials. The baskets also facilitate the easy identification of samples, ensuring accuracy in testing and analysis.

Our baskets find their way into the world of veterinary medicine as well. They are used for storing and organizing veterinary instruments and supplies, ensuring that practitioners have everything they need at their fingertips. The baskets’ ability to withstand rigorous use and cleaning makes them a practical choice for veterinary clinics.

In the realm of dental technology, our baskets are used for holding and organizing impression materials and models. The baskets’ precise design allows for the proper alignment and handling of these delicate items, which is crucial for the accuracy of dental restorations.

The food service industry also benefits from our stainless steel baskets. They are used in hospitals and healthcare facilities for storing and serving food, ensuring that meals are delivered safely and hygienically. The baskets’ ability to maintain a high level of cleanliness is paramount in preventing foodborne illnesses.

Our baskets are also employed in the field of optometry. They are used for organizing and storing lenses, frames, and other optical instruments. The baskets’ design ensures that these items are stored securely and can be easily retrieved when needed.

In the field of prosthetics and orthotics, our baskets are used for sorting and storing various components and materials. The baskets’ durability and resistance to corrosion make them suitable for handling metals, plastics, and other materials used in the fabrication of prosthetics and orthotic devices.

Our stainless steel baskets also find a place in the management of medical waste. They are used for containing and transporting sharps and other hazardous materials, ensuring that waste is handled safely and in compliance with regulations.

Lastly, our baskets are used in radiology departments for organizing and storing X-ray films and other imaging materials. The baskets’ ability to protect sensitive materials from damage and contamination is crucial in maintaining the integrity of radiographic images.

In summary, the applications of our stainless steel baskets are vast and varied. From the operating room to the laboratory, from the dental clinic to the veterinary practice, these baskets are a reliable and essential tool in the healthcare industry. Their ability to maintain cleanliness, durability, and precision makes them an indispensable component in the delivery of quality healthcare services.

Case Studies: Success Stories

In the world of medical-grade stainless steel basket production, our factory has witnessed numerous success stories that showcase the versatility and reliability of our products. From enhancing surgical procedures to optimizing laboratory workflows, these case studies highlight the impact our baskets have on healthcare facilities. Here are a few of these compelling success stories:

In a leading hospital, our medical-grade stainless steel baskets were integrated into the sterilization process. These baskets, designed to withstand rigorous cleaning and sterilization cycles, played a crucial role in ensuring that surgical instruments were safe for use. The baskets’ ability to maintain their integrity and non-reactive surface properties led to a significant reduction in the risk of cross-contamination, improving patient safety and surgical outcomes.

A medical research facility turned to our factory for custom-designed baskets to organize and transport delicate samples. The specialized baskets, crafted with precise dimensions and anti-static properties, allowed researchers to handle their samples with precision and care. The baskets’ durability and ease of use contributed to a more efficient workflow, enabling the facility to double its sample processing capacity without compromising on quality.

In the field of dental care, our stainless steel baskets have become an essential tool for dental technicians. The baskets are used to hold and organize dental impressions, crowns, and bridges during the manufacturing process. Their sturdy construction and hygienic design have reduced the risk of damage to the dental restorations and have significantly improved the efficiency of the technicians’ work.

A veterinary clinic found our baskets invaluable for managing medical supplies and equipment. The baskets’ clear, durable construction allowed veterinary staff to quickly locate the items they needed, reducing the time spent searching for supplies and improving patient care. The baskets also helped maintain a clean and organized workspace, which is critical in a setting where hygiene is paramount.

In a pharmaceutical company, our baskets were instrumental in the packaging and distribution of medication. The baskets’ ability to secure fragile vials and bottles during transit minimized the risk of breakage and ensured that the medication arrived in perfect condition. This reliability was crucial for maintaining the integrity of the pharmaceutical products and upholding the company’s reputation for quality.

One of our most innovative projects involved the development of a stainless steel basket for a medical device company. The basket was designed to hold and stabilize delicate components during the assembly process. Its unique design featured adjustable dividers that could accommodate various sizes and shapes, allowing for flexibility in the production line. The basket’s use significantly reduced the time required for assembly and increased the consistency of the final product.

In a hospital’s intensive care unit, our baskets were employed to organize and store critical medical supplies. The baskets, with their clear, transparent design, allowed nurses and healthcare providers to quickly identify the items they needed in emergencies. This feature was particularly beneficial in high-stress situations, where every second counts.

Our medical-grade stainless steel baskets have also made a difference in the field of prosthetics. A renowned orthopedic center used our baskets to store and transport prosthetic limbs and components. The baskets’ durability and ease of cleaning were crucial in maintaining the cleanliness and functionality of the prosthetics, ensuring that patients received the highest quality care.

These case studies are just a glimpse into the wide range of applications our stainless steel baskets have found in the healthcare industry. From improving patient care to streamlining operational processes, our products continue to make a positive impact, one basket at a time.

The Importance of Reliability in Healthcare

In the healthcare industry, where precision and safety are paramount, the importance of reliability cannot be overstated. From medical equipment to patient care, every aspect of healthcare relies on dependable systems and products. Here’s why reliability is so crucial in this vital sector:

The cornerstone of any effective healthcare system is trust. Patients must have confidence in the equipment that is used to diagnose and treat their conditions. When medical devices fail or fail to perform as expected, it can lead to misdiagnoses, delayed treatment, or even harm to the patient. Reliability ensures that every piece of equipment, from the simplest stainless steel basket to the most complex machines, operates consistently and accurately.

In critical situations, the margin for error is razor-thin. When a doctor needs to perform surgery or a nurse is administering medication, they cannot afford to wait for a faulty device to be fixed. Reliable medical grade stainless steel baskets and other equipment ensure that the right tools are available when they’re needed, minimizing the risk of complications and improving patient outcomes.

Healthcare providers are under immense pressure to deliver quality care efficiently. Reliability in medical equipment streamlines workflows, allowing healthcare professionals to focus on patient care rather than dealing with equipment malfunctions. This efficiency can lead to shorter wait times, more patients seen, and a higher overall standard of care.

The cost implications of unreliable medical equipment are significant. Repairs, replacements, and the time lost due to equipment downtime can all add up. By investing in reliable medical grade stainless steel baskets and other products, healthcare facilities can reduce these costs and allocate more resources to patient care and other critical areas.

Patient safety is the ultimate concern in healthcare. Reliable equipment reduces the likelihood of accidents and adverse events. In the operating room, for example, a faulty instrument or basket could lead to a life-threatening situation. Reliability ensures that all tools are safe to use, reducing the risk of injury to both patients and healthcare workers.

Innovation is a constant in healthcare, with new technologies and treatments emerging all the time. Reliable equipment can adapt to these changes, providing a solid foundation for the integration of new technologies. This adaptability is crucial for maintaining the highest standards of care as the industry evolves.

Regulatory compliance is a stringent requirement in healthcare. Equipment and materials must meet specific safety and quality standards to be approved for use. Reliable medical grade stainless steel baskets and other products not only meet these standards but also provide a clear audit trail that demonstrates compliance. This can be particularly important in the event of a recall or investigation.

Patient satisfaction is closely tied to the reliability of medical equipment. When patients know that the equipment they’re using is trustworthy, they are more likely to have a positive experience. This can lead to higher patient retention rates and a better reputation for the healthcare facility.

In an industry where lives are at stake, the reliability of medical grade stainless steel baskets and other equipment is not just a luxury; it’s a necessity. It’s the foundation upon which quality care is built, ensuring that every patient receives the best possible treatment in a safe and efficient environment.

Contact Us for Your Medical Grade Stainless Steel Basket Needs

Navigating through the complexities of healthcare, it’s imperative to find a reliable partner that can cater to your specific needs. Whether you’re a hospital, clinic, or a medical research facility, knowing where to turn for high-quality medical grade stainless steel baskets is crucial. Here’s how you can get in touch with us to discuss your requirements:

- Our team of experts is on standby, ready to assist you with any inquiries you may have.

- We pride ourselves on offering personalized solutions, tailored to meet the unique demands of your healthcare environment.

- Our customer service line is open from 9 AM to 5 PM, Monday through Friday, ensuring that you can reach us at a convenient time.

- If you prefer email communication, feel free to send your queries to [email protected], and we will respond promptly.

- Our website features a comprehensive FAQ section, where you can find answers to common questions regarding our products and services.

- For a more hands-on approach, we invite you to schedule a virtual tour of our factory, where you can witness our state-of-the-art manufacturing processes firsthand.

- We understand that every healthcare facility has its budget constraints, which is why we offer competitive pricing without compromising on quality.

- If you’re looking to place an order or need assistance with a bulk purchase, our sales team is well-equipped to guide you through the process.

- We offer flexible payment options, including credit cards, purchase orders, and net 30 terms for qualified customers.

- Our dedication to customer satisfaction extends beyond the sale, with ongoing support and maintenance services available to ensure your medical grade stainless steel baskets remain in optimal condition.

- For any urgent requests or special orders, we have a dedicated emergency hotline that you can contact outside of regular business hours.

- If you’re in the Greater Los Angeles area, we also provide local delivery services for your convenience.

- We are committed to sustainability and offer a range of eco-friendly options for our stainless steel baskets, ensuring that your healthcare facility can operate with a green conscience.

- Our team is multilingual, so whether you speak English, Spanish, French, or any other language, we are here to assist you in your preferred tongue.

- We value feedback from our customers and encourage you to fill out our online survey after your experience with us, as it helps us improve our services.

- Should you require any assistance with installation or maintenance, our trained technicians are available to ensure your medical grade stainless steel baskets are properly set up and regularly maintained.

- For organizations looking to establish a long-term partnership, we offer volume discounts and loyalty programs.

- Finally, we are certified by several industry-leading organizations, guaranteeing that our products adhere to the highest standards of quality and safety.

- To get in touch with us, simply visit our website, where you’ll find all the necessary contact information and a direct link to our customer service team.

- We look forward to hearing from you and are confident that our medical grade stainless steel baskets will meet and exceed your expectations.