With the continuous improvement of business automation era, the utility of computerized contact grilling meeting traces has shown considerable advantages in improving production efficiency and reducing charges. this newsletter will explore the use of computerized meeting traces in grill production, examine their effect on production performance and expenses, and stay up for their destiny development tendencies.

Overview of Automated Contact Grill Assembly Line

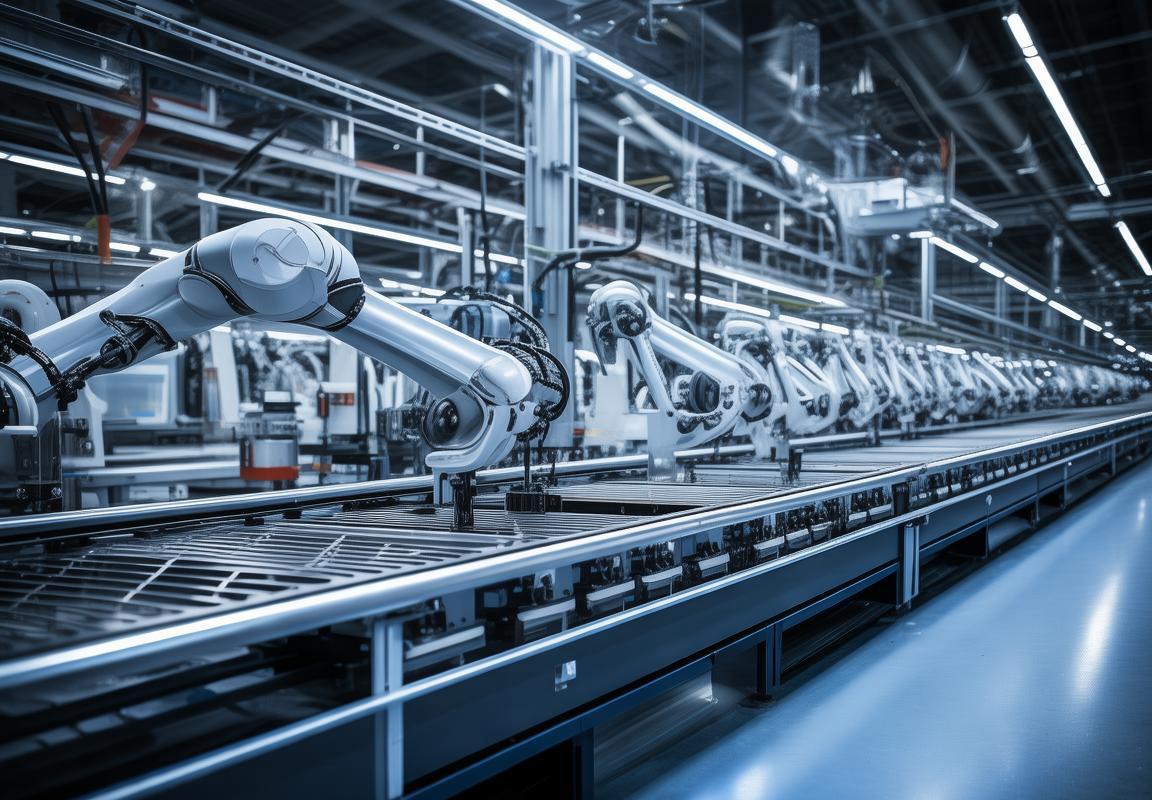

The established order of an automated meeting line for fish fry grills, as a generally used kitchen equipment, is of wonderful significance for improving production efficiency and product quality. This assembly line utilizes computerized system and generation to attain the entire automation of the manufacturing procedure from raw materials to finished merchandise. The assembly line consists of a couple of workstations, along with cutting, welding, assembly, and portray, making sure the steadiness and consistency of fish fry grill manufacturing through specific process design and green gadget collaboration.

inside the computerized touch barbeque grill meeting line, the cutting workstation employs high-precision CNC slicing equipment, capable of accurately reducing the numerous elements of the grill. The welding workstation is ready with an automatic welding robot, which performs unique welding operations thru programming, making sure the firmness and aesthetics of the welds. The assembly workstation makes use of automated meeting system to speedy and as it should be assemble the cut parts into a whole grill.

The painting method uses automated spraying device, which controls the attitude and pace of the spray gun to gain uniform coating of the grill surface. in addition, the meeting line is equipped with detection gadgets to comprehensively inspect the grill for dimensions, look, and capability, ensuring that the product meets quality standards.

The center advantage of the automatic contact fish fry grill meeting line lies in the elevated production efficiency. in comparison to conventional manual meeting methods, the automatic manufacturing line can function continuously for twenty-four hours, considerably shortening the manufacturing cycle. on the identical time, the use of automatic equipment reduces human blunders, enhancing the bypass fee of the goods.

In terms of price control, the automated assembly line reduces usual production fees via decreasing hard work costs and optimizing manufacturing methods. furthermore, the use of automatic equipment reduces harm due to unsuitable operation, decreasing protection prices.

With the continuous development of technology, the future computerized contact fish fry grill assembly line will become greater shrewd. for example, the introduction of artificial intelligence era will permit real-time analysis and prediction of production facts, similarly improving manufacturing performance and product pleasant. additionally, the layout of the meeting line will an increasing number of awareness on environmental safety and electricity conservation to fulfill the requirements of sustainable improvement.

Advantages of Automated Assembly Lines in Grill Production

The application of automated assembly strains in grill manufacturing demonstrates vast benefits inside the following elements:

-

accelerated manufacturing efficiency: in comparison to conventional manual meeting, automatic meeting traces can attain excessive-pace, non-stop manufacturing processes, extensively decreasing the assembly time of grills and enhancing average manufacturing efficiency.

-

Precision and Consistency: computerized assembly strains make sure the consistency of grill dimensions, shapes, and performance via particular mechanical operations and strict excellent control, decreasing human errors and improving product great.

three. reduced labor charges: automated assembly lines decrease the want for guide operations, reducing labor charges and lowering the fee of defective merchandise caused by incorrect guide coping with.

-

more desirable protection: computerized assembly traces reduce the risk of employees directly exposing themselves to high temperatures, high pressures, and other hazardous environments, improving production safety.

-

strength Conservation and cost discount: during operation, computerized assembly strains optimize power use and reduce waste, attaining the dreams of power conservation and cost reduction, in step with green manufacturing standards.

-

Flexibility in Adjustment: computerized meeting lines can quick modify production lines to meet market demand, adapting to the manufacturing of various fashions and specs of grills, thereby enhancing the corporation’s marketplace responsiveness.

-

Ease of upkeep: The design of computerized assembly strains allows each day maintenance and care, lowering the failure rate and increasing the lifespan of the device.

-

superior company image: The software of automated assembly strains reflects an organisation’s technical strength and current control stage, contributing to the development of emblem image and market competitiveness.

The utility of computerized meeting traces in grill production not best improves manufacturing performance and first-rate however additionally reduces fees and risks, bringing multiple benefits to the business enterprise.

Key Technologies and Equipment Configuration

the important thing technologies and equipment configurations concerned inside the computerized contact grill assembly line encompass specific mechanical shape layout, smart manage software program, and efficient warmness conversion systems. under are special descriptions of numerous key technology and system configurations:

-

Mechanical structure design: The mechanical shape of the meeting line have to make sure high precision and balance, which include specific guide tracks, synchronous force systems, and reliable connectors. those designs make sure accurate positioning and fixation of grill additives all through the assembly procedure, reducing errors.

-

Sensors and Detection structures: The assembly line integrates various sensors along with proximity sensors and photoelectric sensors, that are used for actual-time detection of aspect positions, sizes, and nice. those sensors ensure the appropriate set up of every element, thereby growing the skip fee of the goods.

-

Robotics technology: commercial robots, which include six-axis robots, are normally equipped within the automatic meeting line, capable of executing repetitive, high-precision assembly responsibilities. The robot programming is bendy, allowing it to conform to the production desires of different models of grills.

-

manage machine: The middle of the meeting line is the manage machine, which is chargeable for coordinating the workflow of all devices. The manage machine makes use of p.c. (Programmable common sense Controllers) or commercial computer systems to manipulate the robot’s moves, sensor feedback, and the operational popularity of the device thru pre-set packages.

-

warmness Conversion device: The assembly line consists of heating gadgets which includes infrared heaters or electric resistance warmers, which might be used for thermal treatment of the grills. those devices should have speedy response and precise temperature manage talents to make sure the surface treatment satisfactory of the grills.

-

automatic Logistics system: The assembly line is geared up with automatic logistics equipment inclusive of conveyors and stackers for cloth handling and finished product storage. these gadgets paintings in synergy with different components of the meeting line to gain efficient manufacturing logistics control.

-

upkeep and monitoring: The meeting line additionally calls for a preservation and monitoring system to constantly screen the repute of the device through real-time records, providing early warnings of capacity faults to reduce downtime and decorate the reliability of the production line.

through these key technology and device configurations, the automated touch grill meeting line achieves automatic and wise production techniques, notably improving the efficiency and nice of grill manufacturing.

The impact of automated assembly lines on production efficiency and costs

The utility of automated assembly traces in the manufacturing of grills has drastically superior performance and fee manage, as evidenced via the subsequent elements:

-

improved production Paces and elevated Product Turnover costs. automatic assembly lines, via specific time control and continuous go with the flow operations, ensure that every station completes its obligations within the targeted time body, thereby shortening the production cycle and rushing up the glide of merchandise from raw substances to completed goods.

-

reduced exertions expenses and decreased Dependency on Human resources. computerized meeting lines lessen the reliance on a large personnel, thereby decreasing hard work prices. additionally, they decrease the fee of defects caused by guide mistakes, in addition saving costs related to rework or scrapping.

three. Optimized system upkeep and electricity intake. the automatic assembly lines use specific mechanical and electronic gadget, enabling efficient strength usage and reducing energy intake. moreover, the upkeep cycle of the device is extended, decreasing downtime because of system disasters.

- strong Product nice and advanced Consistency. computerized assembly traces make sure the stableness and consistency of grill products through unique production procedures and standardized operations, lowering market risks associated with nice fluctuations.

five. stronger manufacturing Flexibility to adapt to market changes. automated meeting strains can adjust production plans consistent with market call for, speedy transfer manufacturing traces, and adapt to diverse, small-batch manufacturing fashions, thereby improving the organization’s market reaction pace.

- universal reduction in production charges. via expanded production performance, decreased labor prices, optimized strength intake, and stepped forward product great, automatic assembly lines reap an ordinary discount in production fees, enhancing the employer’s market competitiveness.

Future Prospects for the Development of Automated Contact Grilling Assembly Lines

The development possibilities of the automated touch grill assembly line are characterized through a variety of trends:

-

continuous Enhancement of Automation: With the advancement of industry 4.zero, grill assembly strains will adopt more wise manage systems, achieving higher tiers of automation and integration, reducing manual intervention, and improving manufacturing efficiency and product nice.

-

Standardization of wise Detection and maintenance: assembly traces can be geared up with advanced imaginative and prescient detection structures to screen product best in actual-time, ensuring that every grill meets the desired requirements. on the equal time, predictive renovation technologies will lessen gadget downtime and lower preservation prices.

-

Environmental safety and energy performance as Key concerns: destiny assembly lines will place more emphasis on environmental protection and energy performance, adopting strength-saving device and technology to lessen electricity consumption and waste emissions, in step with green manufacturing requirements.

-

increasing Customization: As marketplace call for diversifies, assembly lines will have the capability to quick modify, enabling small-batch, multi-product manufacturing modes to fulfill customers’ customized desires.

-

Deep Integration of Digitization and Networking: assembly strains will rely more on the net of factors and big information evaluation to obtain actual-time collection, analysis, and remarks of manufacturing information, enhancing the accuracy and velocity of decision-making.

-

Shift towards Composite expertise desires: The future improvement of the automatic contact grill assembly line requires composite competencies who are each technically proficient and management-orientated to deal with complex production processes and ever-converting market demands.

-

growing global Cooperation and exchange: With the expansion of the worldwide marketplace, home grill manufacturers will participate extra in global opposition and cooperation, introducing superior foreign technology and ideas to sell their very own technological advancement and innovation.

The future improvement of the automated touch grill meeting line will area greater emphasis on traits consisting of intelligence, environmental safety, customization, digitalization, and globalization to satisfy evolving marketplace needs and decorate commercial competitiveness.