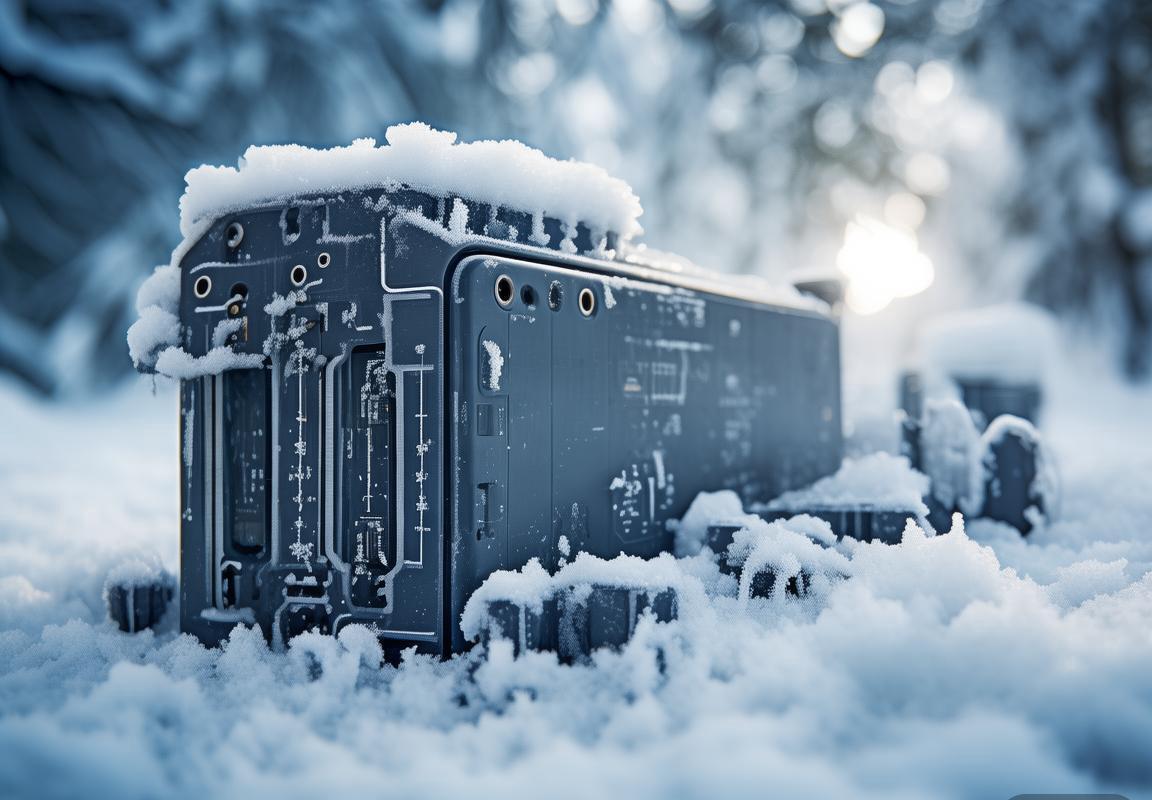

In intense low-temperature environments, the stableness of gadget and substances will become a essential attention. With the intensification of world weather alternate, there is an increasing demand for a “-30°C cold Resistance version” that can maintain solid operation at temperatures as low as -30°C. this newsletter will talk the important thing design points, cloth choice, structural optimization, and the potential market software prospects of this version.

Low Temperature Adaptability Overview

In excessive weather conditions, theadaptability of gadget and products becomes a critical performance indicator. specially under the extreme cold of -30°C, the steadiness of material properties, mechanical structures, and electronic additives is essential for the reliability of the gadget. adaptability particularly entails the bodily and chemical assets adjustments of materials at low temperatures, the conductivity and thermal stability of circuits, in addition to the electricity and toughness of the overall structure. ensuring the everyday operation of products in frigid environments is mainly vital for fields such as aerospace, transportation, and power supply.

Key Points for Designing a 30°C Cold Resistance Model

while designing a cold-resistant model for severe low-temperature environments (-30°C), the following key factors ought to be considered:

-

The material used need to possess great low-temperature overall performance to make sure that the structural power and durability are maintained beneath situations. as an instance, alloys with precise low-temperature impact toughness or unique plastics have to be decided on.

-

The layout must avoid stress concentrations which could occur due to temperature versions. Uniform strain distribution designs must be followed to reduce deformation resulting from cold contraction or thermal expansion.

three. warmness treatment techniques are essential for the low-temperature performance of the model. via precise warmness treatment, the cloth’s low-temperature sturdiness can be progressed, enhancing the model’s impact resistance.

-

Sealability design is vital for the everyday operation of the model in low-temperature environments. Sealants and systems with low-temperature resistance should be decided on to prevent internal medium leakage.

-

electric gadget design need to take into account the impact of low temperatures on insulation properties. Insulating substances with superb low-temperature performance and circuit designs need to be used to ensure stable operation of the system in low-temperature environments.

Material Selection and Structural Optimization

In intense low-temperature environments like -30°C, the selection of materials and structural optimization are important. first of all, it is necessary to remember the low-temperature properties of materials, together with glass fiber bolstered plastics and polytetrafluoroethylene, which can be frequently selected for his or her outstanding low-temperature resistance. Secondly, structural design should ensure sufficient rigidity and power to save you cloth shrinkage and deformation caused by low temperatures.

For connection points, using high-tension bolts and sealing rubber strips is powerful in stopping leakage due to low temperatures. In terms of material thickness, calculations and experimental verification are used to accurately growth the thickness to accommodate low-temperature shrinkage even as fending off immoderate weight advantage. heat treatment techniques are also crucial, with pre-stretching or pre-compression remedies to lessen stress concentration for the duration of low-temperature use.

In structural layout, modular design is adopted to facilitate renovation and substitute, whilst also enhancing ordinary structural flexibility. The layout of reinforcing ribs ought to fully recollect the low-temperature houses of the materials to make certain correct mechanical homes at low temperatures. in addition, for exposed elements, electrical heating or insulation substances are used for protection to prevent the overall performance of gadget from being stricken by the low temperatures.

whilst choosing materials, it’s far really useful to keep away from the usage of plastics and composite materials which are susceptible to, as these substances tend to emerge as hard and brittle at low temperatures. on the equal time, the corrosion resistance of the substances must be considered to extend the carrier lifestyles of the equipment. thru those cloth and structural optimization measures, system may be ensured to function stably in low-temperature environments of -30°C.

Performance Testing and Verification

To make certain the reliability of the -30°C cold tolerance version below severe situations, the subsequent strategies were adopted:

- Low Temperature performance substances: special engineering plastics and alloys with first-rate low-temperature residences had been decided on. these substances keep precise mechanical energy and toughness at low temperatures, stopping phenomena due to temperature drop.

- Insulation design: a couple of layers of insulation cloth had been integrated into the product design, effectively blocking off the impact of outside low temperatures on internal components, ensuring that middle components preserve everyday working temperatures in the low-temperature environment.

- Thermal Cycle testing: The version has been subjected to thermal cycle tests to simulate extreme temperature versions, verifying the steadiness of the materials underneath common temperature modifications and ensuring that the structure will now not be damaged with the aid of thermal expansion and contraction.

- electricity evaluation: Mechanical belongings assessments, which include tensile, compression, and bending, have been carried out on key additives to ensure that the model can face up to expected running loads underneath low-temperature conditions.

- Sealing overall performance checking out: The sealing overall performance of the product has been rigorously examined beneath low-temperature situations to make sure no leaks and to prevent cold air from affecting the operation of inner components.

- electrical overall performance testing: The electronic additives of the version have been tested underneath low-temperature electric overall performance to ensure the conductivity and responsiveness of the circuitry aren’t suffering from the low temperatures.

- sturdiness Verification: lengthy-time period operational exams have been conducted to confirm the sturdiness of the model under low-temperature conditions, ensuring that the product keeps strong performance throughout lengthy-term use.

through these assessments and verifications, the -30°C bloodless tolerance version has completely ensured its overall performance in excessive bloodless environments, imparting dependable technical help for the utility of the product underneath excessive climatic conditions.

Application Prospects and Market Potential

The application prospects of cold resistance models in intense bloodless environments are widespread. With the improvement of polar scientific research, cold chain logistics, outside system, and other fields, there may be an growing demand for products which can operate stably at temperatures as low as -30°C. right here is an evaluation of the marketplace capability in several factors:

-

in the subject of polar clinical studies, there may be a high dependency on cold-resistant device. The application of -30°C cold resistance fashions in polar research stations and studies vessels enables make certain the smooth progress of clinical sports, reduces the danger of system failure because of extreme bloodless, and improves research performance.

-

in the bloodless chain logistics industry, temperature manage is a vital link. when transporting perishable food, prescribed drugs, and other sensitive items, -30°C cold resistance models can make certain that the goods stay sparkling and effective below severe cold situations, assembly the excessive standards of cold chain logistics.

-

inside the outside system market, the pursuit of bloodless resistance is usually increasing. With the popularity of outside activities which includes mountain climbing, exploration, and snowboarding, fans have better requirements for the bloodless-adaptive properties of gadget. -30°C cold resistance fashions will offer protection ensures for those activities.

-

within the army utility subject, combat capability in excessive weather conditions is crucial. In operations in bloodless regions and army sporting activities, -30°C bloodless resistance fashions can decorate the reliability of navy device and improve operational effectiveness.

-

In urban infrastructure, addressing the demanding situations of severe cold. In cold areas, urban heating, water deliver, and power supply structures face sizeable stress. The software of -30°C cold resistance models can improve the cold resistance of these systems, ensuring the everyday operation of the city.

In summary, -30°C cold resistance models show first-rate marketplace ability in a couple of fields. With the continuous development of technology and the increasing purchaser demand, this discipline is anticipated to experience rapid improvement.