Moscow Air Fryer Manufacturer: Innovations and Market Impact

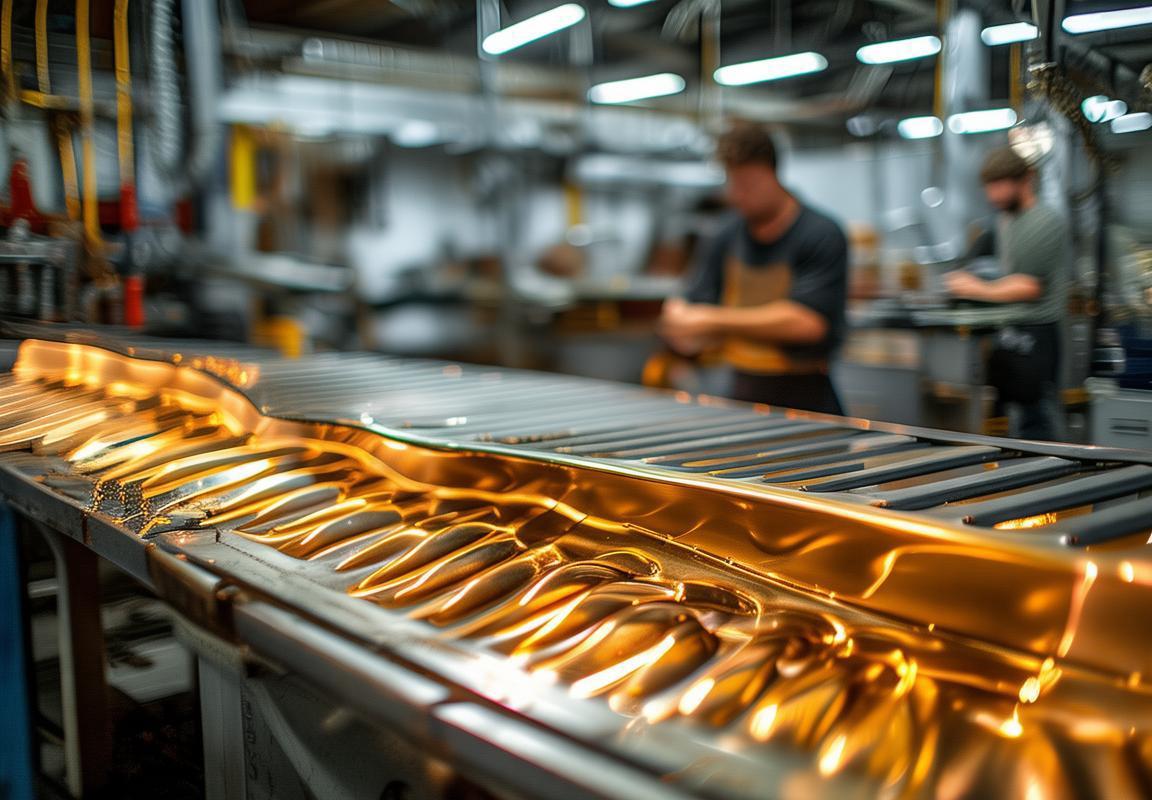

The Moscow air fryer manufacturer has emerged as a leader in the kitchen appliance market with its innovative air fryers. With a deep presence in Russia and a growing international footprint, the company offers healthier cooking alternatives that resonate with consumers seeking convenience and health. Known for their exceptional performance and cutting-edge technology, the Moscow air fryers have become a staple in European and American kitchens. Their commitment to quality, energy efficiency, and sustainability sets them apart, making them a favorite choice for those who value cooking innovation and eco-friendly practices. As the market continues to evolve, the Moscow air fryer manufacturer is poised to lead with its commitment to quality, innovation, and consumer satisfaction.