In the world of food manufacturing, the waffle iron plant stands as a testament to the art of turning simple ingredients into delightful treats. As these facilities evolve, the concept of continuous operation has emerged as a cornerstone for efficiency and productivity. Today, we delve into the intricacies of maintaining such a seamless workflow, exploring the technological advancements, challenges, and case studies that define the landscape of successful waffle iron plants. With a keen eye on the horizon, we also gaze into the future, identifying innovations and trends that are shaping the industry’s path forward.

The Allure of Continuous Operation: Why It Matters for Waffle Iron Plants

In the bustling world of food manufacturing, the waffle iron plant stands as a beacon of innovation and efficiency. At the heart of its operations lies the concept of continuous operation, a term that is not just a buzzword but a driving force behind the success of these plants. But what is it about continuous operation that makes it so captivating for waffle iron plants, and why does it matter so profoundly? Let’s delve into the allure of this operational approach.

To begin with, the continuous operation of a waffle iron plant signifies a relentless flow of production, ensuring that waffles are churned out without pause. This non-stop process is not just about the volume; it’s about the consistency and reliability that keep customers satisfied and the market well-stocked. Imagine a scenario where waffles are available at any time, in any quantity, without the hassle of long production delays. This is the promise that continuous operation brings to the table.

The beauty of continuous operation lies in its ability to streamline the manufacturing process. In a traditional setting, there are often breaks in production, whether for maintenance, machine downtime, or shifts changing over. These interruptions can lead to inconsistencies in quality and increased lead times. However, with continuous operation, these breaks are minimized or even eliminated, allowing for a seamless production line that is as consistent as it is constant.

One of the most compelling reasons for waffle iron plants to adopt continuous operation is the significant boost in efficiency it provides. By running machines non-stop, plants can achieve higher production rates, which means more output with the same resources. This efficiency translates into cost savings, as fewer machines are needed to meet demand, and the energy consumption is optimized. The result is a leaner, more productive operation that can scale up to meet market fluctuations without missing a beat.

Moreover, continuous operation ensures that the quality of waffles is maintained at the highest standard. In a non-stop environment, there is a rigorous emphasis on quality control. Every step of the process, from dough mixing to waffle pressing, is monitored and fine-tuned to perfection. This constant vigilance ensures that every waffle leaving the plant meets the exacting specifications that consumers have come to expect.

Another critical aspect of continuous operation is the reduction in downtime. Downtime is not just an inconvenience; it can be a costly affair. For waffle iron plants, downtime means lost revenue, wasted ingredients, and a gap in the supply chain. By maintaining a continuous flow, plants can minimize these disruptions, leading to a more predictable and stable business operation.

The technological advancements that have made continuous operation possible are nothing short of revolutionary. Automation and robotics have taken the helm, handling tasks that were once the purview of human labor. This not only increases speed and accuracy but also reduces the risk of human error. Advanced control systems are another key component, providing real-time monitoring and adjustment capabilities that keep the production line running smoothly.

Despite the numerous benefits, there are challenges to overcome in maintaining continuous operation. Machine maintenance is crucial, as these systems operate around the clock. Regular upkeep and timely repairs are essential to prevent costly breakdowns and ensure uninterrupted production. Energy consumption is also a concern, as continuous operation can lead to higher energy demands. Efficient energy management is key to balancing production needs with environmental responsibility.

In the realm of waffle iron plants, success stories of continuous operation are numerous. Companies that have embraced this approach have seen their market share grow, their brand reputation solidify, and their profitability soar. These case studies serve as a testament to the power of continuous operation in transforming a waffle iron plant from a mere manufacturer to a market leader.

Looking to the future, the trends in continuous operation for waffle iron plants are exciting. Innovations such as predictive maintenance, which uses data analytics to forecast machine failures, and the integration of Internet of Things (IoT) technology, are poised to revolutionize how plants operate. These advancements will not only further enhance efficiency and quality but also pave the way for a more sustainable and responsive manufacturing process.

In conclusion, the allure of continuous operation for waffle iron plants is undeniable. It represents a golden opportunity to optimize production, ensure quality, and meet the ever-growing demand for waffles. As the industry continues to evolve, the plants that master continuous operation will be the ones that not only survive but thrive in a competitive landscape.

Understanding the Waffle Iron Plant: A Brief Overview

In the heart of the bustling food industry, waffle iron plants stand as vital hubs of production, crafting those delightful, golden-brown waffles that captivate the taste buds of millions. These facilities, often unseen by the public eye, are the beating hearts of the waffle-making process. To truly grasp the significance of continuous operation in these plants, it’s essential to understand their inner workings.

At the core of a waffle iron plant is the machinery, designed to transform batter into the iconic grid pattern that we all recognize. These plants are equipped with a series of interconnected machines that perform each step of the waffle-making process with precision and efficiency. The journey of the batter begins with mixing, where ingredients are combined to create the perfect consistency. From there, the batter is poured onto the hot plates of the waffle iron, where it quickly forms the distinctive ridges and valleys that define the waffle’s texture.

Once the waffle is cooked to perfection, it must be cooled, stacked, and packaged for distribution. This entire process is intricate, requiring a careful balance between temperature control, batter consistency, and timing. Each waffle iron plant is a testament to modern food production, with state-of-the-art equipment that can churn out thousands of waffles in a single shift.

The layout of a waffle iron plant is designed for maximum efficiency. Raw materials, like flour, sugar, eggs, and dairy, are stored in bulk, ensuring a steady supply for the production line. The batter is then mixed and kept warm, ready to be dosed onto the waffles at a consistent rate. The waffle irons themselves are strategically placed to minimize travel time and maximize output. After cooking, the waffles pass through cooling conveyors to reach the required temperature before being stacked and packaged.

Quality control is paramount in these plants, with teams of inspectors monitoring every stage of the process. They check for consistency in size, shape, and color, ensuring that each waffle meets the high standards expected by consumers. This attention to detail is crucial, as it reflects the brand’s commitment to quality and can significantly impact customer satisfaction.

Energy management is another key aspect of waffle iron plants. These facilities require a substantial amount of energy to keep the waffle irons hot and the production line running smoothly. Modern plants often incorporate energy-efficient technologies to reduce their carbon footprint and operational costs. From high-efficiency heating elements to smart energy monitoring systems, these innovations help to maintain a sustainable and cost-effective operation.

The workforce in a waffle iron plant is diverse, from the skilled technicians who maintain and repair the machinery to the operators who manage the production line. Each role is critical to the plant’s success, and there is a strong emphasis on training and continuous improvement. Employees are often cross-trained to handle multiple tasks, which not only increases flexibility but also fosters a culture of teamwork and adaptability.

The logistics of getting waffles from the plant to the consumer’s table are complex. Distribution centers are strategically located to minimize transportation costs and delivery times. Cold chain management is essential to ensure that the waffles remain fresh and appetizing until they reach the store shelves. This involves careful planning and coordination, from inventory management to delivery routes.

Innovation is a driving force behind the evolution of waffle iron plants. As consumer preferences change and new products are introduced, these plants must adapt to meet the demands of the market. This can involve investing in new machinery, developing new recipes, or even exploring alternative ingredients. The ability to innovate and respond quickly to market trends is a key factor in the success of a waffle iron plant.

In summary, waffle iron plants are sophisticated operations that combine advanced technology, rigorous quality control, and a dedicated workforce to produce one of the world’s favorite breakfast treats. From the raw ingredients to the finished product, every step is carefully managed to ensure that each waffle is a testament to the plant’s commitment to excellence. Understanding the intricacies of these plants helps to appreciate the hard work and dedication that go into making those delicious waffles that we love so much.

The Concept of Continuous Operation: What It Means

In the world of manufacturing, the term “continuous operation” is a cornerstone of efficiency and productivity. It refers to the uninterrupted production process, where machinery and systems run without significant pauses or downtime. For a waffle iron plant, this concept is not just about keeping the waffle-making machines humming; it’s about the seamless flow of operations that ensures a steady supply of those delightful, golden-brown waffles.

At its core, continuous operation means that the waffle iron plant operates on a 24⁄7 basis, with a schedule that is designed to maximize output while minimizing breaks. This involves a meticulous planning of shifts, maintenance schedules, and supply chains to ensure that there is a constant stream of raw materials, and the finished products are consistently delivered to the market.

One of the key aspects of continuous operation is the integration of the entire production line. This means that every stage of the waffle-making process—from the unloading of flour and other ingredients to the packaging of the final product—is interconnected and automated. This level of integration ensures that each step flows smoothly into the next, without the need for manual intervention that could disrupt the rhythm of the production.

Another crucial element is the use of advanced technology. Modern waffle iron plants are equipped with state-of-the-art machinery that can handle the demands of continuous production. These machines are designed to operate at high speeds without compromising on quality. Sensors and control systems monitor the entire process, adjusting settings in real-time to maintain optimal performance.

The concept of continuous operation also encompasses the importance of predictive maintenance. By regularly analyzing data from the machinery, manufacturers can identify potential issues before they lead to downtime. This proactive approach not only reduces the risk of breakdowns but also ensures that maintenance work is scheduled during off-peak hours, minimizing the impact on production.

Energy management is another critical factor in achieving continuous operation. Waffle iron plants consume significant amounts of energy to run their operations. Implementing energy-efficient systems and practices is essential to keep costs down and to maintain a sustainable operation. This might include using variable-speed drives to optimize motor performance, or investing in renewable energy sources to power the plant.

The workforce plays a vital role in continuous operation. Employees are trained to work efficiently within the plant’s stringent schedules. They are responsible for monitoring the machines, replenishing materials, and ensuring that the production line runs smoothly. The ability to work in teams and communicate effectively is crucial, as any delay in one area can quickly cascade through the entire process.

Quality control is integral to continuous operation, as it is impossible to sustain a steady output without maintaining high standards. Waffle iron plants use sophisticated testing equipment to ensure that each waffle meets the required specifications. This includes checking for uniformity in size, color, and texture. The quality control process is often automated, with sensors and cameras detecting deviations from the norm and triggering corrective actions.

Moreover, continuous operation requires flexibility. The market demand for waffles can fluctuate, and a plant must be able to adapt quickly. This could mean changing the production mix to include more of a particular type of waffle or altering the production schedule to accommodate peak demand periods. The ability to pivot swiftly without disrupting the continuous flow is a testament to the plant’s operational agility.

Lastly, the concept of continuous operation is not just about the physical plant but also about the logistics of supply and distribution. Ensuring a steady supply of ingredients and a reliable distribution network is crucial. Inventory management systems are used to track materials and products, ensuring that the plant never runs out of essential components or faces delays in shipping.

In summary, the concept of continuous operation in a waffle iron plant is a complex tapestry of interconnected systems, technologies, and processes. It’s about creating a harmonious environment where every element works together to produce high-quality waffles without interruption, meeting the demands of consumers around the clock.

Benefits of Continuous Operation for Waffle Iron Plants

Continuous operation in the context of a waffle iron plant refers to the ability of the facility to run seamlessly without interruptions, ensuring a constant flow of production. This concept is more than just about keeping the machines running; it’s about optimizing the entire production process. Here are some of the key benefits that continuous operation brings to waffle iron plants:

Efficiency and Productivity GainsMaintaining a continuous operation in a waffle iron plant significantly enhances efficiency and productivity. By operating round the clock, these plants can produce a higher volume of waffles in a shorter amount of time. This means that more products can be manufactured and distributed, satisfying the demands of the market without delays.

Reduced Labor CostsContinuous operation can lead to a reduction in labor costs. Since the production line runs continuously, the need for overtime or additional shifts to meet demand is minimized. This not only cuts down on labor expenses but also ensures that workers have a more consistent work schedule, leading to better job satisfaction.

Consistency in QualityA continuous operation ensures that the quality of the waffles remains consistent. With a steady flow of production, there’s less variation in the manufacturing process, which can lead to inconsistencies in the final product. This consistency is crucial for maintaining brand reputation and customer satisfaction.

Predictable Inventory ManagementContinuous operation allows for better inventory management. Since the output is consistent, the plant can predict its inventory needs more accurately. This reduces the risk of overstocking or running out of products, which can both be costly and inefficient.

Energy OptimizationOperating a waffle iron plant continuously can also lead to energy optimization. By maintaining a steady state of production, the plant can optimize its energy use, reducing waste and costs associated with frequent start-ups and shutdowns. This includes the efficient use of heating elements, motors, and other machinery.

Enhanced FlexibilityContinuous operation provides enhanced flexibility in terms of production capacity. If there is a sudden increase in demand, the plant can adjust its production schedule to meet the surge without the need for extensive retooling or additional setup time.

Reduced WasteA continuous operation can help reduce waste in several ways. By minimizing downtime, the plant can avoid the production of defective waffles, which are often discarded. Additionally, the consistent flow of materials and production can prevent overfilling of bins and reduce the risk of spoilage.

Improved Maintenance SchedulingRegular maintenance is crucial for the longevity and efficiency of machinery. With continuous operation, maintenance can be scheduled more effectively. This allows for planned downtime, reducing the risk of unexpected breakdowns that can halt production.

Customer SatisfactionUltimately, the benefits of continuous operation for waffle iron plants translate into higher customer satisfaction. By providing a consistent supply of high-quality waffles, these plants can meet the needs of retailers and consumers more effectively, which can lead to increased loyalty and market share.

Long-Term Cost SavingsThe long-term cost savings associated with continuous operation are substantial. By reducing labor, energy, and waste, and improving efficiency, waffle iron plants can achieve significant savings over time. These savings can be reinvested into further improvements, such as upgrading machinery or expanding the plant.

ScalabilityContinuous operation also allows for easier scalability. As the market grows or as the plant wants to expand, it can do so without a major overhaul of the production process. This scalability ensures that the plant can grow with the market demands.

Innovation and DevelopmentLastly, continuous operation fosters an environment of innovation and development. With a steady stream of production, plants can experiment with new recipes, packaging, and marketing strategies, leading to continuous improvement and potentially new product lines.

In summary, the benefits of continuous operation for waffle iron plants are multifaceted, ranging from efficiency and quality improvements to cost savings and scalability. By embracing this concept, these plants can stay competitive in a rapidly changing market and continue to deliver the high-quality products that consumers expect.

Technological Advancements in Continuous Operation Waffle Iron Plants

In the ever-evolving world of manufacturing, the adoption of continuous operation systems has become a cornerstone for efficiency and productivity. This is particularly true for waffle iron plants, where the ability to maintain a seamless production flow is crucial. Here’s a look at the technological advancements that have propelled these plants into the era of continuous operation.

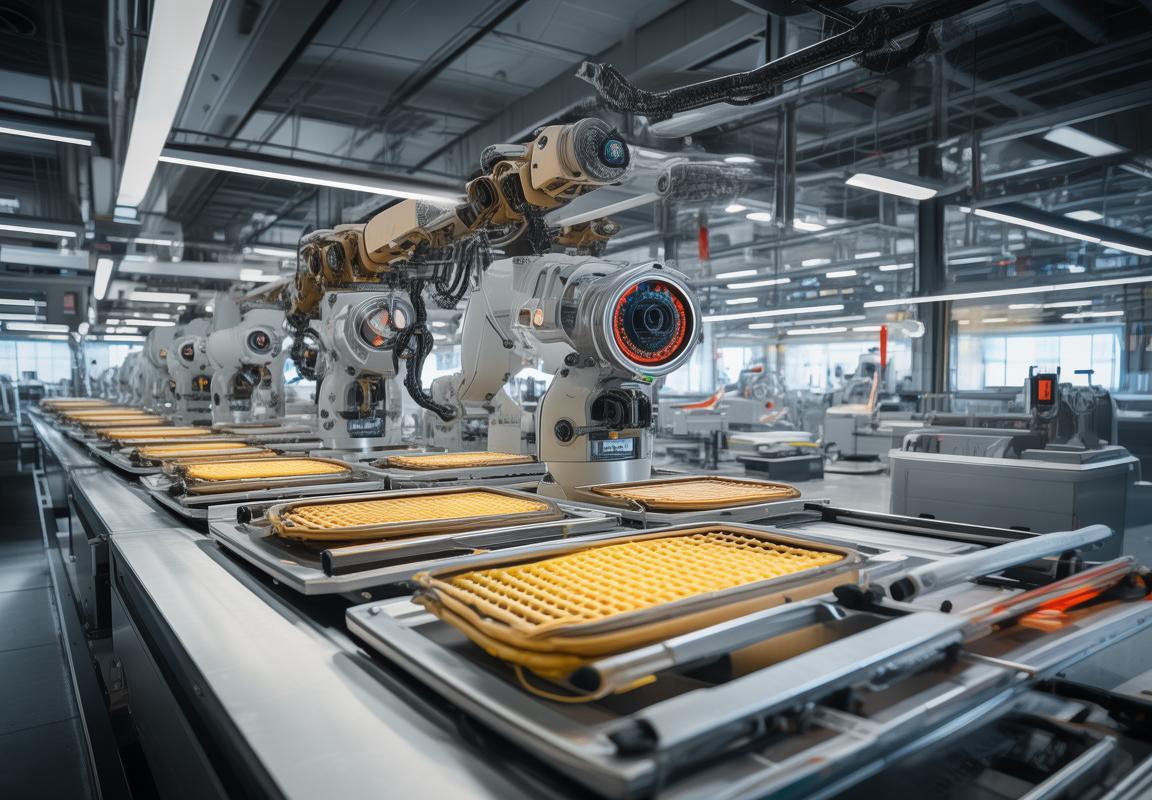

Automation has revolutionized the manufacturing landscape, and waffle iron plants are no exception. Modern facilities are equipped with automated systems that can handle a range of tasks, from ingredient handling to the final packaging of waffles. These systems ensure precision and consistency, reducing the margin for human error and allowing for round-the-clock production.

Robotic technology has taken center stage in continuous operation waffle iron plants. Robots are now capable of performing complex tasks with high accuracy, such as stacking waffles, inspecting them for quality, and even cleaning the production line. These robots are programmed to work in harmony, minimizing downtime and maximizing output.

Advanced control systems are the backbone of continuous operation in waffle iron plants. These systems monitor and adjust the production process in real-time, ensuring that every waffle meets the highest quality standards. They can detect anomalies, predict maintenance needs, and optimize energy usage, all while maintaining a steady production pace.

The integration of IoT (Internet of Things) devices has opened new avenues for continuous operation. Sensors placed throughout the plant collect vast amounts of data, which is then analyzed to improve efficiency. For example, predictive maintenance can be implemented based on data trends, preventing equipment failure and minimizing disruptions.

Energy management systems have become integral to the continuous operation of waffle iron plants. These systems monitor energy consumption and automatically adjust production to optimize energy usage. By reducing waste and increasing efficiency, these systems help lower operational costs and minimize the plant’s environmental footprint.

Waffle iron plants have embraced modular design to facilitate continuous operation. Modular systems allow for easy expansion or reconfiguration, ensuring that the plant can adapt to changing demands without significant downtime. This flexibility is crucial for maintaining a continuous flow of production.

The introduction of smart materials has also had a significant impact. These materials can change properties in response to environmental conditions, such as temperature or pressure. In a waffle iron plant, smart materials can be used to optimize the baking process, ensuring that each waffle is cooked to perfection without overexposure or undercooking.

Process optimization software is another technological marvel that has transformed waffle iron plants. This software analyzes the entire production process and identifies areas for improvement. By fine-tuning the production parameters, the software can increase output while maintaining quality.

Quality assurance has been elevated with the use of AI and machine learning. These technologies can analyze images of waffles and identify defects that might be overlooked by the human eye. The insights gained from this analysis can be used to adjust the production process and prevent similar issues in the future.

Finally, the integration of 3D printing technology has allowed for rapid prototyping and customization. This means that waffle iron plants can quickly adapt to new product designs or market trends, ensuring that they remain competitive in a fast-paced industry.

In conclusion, the technological advancements in continuous operation waffle iron plants have been transformative. From automation and robotics to advanced control systems and energy management, these innovations have paved the way for a more efficient, reliable, and sustainable production process. As the industry continues to evolve, it’s clear that these technologies will play a pivotal role in shaping the future of waffle iron manufacturing.

Challenges and Solutions in Maintaining Continuous Operation

Navigating the complexities of continuous operation in waffle iron plants, there are several challenges that must be addressed to ensure seamless production. Let’s delve into these challenges and the innovative solutions that have emerged to keep these facilities running smoothly.

In the relentless pursuit of efficiency, maintaining continuous operation in waffle iron plants can be fraught with technical and logistical hurdles. One significant challenge is the frequent maintenance required to prevent breakdowns. Wear and tear are inevitable in a high-volume, high-heat environment, and regular maintenance is crucial to keep the machines in optimal condition.

One solution is the implementation of predictive maintenance, which uses advanced sensors and algorithms to anticipate when a machine might fail. By monitoring the performance of key components, predictive maintenance can schedule service before a failure occurs, minimizing downtime and keeping the line moving.

Energy consumption is another challenge, especially in facilities that operate around the clock. The heat required to cook waffles continuously can be substantial, and managing this energy efficiently is essential for cost-effectiveness and environmental sustainability.

Smart energy management systems have been developed to tackle this issue. These systems optimize energy use by adjusting the heat output based on demand and can even integrate renewable energy sources, such as solar or wind power, into the mix. This not only reduces the plant’s carbon footprint but also lowers operational costs.

Material handling is a critical aspect of continuous operation, as the flow of ingredients and finished products must be uninterrupted. The challenge lies in managing the inventory without overstocking or running out of essential items.

Automated inventory management systems have become increasingly popular. These systems use advanced tracking technologies, like RFID and barcode scanning, to monitor stock levels in real-time. This ensures that the waffle iron plant can maintain a steady supply of ingredients and a continuous output of waffles without the risk of delays due to supply chain issues.

The human factor is also a challenge in continuous operation. Fatigue can set in for workers, especially when shifts are long and the pace is relentless. Ensuring that employees are well-rested and alert is crucial for safety and productivity.

Rest periods and shift rotation are key strategies to combat fatigue. Some plants have even introduced wellness programs that focus on employee health, providing resources for stress management and physical fitness. By taking care of their workforce, these plants can maintain a high level of performance throughout the day.

Another challenge is the quality control of the waffles being produced. With continuous operation, it’s essential to maintain consistent quality standards, which can be difficult to achieve when machines are running non-stop.

Quality control systems have evolved to handle this challenge. These systems include automated inspection stations that use high-resolution cameras and AI algorithms to detect any defects in the waffles. By integrating these systems into the production line, plants can identify and rectify issues before they become widespread.

Safety is paramount in any manufacturing environment, and continuous operation plants are no exception. The risk of accidents can increase with the fast-paced environment and longer hours of operation.

To address this, safety protocols are rigorously enforced, and safety training is a regular part of employee training. Additionally, plants have implemented advanced safety technologies, such as machine vision systems that can detect hazards and shut down machinery in real-time to prevent accidents.

Lastly, compliance with regulatory standards is a challenge that must be met. Continuous operation plants must adhere to health, safety, and environmental regulations, which can be complex and ever-changing.

Continuous improvement and compliance management systems are used to stay ahead of these regulations. These systems track changes in standards and ensure that all processes and procedures are up to date. Regular audits and certifications are also conducted to verify compliance.

In conclusion, while maintaining continuous operation in waffle iron plants presents numerous challenges, the industry has responded with a suite of innovative solutions. From predictive maintenance and smart energy management to automated inventory systems and comprehensive safety protocols, these advancements are keeping the waffle production lines rolling smoothly.

Case Studies: Successful Continuous Operation Waffle Iron Plants

In the bustling world of food production, there are a select few waffle iron plants that have mastered the art of continuous operation. These facilities stand as shining examples of how innovation and dedication can lead to sustained success. Let’s take a closer look at a few case studies that highlight the achievements of these waffle iron plants.

At the heart of these success stories is a relentless pursuit of efficiency and quality. One such plant, WaffleWorks Inc., has managed to keep its waffle production lines running smoothly for over a decade. Their dedication to continuous improvement is evident in their approach to every aspect of their operation.

WaffleWorks Inc. has invested heavily in state-of-the-art machinery that not only produces high-quality waffles but also ensures minimal downtime. Their machines are designed to operate 24⁄7, with a robust maintenance schedule that keeps them in peak condition. The plant also employs a team of skilled technicians who are trained to handle any issues that arise, ensuring that the production line remains uninterrupted.

Another remarkable example is Waffle Supreme, a facility known for its commitment to environmental sustainability and continuous operation. The plant has integrated renewable energy sources into its operations, reducing their carbon footprint while maintaining a seamless production process. Their energy-efficient waffle iron machines are capable of producing thousands of waffles each hour without skipping a beat.

The management at Waffle Supreme understands that the key to continuous operation lies in a well-trained workforce. They invest in continuous education for their employees, ensuring that they stay up-to-date with the latest techniques and technologies. This approach has paid off, as the plant has seen a significant reduction in accidents and an increase in productivity.

Yet another success story is that of Waffle Bliss, a small-scale operation that has managed to compete with larger factories through strategic planning and smart technology. The plant has embraced a modular approach to its production line, allowing for quick changes and easy upgrades. This flexibility has enabled Waffle Bliss to adapt to market demands and maintain a steady supply of waffles.

One of the key challenges faced by these plants is the need for constant inventory management. WaffleWorks Inc., for instance, uses advanced inventory tracking systems to monitor raw material usage and predict future demand. This proactive approach ensures that there is no excess waste and that production can continue without interruption.

Waffle Supreme has also tackled this challenge by implementing a lean manufacturing process. They have minimized waste through efficient production techniques and by closely monitoring their supply chain. This has not only helped them maintain continuous operation but has also reduced their overall costs.

Another challenge that waffle iron plants often encounter is maintaining product consistency. Waffle Bliss, for example, has developed a unique quality control system that checks each waffle for uniformity and texture. This ensures that every batch of waffles meets the high standards set by the company, which is crucial for maintaining their reputation and customer loyalty.

In terms of energy management, Waffle Supreme has invested in smart systems that optimize energy use throughout the facility. By analyzing data and adjusting operations accordingly, the plant has significantly reduced its energy consumption, contributing to both cost savings and environmental sustainability.

These case studies of successful continuous operation waffle iron plants demonstrate the importance of a proactive approach to problem-solving, a focus on employee training, and the integration of cutting-edge technology. Whether it’s through innovative machinery, efficient inventory control, or sustainable energy practices, these plants have shown that continuous operation is not just possible but profitable.

The journey to achieving continuous operation in the waffle iron industry is fraught with challenges, but the rewards are substantial. By analyzing these case studies, other waffle iron plants can learn valuable lessons and apply them to their own operations, ultimately enhancing their competitiveness and success in the marketplace.

The Future of Waffle Iron Plants: Innovations and Trends

The continuous evolution of technology has significantly transformed the manufacturing landscape, and waffle iron plants are no exception. As these facilities strive to maintain a seamless flow of production, they’re adopting innovative solutions to keep up with the demands of the market. Here’s a glimpse into the future of waffle iron plants, focusing on the latest innovations and emerging trends.

Innovations in Material ScienceOne of the most notable advancements is the development of high-performance materials that can withstand the intense heat and pressure of waffle iron manufacturing. These materials not only improve the longevity of the waffle irons themselves but also enhance the efficiency of the manufacturing process. Advanced alloys and composites are being used to create more durable and heat-resistant components, reducing the frequency of repairs and downtime.

Automation and Robotics IntegrationAutomation has been a game-changer in the waffle iron industry. Modern plants are increasingly integrating robotic systems to handle repetitive tasks with precision and speed. These robots can assemble, weld, and inspect the waffle irons, ensuring a consistent quality across every batch. The use of AI and machine learning algorithms allows these robots to learn and adapt, improving their performance over time.

Real-Time Monitoring and Predictive MaintenanceWaffle iron plants are now equipped with sophisticated monitoring systems that provide real-time data on the performance of their machinery. These systems can detect anomalies and predict potential breakdowns, allowing for preemptive maintenance. By addressing issues before they cause significant downtime, companies can maintain a continuous operation without compromising quality.

Energy Efficiency and SustainabilityThe environmental impact of manufacturing processes is a critical concern. Waffle iron plants are embracing energy-efficient technologies to reduce their carbon footprint. This includes the use of eco-friendly materials, energy-efficient lighting, and advanced heating systems that minimize energy consumption. Some facilities are even investing in renewable energy sources like solar panels to power their operations.

Smart Packaging and DistributionPackaging is another area where waffle iron plants are innovating. Smart packaging solutions are being developed to ensure the freshness and quality of the waffles until they reach the consumer. These packages often come with sensors that can communicate with the consumer, providing information on storage and usage. Additionally, the logistics of distribution are being optimized through the use of GPS and fleet management systems to ensure timely and efficient delivery.

Customer-Centric DesignThe needs of the consumer are at the heart of the innovation in the waffle iron industry. Companies are investing in research and development to create new shapes, sizes, and flavors of waffles that cater to changing tastes. Customization is becoming more prevalent, with consumers being able to choose from a variety of toppings and finishes. This customer-centric approach not only enhances the product but also strengthens brand loyalty.

Collaboration and Open InnovationTo stay ahead in a rapidly changing market, waffle iron plants are engaging in open innovation initiatives. This involves collaborating with academic institutions, research organizations, and even other companies to share knowledge and resources. By pooling expertise, these collaborations can lead to breakthroughs that might not have been possible individually.

Globalization and Market ExpansionAs the demand for waffles continues to grow, waffle iron plants are looking beyond their local markets to expand globally. This requires not only the development of new products that appeal to international tastes but also the adaptation of manufacturing processes to meet different regulatory standards. The global perspective is driving innovation as companies seek to enter new markets with products that resonate with local consumers.

In summary, the future of waffle iron plants is marked by a relentless pursuit of efficiency, quality, and sustainability. Through innovations in materials, automation, real-time monitoring, energy efficiency, smart packaging, and customer-centric design, these plants are poised to not only meet but exceed the expectations of both consumers and industry stakeholders. As the landscape of manufacturing continues to evolve, so too will the waffle iron industry, ensuring a bright and innovative future.

Conclusion: The Importance of Continuous Operation in the Waffle Iron Industry

In the ever-evolving landscape of the waffle iron industry, the significance of continuous operation cannot be overstated. It’s the heartbeat of a productive and efficient waffle iron plant, ensuring that batches of delightful waffles are churned out without pause. Let’s reflect on why this seamless operation is not just beneficial but crucial for the success of waffle iron plants.

Continuous operation means a consistent flow of production, minimizing downtime and maximizing output. This approach not only meets consumer demands but also allows for strategic planning and resource allocation. The importance of continuous operation in the waffle iron industry is underscored by several key factors:

Efficiency and ProductivityContinuous operation is the linchpin of efficiency in waffle iron plants. By running the production line non-stop, these facilities can maintain a steady stream of waffles, catering to both large orders and daily retail needs. This level of productivity is essential in a market where consumer expectations are high and product availability is a priority.

Quality ControlMaintaining a continuous operation requires stringent quality control measures. Waffle iron plants must ensure that every batch of waffles meets the same high standards, from the consistency of the batter to the texture of the waffles themselves. This consistency is key to building a reputation for quality that customers trust and value.

Resource OptimizationContinuous operation demands a careful balance of resources, including labor, energy, and materials. Efficient use of these resources means lower costs and a reduced environmental footprint. Waffle iron plants that manage to optimize their resources while keeping operations running smoothly are in a stronger position to compete and profit.

Flexibility and ScalabilityThe ability to scale operations up or down is vital in the waffle iron industry. Continuous operation allows plants to quickly adjust to market changes, whether it’s a surge in demand or a shift in consumer preferences. This flexibility is particularly important for those plants that serve multiple markets and need to adapt to various distribution channels.

Innovation and Technological IntegrationThe future of continuous operation in waffle iron plants hinges on innovation and the integration of new technologies. From advanced machinery to smart systems that predict maintenance needs, these innovations are key to keeping operations running smoothly and efficiently.

Challenges in Continuous OperationDespite its many advantages, maintaining continuous operation isn’t without its challenges. Issues like equipment breakdowns, supply chain disruptions, and labor shortages can all impact the seamless flow of production. However, addressing these challenges is part of what makes continuous operation in waffle iron plants so critical.

Equipment ReliabilityThe reliability of equipment is paramount in a continuous operation setting. Waffle iron plants must invest in high-quality machinery that can withstand constant use and is easy to maintain. Regular maintenance and prompt repairs are essential to prevent downtime and keep the production line running.

Supply Chain StabilityA stable supply chain is crucial for continuous operation. Waffle iron plants must have reliable sources for their raw materials and components. Diversifying suppliers and establishing long-term partnerships can help mitigate the risks associated with supply chain disruptions.

Workforce Training and ManagementThe workforce is the backbone of any waffle iron plant. Continuous operation requires skilled and dedicated staff who are trained to handle the demands of round-the-clock production. Effective management practices, including proper scheduling and rest periods, are vital to ensure employee well-being and productivity.

Conclusion: The Importance of Continuous Operation in the Waffle Iron IndustryIn conclusion, the importance of continuous operation in the waffle iron industry cannot be overstated. It is the cornerstone of efficiency, quality, and adaptability in a market where consumer demands are ever-changing. While challenges are inherent in maintaining such a system, the rewards in terms of productivity, cost savings, and market competitiveness make it a strategic imperative for waffle iron plants. As the industry continues to innovate and evolve, embracing continuous operation will remain a key factor in its success.