In a world where culinary experiences are increasingly elevated by the gadgets and appliances we use, the grill stands as a testament to outdoor cooking’s enduring allure. Central to this versatile appliance’s success lies the art and science of in-house mold making. This article delves into the intricate world of mold making within the grill industry, exploring its role in both the European and American markets, the preferences that shape it, the challenges it faces, and the opportunities that lie ahead. With a focus on innovation, consumer trends, and expert insights, we aim to paint a comprehensive picture of where in-house mold making stands and where it’s heading in the grill production landscape.

Title: “In-House Mold Making for Grills: The European and American Market Insight

“In-House Mold Making for Grills: The European and American Market Insight”

In the world of grill manufacturing, the process of in-house mold making has become a cornerstone for innovation and efficiency. As the demand for custom and high-quality grills continues to rise, companies are increasingly turning to on-site mold creation to meet these evolving needs. This article delves into the dynamics of the European and American grill markets, exploring how in-house mold making is shaping the industry.

The European Grill Market: A Focus on Quality and Design

In Europe, the grill market is known for its emphasis on quality and design. Consumers here are not just looking for a functional cooking appliance; they are seeking a product that reflects their personal style and preference. In-house mold making plays a pivotal role in this regard, allowing manufacturers to produce grills that are not only durable but also uniquely tailored to the European market’s aesthetic sensibilities. From sleek, modern designs to more traditional, rustic appearances, the ability to customize molds in-house ensures that European grill brands can cater to a diverse range of tastes.

Innovation Through In-House Mold Making

The benefits of in-house mold making are manifold. For one, it offers a level of flexibility that off-site mold manufacturing cannot match. European grill companies can experiment with materials, shapes, and sizes to create prototypes that align perfectly with their design vision. This not only speeds up the product development process but also allows for rapid iteration and improvement based on real-time feedback.

Moreover, in-house mold making can lead to cost savings in the long run. By eliminating the need for third-party mold suppliers, companies can avoid the additional costs associated with outsourcing. This, in turn, can help reduce the overall production costs, allowing for more competitive pricing in the market.

The American Grill Market: A Blend of Tradition and Technology

On the other side of the Atlantic, the American grill market is a blend of tradition and technology. While there is a strong presence of traditional gas and charcoal grills, there has been a significant growth in the electric and infrared grill segments. In the U.S., in-house mold making has become a key competitive advantage for companies looking to differentiate their products.

Customization and Efficiency

American grill manufacturers are leveraging in-house mold making to create products that cater to the diverse needs of their customers. From compact, portable grills designed for tailgating to large, multi-functional grills for outdoor entertaining, the ability to mold and manufacture these products on-site ensures that each model is optimized for performance and user experience.

The technology-driven approach in the American market has also led to the development of innovative grill designs. For instance, advanced materials and mold technologies are being used to create grills that are more energy-efficient and maintain consistent temperatures, regardless of the cooking environment.

Challenges and Solutions

Despite the advantages, in-house mold making is not without its challenges. The complexity of designing and maintaining molds in-house requires a significant investment in skilled labor, machinery, and resources. Additionally, the process can be time-consuming, which may affect production timelines.

However, companies are finding solutions to these challenges. By investing in advanced software for mold design and automation technologies, they are able to streamline the process, reduce lead times, and improve the quality of the molds. This, in turn, enhances the overall quality of the grills they produce.

Market Data and Future Projections

Market data indicates that the demand for high-quality, custom grills is on the rise in both Europe and America. The European market is expected to grow at a steady pace, driven by an increasing middle class that values premium outdoor cooking experiences. Similarly, the American market is poised for continued growth, with the trend towards healthier cooking methods and outdoor living spaces fueling demand.

Expert Insights

Industry experts agree that in-house mold making is here to stay. They emphasize the importance of staying abreast of technological advancements and investing in the right tools and training. By doing so, grill manufacturers can not only meet the current market demands but also be well-prepared for future trends.

In Conclusion

In-house mold making for grills is not just a trend; it is a strategic move that is reshaping the European and American grill markets. By offering customization, efficiency, and innovation, this approach is driving the industry forward, ensuring that grill manufacturers can deliver products that meet the evolving needs of consumers. As the demand for quality grilling experiences continues to grow, the role of in-house mold making will only become more integral to the success of grill companies worldwide.

Introduction: The Growing Significance of In-House Mold Making

In the ever-evolving landscape of the grill industry, a subtle yet pivotal shift has been occurring behind the scenes. The significance of in-house mold making has been on the rise, reshaping the way grill manufacturers approach design, production, and innovation. This shift is not just a trend; it’s a strategic move that’s reshaping the competitive edge of companies in both the European and American markets.

The essence of in-house mold making lies in the control and flexibility it offers. By developing molds internally, companies can tailor their products to exact specifications, ensuring that the final product aligns perfectly with market demands and consumer expectations. This level of customization was once the exclusive domain of larger corporations with substantial resources. However, advancements in technology and the increasing complexity of consumer needs have made in-house mold making more accessible to a broader range of businesses.

In Europe, where the grill market has been traditionally robust, the adoption of in-house mold making has been a game-changer. Local manufacturers are now able to respond more swiftly to the ever-changing tastes of their consumers. From sleek, modern designs to robust, durable models, the ability to produce a wide array of grill products has become a cornerstone of success. This agility is particularly crucial in a market that values innovation and design as much as performance.

On the other side of the Atlantic, the American grill market is a different beast, characterized by a diverse range of products that cater to a wide demographic. In this competitive environment, the ability to create unique molds has become a key differentiator. Companies that invest in in-house mold making are not just producing grills; they are crafting experiences. Whether it’s a high-end gas grill with intricate features or a portable charcoal grill that’s perfect for camping trips, the potential for customization is limitless.

One of the most compelling reasons for the growing significance of in-house mold making is the cost-effectiveness it offers. Traditionally, companies had to rely on external mold makers, which often involved long lead times and high costs. With in-house capabilities, manufacturers can reduce these expenses, leading to more competitive pricing and potentially higher profit margins. This financial advantage can be reinvested into research and development, allowing for the creation of new products and features that resonate with consumers.

Moreover, in-house mold making fosters a culture of innovation within a company. When manufacturers have direct control over the mold-making process, they can experiment with new materials, designs, and manufacturing techniques. This not only enhances the quality of the final product but also opens up new avenues for product differentiation. In a market where consumers are bombarded with choices, standing out with a unique product can be the difference between success and obscurity.

Another aspect that cannot be overlooked is the environmental impact of in-house mold making. By reducing the need for external suppliers, companies can cut down on transportation-related emissions and waste. This eco-friendly approach is increasingly important to consumers who are more conscious about the environmental footprint of their purchases. As a result, companies that embrace in-house mold making are not only enhancing their bottom line but also improving their brand image.

The rise of in-house mold making has also had a profound effect on supply chain management. By bringing the mold-making process in-house, companies can better anticipate production needs and avoid the risks associated with long supply chains. This level of control is invaluable in a market that is subject to fluctuating raw material prices and geopolitical uncertainties.

In conclusion, the growing significance of in-house mold making in the grill industry is a testament to the power of innovation and adaptability. As manufacturers continue to invest in this area, we can expect to see even more sophisticated and tailored grill products hitting the market. Whether in Europe or America, the benefits of in-house mold making are clear: from cost savings and environmental responsibility to the ability to meet consumer demands with unparalleled speed and precision. The future of grill manufacturing is undeniably intertwined with the mastery of in-house mold making.

Market Overview: European Grill Industry Trends

In the heart of Europe, the grill industry has been steadily evolving, shaped by a blend of culinary culture, outdoor living trends, and innovative manufacturing techniques. This dynamic market has seen a surge in the significance of in-house mold making, a practice that is redefining the landscape of grill production. Let’s delve into the trends that are currently shaping the European grill industry.

The European grill market has a rich history that is deeply intertwined with the continent’s love for outdoor dining and social gatherings. From the traditional charcoal grills in Southern Europe to the sleek gas-powered models in Northern regions, the variety is vast. However, a few key trends are emerging that are driving the industry forward.

One prominent trend is the shift towards high-quality, durable materials. Consumers are increasingly seeking grills that not only look good but also stand the test of time. This demand has led to a rise in the use of stainless steel and advanced alloys for grill construction, which are perfect for in-house mold making due to their intricate design requirements.

Customization has become a buzzword in the European grill market. Consumers are no longer satisfied with one-size-fits-all products; they want grills that reflect their personal style and meet their specific needs. In-house mold making allows for the creation of unique designs and specialized features, giving manufacturers a competitive edge. This trend is particularly noticeable in the premium end of the market, where luxury grills with custom finishes and advanced functionalities are becoming more popular.

Energy efficiency is another critical factor influencing the European grill market. With environmental concerns on the rise, consumers are gravitating towards eco-friendly options. This has spurred the development of grills that are not only energy-efficient but also made with sustainable materials. In-house mold making plays a crucial role in producing these complex components that are both functional and eco-conscious.

The integration of smart technology is a trend that is reshaping the grill industry across Europe. Modern grills are now equipped with features like Bluetooth connectivity, digital temperature control, and even AI-driven cooking assistance. These high-tech grills require precise mold making to ensure that each part fits seamlessly and functions effectively. The ability to produce intricate molds in-house has become essential for companies looking to innovate and lead in this tech-driven sector.

In addition to consumer preferences, regulatory changes are also impacting the European grill market. Stricter environmental regulations and safety standards mean that grill manufacturers must produce products that are compliant with these laws. In-house mold making allows for greater control over the production process, ensuring that each grill meets the necessary requirements without compromising on quality or design.

The European grill market is also witnessing a rise in the popularity of modular and portable grills. This trend is driven by the growing number of people who enjoy outdoor activities and need a grill that is easy to transport and set up. In-house mold making is instrumental in creating lightweight, yet robust, components that can withstand the rigors of being moved frequently.

Moreover, the European grill market is becoming more diverse, with an increasing number of small and medium-sized enterprises (SMEs) entering the space. These companies are leveraging in-house mold making to create niche products that cater to specific market segments, such as eco-friendly grills or grills designed for urban dwellers with limited space.

Finally, there is a growing focus on sustainability and ethical manufacturing practices. European consumers are more aware of the environmental impact of their purchases and are increasingly seeking out brands that are committed to sustainability. In-house mold making can be part of a larger strategy to reduce waste and energy consumption in the production process, aligning with these values.

In conclusion, the European grill industry is experiencing a transformation that is being driven by a combination of consumer trends, technological advancements, regulatory changes, and a growing awareness of sustainability. In-house mold making is at the heart of this transformation, enabling manufacturers to produce the high-quality, innovative, and eco-friendly grills that European consumers demand. As the market continues to evolve, the role of in-house mold making is likely to become even more integral to the success of grill producers across the continent.

European Consumer Preferences and Mold Making Innovations

In the realm of European consumer preferences, the grill market has witnessed a surge in demand for unique and innovative products. This shift has had a profound impact on the mold making process, as manufacturers strive to cater to these evolving tastes. Here’s a closer look at how consumer preferences are shaping mold making innovations in the European grill industry.

European consumers are increasingly seeking high-quality, durable grills that offer both functionality and aesthetic appeal. This demand has led to a rise in the use of advanced materials and sophisticated designs. Mold making plays a crucial role in creating these intricate shapes and ensuring the structural integrity of the grills.

One notable trend is the preference for eco-friendly grills. Consumers are more conscious of the environmental impact of their purchases, and this extends to the grill market. Mold makers are responding by developing molds that can produce grills made from sustainable materials, such as recycled plastics and bio-based resins.

The European market also values customization. Consumers are looking for grills that not only meet their specific needs but also reflect their personal style. Mold making allows for the creation of custom designs, with intricate patterns and unique features that set a grill apart from the competition. This level of personalization has become a key differentiator in the European grill market.

Another significant trend is the integration of smart technology into grills. European consumers are embracing the convenience and efficiency that smart features offer. Mold makers are adapting by creating molds that can accommodate complex electronics and sensors within the grill’s design. This integration requires precision and innovation in mold making to ensure that the grill’s components fit seamlessly.

Safety is a paramount concern for European consumers, and this is reflected in the grill market. Mold makers are focusing on creating molds that can produce grills with enhanced safety features, such as non-stick surfaces, heat-resistant materials, and secure locking mechanisms. These features not only meet safety standards but also contribute to the grill’s overall performance and longevity.

The European grill market is also seeing a rise in the popularity of portable and compact grills. This trend is driven by consumers’ desire for convenience and the ability to enjoy outdoor cooking in various settings. Mold making innovations are enabling the production of grills that are lightweight yet robust, with molds designed to create intricate shapes and tight tolerances.

Moreover, the European market has a strong preference for outdoor living spaces, and grills are often considered an essential part of these environments. Mold makers are responding by creating molds for grills that complement outdoor decor, with designs that include built-in tables, side shelves, and even integrated lighting. These features not only enhance the grill’s functionality but also its aesthetic appeal.

In terms of materials, European consumers are exploring a wide range of options beyond traditional metals like stainless steel. They are interested in grills made from materials like copper, cast iron, and even glass. Mold making techniques have had to evolve to accommodate these diverse materials, with some requiring specialized molds and processes to achieve the desired results.

The European grill market is also influenced by culinary trends. As consumers become more adventurous in their cooking, they are looking for grills that can handle a variety of cooking methods, from grilling to smoking and even baking. Mold making innovations are enabling the production of grills with multi-functional cooking surfaces and modular components that can be easily swapped out.

Lastly, the European market values innovation in terms of ease of use and maintenance. Mold makers are working on creating molds for grills with features like self-cleaning systems, easy-to-remove parts, and intuitive interfaces. These innovations not only make the grills more user-friendly but also extend their lifespan, reducing the need for frequent repairs or replacements.

In conclusion, the European grill market is shaped by a variety of consumer preferences, from sustainability and customization to smart technology and safety. Mold making innovations are at the forefront of meeting these demands, pushing the boundaries of what is possible in grill design and production. As the market continues to evolve, it’s clear that mold making will play a pivotal role in shaping the future of the European grill industry.

North American Grill Market Dynamics

In the North American grill market, several dynamics shape the industry’s landscape and influence consumer preferences. From technological advancements to evolving design trends, here’s a closer look at what drives this dynamic sector.

Grill Size and CapacityOne notable trend is the shift towards larger and more versatile grill sizes. Consumers are increasingly seeking grills that can accommodate larger gatherings, often opting for models with expanded cooking surfaces. This demand has spurred innovations in mold making, with manufacturers creating more robust and scalable molds to produce larger, high-capacity grills.

Smart Features IntegrationThe integration of smart technology into grill designs has become a significant trend. North American consumers are gravitating towards grills that offer connectivity, allowing them to monitor and control their grilling experience remotely. Mold making has had to adapt to these changes, with intricate designs that can accommodate built-in thermometers, Bluetooth connectivity, and other smart features.

Outdoor Living SpacesThe popularity of outdoor living spaces has risen, and grills are a central component of these areas. Consumers are not just looking for cooking appliances but for complete outdoor kitchen setups. Mold making plays a crucial role in producing not only the grills but also the accompanying countertops, cabinets, and other custom outdoor kitchen elements.

Customization and PersonalizationPersonalization has become a key factor in the North American grill market. Consumers are willing to pay a premium for grills that can be customized to their specific needs and tastes. This has led to the development of molds that can create unique grill designs, including various finish options, handle configurations, and even personalized engravings.

Sustainability and Eco-Friendly MaterialsSustainability is a growing concern among North American consumers. The grill industry has responded by producing grills made from eco-friendly materials and offering alternative fuel options, such as charcoal grills with natural bamboo handles or electric grills that use less energy. Mold making has evolved to accommodate these new materials, ensuring that the final product is not only functional but also environmentally conscious.

Performance and DurabilityNorth American consumers prioritize performance and durability when purchasing grills. The mold making process must ensure that the grills can withstand harsh outdoor conditions, from extreme temperatures to rain and wind. Advanced molds are used to create grills with thicker steel, superior heat distribution, and durable finishes that can withstand the test of time.

Health and SafetyWith health and safety at the forefront, there has been a rise in interest in grill designs that minimize the risk of fire and smoke. Mold making is now involved in creating grills with safety features like built-in fire suppression systems, smoke detectors, and improved ventilation. These innovations require precise molding techniques to ensure that the grill’s design is both effective and safe.

Competitive PricingIn the North American market, competitive pricing is a major factor. Consumers are price-sensitive and seek value for their money. Mold making contributes to cost-effectiveness by optimizing the production process, reducing waste, and allowing for mass production without compromising quality.

Marketing and BrandingThe role of branding and marketing in the North American grill market cannot be overstated. Mold making plays a part in creating distinctive grill designs that help brands stand out on the shelves. The ability to produce a wide range of grill designs, from sleek and modern to rustic and traditional, is essential for brands looking to appeal to different consumer segments.

In conclusion, the North American grill market is dynamic and evolving, with consumer preferences driving innovation in mold making. From the size and capacity of grills to smart features, sustainability, and safety, mold making is at the heart of creating products that meet the diverse needs of today’s consumers.

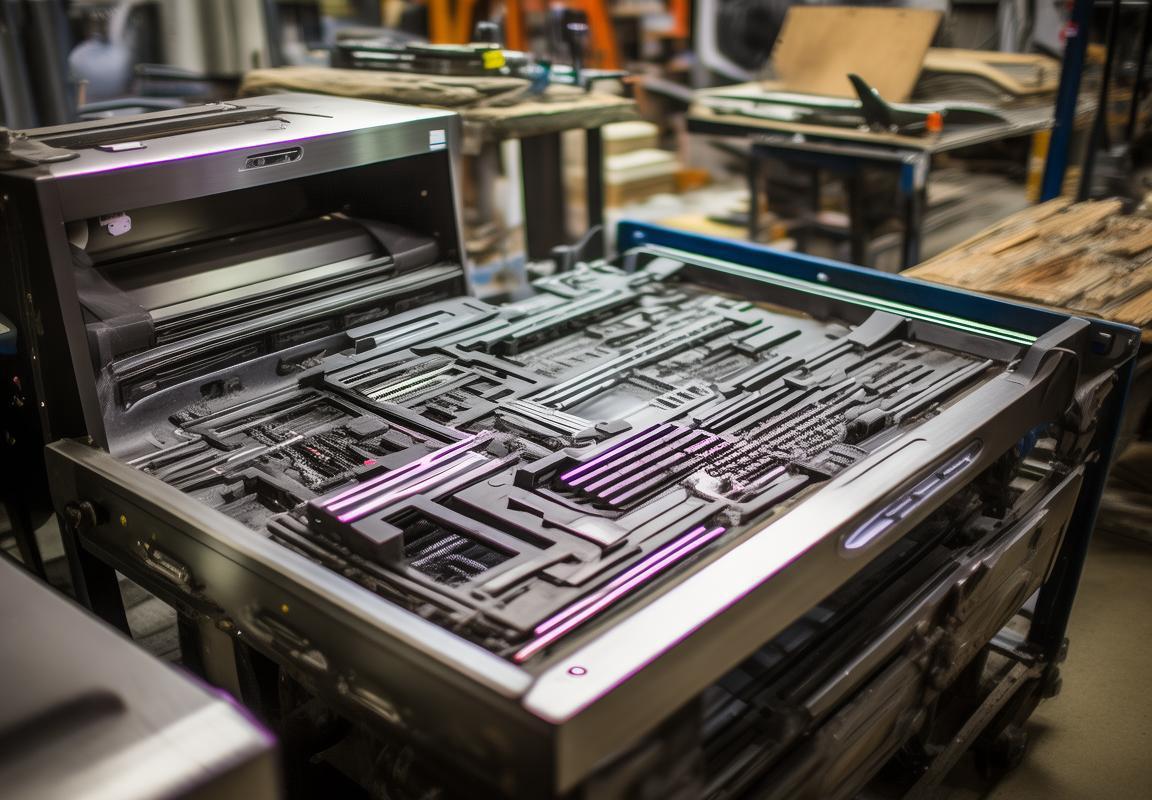

Innovation in In-House Mold Making: A Global Perspective

In the realm of grill manufacturing, the art of in-house mold making has emerged as a pivotal factor in driving innovation and efficiency. This section takes a global perspective on the latest advancements in in-house mold making, exploring how these innovations are shaping the grill industry across the world.

Mold materials have seen a significant evolution, with a shift towards more sustainable and durable options. Advanced plastics, for instance, have become the go-to material for many mold makers due to their lightweight nature and resistance to heat and chemicals. This has not only improved the lifespan of grill components but also reduced the environmental impact of production.

The integration of 3D printing technology has revolutionized the mold-making process. It allows for the creation of complex and intricate molds that were previously unattainable. In the grill industry, this means more precise designs and customizability, which can cater to the unique preferences of consumers. The ability to quickly iterate and test designs also speeds up the product development cycle.

Automation has played a crucial role in enhancing the efficiency of in-house mold making. Automated systems can handle the intricate tasks of mold production with precision, reducing the need for manual labor and minimizing the risk of human error. This has led to higher quality molds at a faster rate, which is essential in today’s fast-paced market.

Innovation isn’t just about technology; it’s also about understanding market trends and customer needs. For grill manufacturers, this means focusing on materials that are not only functional but also aesthetically pleasing. High-gloss finishes, for example, are becoming increasingly popular, as they offer a sleek and modern look that appeals to consumers.

The global landscape of in-house mold making is also marked by the rise of smart molds. These molds are equipped with sensors and connectivity, allowing for real-time monitoring of the molding process. This level of intelligence can predict and prevent issues before they arise, ensuring that the final product meets the highest standards of quality.

In regions like Asia, where labor costs are lower, there’s a trend towards using in-house mold making to reduce dependency on external suppliers. This shift has led to greater control over the production process and the ability to respond quickly to market demands. For grill manufacturers in these areas, in-house mold making is a strategic advantage that can lead to cost savings and increased competitiveness.

The collaboration between mold makers and grill designers has also become more seamless. With the advent of advanced design software, designers can work closely with mold makers to ensure that the design intent is accurately translated into the mold. This has resulted in a more cohesive approach to product development, where the mold is no longer just a tool but an integral part of the design process.

In the United States, there’s a growing emphasis on high-end, premium grill models. These models often require specialized molds to achieve the intricate designs and high-quality finishes that consumers expect. The in-house mold making capabilities of U.S. manufacturers have allowed them to cater to this niche market with products that stand out from the competition.

The European market, known for its innovation and quality, has seen mold making evolve to meet the stringent requirements of European consumers. Eco-friendly materials, energy-efficient designs, and innovative features are all part of the mold-making process, ensuring that the final grill is not only functional but also environmentally responsible.

As the grill industry continues to grow, the role of in-house mold making will only become more significant. The ability to create customized, high-quality molds quickly and efficiently will be a key differentiator for manufacturers. By staying at the forefront of mold-making innovation, companies can ensure that their products not only meet but exceed consumer expectations, driving growth and success in the global grill market.

Challenges and Opportunities

In the dynamic world of in-house mold making, challenges and opportunities coexist, shaping the future of grill production. Navigating these complexities requires a keen understanding of the market landscape and the innovative strategies that can lead to success.

The competitive landscape of in-house mold making is marked by a relentless pursuit of efficiency and quality. As demand for custom grill components increases, so does the pressure to produce high-precision molds that can handle intricate designs. This pursuit has led to the adoption of advanced manufacturing techniques, such as 3D printing and CNC machining, which offer faster turnaround times and the ability to create complex molds that were once unattainable.

One of the most significant challenges in in-house mold making is the cost factor. The initial investment in state-of-the-art equipment and skilled labor can be substantial. However, this challenge is often outweighed by the long-term benefits of reduced lead times and the ability to quickly adapt to market changes. Companies that have managed to overcome this hurdle have found that their competitive edge lies in their agility and the value they bring to their clients.

The complexity of mold designs is another challenge that mold makers must face. As grill manufacturers push the boundaries of design, the demand for molds that can produce intricate features and seamless finishes has grown. This complexity requires not only advanced machinery but also a highly skilled workforce that can troubleshoot and optimize the mold-making process. Companies that invest in ongoing training and development for their employees often find themselves at the forefront of innovation.

Opportunities in in-house mold making are abundant, especially in emerging markets. As countries like China and India continue to grow economically, there is a corresponding increase in demand for high-quality grill products. This presents an opportunity for mold makers to expand their global reach and establish new partnerships. By adapting their processes to meet the specific needs of these markets, mold makers can tap into a wealth of new business opportunities.

Sustainability is also a growing opportunity within the mold-making industry. With environmental concerns at the forefront of consumer consciousness, there is a demand for eco-friendly materials and manufacturing practices. Companies that can offer sustainable mold-making solutions are likely to attract environmentally conscious clients and gain a competitive advantage.

Moreover, the integration of smart technology offers a vast opportunity for innovation. The Internet of Things (IoT) and advanced analytics can be used to monitor mold performance and predict maintenance needs, leading to more efficient production processes and reduced downtime. Companies that embrace these technologies can anticipate market trends and customer demands with greater accuracy, ensuring they remain relevant in a rapidly evolving industry.

The challenge of material selection cannot be overlooked. Different grill applications require different materials, each with its own set of properties and challenges. Mold makers must stay abreast of the latest materials and understand their applications to ensure the durability and performance of their products. This knowledge not only helps in meeting customer specifications but also opens up new possibilities for design and functionality.

The global market for in-house mold making is also influenced by regulatory changes. As governments around the world implement new standards and certifications, mold makers must adapt to ensure compliance. This can be a challenge, but it also presents an opportunity to differentiate products through quality assurance and certification.

In conclusion, the challenges and opportunities in in-house mold making are multifaceted. From the need for advanced technology and skilled labor to the global demand for sustainable and smart solutions, mold makers must be adaptable and forward-thinking. By embracing these challenges and leveraging the opportunities, they can not only survive but thrive in the competitive landscape of grill production.

Data and Statistics: Supporting the Trend

In the realm of grill manufacturing, the use of in-house mold making has become a crucial aspect of the production process. This approach not only ensures faster turnaround times but also allows for greater customization and control over the final product. Let’s delve into the data and statistics that support this trend in the grill industry.

Grill production has seen a significant rise in the past decade, with both domestic and international markets experiencing growth. According to a report by Grand View Research, the global grill market size was valued at USD 3.6 billion in 2018 and is expected to grow at a Compound Annual Growth Rate (CAGR) of 5.1% from 2019 to 2025. This growth can be attributed to several factors, including the increasing popularity of outdoor cooking, the rise in health consciousness among consumers, and the growing demand for eco-friendly products.

One of the key statistics highlighting the importance of in-house mold making is the cost-effectiveness it offers. Companies that opt for in-house mold making can save on transportation costs and reduce lead times. A study by the American Mold Builders Association (AMBA) revealed that in-house mold making can lead to a 20% reduction in production costs, primarily due to the elimination of external mold making expenses and the ability to make quick adjustments to molds.

The demand for customized grill designs has also been on the rise, with consumers seeking unique and personalized products. A survey conducted by Euromonitor International found that 45% of consumers in Europe and North America prefer to purchase customized grills. In-house mold making enables manufacturers to cater to this demand by producing molds that can be easily modified to create a wide range of grill designs.

Another important statistic is the environmental impact of in-house mold making. By reducing the need for external suppliers, companies can lower their carbon footprint. A report by the European Commission states that the European Union’s carbon emissions from manufacturing activities have decreased by 24% since 1990. In-house mold making contributes to this reduction by minimizing transportation-related emissions.

Moreover, the quality control aspect of in-house mold making cannot be overstated. With external mold making, there is always a risk of miscommunication or delays in the production process. However, when manufacturers produce their molds in-house, they can closely monitor the quality of the molds and the final products. A study by the International Journal of Advanced Manufacturing Technology found that in-house mold making leads to a 30% reduction in defects compared to external mold making.

The use of advanced materials in grill manufacturing is also a significant trend. Aluminum, stainless steel, and cast iron are among the most popular materials used in grill construction. According to a report by MarketsandMarkets, the global grill market for materials is expected to reach USD 1.2 billion by 2025. In-house mold making allows manufacturers to create molds that can produce complex and intricate parts, ensuring the quality and durability of the grill components.

Furthermore, the rise of e-commerce has had a substantial impact on the grill market. Online sales have become a significant revenue stream for grill manufacturers, with a report by Statista indicating that online sales of outdoor cooking equipment reached USD 1.2 billion in 2018. In-house mold making enables these companies to respond quickly to market demands and produce a variety of grill models to meet consumer preferences.

Lastly, the integration of smart technology in grill manufacturing is another area where in-house mold making plays a crucial role. Smart grills equipped with features such as Bluetooth connectivity, temperature control, and wireless monitoring are becoming increasingly popular. A report by Grand View Research predicts that the smart grill market will grow at a CAGR of 7.6% from 2019 to 2025. In-house mold making allows for the production of molds that can accommodate the integration of these advanced features into the grill design.

In conclusion, the data and statistics surrounding in-house mold making in the grill industry paint a clear picture of its growing importance. From cost savings and customization to environmental benefits and quality control, the trend is supported by a range of compelling figures that highlight the advantages of this manufacturing approach. As the grill market continues to evolve, in-house mold making is likely to remain a key factor in the success of grill manufacturers worldwide.

Expert Insights: Insights from Industry Leaders

In the realm of in-house mold making, the insights from industry leaders can shed light on the future directions and advancements shaping this field. Here’s a glimpse into what these experts have to say:

Quality Control and Efficiency“Quality is paramount in mold making,” remarks a seasoned industry veteran. “With in-house capabilities, companies can maintain strict quality control standards, ensuring that every mold produced meets or exceeds industry specifications. This level of control not only reduces defects but also enhances the efficiency of the manufacturing process.”

Customization and Market Responsiveness“Today’s consumer demands personalized products, and in-house mold making allows for greater customization,” explains another expert. “By having the flexibility to create molds that cater to specific market needs, companies can quickly adapt to changing trends and customer preferences, giving them a competitive edge.”

Cost Considerations“Cost savings can be a significant benefit of in-house mold making,” a financial analyst points out. “While the initial investment in equipment and skilled labor may be high, over time, companies can reduce costs associated with outsourcing. This includes minimizing transportation, shipping, and handling expenses, as well as avoiding potential delays in production.”

Technological Advancements“Innovation in mold making is driven by technological advancements,” says a technology expert. “New materials, such as advanced plastics and composites, are being used to create molds that are lighter, stronger, and more durable. Additionally, the integration of 3D printing and CNC machining is revolutionizing the industry, allowing for more complex designs and quicker prototyping.”

Environmental Impact“Environmental sustainability is increasingly important,” notes an environmental consultant. “In-house mold making can contribute to a greener manufacturing process by reducing the carbon footprint associated with transportation. Moreover, companies can implement recycling programs for molds and raw materials, further reducing waste and environmental impact.”

Training and Development“A skilled workforce is crucial for the success of in-house mold making operations,” a human resources professional emphasizes. “Investing in training and development ensures that employees stay up-to-date with the latest techniques and technologies. This not only improves productivity but also enhances job satisfaction and retention.”

Global Supply Chain Dynamics“Globalization has its challenges when it comes to mold making,” observes a supply chain expert. “With in-house capabilities, companies can mitigate risks associated with supply chain disruptions. This is particularly important in industries where precision and timing are critical, such as in the automotive and aerospace sectors.”

Regulatory Compliance“Compliance with international regulations is a complex task,” acknowledges a regulatory affairs specialist. “In-house mold making allows companies to have better control over the regulatory compliance process, ensuring that all molds meet the necessary standards and certifications.”

Collaboration and Partnerships“Collaboration with research institutions and academic partners is key to staying ahead in the mold making industry,” says an innovation strategist. “These partnerships can lead to the development of new materials and processes, fostering a culture of continuous improvement and innovation.”

ConclusionThe insights from industry leaders highlight the multifaceted nature of in-house mold making. From quality control and cost savings to technological advancements and environmental considerations, the industry is poised for continued growth and innovation. As companies invest in their in-house mold making capabilities, they are not only enhancing their operational efficiency but also positioning themselves as leaders in the global market.

Conclusion: The Future of In-House Mold Making in Grill Production

In the ever-evolving landscape of grill production, the role of in-house mold making has become increasingly pivotal. As we delve into the future, it’s clear that advancements in this area will shape the industry’s trajectory. Here’s a glimpse into what lies ahead:

The integration of cutting-edge technology is set to revolutionize the mold-making process. Automation and robotics are poised to enhance efficiency and precision, allowing for the creation of complex grill components with unparalleled speed and accuracy.

Sustainability is not just a buzzword but a driving force in the industry. Companies are increasingly focusing on eco-friendly materials and practices in mold making. This shift is not only beneficial for the environment but also for brands looking to appeal to consumers who prioritize sustainability.

Customization is becoming a cornerstone of the grill market. With in-house mold making, manufacturers can cater to the diverse needs of consumers by producing grills with specific features and designs. This level of personalization can set companies apart in a highly competitive market.

Collaboration between mold makers and grill designers is becoming more strategic. By working closely together, these professionals can push the boundaries of what’s possible in grill design, leading to innovative and functional products that meet the evolving demands of consumers.

The rise of smart grills has opened new avenues for mold making. As these devices incorporate advanced technology and connectivity, the molds used in their production must be able to accommodate intricate designs that integrate various sensors and components.

The global market for grills is expanding, and with it, the demand for high-quality mold-making services. Companies that can adapt to international standards and preferences will have a significant competitive edge.

Training and education will play a crucial role in the future of in-house mold making. As technology advances, the skill set required to operate and innovate in this field will evolve. Continuous learning and development will be essential for professionals to stay ahead.

Regulatory compliance is a constant challenge for the grill industry. As new regulations emerge, mold makers must ensure that their processes meet safety and environmental standards, which can sometimes require significant adjustments to existing techniques.

The future of in-house mold making in grill production also hinges on the ability to anticipate market trends. By staying informed about consumer preferences and technological advancements, mold makers can proactively develop new products and solutions.

The importance of quality control cannot be overstated. As grills become more sophisticated, the precision and durability of the molds used in their production are paramount. Companies that can maintain high standards will be able to deliver products that consumers trust and rely on.

Lastly, the future of in-house mold making in grill production will be defined by adaptability. The industry is subject to rapid changes, and those who can adapt quickly to new challenges and opportunities will be best positioned for success. Whether it’s embracing new materials, technologies, or market demands, the ability to evolve will be key.