In the bustling world of kitchenware, finding a brand that guarantees both quality and reliability can be a game-changer. Today, we delve into the realm of an ISO9001 certified kitchenware plant, where craftsmanship meets cutting-edge technology, and where every product tells a story of precision and sustainability. Join us as we explore the journey of this esteemed establishment, and why it stands out as a beacon of excellence in the industry.

Introduction to the ISO9001 Certified Kitchenware Plant

Nestled in the heart of the bustling industrial sector, our ISO9001 certified kitchenware plant stands as a beacon of excellence in the manufacturing world. This facility is not just a place where products are produced; it’s a hub of innovation, quality, and efficiency that has set new standards in the kitchenware industry.

The plant spans over a vast area, equipped with state-of-the-art machinery that whirrs to life each day, driven by the passion and expertise of our dedicated team. Here, every piece of kitchenware is crafted with the utmost care, ensuring that our customers receive products that not only meet but exceed their expectations.

Our commitment to quality is unwavering, and it begins right at the source, with the finest raw materials. We meticulously select and inspect each material, from the highest quality stainless steel to eco-friendly ceramics, to guarantee that our products are not just durable, but also sustainable.

The manufacturing process is a symphony of precision and creativity. Skilled artisans work side by side with cutting-edge technology to transform raw materials into beautifully designed and functional kitchenware. Whether it’s a sleek set of knives, a durable ceramic pot, or a state-of-the-art kitchen gadget, each product undergoes rigorous testing to ensure it meets the stringent ISO9001 standards.

One of the key components of our ISO9001 certification is the focus on continuous improvement. We are constantly analyzing our processes, seeking ways to enhance efficiency and reduce waste. This dedication to optimization means that every product that leaves our plant is not only of the highest quality but also a testament to our relentless pursuit of excellence.

Safety is another cornerstone of our operation. The plant is designed with the latest safety features, and all employees are trained in the latest safety protocols. This ensures that our team can work confidently, knowing they are protected and that our products are being manufactured in a secure environment.

Our product range is extensive, catering to both professional chefs and home cooks alike. From everyday items like spatulas and wooden spoons to specialty pieces like high-precision mandolins and induction cookware, we offer solutions for every culinary need. Each product is designed with the end-user in mind, ensuring comfort, functionality, and aesthetic appeal.

Customization is also a forte of our plant. We understand that no two kitchens are the same, and so we offer a variety of customization options. Whether it’s personalized engraving on a set of knives or custom colors for a collection of kitchen utensils, we work closely with our clients to create kitchenware that truly reflects their style and preferences.

Sustainability is at the forefront of our operations. We are committed to reducing our environmental footprint and have implemented numerous eco-friendly practices throughout our manufacturing process. From energy-efficient lighting to recycling programs, we strive to minimize waste and contribute to a greener planet.

Our commitment to quality and excellence has not gone unnoticed. We have received numerous accolades from industry leaders and have garnered a loyal customer base that values our products for their quality and durability. Customer testimonials speak volumes about the satisfaction we provide, with many praising our attention to detail and the timeless appeal of our kitchenware.

In a world where kitchenware is often overlooked, our ISO9001 certified plant stands out as a testament to what can be achieved when quality, innovation, and sustainability converge. We are proud of the reputation we have built and look forward to continuing to deliver exceptional kitchenware that enhances the culinary experiences of our customers worldwide.

Understanding ISO9001 Certification

ISO9001 certification is a globally recognized standard that serves as a benchmark for quality management systems. It’s a testament to a company’s commitment to continuous improvement, customer satisfaction, and adherence to stringent operational processes. Here’s a deeper dive into what this certification entails:

The ISO9001 standard is developed by the International Organization for Standardization (ISO), an independent, non-governmental international organization that brings together experts to share knowledge and develop voluntary consensus standards. These standards are designed to ensure that products and services are safe, reliable, and of high quality.

One of the key aspects of ISO9001 certification is the focus on process management. It requires organizations to document and optimize their processes to ensure consistency and efficiency. This means that from the initial design of a product to its final delivery, every step is meticulously planned, executed, and monitored.

Customer focus is another cornerstone of ISO9001. The standard mandates that businesses prioritize customer needs and expectations, aiming to deliver products that consistently meet or exceed these requirements. This approach fosters long-term relationships with customers and helps build a strong reputation in the marketplace.

The standard also emphasizes the importance of top management involvement. Leaders are expected to demonstrate leadership and commitment to the quality policy, ensuring that quality objectives are established and integrated into the organization’s strategic direction.

Internal and external communication is crucial in maintaining an ISO9001 certified quality management system. Organizations must have effective communication processes in place to ensure that relevant information is shared with all interested parties, including employees, suppliers, and customers.

Continuous improvement is a core principle of ISO9001. Companies are encouraged to review their processes regularly and make necessary adjustments to enhance efficiency, reduce waste, and improve product quality. This mindset is fostered through the use of statistical tools and data analysis, enabling management to make informed decisions based on facts and figures.

Another vital aspect of ISO9001 is the management of risks and opportunities. Organizations are required to identify potential risks and opportunities that could affect their ability to meet quality objectives and develop plans to address them. This proactive approach helps prevent issues before they arise and ensures that the organization is always one step ahead.

The standard also places significant emphasis on supplier management. ISO9001 requires organizations to select and qualify suppliers based on their ability to consistently provide products and services that meet specified requirements. This ensures that the supply chain is as reliable and high-quality as the products themselves.

Employee involvement is another critical element. ISO9001 recognizes that employees are the most valuable asset of an organization and that their skills, knowledge, and commitment are essential for achieving quality objectives. The standard encourages organizations to provide training and development opportunities to enhance employee competence and motivation.

Documentation is an integral part of ISO9001 certification. Companies must maintain comprehensive records of their quality management system, including procedures, work instructions, and records of activities and results. This documentation serves as a reference for internal audits and third-party assessments, ensuring that the organization is compliant with the standard.

Regular audits are a requirement of ISO9001 certification. These audits are conducted both internally and by external auditors to verify that the quality management system is functioning effectively. Any non-conformities identified during these audits must be addressed promptly, and corrective actions must be implemented to prevent recurrence.

ISO9001 certification is not a one-time achievement but a continuous journey. Organizations must undergo annual surveillance audits and periodic recertification audits to maintain their certification status. This ongoing commitment to quality ensures that the organization remains at the forefront of its industry.

In summary, ISO9001 certification is a comprehensive framework that encompasses process management, customer focus, leadership, communication, continuous improvement, risk management, supplier management, employee involvement, documentation, and auditing. By adhering to this standard, organizations can demonstrate their dedication to delivering high-quality products and services, fostering trust and confidence among their customers and stakeholders.

The Plant: A Brief Overview

Nestled in a serene industrial park, the ISO9001 certified kitchenware plant stands as a beacon of precision and excellence. Spanning across a sprawling 50,000 square feet, the facility is designed to maximize efficiency without compromising on quality. The plant is divided into several key areas, each dedicated to a specific aspect of the manufacturing process.

The heart of the operation is the state-of-the-art production line, where skilled engineers and technicians work tirelessly to ensure that every piece of kitchenware that rolls off the assembly is a testament to craftsmanship. This line is equipped with cutting-edge machinery, including CNC machines for precision cutting, automated welding systems, and robotic painting arms that guarantee a flawless finish.

Adjacent to the production area is the quality control department, where meticulous checks are performed at every stage of the manufacturing process. Here, a team of certified inspectors uses advanced measuring tools and non-destructive testing equipment to verify the integrity and functionality of each product. This rigorous quality assurance protocol ensures that only the finest kitchenware leaves the plant.

The plant also boasts a dedicated R&D center, staffed by a team of innovative designers and engineers. This department is responsible for conceptualizing new products, improving existing designs, and staying ahead of industry trends. The R&D center is equipped with 3D modeling software, rapid prototyping machines, and a comprehensive library of materials, all aimed at pushing the boundaries of kitchenware design.

In the storage and logistics sector, the plant utilizes a sophisticated inventory management system that tracks every item in real-time. This system ensures that raw materials are always on hand, reducing downtime and preventing delays in production. The storage area is climate-controlled to protect sensitive materials and finished goods from environmental factors like humidity and temperature fluctuations.

Safety is paramount at this kitchenware plant, and it is reflected in every aspect of the facility. The plant is fitted with state-of-the-art fire suppression systems, and regular safety drills are conducted to ensure that all employees are prepared for any emergency. The working environment is designed to minimize the risk of accidents, with clear signage, ergonomic workstations, and regular maintenance of machinery.

The plant is also environmentally conscious, with a focus on reducing its carbon footprint. Solar panels are installed on the roof, providing a significant portion of the facility’s energy needs. Waste recycling programs are in place, and eco-friendly materials are used wherever possible to minimize the environmental impact of production.

The administrative and office spaces are designed to foster collaboration and innovation. Employees have access to a range of amenities, including a canteen with healthy meal options, break rooms equipped with comfortable seating and Wi-Fi, and a fitness center to encourage a healthy work-life balance.

In the heart of the plant, a clear, well-lit atrium serves as a central gathering space, where employees can socialize, share ideas, and participate in team-building activities. This space is also used for hosting meetings, training sessions, and company events, promoting a strong sense of community among the workforce.

The ISO9001 certified kitchenware plant is not just a place of work; it’s a testament to the commitment to excellence, innovation, and sustainability. From the moment raw materials arrive at the facility to the final packaging of finished products, every step is carefully monitored and controlled to meet the highest standards of quality and customer satisfaction.

Quality Assurance and Manufacturing Excellence

Nestled within a sprawling industrial park, our ISO9001 certified kitchenware plant stands as a beacon of quality and precision in the manufacturing sector. This facility, a testament to our commitment to excellence, boasts a range of state-of-the-art equipment and a meticulous quality assurance process that ensures every product that leaves our doors meets the highest standards.

The plant is meticulously designed to facilitate a seamless workflow, from raw material handling to finished product dispatch. At the heart of the operation is a robust quality control system that monitors every stage of the manufacturing process. Let’s delve into the specifics.

Innovative Monitoring SystemsThe plant is equipped with cutting-edge monitoring systems that track the production line in real-time. Sensors and cameras are strategically placed to capture every movement of materials and machinery, ensuring that any deviation from the set standards is quickly identified and corrected. This proactive approach to quality control is what sets our kitchenware apart in the market.

Stringent Raw Material StandardsWe understand that the quality of the final product begins with the raw materials. Our plant adheres to strict supplier qualifications, ensuring that only the finest materials are used in the manufacturing process. These materials are rigorously tested for purity and quality before they are processed, guaranteeing the integrity of our products.

Skilled WorkforceThe backbone of our plant is its highly skilled workforce. Employees are trained extensively on the latest manufacturing techniques and quality assurance protocols. From the operators who manage the machinery to the quality inspectors who meticulously check each product, every member of the team plays a crucial role in maintaining our high standards.

Continuous ImprovementOur plant operates on a continuous improvement model. Regular audits and reviews are conducted to identify areas for enhancement. This culture of constant evolution ensures that we stay ahead of industry trends and customer expectations. Whether it’s implementing new technologies or refining existing processes, we are always looking for ways to improve.

Advanced Manufacturing TechniquesThe manufacturing floor is a marvel of modern engineering. Advanced CNC machines, robotic arms, and automated assembly lines work in harmony to produce kitchenware products with precision and efficiency. These technologies not only increase production speed but also reduce waste, ensuring that we are environmentally responsible.

Customization and FlexibilityOur plant is not just about mass production; it’s also about customization. We have the capability to cater to a wide range of customer specifications, from small batch orders to large-scale production runs. This flexibility allows us to meet the diverse needs of our clients, from home chefs to commercial kitchens.

Environmental ComplianceIn an era where sustainability is a key concern, our plant takes pride in its environmental compliance. We have implemented energy-efficient practices and recycling programs to minimize our ecological footprint. From water conservation to waste reduction, every aspect of our operation is designed to be eco-friendly.

Customer SatisfactionAt the end of the day, our quality assurance process is all about delivering customer satisfaction. We understand that kitchenware is not just a product; it’s an essential tool for everyday life. That’s why we go the extra mile to ensure that our products are durable, functional, and aesthetically pleasing.

Certification and RecognitionOur commitment to quality is not just self-evident; it’s externally validated. The ISO9001 certification is a testament to our adherence to international quality management standards. This recognition has been hard-earned and is a source of pride for our entire team.

In summary, our ISO9001 certified kitchenware plant is a hub of excellence, where quality assurance is not just a process but a way of life. From the moment raw materials enter the plant to the moment finished products leave our shelves, every step is carefully monitored and controlled to ensure that our customers receive nothing but the best.

Innovative Technologies in Kitchenware Production

Nestled within the heart of our ISO9001 certified kitchenware plant, innovation thrives in every aspect of our production process. From the moment raw materials enter the facility to the final product leaving our doors, cutting-edge technologies are at play, ensuring that our kitchenware is not just functional but also a testament to modern manufacturing prowess.

Our plant boasts a state-of-the-art automated system that meticulously tracks the progress of each item, from the initial cutting of stainless steel to the intricate detailing on ceramic pieces. Advanced robotics handle tasks that were once the purview of skilled artisans, doing so with precision and consistency.

One of the most remarkable technologies we employ is the use of 3D printing for rapid prototyping. This allows our design team to iterate on new product designs quickly, making adjustments and improvements before moving to full-scale production. The 3D printing process also enables us to create custom pieces for clients, offering a level of personalization that was once unimaginable in the kitchenware industry.

The heart of our operation is our CNC (Computer Numerical Control) machines, which are responsible for the precision cutting and shaping of metals, plastics, and ceramics. These machines are calibrated to the highest standards, ensuring that every piece that leaves our plant meets our stringent quality requirements. The CNC technology not only enhances the efficiency of our production line but also allows for the creation of complex designs that would be impossible with traditional methods.

In the realm of metal fabrication, we utilize laser cutting and welding techniques. Laser cutting offers unparalleled precision, allowing us to produce intricate patterns and shapes with minimal material waste. The laser welding process, on the other hand, ensures that the seams are strong and durable, with minimal distortion, which is critical for the longevity of our kitchenware products.

For our ceramic and glass products, we have invested in high-temperature kilns that are capable of reaching extreme temperatures to cure glazes and vitrify the materials. This technology ensures that our ceramic pieces are not only visually appealing but also resilient, able to withstand the rigors of everyday kitchen use.

Our kitchenware plant also incorporates advanced quality control systems. These systems include automated testing equipment that checks the durability, strength, and functionality of our products. From water-tightness tests for our kitchen sinks to impact resistance checks for our cookware, every product undergoes a rigorous examination before it is deemed ready for market.

In addition to these technologies, we have developed proprietary software that optimizes our supply chain and production schedules. This software integrates with our manufacturing equipment, providing real-time data that helps us manage inventory, streamline production, and minimize downtime.

Our commitment to innovation extends beyond our manufacturing floor. We actively engage with research institutions and academic partners to stay ahead of the curve in material science and design. This collaboration has led to the development of new materials and manufacturing techniques that not only enhance the performance of our kitchenware but also reduce our environmental impact.

The result of these technological advancements is a suite of kitchenware products that are not just ahead of the curve but also set new standards for quality and functionality. From sleek, minimalist designs to highly durable and eco-friendly pieces, our offerings cater to a wide range of customer needs and preferences. It’s this blend of cutting-edge technology, meticulous craftsmanship, and a relentless pursuit of excellence that makes our kitchenware stand out in a crowded market.

Product Range and Customization Capabilities

In our kitchenware plant, we pride ourselves on offering a diverse array of products that cater to various needs and tastes. From the most basic kitchen utensils to sophisticated cooking equipment, our range is designed to enhance the culinary experience of every user. Let’s delve into the details of what we offer and the customization capabilities that set us apart.

Our collection includes a vast selection of cookware, from stainless steel pans to non-stick skillets. Each piece is crafted with precision, ensuring durability and longevity. We offer various sizes and shapes, allowing chefs and home cooks alike to find the perfect fit for their cooking styles.

Moving beyond cookware, we have a range of bakeware that is second to none. Baking sheets, loaf pans, and molds are designed with intricate details that not only make them functional but also visually appealing. Whether it’s for professional use or home baking, our bakeware is engineered to withstand high temperatures and maintain even heat distribution.

When it comes to kitchenware, we understand that aesthetics play a significant role. That’s why our collection also includes a variety of decorative items, such as elegant serving platters, rustic wooden cutting boards, and colorful glassware. These items are not just practical; they also add a touch of personality to any kitchen.

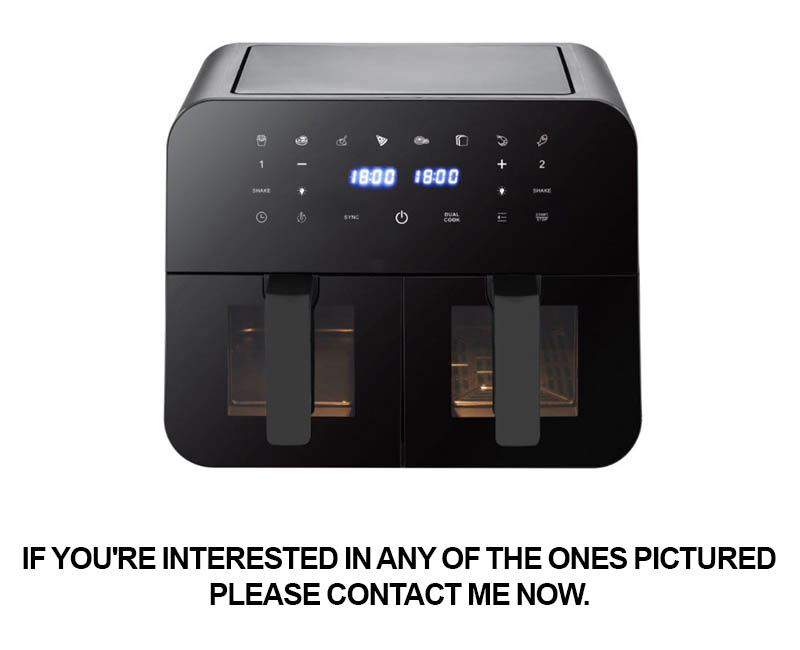

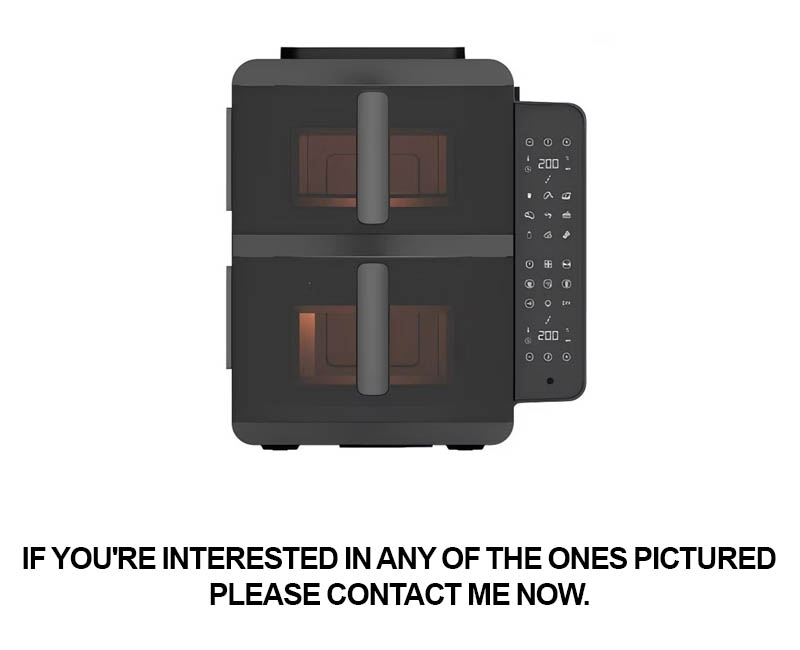

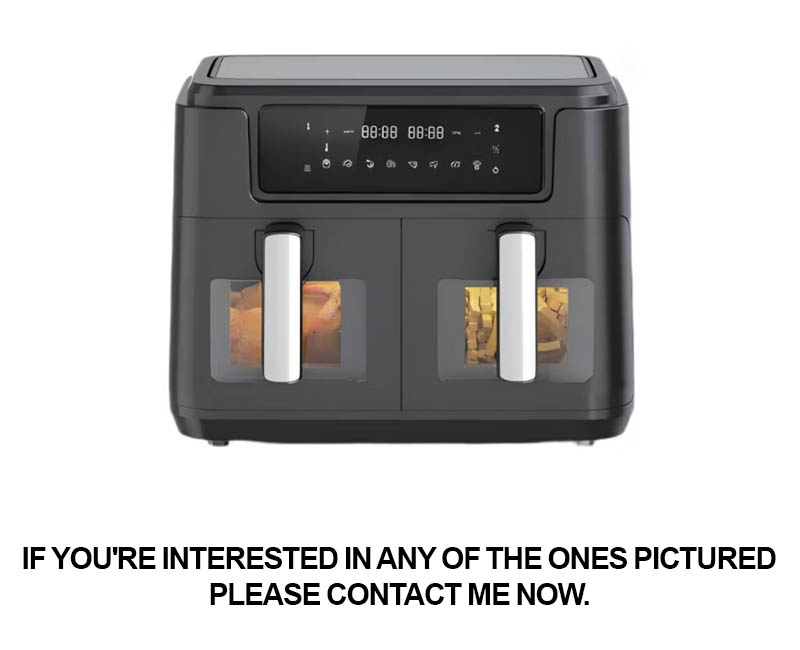

We also offer a range of kitchen appliances that are both powerful and user-friendly. From blenders to toasters, each appliance is designed to simplify daily cooking tasks and improve efficiency. Our appliances are built with the latest technologies, ensuring that they are energy-efficient and long-lasting.

One of our standout features is the ability to cater to specific customer needs through customization. We understand that every kitchen has its unique requirements, and our customization capabilities allow us to tailor our products accordingly.

Our cookware, for instance, can be engraved with custom messages or designs, making it a perfect gift for any occasion. Whether it’s a personal message, a logo, or a special symbol, our skilled artisans can bring these ideas to life on your kitchenware.

In the bakeware department, we offer personalized baking sheets with custom designs or the option to create unique molds for special recipes. This level of customization allows bakers to express their creativity and make every batch of baked goods special.

Our range of kitchen accessories extends to custom-fit utensil sets, where we can match the design and materials to the client’s preference. From ergonomic handles to specific shapes and sizes, our customization ensures that each utensil is a perfect match for the user’s hand and kitchen.

Moreover, we provide custom options for decorative items, allowing customers to create a cohesive and personalized kitchen aesthetic. Whether it’s a set of coordinating glassware or a unique wooden cutting board, the possibilities are endless.

For businesses looking to establish their brand in the kitchenware market, we offer branded items that can be designed to reflect their corporate identity. From branded cutting boards for corporate events to custom coffee makers for offices, we ensure that each item serves as a powerful brand ambassador.

Our customization goes beyond just physical changes. We also offer personalized customer service, where we work closely with clients to understand their unique needs and provide solutions that fit seamlessly into their kitchen setup.

In conclusion, our product range is extensive, and our customization capabilities are unmatched. Whether you’re a professional chef, a home baker, or a business looking to elevate your brand, our kitchenware plant offers the flexibility and quality to meet your every requirement. From the most traditional items to the most innovative designs, we are committed to bringing you the best of what the kitchenware world has to offer.

Sustainability Initiatives

In the heart of our kitchenware plant, sustainability is not just a buzzword; it’s a commitment woven into the very fabric of our operations. From the materials we choose to the energy we conserve, every aspect of our plant reflects a dedication to the environment and future generations.

We’ve invested in cutting-edge recycling facilities that process materials like plastic, metal, and glass, turning them into raw materials for new products. This closed-loop system minimizes waste and reduces our carbon footprint. The plant operates on a zero-waste policy, ensuring that every piece of scrap is either recycled or repurposed.

Our energy-efficient lighting and HVAC systems are designed to significantly cut down on energy consumption. We’ve installed motion sensors and LED lighting to reduce unnecessary power use during non-peak hours. In addition, our manufacturing processes are optimized to use less energy, ensuring that our production runs smoothly without excess waste.

Water conservation is another cornerstone of our sustainability efforts. We’ve implemented state-of-the-art water recycling systems that filter and reuse water in our production processes, drastically reducing the amount of water we need to source from external sources. Our plant also boasts rainwater harvesting systems that collect and store rainwater for use in non-potable applications.

We’re not just focusing on our own operations; we’re also working with our supply chain to ensure that they adhere to sustainable practices. Our partners must meet strict criteria for environmental responsibility, from sourcing materials to handling waste. This collaborative approach ensures that our entire supply chain reflects our commitment to sustainability.

Innovation plays a pivotal role in our sustainability initiatives. We’ve developed a range of eco-friendly kitchenware products that are not only durable but also designed with the environment in mind. These products are crafted from sustainable materials and are fully recyclable at the end of their lifecycle.

Our plant is equipped with advanced systems for monitoring and managing emissions. We regularly test and adjust our processes to minimize greenhouse gas emissions and other pollutants. This commitment to clean air is a testament to our broader environmental ethos.

We also prioritize the health and safety of our employees, recognizing that a sustainable work environment is essential. Our plant is designed with ergonomic considerations and features clean air ventilation to ensure a healthy atmosphere for all workers. We provide training on sustainable practices and encourage employees to take an active role in our environmental initiatives.

Our commitment to sustainability extends beyond our operational practices. We’re actively involved in community programs that promote environmental education and conservation. We organize workshops and events to raise awareness about the importance of sustainable living, encouraging our employees and the local community to take action.

Our dedication to sustainability is reflected in our certifications and awards. We’ve been recognized by various environmental organizations for our efforts, and we take pride in leading the way in sustainable kitchenware production. As we continue to innovate and evolve, our goal remains the same: to provide high-quality, eco-friendly kitchenware that respects the planet and its resources.

Our packaging solutions are another aspect where sustainability is at the forefront. We’ve moved away from single-use plastics and now use biodegradable materials for our packaging. This not only reduces our environmental impact but also sets a standard for our industry peers to follow.

Our kitchenware plant is a beacon of sustainability, demonstrating that it’s possible to create exceptional products while caring for the world around us. Through our relentless pursuit of excellence, we’re not just manufacturing kitchenware; we’re crafting a legacy of environmental responsibility and innovation.

Customer Testimonials and Industry Recognition

In the heart of our kitchenware plant, there’s a testament to our commitment to excellence—a wall adorned with customer testimonials and industry accolades. These are more than just words; they are the echoes of satisfaction from our valued clients and the stamp of approval from respected peers within the industry.

From the smallest kitchen gadget to the most elaborate set of cookware, every piece we produce is a reflection of our dedication to quality and innovation. Here’s a glimpse into the stories and recognition that our products have garnered:

“Absolutely delighted with the quality and craftsmanship of the knife set I received. The blades are sharp, and the handle is ergonomic, making cooking a joy.” – Jane D., San Francisco, CA

Our products have not only been praised by individual consumers but also by renowned chefs and culinary experts. Chef Michael Thompson, a James Beard Award winner, shared, “The cookware from this plant is top-notch. The non-stick surface is exceptional, and the cook times are significantly reduced, which is a game-changer in the kitchen.”

Industry recognition is a reflection of our relentless pursuit of perfection. We’ve been honored with multiple “Best of” awards by leading home and kitchen magazines, including “Best Non-Stick Cookware” by Home & Garden and “Top Cookware Brand” by Kitchen & Bath Ideas.

The testimonials and awards are a reminder of the trust placed in us by our customers. Here are a few more examples:

“Every time I use my ceramic coffee mug from this brand, I’m reminded of the timeless design and quality that comes with it. It’s become a staple in my morning routine.” – Emily L., Austin, TX

“I purchased a set of stainless steel mixing bowls, and I must say, they are a dream to work with. The heavy-duty construction ensures that they won’t bend or crack, and the non-slip base is a game-changer.” – David R., Chicago, IL

Our industry recognition also includes partnerships with some of the most prestigious culinary schools and institutions. We’ve been featured in the curriculum of culinary arts programs at institutions like the Culinary Institute of America, where students are taught the importance of using high-quality tools to achieve professional-level results.

The testimonials and industry recognition are a clear indicator of our success in delivering products that not only meet but exceed expectations. It’s through the eyes of our customers and the ears of our peers that we continue to evolve and improve, ensuring that every piece we produce is a symbol of the trust and respect we hold dear.

Conclusion: Trusting the ISO9001 Certified Kitchenware Expert

In a world where quality and reliability are paramount, the trustworthiness of a kitchenware brand is not just a testament to its products but also to its commitment to excellence. When a kitchenware plant holds the ISO9001 certification, it signifies a level of dedication to quality assurance and customer satisfaction that stands out in the competitive market. Choosing such an expert is akin to investing in peace of mind, knowing that every piece you bring into your kitchen is crafted with precision and care. Here’s why placing your trust in an ISO9001 certified kitchenware expert is a decision you won’t regret.

The ISO9001 standard is not just a label; it’s a comprehensive set of requirements that an organization must meet to demonstrate its ability to consistently provide products and services that meet customer and regulatory requirements. For a kitchenware plant, this means adhering to strict quality control measures, from raw material sourcing to final product delivery. This commitment to excellence ensures that every item that leaves the facility is a reflection of the highest manufacturing standards.

Customers often share their experiences with the brands they trust, and the testimonials from satisfied clients of an ISO9001 certified kitchenware expert are a testament to the brand’s reliability. These stories range from personal anecdotes of how a particular pan transformed a home cook’s culinary journey to the seamless customer service that made the shopping experience memorable. These testimonials serve as a bridge between the product and the consumer, fostering a sense of community and loyalty.

Industry recognition is another indicator of the expertise and reputation of an ISO9001 certified kitchenware expert. Awards and accolades from trade associations and consumer organizations highlight the brand’s innovation, quality, and contribution to the industry. Such honors are not easily won and speak volumes about the brand’s standing among its peers and within the broader marketplace.

The trustworthiness of an ISO9001 certified kitchenware expert is further reinforced by the brand’s dedication to ethical practices. This includes ensuring that the production process is environmentally friendly, with a focus on sustainability and minimal waste. It’s not just about creating products that last; it’s about doing so in a way that respects the planet and its resources.

In an era where consumers are more aware and conscious of where their products come from, the transparency offered by an ISO9001 certification is invaluable. Customers can feel confident that the kitchenware they purchase is not only of high quality but also meets the highest standards of safety and regulatory compliance. This peace of mind is something that money cannot buy, and it’s a significant factor in why customers continue to choose an ISO9001 certified kitchenware expert over competitors.

The journey of an ISO9001 certified kitchenware expert is often marked by continuous improvement. The brand is not content with standing still; it’s always looking for ways to innovate and enhance its offerings. This relentless pursuit of excellence means that customers can expect new, cutting-edge products that not only meet their current needs but also anticipate future trends.

When you consider the sheer volume of kitchenware available on the market, the choice can be overwhelming. However, knowing that you’re purchasing from an ISO9001 certified expert simplifies the decision-making process. It means that you’re getting more than just a product; you’re getting a promise of quality, reliability, and a brand that stands behind its products with pride.

In conclusion, trusting the ISO9001 certified kitchenware expert is a decision that resonates with confidence and foresight. It’s about recognizing that a brand that has achieved this level of certification is one that values its customers, respects the industry, and is committed to delivering products that are not just excellent but also responsible. With an ISO9001 certified kitchenware expert, you’re not just buying kitchenware; you’re investing in a future where quality and trust are synonymous with the products you use every day.