In today’s fast-paced world, innovation is the cornerstone of success, especially in the dynamic field of kitchen appliances. The ability to turn ideas into tangible products swiftly is not just a luxury; it’s a necessity. This is where the significance of rapid prototyping comes into play, offering a streamlined path to bring new concepts to life. By diving into the intricacies of this process, we can uncover the secrets behind its power and the impact it has on shaping the future of kitchen appliances.

Understanding the Importance of Rapid Prototyping

Rapid prototyping is a cornerstone of innovation, especially in the fast-paced world of technology and design. It’s not just about creating a model; it’s about turning ideas into tangible products with unprecedented speed. The importance of rapid prototyping cannot be overstated, as it plays a pivotal role in several key areas.

Innovation is the lifeblood of any industry, and rapid prototyping is its pulse. It allows companies to test and iterate their concepts quickly, ensuring that the final product is not just innovative but also meets the needs of the market. By reducing the time from concept to prototype, businesses can stay ahead of the curve and capture market opportunities that might otherwise slip through their fingers.

One of the most significant benefits of rapid prototyping is the ability to gather feedback early and often. This iterative process means that designers and engineers can refine their ideas based on real-world usage, making the final product more user-friendly and effective. By involving potential users in the testing phase, companies can ensure that the end product resonates with the target audience, leading to higher customer satisfaction and loyalty.

The cost of developing a new product can be substantial, but rapid prototyping can significantly reduce these costs. Traditional manufacturing processes often involve multiple stages, each with its own set of expenses. Rapid prototyping streamlines this process, allowing for cost-effective modifications and adjustments without the need for large-scale production runs. This not only saves money but also allows for more experimentation and exploration of different design options.

Time is a critical factor in the competitive landscape of today’s markets. Rapid prototyping can shave weeks, if not months, off the development timeline. This agility is particularly valuable in industries where technology evolves rapidly, such as consumer electronics and automotive. Being able to bring a product to market faster can mean the difference between leading the market or being overshadowed by competitors.

Another important aspect of rapid prototyping is the ability to test the viability of a product in a real-world environment. Physical prototypes allow engineers to assess the durability, functionality, and usability of a product. This hands-on testing can reveal issues that might not be apparent in simulations or theoretical models, leading to a more robust and reliable end product.

Collaboration is also enhanced through rapid prototyping. It brings together designers, engineers, and other stakeholders in a tangible, interactive environment. This cross-functional collaboration fosters creativity and innovation, as team members can see and touch the product they are working on. It also helps in breaking down silos, as each team member’s expertise is valued and integrated into the final design.

The environmental impact of manufacturing cannot be ignored, and rapid prototyping offers a more sustainable approach. By reducing the amount of material used in the development process and minimizing waste, companies can contribute to a greener planet. Moreover, the ability to iterate quickly means that resources are not wasted on products that may not make it to market, further reducing the carbon footprint.

Innovation is not just about creating new products; it’s also about making improvements to existing ones. Rapid prototyping allows for continuous improvement, as companies can release updates and enhancements to their products more frequently. This iterative approach keeps products fresh and relevant, ensuring that they remain competitive in the long term.

Lastly, rapid prototyping can serve as a powerful tool for marketing and communication. A physical prototype can be used to demonstrate a product’s features and benefits to investors, partners, and customers. This visual representation can be much more compelling than a set of specifications or a digital rendering, helping to build excitement and anticipation for the final product.

In conclusion, rapid prototyping is a multifaceted tool that drives innovation, reduces costs, saves time, improves product quality, fosters collaboration, and supports sustainability. Its importance in the development of new products cannot be underestimated, as it is a key driver of success in today’s dynamic and competitive markets.

Introducing the 15-Day Rapid Prototyping Service

In today’s fast-paced world, innovation is key to staying ahead of the competition. Our 15-Day Rapid Prototyping Service is designed to be your go-to solution for bringing ideas to life swiftly and efficiently. Here’s a closer look at what makes this service unique and invaluable.

Our streamlined process begins with a deep understanding of your needs. We take the time to listen and analyze your project requirements, ensuring that every detail is accounted for. This initial phase sets the stage for a successful and timely outcome.

With a team of seasoned experts in various fields, we have the skill set to tackle projects of all complexities. From mechanical engineers to software developers, our multidisciplinary team collaborates seamlessly to turn your concept into a tangible prototype.

Time is of the essence in the tech industry, and our service prides itself on delivering results in just 15 days. This rapid turnaround time is achieved through a combination of advanced technologies and efficient project management practices.

We don’t just stop at creating a prototype; we ensure it’s a functional one. Our commitment to quality means that every aspect of your design is thoroughly tested and refined. This approach minimizes the risk of costly redesigns and ensures that your final product meets the highest standards.

Our 15-Day Rapid Prototyping Service is flexible and adaptable. Whether you’re working on a small-scale project or a large-scale product, we have the resources and expertise to scale our services to fit your needs. This flexibility allows us to cater to startups and established corporations alike.

Communication is key throughout the entire process. We maintain open lines of communication with our clients, providing regular updates and insights. This ensures that you are always in the loop and can provide feedback at any stage of the prototyping process.

Innovation is at the heart of our service. We leverage cutting-edge technologies such as 3D printing, CNC machining, and virtual reality to create prototypes that are not only functional but also visually stunning. This allows you to visualize your product before it’s even fully developed.

Our prototyping service is also environmentally conscious. We use sustainable materials and practices to minimize our carbon footprint and support a greener future. This commitment to sustainability is an added bonus for businesses looking to align their operations with eco-friendly initiatives.

Cost-effectiveness is a significant advantage of our 15-Day Rapid Prototyping Service. By providing a quick and efficient solution, we help you save on both time and resources. This can lead to significant cost savings, especially when compared to traditional prototyping methods that can take weeks or even months.

Collaboration is a cornerstone of our service. We work closely with clients to ensure that their vision is brought to life exactly as intended. This collaborative approach fosters creativity and innovation, resulting in a final product that exceeds expectations.

We understand that every project is unique, which is why we offer customization options. Whether you need a simple tweak to an existing design or a complete overhaul, our team is equipped to deliver a tailored solution that meets your specific requirements.

Our service also extends beyond the initial prototyping phase. We offer ongoing support and can assist with further development, testing, and production. This comprehensive approach ensures that you have a seamless transition from concept to market.

In conclusion, our 15-Day Rapid Prototyping Service is a powerful tool for businesses looking to innovate quickly and effectively. With a focus on quality, efficiency, and collaboration, we are well-positioned to help you bring your ideas to life in a fraction of the time it would take with traditional methods.

The Need for Speed in the Kitchen Appliance Market

In an era where consumer expectations are rapidly evolving, the kitchen appliance market is no exception. The demand for innovation, efficiency, and user-friendliness is higher than ever. This shift has necessitated a shift in how products are developed and brought to market.

The pace at which technology advances in the kitchen appliance industry is staggering. New features are introduced almost daily, and manufacturers must keep up to remain competitive. From smart refrigerators that can predict shopping lists to cooktops that adjust to individual cooking preferences, the market is constantly buzzing with new ideas.

Customers today are not just looking for the latest gadgets; they are seeking appliances that can seamlessly integrate into their lives. The need for speed in the kitchen appliance market is driven by several key factors.

Customization is a growing trend that’s shaping the kitchen appliance landscape. Consumers are no longer satisfied with one-size-fits-all solutions. They want appliances that can be tailored to their specific needs, whether it’s the size of their kitchen, their dietary preferences, or their cooking habits. This demand requires manufacturers to act swiftly, ensuring that they can offer a variety of customizable options that cater to a diverse audience.

The competition is fierce, and time-to-market is a critical differentiator. Companies that can bring their products to market faster have a significant advantage over those that lag behind. This is especially true for emerging technologies that have the potential to disrupt the market. By offering a 15-day rapid prototyping service, manufacturers can capitalize on these opportunities before they become obsolete.

Product lifecycle management is also a factor. In the kitchen appliance market, products have a relatively short shelf life. Trends change rapidly, and what’s popular today may be outdated tomorrow. A quick prototyping service allows companies to iterate quickly, testing new designs and features, and bringing to market only the most effective solutions.

Another aspect of the need for speed is the increasing importance of sustainability. Consumers are more conscious of the environmental impact of their purchases, and manufacturers are under pressure to produce appliances that are energy-efficient and eco-friendly. Rapid prototyping enables companies to test and refine these sustainable designs more efficiently, ensuring that they can meet these evolving demands without delay.

Consumer behavior has shifted, with a greater emphasis on convenience and ease of use. Appliances that are not intuitive or that require extensive installation and setup procedures can quickly become outdated. The kitchen appliance market needs to respond with solutions that are easy to use and understand, and a quick prototyping service allows for the testing of user interfaces and experiences to ensure they meet these expectations.

Regulatory compliance is another area where speed is of the essence. Standards and regulations change frequently, and manufacturers must ensure that their products adhere to these guidelines. A rapid prototyping service can help companies stay ahead of these changes, making necessary adjustments quickly and efficiently.

Moreover, the global nature of the kitchen appliance market means that manufacturers must consider international differences. Rapid prototyping allows for the creation of products that can be easily adapted to different markets, cultures, and regulatory environments, ensuring that the product launch is as smooth and swift as possible.

In conclusion, the kitchen appliance market thrives on innovation, and innovation requires speed. The ability to quickly prototype, test, and iterate on new designs and features is essential for staying relevant and competitive. As the market continues to evolve, the need for speed will only grow, and companies that can meet this demand will be the ones that lead the way in the ever-changing landscape of kitchen appliances.

How Our Service Stands Out

In today’s fast-paced kitchen appliance market, standing out is not just about innovation; it’s about efficiency and adaptability. Our 15-Day Rapid Prototyping Service is designed to set us apart in several key ways.

Our team is a blend of seasoned professionals who bring a wealth of experience in kitchen appliance design and manufacturing. This collective expertise means we’re not just creating prototypes; we’re crafting solutions that are both functional and future-ready.

We pride ourselves on our state-of-the-art facilities, which are equipped with the latest technology. This means our prototypes are not only developed quickly but also with precision. Our advanced machinery and tools ensure that every detail is accounted for, from the smallest of components to the overall design.

Speed is a cornerstone of our service, but we never compromise on quality. Our rigorous quality control process ensures that every prototype meets the highest standards before it leaves our workshop. This commitment to excellence means that our clients receive prototypes that are not just fast but also reliable and robust.

Customization is at the heart of our approach. We understand that no two clients are the same, which is why we offer tailored solutions. Whether it’s a specific feature, material, or design aesthetic, our service is flexible enough to accommodate a wide range of needs.

Communication is key in the kitchen appliance industry. We maintain open lines of dialogue with our clients, ensuring that their input is not only heard but also integrated into the prototyping process. This collaborative approach helps us deliver products that align perfectly with our clients’ vision.

Our service is not just about creating a prototype; it’s about providing a comprehensive solution. We offer support from initial concept to final product, including advice on design, materials, and manufacturing processes. This holistic approach saves our clients time and resources, as they don’t have to seek out multiple service providers.

We’ve built a reputation for our ability to turn around prototypes in a mere 15 days. This quick turnaround is a testament to our streamlined process and dedicated team. It allows clients to bring their products to market faster, gaining a competitive edge in a market that demands innovation at a rapid pace.

Our commitment to sustainability is another differentiator. We use eco-friendly materials and manufacturing practices that minimize our environmental footprint. This not only aligns with the values of many of our clients but also positions us as a responsible and forward-thinking partner.

Innovation is not a one-time event; it’s a continuous journey. Our service is designed to support clients at every stage of their product development cycle. We offer follow-up support and are ready to iterate on designs as needed, ensuring that our clients stay ahead of the curve.

Our pricing structure is transparent and competitive. We believe in providing value for money, which is why we offer flexible pricing plans that align with our clients’ budgets. This affordability makes our 15-Day Rapid Prototyping Service accessible to startups and established brands alike.

In the kitchen appliance market, where trends can shift overnight, agility is crucial. Our service is built to be adaptable, ready to pivot and accommodate changes in design, technology, or market demands. This agility means our clients can respond quickly to new opportunities.

Our dedication to customer satisfaction is unwavering. We understand that a successful prototype is one that not only meets technical specifications but also exceeds expectations. Our focus on customer service ensures that our clients feel supported throughout the prototyping process and beyond.

In a market where speed and quality are paramount, our 15-Day Rapid Prototyping Service is a beacon of efficiency and reliability. From our expert team to our cutting-edge facilities, every aspect of our service is designed to stand out, making us the go-to choice for brands and innovators looking to bring their ideas to life swiftly and effectively.

Success Stories and Case Studies

In the fast-paced world of kitchen appliance innovation, our 15-Day Rapid Prototyping Service has been the cornerstone of several groundbreaking successes. Let’s delve into a few of these stories to see how our service has made a tangible impact.

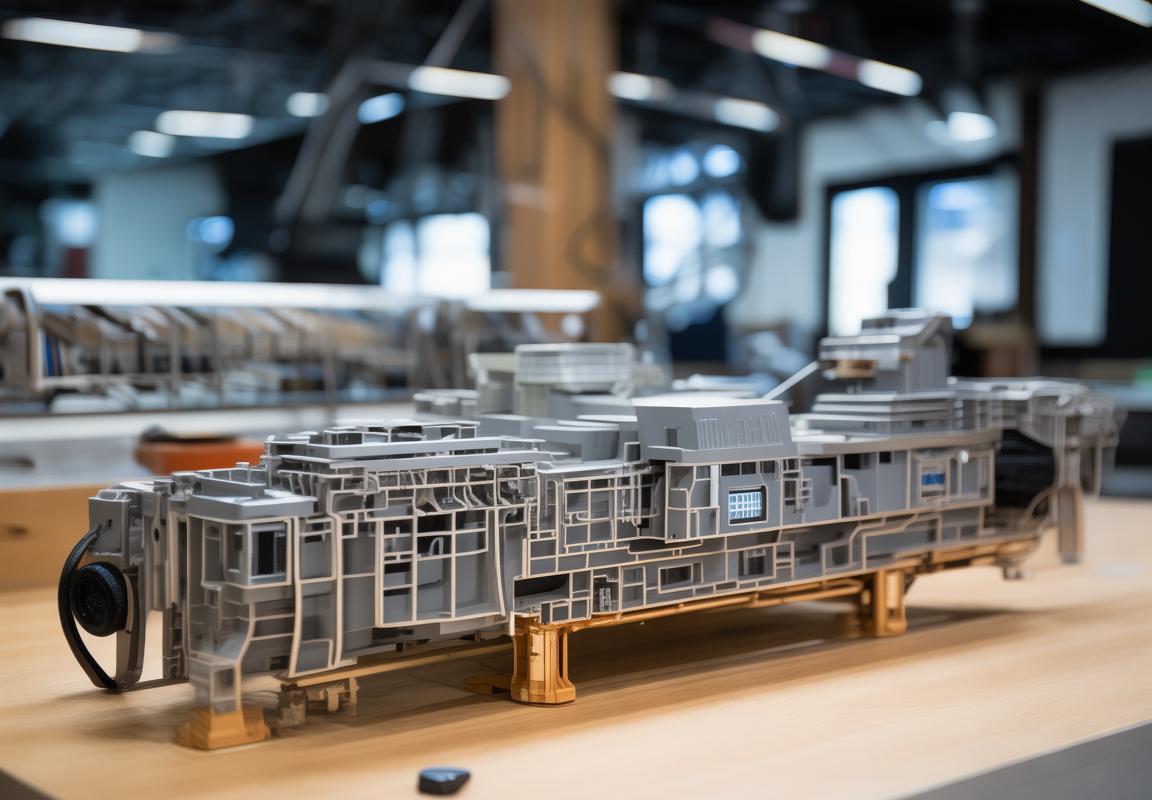

Our first success story involves a small startup that came to us with a vision for a new type of countertop oven. They needed a prototype to showcase at a major industry trade show in just two weeks. Our team worked tirelessly, leveraging our advanced 3D printing and CNC machining capabilities to create a fully functional prototype within the tight deadline. The oven was a hit at the show, and the startup secured multiple partnerships and funding opportunities as a result.

Another case study involves a well-established kitchen appliance brand that was facing stagnation in their product development cycle. They had been struggling to bring new ideas to market due to lengthy prototyping processes. After switching to our 15-Day Rapid Prototyping Service, they were able to test multiple iterations of a new blender design within the span of a month. This rapid iteration allowed them to identify the most user-friendly and efficient design, which ultimately led to a product that was not only a commercial success but also received accolades from consumer review sites.

In a third instance, a global kitchen appliance manufacturer was dealing with a design flaw in one of their high-end ranges. The issue was discovered late in the production cycle, and a traditional prototyping process would have taken months to address. With our service, they were able to create a prototype and test various solutions within a week. The swift response helped them to avert a costly recall and maintain their brand reputation.

One of our more unique projects involved a company looking to develop a smart kitchen appliance that could integrate with home automation systems. They had a concept but needed a tangible prototype to demonstrate the appliance’s capabilities. Our team quickly assembled a cross-functional team of engineers, designers, and software developers to create a fully functional prototype that included both hardware and software elements. The prototype was presented to potential investors, who were impressed by the seamless integration and user-friendly interface, leading to a successful funding round.

A fourth success story comes from the healthcare sector, where a company needed a prototype for a specialized kitchen appliance designed to assist individuals with mobility challenges. Time was of the essence, as the appliance was intended for a medical conference. Our rapid prototyping service allowed them to create a fully operational prototype in just 10 days. The appliance was well-received by both healthcare professionals and patients, and it is now in the final stages of regulatory approval.

In one notable case, a startup was developing a new type of kitchen gadget that promised to revolutionize meal prep. They had a working prototype but needed a more refined version to pitch to potential customers. Our service provided them with a sleeker, more durable prototype that showcased the gadget’s potential. The improved design led to a successful Kickstarter campaign, and the gadget is now in production.

A fifth story involves a large kitchen appliance brand that wanted to test the market’s reaction to a new line of eco-friendly appliances. They used our rapid prototyping service to create a series of prototypes that varied in design and features. The prototypes were then distributed to a select group of consumers, who provided valuable feedback. This feedback was instrumental in shaping the final product, which was launched with great success and has since become a cornerstone of the brand’s sustainability initiatives.

These stories illustrate the versatility and effectiveness of our 15-Day Rapid Prototyping Service. From startups to established brands, our service has been a catalyst for innovation, helping to bring new and improved products to market faster than ever before. The ability to quickly iterate and test designs has not only shortened product development cycles but has also opened doors to new markets and opportunities for growth.

The Science Behind Our Quick Prototyping Process

In the fast-paced world of product development, our 15-day rapid prototyping service thrives on a blend of cutting-edge technology and innovative methodologies. Here’s a peek into the science that powers our quick prototyping process:

Precision 3D Printing TechniquesWe harness the power of advanced 3D printing technologies to create prototypes with precision and detail. From Fused Deposition Modeling (FDM) to Stereolithography (SLA), our team selects the best method to ensure the accuracy of the final product.

Automated Design SoftwareOur designers rely on automated design software that allows for rapid iteration and optimization. Tools like SolidWorks, AutoCAD, and Fusion 360 streamline the design process, reducing the time from concept to prototype.

Material Selection and TestingChoosing the right materials is crucial for a successful prototype. We conduct extensive material testing to ensure the selected materials are suitable for the intended use, balancing durability with cost-effectiveness.

Customized Build EnvironmentsOur rapid prototyping service operates in custom-built environments that are optimized for speed and quality. These spaces are equipped with state-of-the-art equipment and controlled for temperature and humidity to prevent warping and other defects.

Advanced CNC MachiningFor complex geometries and high-precision parts, Computer Numerical Control (CNC) machining is employed. Our CNC machines are capable of producing intricate details and tight tolerances, ensuring that prototypes closely resemble the final product.

Automated Quality ControlQuality is non-negotiable in our rapid prototyping process. We use automated quality control systems to inspect prototypes for any deviations from the design specifications, catching issues early and preventing costly mistakes.

Collaborative Design WorkflowsOur team operates in a collaborative environment that fosters communication and idea sharing. Designers, engineers, and other stakeholders work closely together, using cloud-based platforms to access and modify prototypes in real-time.

Customized Prototyping SchedulesWe understand that time is of the essence, so we’ve developed customized prototyping schedules. These schedules are tailored to the specific needs of each project, ensuring that prototypes are ready when they’re needed without compromising on quality.

Iterative Prototyping PhilosophyOur approach to rapid prototyping is iterative. We believe that multiple iterations are necessary to refine the design and uncover potential issues. This philosophy allows us to optimize the product design and ensure that it meets the highest standards.

Advanced Simulation and AnalysisBefore a prototype is even built, we use advanced simulation and analysis tools to predict how the product will perform under various conditions. This helps us identify potential problems early and refine the design accordingly.

Innovative Supply Chain ManagementOur supply chain is designed to be efficient and responsive. By working with trusted partners and suppliers, we can quickly source materials and components, ensuring a seamless prototyping process.

Expert Technical SupportOur team of experts is on standby to provide technical support throughout the rapid prototyping process. From material selection to assembly, our engineers are there to ensure that every step is executed with precision.

Continuous Improvement and R&DWe’re committed to continuous improvement and research and development. This means regularly updating our processes and technologies to stay ahead of the curve and deliver the best possible prototypes to our clients.

In essence, the science behind our quick prototyping process is a symphony of technology, innovation, and expertise. It’s a recipe for success that has allowed us to deliver high-quality prototypes in record time, time and time again.

Cost-Effectiveness and Return on Investment

Navigating the fine balance between time and resources, cost-effectiveness in rapid prototyping is a critical factor that can make or break a project. Understanding the return on investment (ROI) in this context is key to making informed decisions. Let’s delve into how our service achieves both efficiency and economic viability.

Efficient design software and tools are at the heart of our quick prototyping process. By utilizing cutting-edge CAD (Computer-Aided Design) software, we can create detailed and accurate 3D models within hours. This streamlined approach minimizes the time spent in the design phase, allowing us to focus on the actual prototyping.

Customization is a hallmark of our service, but it doesn’t come at a premium. We’ve optimized our processes to offer a high degree of personalization without incurring excessive costs. Our modular approach means that clients can select and combine components to fit their specific needs, without the need for a complete overhaul of the design.

The manufacturing side of our rapid prototyping service is equally impressive. We’ve partnered with precision manufacturers who specialize in quick turnaround times. This means that once the design is finalized, the transition from digital model to physical prototype is rapid, often within days rather than weeks or months.

Quality control is non-negotiable, and we’ve integrated rigorous testing into our process. By using high-quality materials and ensuring that each prototype meets stringent quality standards, we’re able to deliver products that not only look great but also perform as expected.

In the realm of cost-effectiveness, our service shines through its scalability. Whether you’re a small startup or a large corporation, our solutions are tailored to your scale. This means that you can invest in as much or as little of our service as needed, without committing to a fixed, high-cost package.

The cost-saving benefits of our rapid prototyping service are not just limited to the immediate production phase. By identifying potential design flaws early on, we help our clients avoid costly rework and redesigns in the later stages of product development. This proactive approach saves time and resources in the long run.

Another aspect that contributes to the cost-effectiveness of our service is the ability to iterate quickly. In today’s fast-paced market, the ability to test and refine a product multiple times in a short span can lead to significant improvements without the associated high costs of traditional prototyping.

Our track record in delivering prototypes that turn into successful products speaks volumes. Clients have seen their ROI not just in the financial sense but also in the form of enhanced product quality, faster time-to-market, and improved customer satisfaction. For instance, a tech startup we worked with was able to validate their product concept within two weeks, leading to a swift pivot that resulted in a product that resonated with their target audience.

Innovation is expensive, but it doesn’t have to be prohibitively so. Our service ensures that innovation remains accessible by providing a cost-effective solution that doesn’t compromise on quality or speed. The ROI is not just measured in the financial savings but also in the competitive edge gained by being first to market with a superior product.

Lastly, the flexibility of our service means that clients can adapt to market changes without incurring additional costs. As the market evolves, so can their product design, ensuring that they remain relevant and competitive.

By focusing on these key aspects of cost-effectiveness and ROI, our rapid prototyping service continues to be a beacon of efficiency and value for our clients. The proof is in the numbers and the success stories of those who have leveraged our service to bring their ideas to life.

Future Trends in Kitchen Appliances and How We’re Preparing

In the ever-evolving landscape of kitchen appliances, staying ahead of the curve is crucial. Innovations are no longer just about convenience; they’re about efficiency, sustainability, and connectivity. As we look to the future, several trends are emerging that will shape the kitchen appliances market. Here’s how we’re preparing for these changes.

The rise of smart appliances is undeniable. Devices that can connect to the internet and be controlled remotely are not just trendy; they’re becoming a necessity. We’re focusing on developing appliances that not only integrate seamlessly with smart home systems but also offer intuitive user interfaces and predictive maintenance capabilities.

Energy efficiency is no longer just a regulatory requirement; it’s a consumer expectation. As environmental concerns grow, so does the demand for appliances that consume less energy. Our research and development team is hard at work on appliances that not only meet but exceed the latest energy-saving standards.

Customization is key in the modern kitchen. Consumers are looking for appliances that can be tailored to their specific needs and preferences. We’re investing in modular designs that allow users to upgrade or replace parts without having to discard the entire appliance.

Health and wellness are taking center stage in kitchen appliance innovation. There’s a growing interest in appliances that can help prepare healthier meals, from sous-vide cookers that ensure even cooking to air fryers that reduce oil usage. We’re exploring how to incorporate these features into our products while maintaining ease of use.

Sustainability is not just about the materials used but also about the lifecycle of the appliance. Our focus is on designing products that are durable, repairable, and recyclable. We’re also looking into renewable energy sources and biodegradable materials to reduce the environmental impact of our appliances.

Voice control and AI integration are becoming more prevalent in everyday life. We’re working on appliances that can be controlled via voice commands, making the kitchen experience more accessible and hands-free. This also opens up new possibilities for data collection and personalized recommendations.

Innovation in kitchen appliances is not just about adding new features; it’s about creating a cohesive ecosystem. We’re focusing on interoperability, ensuring that our appliances can communicate and work together to provide a seamless cooking experience.

The kitchen of the future will be a hub of interconnected devices, each contributing to the overall efficiency and comfort of the space. We’re preparing for this by developing appliances that can learn from user habits and adjust settings accordingly.

As technology advances, we’re also considering the impact on user experience. Our appliances are designed to be intuitive, reducing the learning curve for new users while still offering advanced features for those who want to delve deeper into their culinary pursuits.

The kitchen appliances market is on the brink of a new era, and we’re at the forefront, ready to meet the challenges and opportunities that lie ahead. From smart connectivity to sustainable design, we’re committed to delivering solutions that not only meet but exceed customer expectations.

How to Get Started with Our 15-Day Rapid Prototyping Service

Navigating the world of product development can be complex, but with our 15-Day Rapid Prototyping Service, we’ve streamlined the process to make it as straightforward as possible. Here’s a step-by-step guide on how to kickstart your journey with us.

-

Identify Your Needs and GoalsStart by clearly defining what you’re looking to achieve. Whether it’s a new kitchen appliance, a component upgrade, or a complete redesign, having a clear vision sets the foundation for your project.

-

Contact Our TeamReach out to our team with your initial inquiry. You can do this via email, phone, or through our online contact form. Provide a brief description of your project, including any specific requirements or constraints.

-

Initial ConsultationOnce we receive your inquiry, we’ll schedule an initial consultation. This is an opportunity for us to understand your project in more depth and for you to ask any questions you might have about our service.

-

Project Brief and Scope DefinitionBased on the consultation, we’ll prepare a detailed project brief that outlines the scope of work, timelines, and any preliminary costs. This document will serve as a roadmap for the project and ensure everyone is aligned on the objectives.

-

Design and ConceptualizationOur team of designers and engineers will begin the conceptualization phase. This involves brainstorming, sketching, and using 3D modeling software to visualize the prototype. We’ll iterate on these designs until we have a concept that meets your requirements.

-

Material Selection and SourcingWith the design concept in place, we’ll select the appropriate materials for your prototype. This includes ensuring compliance with safety standards and regulatory requirements. Our network of suppliers allows us to source high-quality materials efficiently.

-

Prototype ConstructionOnce materials are sourced, the construction phase begins. We use advanced manufacturing techniques, such as CNC machining, 3D printing, and injection molding, to create your prototype. This process is closely monitored to ensure accuracy and quality.

-

Testing and IterationAfter the initial prototype is built, it undergoes rigorous testing to validate its design and functionality. This stage is crucial for identifying any potential issues that need to be addressed before moving forward. We’ll work with you to make any necessary adjustments.

-

Finalization and DeliveryOnce the prototype meets all specifications and passes the testing phase, we’ll finalize the design. We’ll then deliver the prototype to you, along with a detailed report outlining the development process, findings, and recommendations for next steps.

-

Feedback and Next StepsAfter you receive the prototype, we encourage you to provide feedback. This is an opportunity to discuss any modifications or improvements that can be made. Based on your feedback, we can either proceed with a final production run or explore other options.

-

Documentation and SupportThroughout the process, we’ll provide comprehensive documentation, including design files, manufacturing instructions, and any relevant certifications. Our support doesn’t end with delivery; we’re here to assist with any post-prototype inquiries or issues that may arise.

-

Scheduling and DeadlinesOur 15-Day Rapid Prototyping Service is designed to be quick, but it’s also about quality. We’ll work with you to set realistic deadlines that align with your project timeline. We understand the importance of meeting milestones and will communicate any potential delays promptly.

-

Customization and FlexibilityWe recognize that each project is unique. Our service is designed to be flexible, allowing for customization at every stage. Whether you need a one-off prototype or a series of modifications, we’re equipped to handle your specific needs.

-

Affordability and ValueDespite the speed, our service is designed to provide excellent value for money. We aim to deliver a high-quality prototype that stands up to scrutiny without breaking the bank. Our competitive pricing ensures that you get the best possible return on investment.

-

Long-Term PartnershipsOur goal is not just to deliver a single prototype but to establish a long-term partnership. We believe in building relationships with our clients based on trust, quality, and mutual success. Let us know if you’re interested in exploring further collaborations.

By following these steps, you’ll be well on your way to experiencing the benefits of our 15-Day Rapid Prototyping Service. Our commitment to speed, quality, and customer satisfaction makes us the ideal partner for your product development needs.

Conclusion

In wrapping up, it’s clear that the journey of innovation isn’t just about ideas; it’s about execution. The rapid pace of technological advancements has reshaped industries, and the kitchen appliance market is no exception. The evolution from traditional appliances to smart, interconnected devices reflects a shift in consumer expectations and technological capabilities.

As we reflect on our 15-Day Rapid Prototyping Service, it’s evident that speed and efficiency are not just buzzwords but critical factors in staying competitive. By condensing the prototyping process into a mere 15 days, we’ve created a service that’s not just fast but also flexible and responsive to the dynamic needs of the market.

The success stories and case studies we’ve encountered highlight the transformative power of our service. Companies that once struggled to bring their innovative concepts to life now see tangible results in a fraction of the time. This swift transformation is not just a testament to our process but also to the collaborative spirit that drives us.

The science behind our quick prototyping process is a blend of cutting-edge technology, skilled engineers, and a streamlined workflow. Each step is meticulously designed to ensure that every prototype is not only functional but also ready for real-world testing. This commitment to quality and efficiency has set us apart in the industry.

When it comes to cost-effectiveness and return on investment, our service stands out. The quick turnaround time means that companies can bring their products to market faster, capturing market share and customer loyalty before competitors can respond. The reduced time to market also translates to lower development costs, making our service a smart financial decision.

Looking ahead, the future of kitchen appliances is poised to be marked by even more sophisticated technologies and smart functionalities. We’re preparing for this future by continuously refining our processes, investing in new technologies, and staying attuned to the evolving needs of our clients.

In conclusion, our 15-Day Rapid Prototyping Service isn’t just a service; it’s a strategic advantage. It allows businesses to innovate swiftly, test thoroughly, and launch confidently. The feedback we’ve received has been overwhelmingly positive, with clients praising our ability to turn ideas into reality with remarkable speed and precision.

The journey of innovation is never straightforward, but with our service, it becomes more manageable. Whether you’re a startup with a groundbreaking idea or an established brand looking to stay ahead, our service is designed to be your partner in innovation. We’re here to turn your vision into a reality, one prototype at a time. The future is fast, and we’re ready to help you get there.