As the culinary landscape evolves, so too do the appliances designed to enhance our cooking experiences. One such innovation that has quietly gained popularity is the double basket air fryer. This versatile kitchen gadget is not just a trend; it’s a game-changer that’s reshaping how we approach healthy, delicious meals at home. In this article, we delve into the world of double basket air fryer factories, exploring how these marvels are made, the technology behind them, their impact on the market, and the benefits of purchasing directly from the source. Join us as we uncover the secrets of these factories and their contribution to the kitchen appliance revolution.

Introduction to Double Basket Air Fryer Factories

In the ever-evolving world of kitchen appliances, the double basket air fryer has emerged as a game-changer. These innovative appliances have taken the culinary scene by storm, and at the heart of their production lies the double basket air fryer factory. Let’s take a closer look at what goes on behind the scenes in these bustling facilities.

Factory floors are abuzz with activity, as workers move with a sense of purpose. The air is filled with the sounds of machinery and the clinking of metal as various components are assembled. These factories are the backbone of the double basket air fryer industry, where innovation meets efficiency.

From the moment raw materials arrive at the factory, the journey to creating a double basket air fryer begins. High-quality stainless steel, durable plastic, and advanced electrical components are sourced from reputable suppliers to ensure the longevity and performance of the final product.

The assembly line is a symphony of precision. Workers carefully and secure the metal components, ensuring that each piece fits seamlessly into its designated place. The double basket design, which allows for simultaneous cooking of two different foods, is a hallmark of these fryers. It’s a delicate balance of engineering and design that makes these appliances stand out.

Inside the factory, you’ll find cutting-edge technology that facilitates the production process. Computer numerical control (CNC) machines are used to precision-cut the metal, ensuring uniformity and reducing the likelihood of errors. This level of automation not only speeds up the process but also ensures consistency in the quality of each unit.

Quality control is paramount in the double basket air fryer factory. Each fryer undergoes a rigorous inspection to ensure that it meets the highest standards. Testers apply pressure to the baskets, check for leaks, and verify that all electrical components are functioning correctly. This thorough process guarantees that customers receive a product that is both safe and reliable.

Innovation is the lifeblood of these factories. Engineers are constantly at work, experimenting with new materials and designs to improve the double basket air fryer. Energy efficiency, cooking time, and ease of use are all areas that are constantly being refined. The goal is to create an appliance that not only performs well but also aligns with the changing demands of consumers.

Safety is a top priority in these factories. Workers are trained to follow strict protocols to prevent accidents and ensure a safe working environment. Protective gear, clear signage, and regular safety drills are all part of the daily routine. This commitment to safety is reflected in the end product, which is designed with user safety in mind.

The double basket air fryer factory is a hub of activity from morning till night. As the sun sets, the factory remains lit by the glow of workstations and machinery. The production line never stops, as each unit is meticulously crafted and inspected before being packaged and prepared for shipping.

The packaging process is as meticulous as the assembly and quality control. Each double basket air fryer is carefully wrapped in protective materials to prevent damage during transit. Packaging also includes user manuals, safety warnings, and warranty information to ensure that customers are well-informed about their new purchase.

As the factory operates around the clock, the demand for double basket air fryers continues to grow. These appliances are not just a trend; they are a testament to the power of innovation and the commitment to excellence. The factory’s output is a reflection of the hard work, dedication, and passion that goes into every single unit.

In conclusion, the double basket air fryer factory is a marvel of modern manufacturing. It combines cutting-edge technology with a focus on quality and safety to produce a product that is loved by consumers worldwide. As the industry continues to evolve, these factories will remain at the forefront, driving innovation and satisfying the ever-growing appetite for healthier, more efficient cooking solutions.

The Rise of the Double Basket Air Fryer

The double basket air fryer has emerged as a game-changer in the culinary world, captivating the attention of home chefs and professionals alike. Its popularity has surged, and for good reason. These innovative appliances offer a healthier alternative to traditional deep-frying, all while providing the convenience of a multifunctional kitchen gadget. The rise of the double basket air fryer can be attributed to several key factors.

Cooking enthusiasts are constantly seeking new ways to prepare their favorite fried dishes with minimal oil. The double basket air fryer addresses this demand by utilizing advanced technology to circulate hot air around food, which effectively cooks it without the need for excessive oil. This feature has quickly made it a favorite among those looking to maintain a balanced diet without sacrificing taste.

As health consciousness has grown, so too has the demand for cooking methods that align with a healthier lifestyle. The double basket air fryer’s ability to cook food with less oil than traditional frying methods has made it a darling in the health-conscious community. This has led to a significant increase in sales, as more people seek out appliances that promote healthier eating habits.

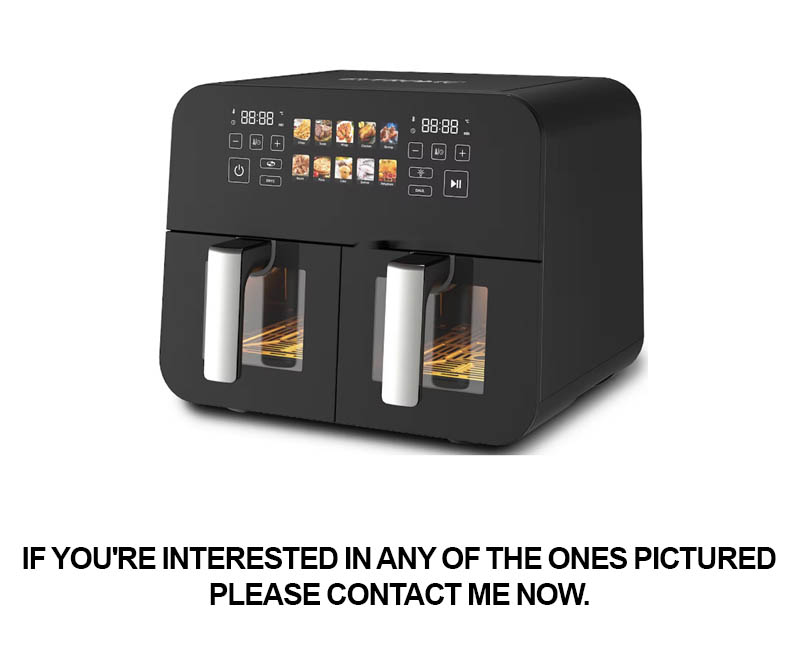

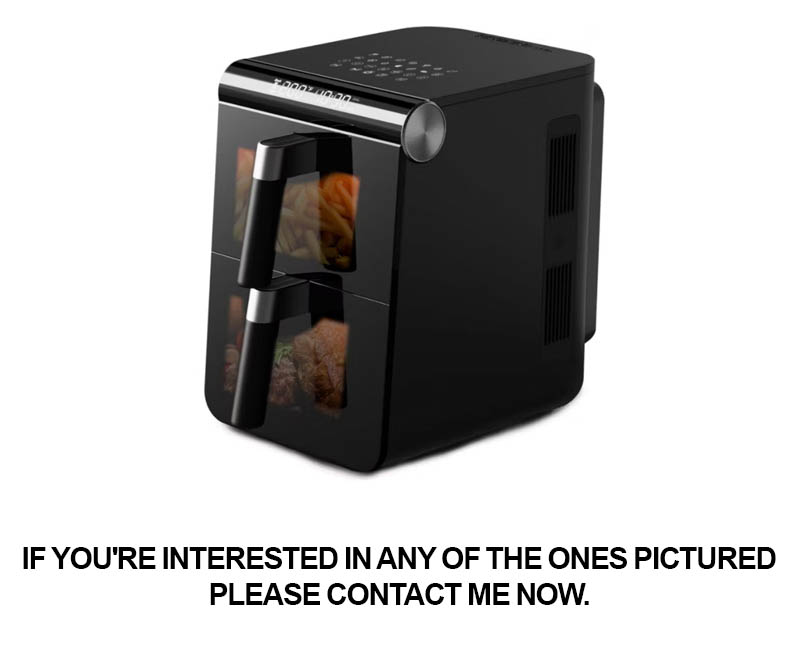

The versatility of the double basket air fryer is another reason for its meteoric rise. It can handle a variety of recipes, from crispy French fries to tender chicken wings, with ease. Its dual basket design allows for simultaneous cooking, which means you can prepare different types of food at the same time without cross-contamination. This has made it a time-saving tool in busy kitchens, whether at home or in a commercial setting.

Technology has played a pivotal role in the double basket air fryer’s ascent. Modern appliances are equipped with smart features like digital temperature controls, timer settings, and even app connectivity. These advancements have made cooking with an air fryer more accessible and user-friendly. Users can now monitor and adjust their cooking process from their smartphones, ensuring perfect results every time.

The double basket air fryer has also been embraced by the foodservice industry. Restaurants and cafes have discovered that these appliances can help reduce operational costs by cutting down on oil usage and food waste. The ability to cook a large volume of food at once has made the double basket air fryer a valuable asset in commercial kitchens, leading to increased adoption in this sector.

Moreover, the double basket air fryer has benefited from the growing interest in homemade cooking. With social media platforms like Instagram and TikTok buzzing with cooking challenges and recipes, home chefs are always on the lookout for new and exciting ways to showcase their culinary skills. The double basket air fryer provides them with the tools to create professional-quality dishes without the need for a commercial kitchen.

As the world becomes more environmentally conscious, the double basket air fryer’s eco-friendly credentials have also contributed to its rise. By reducing the amount of oil and energy required to cook food, these appliances align with the principles of sustainability. This has made them not just a trend, but a responsible choice for environmentally aware consumers.

In recent years, there has been a shift towards local and artisanal products. The double basket air fryer has capitalized on this trend by allowing home cooks to create their own versions of gourmet snacks and meals. This has sparked a new wave of culinary creativity, as people experiment with unique flavors and textures.

The rise of the double basket air fryer has also been fueled by the appliance’s ease of use. Unlike traditional ovens and fryers, which require careful monitoring and temperature control, the air fryer’s automated processes make cooking a breeze. Even those new to cooking can achieve impressive results with minimal effort.

Lastly, the affordability of double basket air fryers has made them accessible to a wide range of consumers. As prices have dropped, more and more people have been able to bring these innovative appliances into their homes, further propelling their popularity.

In summary, the double basket air fryer’s rise can be attributed to its health benefits, versatility, technological advancements, cost-effectiveness, and its alignment with current lifestyle trends. As these factors continue to drive demand, it’s clear that the double basket air fryer is not just a fleeting fad but a sustainable and impactful addition to the kitchen landscape.

Understanding the Features of a Double Basket Air Fryer

The double basket air fryer has become a staple in modern kitchens, offering a healthier and more convenient way to cook. Here are some key features that make this appliance stand out:

-

Dual Baskets for Versatility: One of the most notable features of a double basket air fryer is its two separate compartments. This design allows for cooking two different types of food simultaneously, which is perfect for families or those hosting gatherings. You can fry chicken wings while roasting vegetables in the other basket, ensuring a variety of flavors and textures without the need for multiple appliances.

-

Even Cooking and Less Oil: The technology behind air fryers uses hot air to circulate around the food, creating a crispy outer layer while keeping the inside tender. With a double basket, this even cooking is achieved across both compartments. Additionally, the reduced need for oil compared to traditional frying methods makes these appliances a healthier choice for those looking to cut down on fat intake.

-

Large Capacity for Bigger Meals: The double basket design often comes with a larger overall capacity, making it ideal for preparing meals for larger groups. Whether you’re cooking for a family of four or hosting a dinner party, these air fryers can handle the load, ensuring that everyone gets their share of delicious, crispy food.

-

Easy to Clean: One of the challenges of cooking with multiple baskets is the cleanup. However, double basket air fryers are designed with convenience in mind. The baskets are typically removable and dishwasher-safe, making cleaning a breeze. This feature is especially appreciated by those who prefer to spend less time on dishes and more time enjoying their meals.

-

Programmable Settings: Many double basket air fryers come with a range of pre-programmed settings that make cooking simple and foolproof. From chicken to fish, from fries to cookies, these settings automatically adjust the temperature and cooking time to ensure the best results every time. Users can also set their own custom programs for even more control over their cooking process.

-

Safety Features: Safety is a top priority in kitchen appliances, and double basket air fryers are no exception. These units often include features like automatic shut-off, which turns off the appliance once the cooking time is complete or if the unit is left unattended. Some models also have cool-touch handles and a non-slip base to prevent accidents and spills.

-

Energy Efficiency: Air fryers are known for their energy efficiency, and the double basket design doesn’t compromise on this aspect. These appliances use significantly less energy than deep fryers, making them a more environmentally friendly option. Cooking with a double basket air fryer can help lower your utility bills while still providing great-tasting food.

-

Compact and Space-Saving: Despite their larger capacity, double basket air fryers are designed to be compact and space-saving. They can often fit into a kitchen drawer or cabinet, making them a great choice for those with limited counter space. Their sleek design also contributes to a more organized and clutter-free kitchen.

-

Healthy Frying Alternatives: For those who love fried foods but are conscious of their health, the double basket air fryer offers a guilt-free alternative. By using less oil and providing a healthier cooking method, these appliances allow you to enjoy your favorite fried dishes without the negative health implications.

-

Versatile Cooking Options: Beyond the traditional fried foods, double basket air fryers can be used for a variety of cooking methods, including roasting, grilling, and baking. This versatility means you can use the same appliance for a wide range of recipes, from crispy French fries to juicy roasted chicken, to even making homemade pizza.

The double basket air fryer has certainly made a name for itself in the kitchen appliance market, and its features are what set it apart from other cooking methods. Whether you’re looking to improve your health, save time, or simply enjoy a wider variety of delicious foods, this appliance offers a compelling solution for modern cooks.

How Double Basket Air Fryer Factories Operate

In the bustling world of kitchen appliances, the double basket air fryer has emerged as a game-changer. These factories, dedicated to crafting these versatile kitchen gadgets, operate with a meticulous precision that ensures each unit meets the highest standards. Let’s take a peek into the inner workings of these factories.

The production line for double basket air fryers is a marvel of modern engineering. It begins with raw materials, carefully selected for their quality and durability. Aluminum, often used for its excellent heat conductivity, is sliced into thin sheets to form the baskets. These sheets are then meticulously folded and shaped, often requiring multiple presses to achieve the precise contours of the basket.

Once the baskets are formed, they move through a series of quality checks. Each basket is examined for any defects, such as dents or irregularities in the shape. Only those that meet the stringent quality standards are allowed to proceed. This meticulous inspection process is crucial, as the baskets are the heart of the air fryer and must be able to withstand high temperatures without warping.

Next, the baskets are treated to enhance their non-stick properties. A specialized coating is applied, and the process involves a controlled heat treatment to ensure the coating bonds effectively to the aluminum. This non-stick coating is not just for convenience; it’s essential for maintaining the hygiene and longevity of the air fryer.

As the baskets move along the line, they are paired with their counterparts. This pairing is done with great care to ensure that each basket fits perfectly into the other. The assembly of the baskets is a delicate task, as any misalignment could lead to inefficient air circulation and uneven cooking.

Once the baskets are assembled, the body of the air fryer is constructed. The body is typically made of metal or high-quality plastic, chosen for its ability to withstand heat and potential impact. The body parts are(welded) together with precision, and any gaps or imperfections are carefully sealed to prevent heat loss.

The heating element is then installed. This is a crucial component, as it directly affects the cooking temperature and efficiency. The heating element must be able to reach the desired temperature quickly and maintain it consistently throughout the cooking cycle. It’s installed with great care to ensure it fits snugly and is electrically insulated to prevent any risks of(short circuit).

Inside the air fryer, there’s also a fan that drives the air circulation. This fan is vital for the even cooking that air fryers are known for. The fan is carefully positioned and secured within the unit, ensuring that it operates silently and efficiently.

As the air fryer takes shape, the electronics are integrated. This includes the control panel, which may feature digital displays, buttons, and sometimes a timer or programmable settings. The electronics are tested for functionality and durability, ensuring that they can withstand the demands of everyday use.

Before the air fryer leaves the factory, it undergoes a series of final tests. These include checking the heating element, fan operation, and overall electrical safety. The air fryer is also tested for noise levels and heat distribution to ensure it meets the expected performance standards.

Once all tests are passed, the air fryer is packaged. The packaging process involves placing the air fryer into a protective box, which is then sealed with a label that includes the product’s specifications and a barcode for easy tracking. The boxes are then transported to distribution centers, ready to be shipped to retailers and directly to consumers.

The operation of a double basket air fryer factory is a symphony of precision, efficiency, and quality control. From the selection of materials to the final packaging, every step is designed to ensure that the end product is not just a kitchen gadget, but a reliable and enjoyable cooking companion.

The Manufacturing Process Explained

In the world of kitchen appliances, the double basket air fryer has emerged as a game-changer. Let’s dive into the intricacies of the manufacturing process that brings this versatile kitchen gadget to life.

The production journey begins with the selection of high-quality materials. These are typically durable metals, like stainless steel for the exterior and aluminum for the frying basket, which ensures even heating and easy cleaning. The metal is sourced from reputable suppliers and undergoes a strict quality check to prevent any defects from reaching the assembly line.

Once the raw materials are acquired, they are transported to the factory floor, where the transformation into a double basket air fryer commences. The metal sheets are first cut to size using precision machinery, ensuring that each piece is perfect for the design specifications. The cutting process is meticulous to maintain the integrity of the materials.

After cutting, the metal is bent and formed into the various parts of the air fryer, such as the body, handles, and basket supports. This stage requires skilled workers to handle the machinery carefully, as any error can lead to a compromised product. Specialized tools are used to shape the metal into the desired contours without damaging the surface.

The formed parts are then cleaned to remove any burrs or impurities. This is a critical step, as even the smallest particle of metal shavings can interfere with the cooking process or the overall performance of the air fryer. Clean parts are prepped for the next phase of the manufacturing process.

Next comes the painting and finishing stage. The metal components are coated with a high-quality, heat-resistant paint to protect them from rust and to enhance their aesthetic appeal. The paint is applied in layers, with each coat being allowed to dry and cure before the next is applied. This ensures a durable and even finish.

The interior of the air fryer, which is in direct contact with the food, is lined with a non-stick material. This coating is essential for easy food release and cleaning. Workers apply the non-stick lining with great precision, making sure that there are no gaps or air bubbles, which could affect the performance of the fryer.

With the exterior and interior prepared, the parts are assembled. This is a highly technical process that involves the precise alignment and attachment of components. Workers use a variety of tools, including bolts, screws, and clips, to ensure a secure fit. The assembly line is designed to minimize human error, with each worker responsible for a specific task to maintain consistency.

As the air fryer takes shape, it moves through various checkpoints where quality control inspectors examine the product. They check for loose parts, gaps, and any other issues that might have occurred during assembly. Any defective units are set aside for rework or disposal.

Once the air fryer is fully assembled, it undergoes rigorous testing. These tests include checking the temperature distribution, power consumption, and safety features. The air fryer is also subjected to drop tests and vibration tests to simulate real-world use and ensure it can withstand potential accidents or movements.

After passing the testing phase, the units are packaged. This involves selecting the appropriate boxes, foam inserts, and other protective materials to safeguard the air fryer during shipping. The packaging process is carefully monitored to ensure that each unit is secure and will arrive in perfect condition.

The final step in the manufacturing process is quality assurance. Each unit is inspected one last time before it is labeled and prepared for shipping. This ensures that the customer receives a product that meets the highest standards of performance and safety.

In the world of double basket air fryer factories, attention to detail is paramount. From the careful selection of materials to the meticulous assembly and rigorous testing, every step is crucial in delivering a product that can withstand the demands of everyday cooking. The result is an air fryer that not only saves time and effort but also offers a healthier alternative to traditional frying methods.

Quality Control in Double Basket Air Fryer Production

In the bustling world of double basket air fryer production, ensuring quality is paramount. Here’s a glimpse into the meticulous process that guarantees these appliances meet high standards:

The production line hums with activity as workers meticulously inspect each component before assembly. Every part, from the smallest screw to the largest basket, is checked for defects, ensuring that only the highest quality materials are used.

Inspectors wield magnifying glasses, examining the surfaces of the metal components for any signs of rust or damage. The integrity of the materials is crucial, as any weakness could compromise the air fryer’s performance and safety.

Once the parts are deemed fit, they are transported to the assembly line. Here, skilled technicians carefully piece together the air fryer, ensuring that each component fits perfectly. The double basket system, in particular, requires precision, as it must allow for even cooking without any interference between the two baskets.

During the assembly process, quality control engineers conduct regular checks. They test the fryer’s heating elements to ensure they reach the correct temperature and maintain consistency. The timers and controls are also tested to verify they respond accurately to user inputs.

The air fryer is then subjected to a series of functional tests. Engineers check for proper ventilation, ensuring that the hot air circulates effectively to cook the food evenly. The baskets are tested for stability and ease of use, making sure they slide smoothly into place and lock securely.

Safety is a top priority, so every air fryer is tested for electrical conductivity to prevent any risks of electric shock. The exterior is inspected for any sharp edges or rough spots that could cause injury.

After passing the initial functional tests, the air fryer is subjected to a series of endurance tests. It is cooked at high temperatures for extended periods to simulate years of regular use. This process helps to identify any potential weaknesses or failures that might occur over time.

Once the endurance tests are complete, the air fryer is disassembled and each component is thoroughly cleaned. This is not only a hygiene measure but also an opportunity to inspect the parts for any signs of wear or damage that may have occurred during the testing phase.

The components are then reassembled, and the air fryer is subjected to a final round of checks. This includes a visual inspection, a functional test, and a safety check. Only when all these tests are passed does the air fryer earn its quality seal of approval.

Throughout the production process, engineers and technicians keep detailed records of each step. This documentation is crucial for traceability, allowing the factory to quickly identify and address any issues that may arise.

In the final stages, the air fryers are packaged with care. Each unit is wrapped in protective materials to prevent damage during shipping. The packaging also includes all necessary documentation, such as user manuals and warranty information.

The rigorous quality control process in double basket air fryer production is what sets these appliances apart. It’s a testament to the commitment to excellence that ensures customers receive a product that not only performs well but also stands the test of time.

Innovation and Technology in Factory Settings

In the realm of double basket air fryer factories, innovation and technology play a pivotal role in driving efficiency and quality. These factories are hubs of cutting-edge machinery and skilled workers, all contributing to the creation of high-quality appliances. Here’s a glimpse into how these elements intertwine within the factory setting.

The factory is a sprawling complex, with each section dedicated to a specific aspect of the manufacturing process. From raw materials to finished products, every step is meticulously managed. One of the most striking features is the automated systems that oversee the production line.

Automation is not just limited to the assembly of the air fryer itself but extends to the handling of materials and the quality control process. Robots carefully sort and package the raw materials, ensuring that only the best components are used. This precision not only reduces waste but also guarantees that each fryer is made from top-notch parts.

Within the factory, there’s a significant emphasis on cleanroom technology. These controlled environments are crucial for maintaining the integrity of the air fryers. The air inside these rooms is constantly filtered to remove any particles that could contaminate the components. Workers wear specialized clothing to prevent the introduction of foreign objects, and the environment is monitored around the clock.

The assembly line itself is a marvel of modern engineering. Workers, equipped with advanced tools and guided by holographic displays, perform precise tasks with remarkable speed. The fryers move along the line, each component being attached with precision, from the heating elements to the fan blades.

Innovation isn’t just about the machinery; it’s also about the software that manages it. Factories utilize sophisticated software systems that optimize production schedules, predict maintenance needs, and even anticipate market trends. This level of intelligence allows for a dynamic production environment that can adapt to changes swiftly.

Energy efficiency is another critical factor in factory settings. Air fryer factories are equipped with energy-saving technologies to reduce their carbon footprint. LED lighting, smart heating systems, and energy-efficient machinery are all part of the arsenal used to minimize energy consumption.

Safety is paramount in these facilities. Workers are trained in the latest safety protocols, and the factory is equipped with state-of-the-art safety features. In the event of a malfunction, emergency shut-offs and safety interlocks are triggered to prevent accidents. Regular safety drills and inspections ensure that the workforce is always prepared.

One of the most innovative aspects of modern factory settings is the use of 3D printing for prototypes and small batches of components. This technology allows for rapid design iterations and the production of customized parts, which is invaluable in the development of new products.

Moreover, the integration of IoT (Internet of Things) devices in the factory setting has revolutionized the way production is monitored and managed. Sensors throughout the factory collect data on everything from temperature and humidity to machine performance. This data is then analyzed to improve processes, predict maintenance, and even optimize the layout of the factory floor.

Innovation also extends to the packaging process. Factories now use automated systems that can apply labels, seal boxes, and even customize packaging to fit different market requirements. This not only speeds up the packaging process but also ensures that each air fryer is protected during shipping.

In conclusion, the intersection of innovation and technology in double basket air fryer factories is a testament to human ingenuity. The seamless integration of advanced machinery, smart software, and a focus on safety and efficiency paints a picture of a modern manufacturing environment that is both productive and sustainable.

The Impact of Double Basket Air Fryers on the Market

In the ever-evolving world of kitchen appliances, the introduction of double basket air fryers has undeniably left a mark. These versatile devices have not only revolutionized the way we cook but have also had a significant impact on the market. From consumer demand to industry trends, the influence of double basket air fryers is multifaceted.

The demand for healthier cooking options has surged, and double basket air fryers have capitalized on this trend. Offering a healthier alternative to traditional frying methods, these appliances use minimal oil to achieve delicious, crispy results. This has been particularly appealing to health-conscious consumers who want to enjoy their favorite fried foods without the guilt.

Moreover, the convenience factor of double basket air fryers has been a game-changer. With the ability to cook two different foods simultaneously, these appliances save time and effort. Whether you’re preparing a side dish for your main course or need to cook for a crowd, the dual basket feature allows for efficient multitasking in the kitchen.

The market for double basket air fryers has seen a surge in innovation and variety. Manufacturers are continuously introducing new models with advanced features, such as programmable settings, adjustable temperature controls, and even wireless connectivity. This has led to a diverse range of options for consumers, catering to different cooking preferences and dietary needs.

The rise of e-commerce has also played a pivotal role in the impact of double basket air fryers on the market. Online platforms have made it easier for manufacturers to reach a broader audience, and consumers can now purchase these appliances from the comfort of their homes. This has not only increased accessibility but has also created a competitive landscape where brands are constantly striving to outdo each other in terms of quality, features, and price.

As health concerns continue to grow, the market for double basket air fryers is expected to expand further. With the increasing awareness of the benefits of air frying, more consumers are likely to make the switch from traditional frying methods. This shift has even prompted some chefs and restaurants to incorporate air fryers into their cooking routines, showcasing the versatility and appeal of these appliances.

In terms of industry trends, the double basket air fryer market is witnessing a shift towards sustainability. As environmental concerns become more pressing, manufacturers are focusing on producing appliances that are energy-efficient and have a lower carbon footprint. This has led to the development of air fryers that use less energy and are made from recycled materials, aligning with the values of eco-conscious consumers.

The impact of double basket air fryers on the market is also evident in the rise of DIY cooking and baking. The ease of use and the ability to cook a variety of dishes without the need for deep fryers or ovens has encouraged many to experiment with new recipes at home. This has created a niche market for specialized air fryer accessories and cookbooks, further driving the popularity of these appliances.

Lastly, the global pandemic has accelerated the trend towards home cooking. With people spending more time at home, there has been a heightened interest in kitchen appliances that can simplify and enhance the cooking experience. Double basket air fryers have played a crucial role in this shift, offering a convenient and healthful way to enjoy a variety of foods without the need for extensive kitchen space or equipment.

In summary, the impact of double basket air fryers on the market is profound. From promoting healthier eating habits to driving innovation in appliance design, these versatile kitchen gadgets have changed the landscape of cooking and are here to stay. With the continued growth in consumer demand and technological advancements, the market for double basket air fryers is poised to expand, catering to a diverse range of needs and preferences.

The Benefits of Buying from a Double Basket Air Fryer Factory

In today’s fast-paced world, convenience is king, and the double basket air fryer has emerged as a game-changer in the kitchen appliances market. Buying from a double basket air fryer factory offers a host of benefits that cater to both consumers and businesses alike. Here’s a closer look at why purchasing directly from these factories can be a smart choice.

The direct connection with the manufacturer means that you’re getting products that are tailored to meet the highest standards. Factories often have a better understanding of market trends and consumer needs, ensuring that their products are designed with the latest features and innovations. This direct line also allows for more personalized customer service, as factories can often provide more detailed information about their products and offer solutions to any issues that may arise.

When you buy from a factory, you’re typically dealing with bulk orders, which can significantly reduce the cost per unit. This cost-effectiveness is passed on to the consumer, making high-quality double basket air fryers more accessible. Additionally, factories often have streamlined production processes that minimize waste, further optimizing costs.

Factory-direct sales eliminate the need for middlemen, which means the product you receive is the product that was manufactured. This direct-to-consumer model ensures that there’s no room for error or misrepresentation, providing peace of mind that what you’re getting is exactly what you expect.

The quality control measures in a factory setting are rigorous and consistent. Factories invest heavily in quality assurance to maintain their reputation and customer satisfaction. This level of control ensures that every double basket air fryer that leaves the factory meets stringent safety and performance standards.

Buying from a factory also means you’re supporting local businesses and the local economy. When you purchase directly from a factory, you’re investing in the local workforce and contributing to the community’s economic health. This can lead to a more sustainable and resilient local economy.

Factory-direct sales often come with a wider range of product options. Factories can customize their products to meet specific market demands, offering different sizes, colors, and features. This variety allows consumers to find the perfect double basket air fryer that suits their needs and preferences.

Another benefit is the potential for after-sales support. Factories that sell directly to consumers are more likely to offer comprehensive customer service, including warranty coverage and technical support. This support can be invaluable when dealing with complex appliances like double basket air fryers.

The environmental impact of buying from a factory is also worth considering. By reducing the number of intermediaries in the supply chain, less packaging and transportation are required, which can lead to a smaller carbon footprint. This eco-friendly approach aligns with the growing demand for sustainable and environmentally conscious products.

Factories often have the capability to produce custom orders, which is particularly beneficial for businesses looking to resell or distribute double basket air fryers. Whether it’s branding the appliance with a company logo or creating a specialized model for a particular market segment, factories can accommodate these requests, providing a unique selling proposition for businesses.

Lastly, buying from a factory can lead to a more transparent supply chain. Consumers can trace the origin of their double basket air fryer, ensuring that it was produced under fair labor conditions and sustainable practices. This transparency builds trust and can be a significant selling point for brands looking to differentiate themselves in a crowded market.

In conclusion, the benefits of buying from a double basket air fryer factory are multifaceted. From cost savings and quality assurance to a wider range of options and environmental benefits, the factory-to-consumer model offers a compelling choice for those in the market for these innovative kitchen appliances.

Conclusion: The Future of Double Basket Air Fryer Factories

In today’s fast-paced culinary world, the double basket air fryer has emerged as a game-changer, revolutionizing how we approach healthy cooking. As these appliances continue to gain popularity, it’s worth reflecting on the benefits of purchasing from a reputable double basket air fryer factory. Not only do these factories offer a variety of models, but they also provide assurance of quality, durability, and innovation.

The direct relationship between factories and consumers eliminates the middleman, leading to more competitive pricing. By buying directly from the source, customers can often secure better deals and discounts, which is particularly appealing in an era where value for money is a top priority. Factories have the advantage of bulk purchasing materials, which translates to lower costs that can be passed on to the end consumer.

Moreover, factories specializing in double basket air fryers often have a keen eye for design and functionality. They understand the needs of modern cooks and strive to create appliances that not only save time but also offer versatility. This focus on innovation means that customers can expect features like adjustable temperature settings, timer controls, and even smart connectivity, making the cooking experience more intuitive and enjoyable.

When you purchase from a double basket air fryer factory, you’re also investing in the longevity of the product. These factories adhere to strict quality control measures, ensuring that each air fryer is built to last. From the sturdy construction of the outer casing to the precision engineering of the heating elements, every aspect of the manufacturing process is optimized for durability.

Additionally, buying directly from the factory allows for a more personalized experience. Customers can often request custom features or modifications to the standard models, catering to their specific cooking preferences or kitchen layouts. This level of customization is often not available when purchasing through retail channels, as the focus is usually on mass production.

Another significant benefit is the support and warranty provided by these factories. With a direct line to the manufacturer, customers can expect prompt service and repairs should any issues arise. This assurance of ongoing support is crucial for peace of mind, especially when investing in a high-quality kitchen appliance.

The factories also contribute to environmental sustainability by minimizing packaging and reducing transportation emissions. By cutting out the need for excessive packaging and multiple layers of distribution, the environmental footprint is significantly reduced. This commitment to sustainability is becoming increasingly important to consumers who are conscious about their ecological impact.

In terms of the latest trends, double basket air fryer factories are at the forefront of integrating new technologies. They often invest in research and development to bring cutting-edge features to their products, such as anti-bacterial coatings, energy-saving modes, and enhanced safety features. These advancements not only improve the user experience but also set new standards in the industry.

Furthermore, buying from a factory ensures that customers are getting the most up-to-date models. Retailers may have limited inventory, and older models might still be on shelves. Factories, on the other hand, can quickly adapt to market demands and offer the latest innovations right off the assembly line.

The benefits of purchasing from a double basket air fryer factory are manifold. From competitive pricing and innovative features to personalized service and environmental responsibility, these factories are the heartbeat of the air fryer market. They are not just producing appliances; they are shaping the future of healthy cooking, and by buying directly, consumers are not just purchasing a product but also investing in the ongoing evolution of this technology.

As the demand for healthier cooking methods continues to grow, so does the importance of factory-direct sales. The transparency and control that factories offer over the production process and product quality are invaluable to consumers. In an era where trust in brands is paramount, the direct relationship between factory and consumer is a powerful force in the market.

In conclusion, the future of double basket air fryer factories lies in their ability to innovate, maintain high standards of quality, and provide exceptional customer service. By focusing on these aspects, factories can continue to lead the market and deliver products that not only enhance the cooking experience but also contribute to a healthier lifestyle for consumers worldwide.