In the ever-evolving landscape of technology, the kitchen appliance industry has been a fertile ground for innovation. As consumers demand more advanced and reliable kitchen gadgets, the role of artificial intelligence (AI) in production quality control has become increasingly pivotal. This shift is not just reshaping how appliances are made but also how they are perceived and trusted by consumers. This article delves into the multifaceted impact of AI on the kitchen appliance sector, exploring its benefits, challenges, and the transformative power it wields.

Introduction to AI-Driven Production Quality Control in Kitchen Appliances

In the fast-paced world of kitchen appliances, where innovation meets necessity, the role of quality control has become more critical than ever. Enter the revolution brought about by AI-driven production quality control, a game-changer that’s reshaping the landscape of the kitchen appliance industry. This dynamic approach leverages the power of artificial intelligence to ensure that every product leaving the factory floor meets the highest standards of excellence.

The integration of AI into the production process marks a significant shift from traditional methods of quality assurance. While manual inspections and visual checks have been the norm, they are time-consuming and prone to human error. AI, on the other hand, offers a level of precision and consistency that can significantly reduce defects and improve overall product quality.

In the European and American kitchen appliance markets, where consumers demand the latest technology and superior performance, the adoption of AI-driven quality control systems is not just a trend; it’s a necessity. These markets are highly competitive, with brands vying for a share of an increasingly discerning consumer base. AI provides a competitive edge by enabling manufacturers to produce more reliable and efficient appliances.

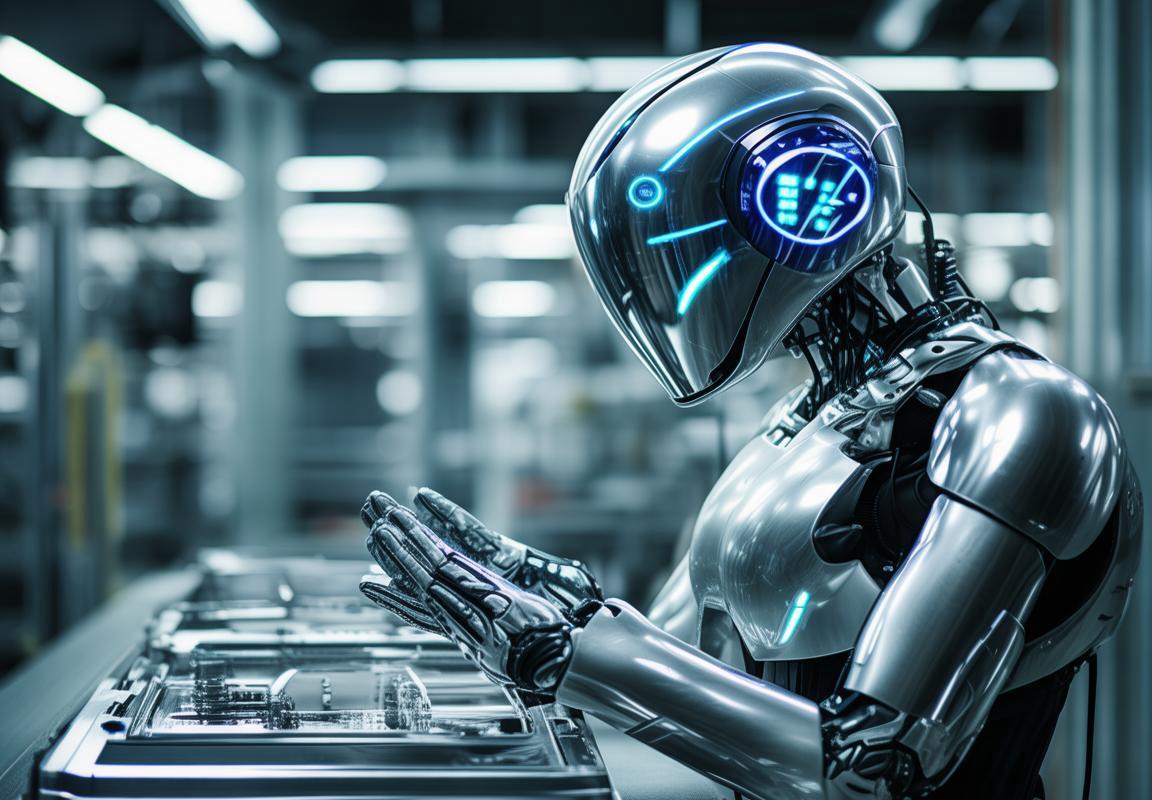

At the heart of AI-driven production quality control is the ability to analyze vast amounts of data in real-time. Sensors and cameras installed throughout the production line capture detailed information about each appliance’s components and assembly process. This data is then processed by AI algorithms, which can detect anomalies, predict potential failures, and flag products that do not meet the predefined quality criteria.

One of the most notable features of AI-driven quality control systems is their ability to learn and adapt. Through machine learning, these systems can continuously improve their performance by recognizing patterns and trends that may indicate quality issues. This not only enhances the current production cycle but also paves the way for better processes in the future.

For manufacturers, the benefits of AI-driven production quality control are substantial. Efficiency is a key advantage, as AI can automate many of the quality control tasks that were previously done manually. This not only saves time but also reduces labor costs. Moreover, the reduction in defects means fewer returns and repairs, which in turn lowers warranty claims and associated costs.

Consumers, too, stand to gain from this technological advancement. The assurance of high-quality appliances leads to increased trust in the brand and a positive consumer experience. As the reliability of kitchen appliances improves, so does the satisfaction of users who rely on these devices for their daily needs.

However, the journey to implementing AI-driven quality control is not without its challenges. One of the primary concerns is the integration of AI into existing production lines. Manufacturers must invest in the necessary infrastructure and ensure that their workforce is trained to work alongside AI systems. Additionally, there are concerns about the cost of implementing such systems, which can be significant, especially for smaller companies.

Data privacy and security are also critical considerations. As AI systems rely on vast amounts of data, ensuring that this information is protected is paramount. Manufacturers must adhere to strict data protection regulations and implement robust security measures to prevent unauthorized access or breaches.

Looking ahead, the future of AI in kitchen appliance production is bright. With advancements in technology, we can expect AI-driven quality control to become even more sophisticated. The potential for predictive maintenance, where AI can foresee and prevent equipment failures, is enormous. This could lead to even greater efficiency and cost savings for manufacturers.

In conclusion, AI-driven production quality control in the kitchen appliance industry is not just a buzzword; it’s a transformative force. By harnessing the power of AI, manufacturers can produce appliances that are not only of superior quality but also more reliable and efficient. As the industry continues to evolve, the role of AI will undoubtedly become even more integral to the success of kitchen appliance brands worldwide.

The Evolution of Quality Control in the Kitchen Appliance Industry

The journey of quality control in the kitchen appliance industry has been a testament to innovation and relentless pursuit of excellence. From the early days of manual inspections to the sophisticated AI-driven systems of today, the evolution has been marked by significant milestones.

In the early 20th century, the manufacturing process for kitchen appliances was rudimentary. Quality control was often a hit-or-miss affair, relying heavily on the skills and attention to detail of human inspectors. These inspectors would meticulously examine each unit, looking for any signs of defects or imperfections. While this method had its merits, it was time-consuming and prone to human error.

As the industry grew, so did the demand for more efficient and reliable quality control methods. The advent of the 1950s and 1960s saw the introduction of statistical process control (SPC), which allowed manufacturers to monitor and control the quality of their products in real-time. SPC involved collecting data on the manufacturing process and using statistical analysis to identify trends and potential issues before they became significant problems.

This shift towards data-driven quality control marked a significant turning point. It allowed manufacturers to make informed decisions based on factual evidence, rather than relying on the subjective judgments of inspectors. However, SPC still required a considerable amount of manual labor and could only provide insights into the process as a whole, rather than focusing on individual components or units.

The 1980s brought about another major advancement with the introduction of automated inspection systems. These systems used cameras and sensors to detect defects on the production line, significantly reducing the need for human inspectors. While this was a step forward in efficiency, the technology was still somewhat limited in its ability to identify complex defects or variations in materials.

The true breakthrough came in the late 1990s and early 2000s with the rise of AI and machine learning. These technologies enabled manufacturers to develop more sophisticated quality control systems that could analyze vast amounts of data and identify patterns that were previously undetectable by human inspectors. AI-driven systems could now not only inspect individual units but also predict potential issues before they occurred, thanks to their ability to learn from historical data and adapt to new challenges.

In the European and American markets, where kitchen appliances are a staple of modern life, the adoption of AI-driven quality control has been particularly rapid. These regions have been at the forefront of integrating advanced technologies into their manufacturing processes, recognizing the competitive advantage that such systems can provide.

European manufacturers, known for their emphasis on design and innovation, have leveraged AI to ensure that their appliances not only look sleek and modern but also operate with unparalleled precision. The stringent quality standards in Europe have necessitated the development of highly sophisticated AI algorithms that can detect even the most subtle of defects.

Similarly, in the United States, where the kitchen appliance market is diverse and highly competitive, AI-driven quality control has become a key differentiator. American manufacturers have used AI to streamline their production lines, reduce waste, and improve overall efficiency. The result is a market filled with appliances that are not only reliable but also environmentally friendly.

The evolution of quality control in the kitchen appliance industry has been a continuous cycle of improvement. From the simple, manual inspections of the past to the highly advanced AI-driven systems of today, the industry has made remarkable strides. As technology continues to advance, it’s clear that the future of quality control will be even more integrated, with AI playing an even more significant role in ensuring that every kitchen appliance meets the highest standards of performance and reliability.

Understanding the European and American Kitchen Appliance Markets

The European kitchen appliance market is characterized by a strong emphasis on innovation, energy efficiency, and eco-friendly designs. With a high penetration rate of kitchen appliances, consumers in Europe are increasingly seeking smart and connected devices that enhance their daily lives. Brands like Siemens, Bosch, and Miele have long been leaders in this region, offering a wide range of products from dishwashers to refrigerators that cater to both the premium and mid-range segments. The market is also influenced by stringent environmental regulations, which push manufacturers to develop more sustainable appliances.

In the United States, the kitchen appliance market is marked by a diverse consumer base with varying preferences and budgets. American consumers tend to value functionality and durability, often opting for appliances that can withstand heavy use in larger households. Brands such as Whirlpool, KitchenAid, and GE are well-recognized for their reliable and high-quality products. The market is also driven by the rise of smart appliances, which are becoming more popular as consumers look to integrate technology into their homes. Additionally, the U.S. market is sensitive to trends like the “open kitchen” concept, which has led to a demand for sleeker, integrated appliances.

In Europe, the kitchen appliance market is segmented not only by product type but also by region. For instance, in Northern Europe, there’s a preference for minimalist designs and high-tech features, while Southern Europe may lean more towards traditional and practical appliances. The market is also influenced by the lifestyle of the consumers; in countries like Germany and the UK, there’s a strong focus on energy efficiency, which is reflected in the popularity of A++ rated appliances. In contrast, in countries like Italy and Spain, the aesthetic appeal of appliances is often a key factor in the purchasing decision.

The American market, on the other hand, is witnessing a shift from large, bulky appliances to compact, space-saving models, especially in urban settings where space is at a premium. The “millennial” demographic is also playing a significant role in shaping the market, with a growing interest in smart kitchen gadgets that offer convenience and can be controlled remotely. The U.S. market is also driven by the trend of customization, where consumers can choose specific features and finishes for their appliances to match their personal style.

Both markets have unique selling points. In Europe, the emphasis on sustainability and innovation is a significant differentiator. Brands that can demonstrate a commitment to the environment and technological advancements tend to have a competitive edge. American consumers, however, are more influenced by brand reputation and the overall user experience. The American market values a seamless integration of technology into everyday life, and appliances that offer this often command a premium price.

Distribution channels also play a crucial role in both the European and American markets. In Europe, the market is highly fragmented, with a mix of large retailers, small local stores, and online sales. Online sales are growing, particularly in countries like the UK and Germany, where consumers are increasingly comfortable with online shopping. In the U.S., the market is dominated by large home improvement stores and department stores, with online sales also gaining momentum, especially through platforms like Amazon.

The European and American kitchen appliance markets may differ in their preferences and purchasing behaviors, but both are dynamic and evolving. As consumer demands change, so too do the products and services offered by manufacturers. Understanding these markets requires a nuanced approach, one that takes into account not only the products themselves but also the broader cultural and regulatory landscapes that shape them.

The Role of AI in Enhancing Production Quality

In the realm of kitchen appliance manufacturing, the integration of AI has revolutionized the quality control process. From predictive analytics to machine learning, the role of AI in enhancing production quality is multifaceted and transformative.

Automated inspection systems, powered by AI, can analyze product specifications and identify anomalies with unprecedented speed and accuracy. These systems are trained on vast datasets, allowing them to recognize even the most subtle defects that might escape human eyes. In the case of European and American markets, where high-quality standards are a must, AI-driven inspections have become a cornerstone of production.

Machine learning algorithms enable appliances to learn from their experiences, improving over time. By continuously analyzing production data, these algorithms can adapt to changing patterns and conditions, ensuring that each unit meets stringent quality benchmarks. This evolution is particularly significant in the American market, where there’s a strong consumer preference for cutting-edge technology.

Quality assurance is no longer just about checking for defects; it’s about preventing them. AI’s predictive capabilities can forecast potential issues before they occur, allowing for preemptive maintenance and adjustments. This proactive approach not only improves the final product’s quality but also increases efficiency and reduces downtime in the manufacturing process.

In the European market, where sustainability is a key concern, AI-driven quality control also plays a role in energy efficiency. AI can optimize the performance of appliances, ensuring they meet energy-saving regulations without compromising on functionality. This not only appeals to environmentally conscious consumers but also helps manufacturers stay competitive in a market segment that values eco-friendly products.

The AI’s role extends to supply chain management as well. By analyzing supplier data, AI can identify the most reliable components and materials, thus ensuring that the entire production process is built on a solid foundation of quality. This integration of AI across the supply chain is particularly pronounced in the American market, which has a robust and highly competitive supply network.

AI’s contribution to production quality is not just about the final product; it’s also about the process itself. By automating repetitive tasks, AI frees up human workers to focus on more complex, value-added activities. This shift in the production process has been well-received in the European market, where there’s a strong emphasis on worker safety and employee satisfaction.

Moreover, AI’s ability to monitor and adjust processes in real-time allows for just-in-time manufacturing, reducing waste and inventory costs. In the American market, where efficiency is key, this capability has become a significant advantage for companies looking to streamline their operations and improve their bottom line.

Another aspect of AI’s role in enhancing production quality is its ability to provide actionable insights. By analyzing production data, AI can offer manufacturers valuable information on how to optimize their processes, improve product design, and even anticipate future market trends. This data-driven decision-making is particularly crucial in the European market, which is known for its rigorous adherence to regulations and safety standards.

In summary, the role of AI in enhancing production quality is pivotal. It drives efficiency, improves product reliability, optimizes supply chain operations, and allows for data-driven decision-making. Whether in Europe or America, the adoption of AI in kitchen appliance manufacturing is not just a trend; it’s a necessity in a market that demands excellence in every aspect of the product lifecycle.

Key Features of AI-Driven Quality Control Systems

AI-driven quality control systems have revolutionized the manufacturing landscape, especially in the kitchen appliance industry. These systems are equipped with advanced technologies that not only streamline production but also ensure that each appliance meets stringent quality standards. Here are some key features that define these innovative systems:

1. Real-Time Monitoring and Data CollectionAI systems are capable of continuously monitoring production lines in real-time. They collect vast amounts of data on various aspects of the manufacturing process, from raw material handling to final product assembly. This data collection is crucial for identifying patterns and anomalies that might affect the quality of the final product.

2. Machine Vision and Image RecognitionMachine vision technology, a core component of AI, plays a pivotal role in quality control. It uses cameras to capture images of components and products at various stages of production. Advanced image recognition algorithms then analyze these images to detect defects such as misalignments, cracks, or imperfections that may go unnoticed by the human eye.

3. Predictive AnalyticsBy leveraging historical data and real-time insights, AI-driven systems can predict potential quality issues before they occur. Predictive analytics helps manufacturers anticipate and address problems early, reducing the risk of defective products reaching the market.

4. Adaptive Learning and Self-OptimizationOne of the most remarkable features of AI systems is their ability to learn and adapt. These systems can analyze feedback from the production line and adjust their algorithms accordingly. This self-optimization ensures that the quality control process becomes more efficient over time, as the system fine-tunes its parameters based on real-world data.

5. Integration with IoT DevicesAI quality control systems often integrate with the Internet of Things (IoT), which allows for a holistic approach to production monitoring. IoT devices can provide additional data on environmental factors such as temperature, humidity, and vibration levels, which can all impact the quality of kitchen appliances.

6. Enhanced TraceabilityWith AI, manufacturers can achieve a higher level of traceability in their production process. Each component and product can be tracked throughout the entire manufacturing journey, from sourcing raw materials to final assembly. This not only ensures quality but also aids in recall processes if a defect is detected.

7. Automated Defect DetectionThe integration of AI with robotic arms and automated systems enables the detection of defects in real-time. Robots equipped with AI can perform tasks such as sorting, inspecting, and packaging with precision, minimizing the chance of human error and ensuring consistent quality.

8. Customizable Quality ParametersAI-driven quality control systems can be tailored to specific quality parameters required by different products and industries. This flexibility allows manufacturers to implement the most appropriate quality control measures for each item in their production line.

9. Reduced Need for Human InterventionWhile human oversight remains crucial, AI can significantly reduce the need for manual inspection. This not only cuts down on labor costs but also increases the speed of production, as automated systems can work around the clock without fatigue.

10. Improved Reporting and DocumentationAI systems can generate detailed reports on production quality, including metrics such as defect rates, efficiency improvements, and cost savings. This comprehensive documentation is invaluable for compliance purposes, as well as for continuous improvement initiatives.

In summary, the key features of AI-driven quality control systems in kitchen appliances encompass real-time monitoring, advanced vision capabilities, predictive analytics, adaptive learning, IoT integration, enhanced traceability, automated defect detection, customizable parameters, reduced human intervention, and improved reporting. These features collectively contribute to a more efficient, reliable, and cost-effective production process, setting new standards in the industry.

Benefits for Manufacturers: Efficiency and Cost-Effectiveness

In the ever-evolving landscape of kitchen appliance manufacturing, the adoption of AI-driven quality control systems has become a game-changer for manufacturers. These systems bring a host of benefits that not only enhance efficiency but also contribute to significant cost savings. Let’s delve into how these advantages can reshape the way appliances are produced.

Automation Reduces Human ErrorThe integration of AI into quality control processes significantly reduces the likelihood of human error. Manual inspection can be prone to fatigue, oversight, and inconsistency, leading to faulty products. AI systems, on the other hand, operate tirelessly, providing precise measurements and analysis that are consistently accurate. This reduction in errors ensures that only top-quality products reach the market.

Enhanced Speed and ScalabilityAI-driven quality control systems can process and analyze vast amounts of data at incredible speeds. This rapid analysis allows for quick responses to quality issues, leading to more efficient production lines. Moreover, these systems are scalable, meaning they can easily adapt to changes in production volume without sacrificing quality or performance.

Predictive Maintenance for LongevityBy continuously monitoring the health of machinery and identifying potential issues before they escalate, AI systems can extend the lifespan of production equipment. This proactive approach to maintenance not only reduces downtime but also prevents costly repairs or replacements, leading to substantial savings over time.

Streamlined Supply Chain ManagementQuality control extends beyond the production line to encompass the entire supply chain. AI systems can track and analyze the quality of raw materials, components, and finished products, ensuring that only the highest standards are maintained throughout the supply chain. This streamlining can lead to better supplier relationships and a more reliable supply of high-quality parts.

Cost Reduction Through Preventive MeasuresThe predictive capabilities of AI-driven systems allow manufacturers to identify and address quality issues before they become widespread. This preventive approach can save thousands, if not millions, in recall costs and potential legal liabilities. By addressing issues early on, manufacturers can also avoid the expense of reworking or scrapping products.

Increased Customer SatisfactionUltimately, the efficiency and quality of products directly impact customer satisfaction. With AI-driven quality control systems, manufacturers can produce appliances that meet or exceed customer expectations, leading to higher levels of customer loyalty and positive brand reputation.

Improved Compliance and Regulatory StandardsIn many industries, adherence to regulatory standards is critical. AI-driven quality control systems can help manufacturers ensure compliance with various regulations, reducing the risk of fines and other penalties. These systems can document and track every aspect of the production process, providing a clear audit trail that satisfies regulatory requirements.

Employee Training and DevelopmentWhile AI systems automate many quality control tasks, they also serve as powerful tools for employee training and development. Workers can learn from the AI’s analysis and make informed decisions based on data-driven insights. This not only enhances the skill set of the workforce but also fosters a culture of continuous improvement within the organization.

Data-Driven Decision MakingAI systems provide manufacturers with invaluable data about their production processes. This data can inform strategic decisions, from optimizing production lines to identifying areas for innovation. The ability to make decisions based on concrete, real-time data can lead to more agile and responsive manufacturing practices.

Environmental Impact and SustainabilityIn addition to the financial benefits, AI-driven quality control systems can also contribute to environmental sustainability. By reducing waste, minimizing downtime, and improving efficiency, these systems can help manufacturers reduce their carbon footprint and contribute to a more sustainable future.

In conclusion, the benefits of AI-driven quality control systems for manufacturers are multifaceted. From reducing costs and improving product quality to enhancing customer satisfaction and environmental sustainability, these systems are a cornerstone of modern manufacturing success. As technology continues to advance, the integration of AI into quality control is not just a trend but a necessity for those looking to thrive in the competitive kitchen appliance market.

Consumer Impact: Trust and Innovation

In the ever-evolving landscape of kitchen appliances, consumer trust and innovation are paramount. The intersection of these two elements has been significantly shaped by advancements in technology, particularly in the realm of AI-driven quality control. Here’s how these factors are intertwining to impact the consumer experience:

The rise of smart appliances has not only changed the way we interact with our kitchen tools but has also raised expectations for reliability and performance. Consumers now seek appliances that not only simplify daily tasks but also offer a seamless and integrated experience. AI-driven quality control systems play a crucial role in meeting these expectations by ensuring that each product meets stringent standards.

With the integration of AI, manufacturers can provide a level of precision and consistency that was once unattainable. This means that the consumer can expect a refrigerator that maintains the perfect temperature, a dishwasher that cleans without a single spot, and an oven that perfectly bakes every time. The trust that comes with such reliable performance is invaluable, as it fosters a long-term relationship between the consumer and the brand.

Innovation, on the other hand, is driven by the constant push to improve upon existing technologies. AI-driven quality control systems enable manufacturers to innovate by quickly identifying areas for improvement and implementing changes without disrupting the production line. This agility allows for the introduction of new features and functionalities that can revolutionize the way consumers use their kitchen appliances.

The impact on consumer trust is clear when looking at the data. According to a survey by the Consumer Technology Association, 70% of consumers are more likely to purchase a smart kitchen appliance if it has a high rating for reliability. AI-driven quality control systems contribute to this reliability by reducing defects and improving the overall quality of the product.

Moreover, the innovation brought about by AI in quality control can lead to more sustainable and energy-efficient appliances. Consumers are increasingly aware of the environmental impact of their purchases, and AI-driven systems can help create appliances that are not only high-performing but also eco-friendly. This dual focus on performance and sustainability resonates with today’s environmentally conscious consumer.

The integration of AI also allows for a more personalized experience. Smart appliances can learn from usage patterns and adjust settings to individual preferences, creating a more intuitive and tailored experience. This level of personalization not only enhances the consumer’s satisfaction but also fosters a deeper level of trust in the brand.

However, the consumer impact of AI-driven quality control is not without its challenges. There is a growing concern about data privacy and security. Consumers must feel confident that their data is being handled responsibly and that their personal information is protected. Brands that can address these concerns while maintaining high-quality standards will gain a competitive edge.

Additionally, the rise of AI-driven appliances has also sparked discussions about the future of work. As appliances become more advanced, there is a potential shift in the types of jobs available in the kitchen appliance industry. Consumers will need to adapt to these changes, understanding that while some tasks may become automated, the human element in design and customer service will remain crucial.

In conclusion, the role of AI in enhancing production quality has a profound impact on consumer trust and innovation. By delivering reliable, efficient, and sustainable products, manufacturers can build a loyal customer base. The challenge lies in balancing technological advancements with ethical considerations and ensuring that the consumer remains at the heart of the innovation process.

Challenges and Considerations for AI Implementation

The integration of AI into production processes, particularly in the kitchen appliance industry, brings about a myriad of challenges and considerations that must be carefully navigated to ensure successful implementation.

Understanding the nuances of data handling is crucial. AI systems require vast amounts of data to learn and optimize. However, the collection and storage of this data must comply with privacy laws and ethical standards. Ensuring that consumer data is protected and used responsibly is a non-negotiable.

Adapting to AI-driven systems can disrupt existing workflows. Employees may resist changes, leading to a need for comprehensive training programs. The transition might also require rethinking job roles and responsibilities, which can be a sensitive issue for both management and workers.

The technology itself can be complex and expensive to implement. High-quality AI solutions often come with a significant price tag, which can be a barrier for smaller manufacturers. Additionally, the ongoing maintenance and updates required for AI systems can add to the operational costs.

Integration with existing systems is another challenge. Compatibility issues can arise when trying to integrate AI into legacy equipment or software. This requires careful planning and potentially significant investments in upgrading or replacing existing infrastructure.

Ethical concerns are at the forefront. The use of AI in quality control raises questions about job displacement and the potential for bias in AI algorithms. Ensuring that AI systems are fair and unbiased is essential to maintain public trust.

Regulatory compliance is a persistent challenge. The kitchen appliance industry is heavily regulated, and AI systems must adhere to these regulations without compromising their effectiveness. This often means navigating a complex web of international and local laws.

Customization and scalability are also considerations. AI systems must be flexible enough to cater to the diverse needs of different products and production lines. This requires a level of adaptability that can be difficult to achieve, especially for manufacturers with a wide range of products.

The need for ongoing monitoring and evaluation cannot be overstated. AI systems must be continuously monitored to ensure they are performing as intended and to address any issues that may arise. This requires a dedicated team with expertise in AI and data analysis.

The cultural aspect of AI implementation cannot be ignored. The acceptance and understanding of AI among employees and stakeholders vary widely. Cultivating a culture that embraces technology and change is essential for the successful adoption of AI in the production process.

Lastly, the impact on the supply chain must be carefully managed. AI-driven quality control can affect suppliers and distributors, requiring new strategies for collaboration and communication. Ensuring that the entire supply chain can adapt to these changes is critical for the overall success of AI implementation.

In conclusion, while the benefits of AI-driven quality control are clear, the challenges and considerations are equally significant. Manufacturers must approach AI implementation with a comprehensive strategy that addresses these issues head-on, ensuring a smooth transition to a more efficient and effective production process.

Data Privacy and Security in AI-Driven Quality Control

In the realm of AI-driven quality control, data privacy and security are paramount concerns. Ensuring that sensitive information remains protected while leveraging AI’s capabilities is a delicate balance. Here’s a closer look at the challenges and considerations in this critical area.

The increasing reliance on AI for quality control in kitchen appliances has brought about a surge in data collection. This wealth of information, while invaluable for improving production processes, also poses significant risks if not handled properly. Customer data, manufacturing metrics, and even predictive analytics can all be compromised if not secured.

As AI systems analyze vast amounts of data to detect defects and optimize production, the risk of a data breach grows. The potential consequences of such breaches are severe, including financial loss, reputational damage, and legal implications. Manufacturers must therefore prioritize robust security measures to safeguard their data.

One of the key challenges in maintaining data privacy and security is the complexity of integrating AI into existing systems. Legacy systems may not be designed with the necessary security protocols, making them vulnerable to attacks. This necessitates a thorough assessment of current infrastructure and the implementation of comprehensive updates to ensure compatibility and security.

Moreover, the ethical implications of data use in AI-driven quality control cannot be overlooked. Consumers are increasingly aware of how their data is collected and used, and they expect transparency and consent. Manufacturers must be transparent about what data is collected, how it is used, and how long it is retained. This requires clear policies and practices that align with privacy regulations such as GDPR and CCPA.

The role of third-party vendors in AI implementation also presents a unique set of challenges. When manufacturers outsource parts of their AI infrastructure, they must ensure that these vendors adhere to the same stringent data security standards. This often means conducting thorough due diligence to verify the security protocols in place at these third-party providers.

In the context of AI-driven quality control, the security of the data itself is crucial. Encryption is a fundamental tool in this regard, ensuring that even if data is intercepted, it remains unreadable and unusable by unauthorized parties. However, implementing strong encryption can be complex and requires ongoing management to ensure its effectiveness.

Additionally, the dynamic nature of data means that security measures must be continually updated to keep pace with evolving threats. This includes regular security audits, employee training on data protection, and staying informed about the latest security technologies and best practices.

The use of machine learning algorithms in AI-driven quality control introduces another layer of complexity. These algorithms learn from data, which means they can inadvertently pick up and perpetuate biases present in the training data. Ensuring that these biases are not reflected in the quality control outcomes is essential for maintaining fairness and avoiding discrimination.

In terms of compliance, manufacturers must navigate a complex web of regulations and standards. This includes not only data protection laws but also industry-specific regulations that govern the handling of sensitive information. Staying compliant with these regulations requires a comprehensive understanding of the legal landscape and the ability to adapt to changes quickly.

The importance of data privacy and security in AI-driven quality control cannot be overstated. As manufacturers continue to embrace AI to enhance production quality, they must prioritize these aspects to build trust with consumers and maintain a competitive edge. This involves a multi-faceted approach that encompasses robust security measures, ethical considerations, and ongoing vigilance against emerging threats. Only through such a comprehensive strategy can manufacturers ensure that the benefits of AI-driven quality control are realized without compromising the integrity of their data and the trust of their customers.

Predictions for the Future of AI in Kitchen Appliance Production

In the rapidly evolving landscape of kitchen appliance production, AI is poised to revolutionize how we approach design, manufacturing, and quality control. Here are some predictions for the future of AI in this sector:

The integration of AI into kitchen appliance production is expected to lead to more personalized and user-centric designs. Manufacturers will be able to gather vast amounts of data from users’ preferences and habits, enabling them to create appliances that are not just functional but also tailored to individual needs. Imagine a refrigerator that suggests recipes based on your dietary preferences or a stove that adjusts cooking times based on the ingredients you’ve added.

AI will also play a significant role in predictive maintenance, reducing downtime and the need for frequent repairs. By analyzing usage patterns and sensor data, appliances can predict when a component might fail and schedule maintenance proactively. This shift from reactive to proactive service will not only save money but also enhance the overall user experience.

With advancements in AI, the production line itself will become smarter, capable of real-time quality control. Robots and automated systems will be able to inspect and test products with precision, ensuring that each appliance meets the highest standards before it reaches the consumer. This will lead to a decrease in defective products and a significant improvement in product consistency.

Customization will become more accessible as AI algorithms optimize the production process for a wide range of configurations. Consumers will have the option to select features and even colors for their appliances, with AI ensuring that the final product is both aesthetically pleasing and efficient.

Energy efficiency will be another focus area, with AI helping to design appliances that consume less power while still delivering peak performance. AI can optimize the design of motors, heating elements, and cooling systems to minimize energy use, which is not only environmentally friendly but also cost-effective for consumers.

The rise of AI in kitchen appliance production will also bring about new business models. Subscription services, for example, could become more prevalent, offering consumers ongoing maintenance, updates, and even the option to swap out appliances as technology advances.

As AI becomes more deeply integrated into the production process, there will be a need for robust cybersecurity measures. The interconnected nature of these appliances means that they will be part of a larger network, and protecting that network from cyber threats will be paramount.

The regulatory environment will also adapt to the new realities of AI in kitchen appliance production. Governments and industry bodies will likely develop new standards and certifications to ensure that AI systems are reliable, transparent, and ethical.

In terms of labor, there will be a shift in the roles of human workers. While some jobs may be automated, new roles will emerge that require a blend of technical expertise and human intuition. For instance, there will be a demand for “AI wranglers” who can manage and optimize AI systems in a way that maximizes their potential without compromising on safety or ethical considerations.

Education and training will play a crucial role in preparing the workforce for this new era. Workers will need to be upskilled to understand and work alongside AI, ensuring that the benefits of AI are fully realized while mitigating potential risks.

The future of AI in kitchen appliance production is not just about technology; it’s about creating a seamless and intuitive user experience that combines the best of human ingenuity with the precision and efficiency of artificial intelligence. As we move forward, the key will be to balance innovation with responsibility, ensuring that the benefits of AI are shared widely and responsibly.

Conclusion: The Transformative Power of AI in the Kitchen Appliance Sector

In the kitchen appliance sector, AI’s transformative power is undeniable. As technology continues to evolve, the impact of AI on production processes, quality control, and consumer experiences is profound. Here’s a look at how AI is reshaping the industry and what it means for the future.

The integration of AI into kitchen appliance production has streamlined manufacturing processes, reducing waste and improving efficiency. AI-driven systems can predict maintenance needs, optimize production schedules, and even adjust manufacturing parameters in real-time to ensure consistent quality. This level of precision was once unattainable, but now, it’s becoming the norm.

As AI systems become more sophisticated, they’re not just improving production; they’re also enhancing the consumer experience. Smart appliances can learn from usage patterns, offering personalized settings and predictive maintenance to extend the life of the product. This shift towards personalized service is changing how consumers interact with their kitchen appliances.

The rise of AI in the kitchen appliance sector is also driving innovation. Companies are now exploring new materials, designs, and functionalities that were once considered science fiction. From voice-activated ovens to self-cleaning refrigerators, the possibilities are vast. This innovation is not just limited to new products; it’s also about improving existing ones, making them more intuitive and efficient.

Despite the many benefits, the adoption of AI in kitchen appliance production is not without its challenges. There’s a significant investment required in technology and training. Moreover, the industry must grapple with the ethical implications of AI, such as job displacement and data privacy concerns. Balancing these issues is crucial for the successful integration of AI.

Data privacy and security are at the forefront of these concerns. As AI systems collect and analyze vast amounts of data, ensuring that this information is protected is paramount. Manufacturers must adhere to strict data protection regulations and implement robust security measures to prevent unauthorized access. This is not just a legal requirement; it’s a trust-building exercise with consumers who are increasingly aware of the value of their personal information.

Looking ahead, the future of AI in kitchen appliance production is bright but complex. The industry will need to address the challenges of technology integration, workforce transformation, and consumer acceptance. Collaboration between manufacturers, technology providers, and regulatory bodies will be key to navigating these complexities.

One prediction is that AI will become even more deeply integrated into the production process, with machines learning from each other and continuously improving. This could lead to a self-evolving production line that not only optimizes quality but also adapts to new market demands and consumer preferences.

Another trend to watch is the rise of AI in after-sales service. As appliances become smarter, they’ll also be more connected, allowing manufacturers to offer predictive maintenance and personalized support. This could shift the focus from product sales to a long-term relationship with the consumer, ensuring ongoing satisfaction and brand loyalty.

In conclusion, the transformative power of AI in the kitchen appliance sector is undeniable. While challenges remain, the potential for innovation and efficiency is vast. As the industry continues to evolve, it will be crucial for all stakeholders to work together to harness the full potential of AI while addressing the associated risks and concerns. The future of kitchen appliances is not just about technology; it’s about creating a seamless, intelligent, and sustainable kitchen experience for consumers worldwide.