As we delve into the evolving landscape of kitchen appliances in the European and American markets, it’s evident that technology is reshaping the way we interact with our culinary companions. From smart ovens that learn your preferences to refrigerators that double as a grocery manager, the integration of artificial intelligence (AI) is not just a trend—it’s a revolution. This transformation is driven by the relentless pursuit of efficiency, precision, and convenience, all of which are made possible through the innovative use of AI in production quality control. In this exploration, we’ll uncover the intricate dance between technology and kitchen appliances, and how this fusion is setting the stage for a new era of culinary excellence.

I.TheRiseofSmartKitchenAppliancesin欧美

The landscape of the kitchen in has been significantly transformed by the advent of smart kitchen appliances. Once a domain of manual labor and traditional cooking methods, today’s kitchens are teeming with innovative gadgets that not only streamline cooking processes but also offer a level of connectivity and intelligence that was once unimaginable.

These smart appliances have found their way into the hearts and homes of many, largely due to the convenience and efficiency they bring to daily life. From the simple toasters to the sophisticated ovens, refrigerators, and dishwashers, the integration of smart technology has become a norm, rather than an exception.

The trend of smart kitchen appliances in can be attributed to several factors. First, the increasing demand for time-saving solutions in a fast-paced lifestyle has led to a surge in the popularity of these devices. With long work hours and busy schedules, many consumers seek ways to simplify their daily routines, and smart appliances offer a convenient way to do so.

Second, the rise of technology literacy has played a pivotal role. As more people become comfortable with digital devices and understand the benefits of connectivity, they are more inclined to invest in smart kitchen appliances that can be controlled remotely via smartphones or voice assistants.

Moreover, the evolution of smart home ecosystems has been a significant driver. As homes become smarter and more integrated, kitchen appliances that can communicate with each other and with other smart home systems are becoming more attractive. For example, a smart oven that can be controlled by a smartphone and linked to a refrigerator to track ingredients is not just a kitchen gadget; it’s a piece of the larger smart home puzzle.

The design of smart kitchen appliances has also become more user-friendly and aesthetically pleasing. Manufacturers are not just focusing on functionality; they are also considering the design and the way these devices fit into the home environment. Sleek lines, intuitive interfaces, and seamless integration with modern kitchen designs have all contributed to the growing appeal of smart kitchen appliances.

In terms of market growth, the smart kitchen appliances sector has seen remarkable expansion. According to a report by MarketsandMarkets, the global smart kitchen appliances market size is projected to reach USD 39.2 billion by 2025, at a CAGR of 8.8% during the forecast period. This growth is driven by the increasing adoption of smart appliances in developed countries, such as the USA, Germany, the UK, and France, where consumers have a higher disposable income and are more likely to invest in premium smart appliances.

One of the key factors fueling this growth is the integration of advanced features. Smart appliances are now equipped with sensors, IoT (Internet of Things) capabilities, and even AI (Artificial Intelligence) to enhance performance and user experience. For instance, smart refrigerators can analyze the contents and suggest recipes based on available ingredients, while smart ovens can be preheated remotely and adjusted to the perfect temperature with a simple tap on a smartphone.

Furthermore, the trend of personalized cooking experiences is on the rise. Smart kitchen appliances can learn users’ preferences and adjust settings accordingly, ensuring that every dish is tailored to individual taste. This level of customization is a game-changer in the kitchen, as it allows for greater culinary exploration and convenience.

The environmental benefits of smart kitchen appliances are also becoming more evident. Energy-efficient features and smart energy management systems are helping to reduce carbon footprints and lower utility bills. For example, smart dishwashers can optimize the washing cycle based on the load size and soil level, saving water and energy.

In conclusion, the rise of smart kitchen appliances in is a multifaceted phenomenon, driven by changing consumer lifestyles, technological advancements, and a growing desire for personalized and efficient living. As these appliances continue to evolve, they are not only becoming more integrated into our daily lives but are also shaping the future of how we interact with our homes.

II.TheRoleofAIinEnhancingProductionQuality

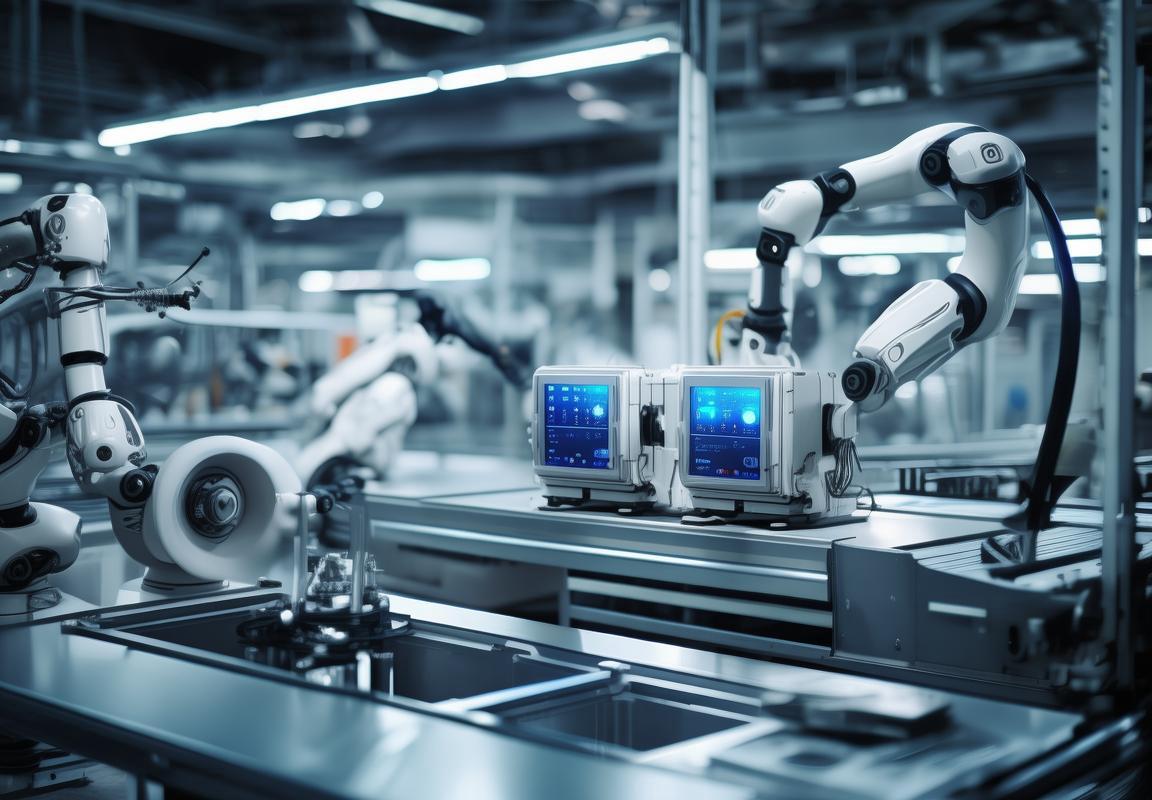

In the modern era of kitchen appliances, AI has emerged as a transformative force, significantly enhancing production quality in the manufacturing process. From the assembly line to the final product, AI’s integration has brought about a new level of precision and efficiency.

AI systems are now capable of analyzing vast amounts of data to identify patterns and anomalies that humans might overlook. This data-driven approach ensures that every aspect of production is scrutinized, leading to better quality control measures. For instance, during the manufacturing of kitchen appliances, AI algorithms can monitor the performance of machines, detect wear and tear, and predict maintenance needs, thus preventing costly breakdowns.

Automated machine learning (ML) models have become integral to the production quality of kitchen appliances. These models are trained on historical data, enabling them to make predictions about the likelihood of defects in real-time. By continuously learning and adapting, these AI systems can provide insights that guide manufacturers in making informed decisions about product design, material sourcing, and manufacturing processes.

The precision of AI in detecting and correcting errors is unparalleled. In the context of kitchen appliances, this means that the accuracy of components such as motors, heating elements, and sensors can be meticulously checked and adjusted. For example, in a dishwasher production line, AI can ensure that each spray arm delivers the correct pressure and angle, leading to improved cleaning performance.

In addition to predictive maintenance and quality checks, AI also plays a role in optimizing the supply chain. By analyzing consumption trends and inventory levels, AI can forecast demand and streamline the procurement process. This not only ensures that manufacturers have the right parts at the right time but also reduces waste and environmental impact.

The use of AI in production quality control has also led to the development of adaptive systems. These systems can adjust their parameters based on real-time feedback, ensuring that each unit produced meets the highest standards. For instance, AI can control the temperature and pressure in a refrigerator manufacturing process to ensure that each unit maintains optimal cooling performance.

Moreover, AI-driven quality control systems facilitate better communication between various stages of the production process. Through the integration of AI into the production floor, there’s a seamless flow of information that allows for quick response times to any issues that arise. This real-time data exchange means that any deviation from the desired quality standard can be identified and corrected immediately.

Another key aspect of AI’s role in enhancing production quality is the reduction of human error. By automating repetitive tasks, AI frees up human workers to focus on more complex and creative aspects of the manufacturing process. This not only increases productivity but also ensures that the quality of the final product is not compromised by human fatigue or inconsistencies.

The integration of AI into the production process has also led to the creation of smart, interconnected appliances. These devices can communicate with each other and with the consumer, providing real-time data that can be used to further improve product performance and customer satisfaction.

In conclusion, AI has revolutionized the way kitchen appliances are produced, making quality control more robust, efficient, and predictive. As technology continues to advance, the synergy between AI and manufacturing processes will likely result in even more sophisticated and reliable kitchen appliances that meet the evolving demands of consumers in the market.

III.AI-DrivenProductionQualityControl:HowItWorks

In the realm of kitchen appliance manufacturing, the integration of Artificial Intelligence (AI) has revolutionized the way quality control is managed. This transformation is not just limited to monitoring products but encompasses a holistic approach that ensures every aspect of the production process meets the highest standards. Here’s a delve into how AI-driven production quality control operates:

Real-Time Monitoring

At the core of AI-driven quality control is real-time monitoring. Advanced sensors and cameras are strategically placed throughout the manufacturing line to capture every movement and process. These sensors can detect anything from temperature fluctuations to the precise positioning of components. AI algorithms analyze this data in real-time, flagging any deviations from the expected norms. This immediate feedback loop allows manufacturers to correct issues on the spot, preventing defective products from progressing through the line.

Machine Learning for Pattern Recognition

Machine learning algorithms are trained on vast datasets to recognize patterns that are indicative of quality issues. Over time, these systems become increasingly adept at identifying anomalies that human inspectors might overlook. For example, in the assembly of a refrigerator, AI can detect inconsistencies in the alignment of panels or the uniformity of the cooling system’s performance. By learning from historical data and feedback, the AI continuously refines its ability to predict and prevent defects.

Predictive Maintenance

AI’s predictive capabilities extend to maintenance. By analyzing the performance data of machinery, AI can predict when equipment might fail or when routine maintenance is due. This proactive approach minimizes downtime and reduces the risk of equipment failure during production, which could lead to a batch of defective products. By keeping the machinery in optimal condition, manufacturers can ensure a steady stream of high-quality appliances.

Automated Adjustments

One of the most innovative aspects of AI-driven quality control is the ability to make automated adjustments. If the AI detects a quality issue, it can communicate with the manufacturing equipment to make on-the-fly changes. For instance, if a cutting machine is slightly off, the AI can send signals to the motors to adjust the blade’s position, ensuring the next item is cut to the correct specifications. This real-time adjustment capability ensures that any deviation is corrected immediately, maintaining product consistency.

Quality Control Protocols

AI-driven systems also implement rigorous quality control protocols. This involves setting specific parameters for each step of the production process. The AI monitors these parameters and can halt the line if any critical thresholds are exceeded. For example, during the painting stage, the AI can check the thickness and uniformity of the paint coat, ensuring it meets the required standards. If a deviation is detected, the AI can trigger a re-painting process for the affected items.

Data-Driven Decision Making

AI compiles extensive data on product performance, manufacturing processes, and quality issues. This data is invaluable for making informed decisions. By analyzing trends and patterns, manufacturers can identify areas for improvement and implement changes that have a measurable impact on quality. This data-driven approach allows for continuous optimization of the production process, leading to a higher quality end product.

Integration with IoT

The AI-driven quality control systems are often integrated with the Internet of Things (IoT). This allows for a seamless flow of data across the production floor. IoT devices can collect data from various sources, such as inventory levels, energy consumption, and environmental conditions. When combined with AI, this information provides a comprehensive view of the production environment, enabling real-time adjustments and predictive analytics.

Feedback Loops

AI-driven quality control systems create feedback loops that are crucial for continuous improvement. After a batch of products is manufactured, the AI analyzes the feedback from customers and service technicians. This information is used to further refine the quality control algorithms and to make adjustments to the production process. Over time, this iterative process leads to a cumulative increase in product quality and reliability.

In summary, AI-driven production quality control is a sophisticated system that employs real-time monitoring, machine learning, predictive maintenance, automated adjustments, and data-driven decision-making. By integrating these elements, manufacturers can achieve a level of quality that was previously unattainable, ensuring that every kitchen appliance leaving the factory floor meets the highest standards.

IV.BenefitsofAI-DrivenQualityControlinKitchenAppliances

In the realm of kitchen appliances, the integration of AI-driven quality control has revolutionized the manufacturing process. This innovative approach offers a multitude of benefits that not only enhance the final product but also streamline operations and elevate customer satisfaction. Here’s a closer look at some of the key advantages:

-

Consistency in Product QualityThe beauty of AI-driven quality control lies in its ability to maintain consistent standards across all batches of kitchen appliances. By continuously monitoring the production line, AI systems can identify deviations from the established quality benchmarks and make real-time adjustments. This ensures that each appliance leaving the factory meets the same high standards, reducing the likelihood of defects and improving customer trust.

-

Enhanced Precision and AccuracyTraditional quality control methods often rely on manual inspections, which can be time-consuming and prone to human error. AI, on the other hand, brings precision and accuracy to the table. With its advanced algorithms and sensors, it can detect even the most minute imperfections that might go unnoticed by the human eye. This level of detail ensures that every component and assembly is perfect, leading to appliances that are durable and reliable.

-

Predictive MaintenanceOne of the standout features of AI-driven quality control is its predictive maintenance capabilities. By analyzing data collected during the production process, AI can foresee potential issues before they arise. This proactive approach allows manufacturers to address problems early on, preventing costly downtime and extending the lifespan of machinery. For kitchen appliances, this means fewer repairs and a longer lifespan for the consumer.

-

Resource OptimizationThe efficiency of AI-driven quality control is not just about improving the end product; it’s also about optimizing resources. By reducing the need for manual inspections, companies can allocate their workforce more effectively, focusing on tasks that require human creativity and judgment. Additionally, AI’s ability to optimize the production line reduces waste, leading to a more sustainable and environmentally friendly manufacturing process.

-

Customization and PersonalizationAI-driven quality control can also pave the way for greater customization and personalization in kitchen appliances. By analyzing consumer usage patterns and preferences, manufacturers can tailor their products to meet specific needs. This not only enhances the customer experience but also opens up new markets and opportunities for innovation.

-

Data-Driven Decision MakingWith AI collecting and analyzing vast amounts of data, manufacturers gain valuable insights into their production processes. This data-driven decision making allows for continuous improvement and the identification of new opportunities. For example, AI can identify which features are most popular or which aspects of the product design need improvement, leading to a more responsive and adaptable product development cycle.

-

Safety and ComplianceIn the kitchen appliances industry, safety is paramount. AI-driven quality control systems can help ensure that all products meet the necessary safety standards. By monitoring for potential hazards and alerting operators to risky conditions, AI can significantly reduce the risk of accidents and recalls.

-

Customer Satisfaction and LoyaltyUltimately, the benefits of AI-driven quality control in kitchen appliances translate to higher customer satisfaction. Appliances that are consistently reliable, safe, and tailored to individual needs are more likely to be appreciated by consumers. This leads to increased customer loyalty and a positive brand reputation.

-

Cost Reduction Over TimeWhile the initial investment in AI technology can be significant, the long-term cost savings are substantial. By reducing defects, improving efficiency, and lowering maintenance costs, AI-driven quality control can lead to a more cost-effective production process. These savings are often passed on to consumers, making high-quality kitchen appliances more accessible.

-

Global Market CompetitivenessIn a highly competitive global market, the adoption of AI-driven quality control can give manufacturers a competitive edge. The ability to produce superior products at a consistent rate can help companies differentiate themselves and capture a larger share of the market.

By harnessing the power of AI, kitchen appliance manufacturers are not just improving the quality of their products; they are also reshaping the future of the industry. The benefits of AI-driven quality control are far-reaching, offering a path to innovation, efficiency, and customer delight.

V.CaseStudies:SuccessfulImplementationsofAIinKitchenAppliances

In the realm of kitchen appliances, the integration of AI has revolutionized the way products are designed, manufactured, and monitored. Let’s delve into a few case studies that showcase the successful implementation of AI in this industry.

-

Bosch’s Smart Dishwasher: The German appliance giant, Bosch, has integrated AI into their dishwasher models to optimize cleaning cycles. The AI system analyzes the type of load and adjusts the cleaning program accordingly, ensuring that dishes are cleaned to the highest standard without wasting water or energy.

-

Whirlpool’s KitchenAid Mixers: Whirlpool’s KitchenAid brand has introduced AI-powered mixers that can learn and adapt to the user’s mixing habits. The AI analyzes the amount of time spent on different mixing tasks and suggests optimal settings for future use, enhancing the user experience and ensuring consistent results.

-

Samsung’s Smart Refrigerators: Samsung’s smart refrigerators utilize AI to track the contents inside and suggest meal ideas based on the available ingredients. The AI also monitors the freshness of the food and sends alerts when items are nearing expiration, helping consumers reduce food waste.

-

LG’s AI Oven: LG’s AI oven uses a combination of sensors and AI algorithms to monitor cooking conditions in real-time. It adjusts the temperature and cooking time automatically, resulting in perfectly cooked meals every time. The AI also provides tips for cooking different types of food, making it easier for users to experiment with new recipes.

-

GE’s Smart Coffee Makers: General Electric’s smart coffee makers incorporate AI to learn the user’s preferences and brewing habits. The AI system can adjust the strength, temperature, and timing of the brew to match the user’s taste, ensuring a personalized coffee experience.

-

Miele’s Smart Laundry Machines: Miele’s AI-powered laundry machines use sensors to detect the type of fabric and soil level, then selects the most appropriate wash cycle. The AI system also optimizes the amount of water and energy used, making laundry day more efficient and eco-friendly.

-

Dyson’s Airblade Hand Dryers: Dyson’s Airblade hand dryers utilize AI to monitor the number of users and adjust the drying time accordingly. This not only ensures that hands are dried efficiently but also conserves energy by not running the dryer when it’s not in use.

-

Breville’s Smart Kettles: Breville’s smart kettles use AI to predict the time it will take to boil water based on the desired temperature and the amount of water in the kettle. The AI also helps users avoid over-boiling by shutting off the kettle when the water reaches the desired temperature.

These case studies highlight the transformative impact of AI on kitchen appliances. By leveraging AI, manufacturers are not only improving the functionality and efficiency of their products but also enhancing the overall user experience. As AI technology continues to advance, we can expect to see even more innovative applications in the kitchen appliance industry.

VI.ChallengesandConsiderationsforAIIntegration

Understanding the intricacies of integrating AI into kitchen appliances is no small feat. From ensuring data security to training sophisticated algorithms, the path to successful implementation is paved with challenges and considerations that must be carefully navigated.

In the realm of AI integration, one of the most significant challenges is ensuring the security of the data that powers these smart devices. Consumer trust is paramount, and any breach could have severe consequences. Manufacturers must implement robust cybersecurity measures to protect sensitive user information, such as usage patterns and personal preferences, from falling into the wrong hands.

Moreover, the development of AI algorithms requires a substantial amount of data, often collected over time from various sources. This data needs to be cleaned, structured, and anonymized to prevent any potential privacy violations. The challenge lies in striking a balance between using data to enhance the AI’s performance and respecting the privacy and ethical boundaries set by regulations like GDPR.

The complexity of AI systems also brings forth the need for ongoing maintenance and updates. AI algorithms are not set in stone; they evolve and improve over time. This means that manufacturers must have a dedicated team to continuously monitor and refine these systems, ensuring that they remain effective and secure. The costs associated with this level of support can be substantial, and it requires a long-term commitment to the technology.

Moreover, integrating AI into kitchen appliances requires a deep understanding of both the appliances themselves and the technology behind AI. Engineers and designers must collaborate closely to ensure that the AI components are seamlessly integrated into the existing product design. This can be particularly challenging when dealing with legacy appliances that were not initially designed with AI in mind.

Training AI systems also presents its own set of challenges. It requires a large and diverse dataset to create a model that can accurately predict and adjust to various scenarios. Gathering such a dataset can be time-consuming and expensive. Additionally, the training process itself can be resource-intensive, demanding powerful computing resources and skilled data scientists.

There’s also the issue of scalability. As AI technology becomes more prevalent, manufacturers must ensure that their AI-driven appliances can handle the growing number of connected devices and the increasing complexity of tasks. This requires scalable infrastructure and software solutions that can adapt to changing demands without compromising on performance or security.

Furthermore, the integration of AI into kitchen appliances must consider the end-user experience. While AI can greatly enhance functionality and efficiency, it should not come at the cost of usability. Users need to be able to interact with the AI system intuitively and should not require a degree in computer science to operate their appliances.

Lastly, regulatory compliance is a critical consideration. Manufacturers must ensure that their AI-driven appliances adhere to all relevant industry standards and regulations. This includes not only safety and performance standards but also ethical guidelines regarding AI usage. Navigating this complex landscape requires a keen understanding of legal requirements and the ability to anticipate and address any emerging regulatory changes.

In conclusion, while the integration of AI into kitchen appliances offers tremendous potential for innovation and efficiency, it is not without its challenges. From data security and privacy concerns to the ongoing maintenance of AI systems and the need for scalable solutions, manufacturers must address these considerations thoughtfully to create a future where AI-driven kitchen appliances are not only smart but also safe, secure, and user-friendly.

VII.TheFutureOutlook:Predictionsforthe欧美KitchenAppliancesMarket

The integration of AI into kitchen appliances is not just a trend; it’s a transformative shift that promises to redefine how we interact with our daily culinary tools. As we delve into the future, several predictions are emerging that highlight the direction the kitchen appliances market is heading.

In the realm of smart kitchen appliances, the future looks to be increasingly interconnected. Predictions suggest that appliances will not only be smarter but also more collaborative, working together to create a seamless cooking experience. For instance, a smart oven could communicate with a refrigerator to optimize cooking times based on the ingredients stored inside, ensuring that meals are prepared efficiently and with minimal waste.

Energy efficiency is another area where the market is expected to see significant advancements. As environmental concerns grow, kitchen appliances are likely to become more energy-saving, thanks to AI-driven systems that adjust settings based on usage patterns and environmental conditions. This not only benefits consumers by reducing utility bills but also contributes to a greener planet.

Customization is set to become a hallmark of the future kitchen appliances market. AI algorithms will allow appliances to learn from user preferences, tailoring their performance to individual cooking styles and dietary needs. This could range from a coffee maker that learns your preferred strength to a microwave that adjusts cooking power based on the food’s type and thickness.

The rise of voice-controlled appliances is also predicted to become more sophisticated. While voice commands are already a common feature, the future will see more nuanced interactions, where appliances can understand context and carry out complex tasks based on verbal instructions. This could mean a fridge that not only reminds you to buy milk but also suggests recipes that use the ingredients you have on hand.

In terms of security, the integration of AI will likely bring about enhanced safety measures. As appliances become more connected, cybersecurity will play a crucial role in protecting consumer data. Predictions indicate that appliances will incorporate advanced encryption and authentication protocols to prevent unauthorized access and ensure privacy.

The impact of AI on kitchen appliances extends beyond consumer convenience. In the professional kitchen, AI is expected to revolutionize foodservice operations. Predictions suggest that AI will optimize menu planning, inventory management, and even cooking processes, leading to more efficient and cost-effective restaurant operations.

As the market evolves, there is also an expectation for a greater emphasis on sustainability. Appliances will not only be designed to last longer but also to be more easily recyclable at the end of their life cycle. This could involve the use of recycled materials in their construction and the development of modular designs that allow for easier repair and replacement of parts.

The global kitchen appliances market is also likely to see a rise in the adoption of AI in emerging markets. As these regions experience economic growth and an increasing middle class, there will be a demand for smart, efficient appliances that offer advanced functionality at a reasonable price point.

In conclusion, the future of the kitchen appliances market is poised to be marked by increased intelligence, connectivity, and sustainability. AI will continue to be at the forefront, driving innovation and shaping the way we cook, live, and interact with our kitchen environments. The predictions for this market are as diverse as they are exciting, promising a future where the kitchen is not just a room but a hub of technological innovation and convenience.

VIII.Conclusion:TheIntersectionofTechnologyandKitchenAppliancesin欧美

In the ever-evolving landscape of kitchen appliances, the fusion of technology and everyday living has reached new heights. The integration of smart features and AI-driven innovations has transformed how we interact with our kitchen tools, promising a future that’s not just efficient but also intuitive. This conclusion reflects on the impact of technology on kitchen appliances in the market and the implications for consumers and manufacturers alike.

The sleek design of modern kitchen appliances has become less about brute function and more about seamless integration into our homes. Smart refrigerators, ovens with built-in Wi-Fi, and voice-activated dishwashers are not just trendy; they represent a significant shift in how appliances are perceived and utilized. The line between kitchen equipment and smart devices has blurred, creating an environment where technology is not just an accessory but an essential part of daily life.

Manufacturers are racing to incorporate AI into their product lines, offering solutions that anticipate and cater to consumer needs. The ability to customize settings based on usage patterns, diagnose issues before they become problems, and provide maintenance tips is changing the way appliances are maintained and valued. This proactive approach not only enhances the lifespan of the appliances but also educates the user on the importance of care and maintenance.

In the realm of cooking, the precision and control that AI brings to kitchen appliances are remarkable. Smart ovens and cooktops can now adjust their settings in real-time to ensure consistent cooking temperatures, while smart dishwashers can optimize their cleaning cycles based on the type of load. These advancements have not only improved the quality of the end product but have also reduced energy consumption, making modern appliances more environmentally friendly.

The convenience factor is undeniable. With voice-activated commands and remote control capabilities, kitchen appliances have become more accessible to people with mobility issues or those simply looking to streamline their routines. The ability to manage appliances through smartphones or smart home systems means that the kitchen can be managed from anywhere, adding a new layer of convenience to a space that has traditionally been limited to a specific area of the home.

From a consumer perspective, the intersection of technology and kitchen appliances has led to increased satisfaction. The expectation of a kitchen that not only performs its traditional functions but also connects with other smart devices and offers personalized experiences has raised the bar for what we consider essential in kitchen technology. This shift has also sparked a demand for better design, as aesthetics have become just as important as functionality.

For manufacturers, the challenge lies in balancing innovation with consumer expectations. The cost of incorporating AI and advanced technology into appliances can be significant, and there’s a risk of overwhelming customers with features they may not fully understand or need. The need for user-friendly interfaces and clear communication about the benefits of each feature is crucial in ensuring that the investment in smart appliances pays off.

Looking ahead, it’s clear that the trajectory of kitchen appliances in the market is one of continuous advancement. As AI and machine learning become more sophisticated, we can expect even greater personalization and efficiency. Appliances will not only be connected but also predictive, capable of learning from user habits and adapting to changing needs. The future kitchen could very well be a reflection of our personal tastes, dietary preferences, and even the way we interact with our living spaces.

In conclusion, the intersection of technology and kitchen appliances in the market represents a transformative era for both consumers and manufacturers. It’s an era where the kitchen is no longer just a place for cooking but a hub of innovation, where every day is an opportunity to explore new ways of living, cooking, and interacting with our surroundings.