In recent years, the culinary landscape has been transformed by the growing popularity of made-to-order cuisine. This shift in dining preferences has had a ripple effect across the food industry, leading to innovative approaches in food preparation and service. One such innovation that has emerged is the factory-made contact grill, offering a blend of convenience and quality that resonates with both chefs and consumers alike. This article delves into the intricacies of the contact grill manufacturing process, the benefits of factory-made units, and the broader impact on the market and consumer behavior.

Introduction to Contact Grill

Contact grills have become a staple in the world of outdoor cooking, offering a unique and efficient way to prepare a variety of foods. These sleek appliances, often found in modern kitchens and outdoor patios, are designed to cook food by pressing it between two heating surfaces, allowing for even heat distribution and a delicious sear. In this article, we delve into the fascinating world of contact grills, exploring their history, functionality, and the importance of made-to-order factories in their production.

The concept of a contact grill originated in the early 20th century, with the first models being large and primarily used in commercial settings. These early grills were typically found in restaurants and catering businesses, where they were prized for their ability to cook a large number of foods quickly and evenly. Over time, the technology improved, and contact grills began to find their way into home kitchens, becoming a favorite among grill enthusiasts and culinary adventurers.

One of the key features of a contact grill is its ability to cook food on both sides simultaneously. This dual-sided cooking process not only saves time but also ensures that the food is cooked thoroughly and develops a perfect sear. The design of these grills often includes a hinge that allows the top plate to close tightly around the food, creating a sealed environment that traps heat and moisture, leading to tender and juicy results.

The heating elements in contact grills are typically made of metal, which allows for rapid heat-up and efficient cooking. These elements are strategically placed to ensure that the heat is distributed evenly across the cooking surface, which is crucial for achieving consistent results. Many modern contact grills also come with adjustable temperature controls, giving users the flexibility to cook a wide range of foods, from delicate fish to hearty steaks.

In recent years, the demand for made-to-order products has surged, and the contact grill industry is no exception. Made-to-order factories play a crucial role in meeting this demand by customizing grills to meet specific requirements and preferences. These factories often work closely with designers and manufacturers to create innovative and specialized contact grills that cater to niche markets and individual needs.

One of the benefits of working with a made-to-order factory is the ability to choose from a wide array of materials and finishes. From stainless steel to cast aluminum, these factories can produce grills that not only look great but also offer superior durability and performance. Additionally, customers can often select from various cooking surfaces, such as non-stick coatings or porcelain-enameled plates, depending on their preferred cooking style and maintenance preferences.

Another advantage of made-to-order factories is their ability to incorporate advanced features into contact grills. For example, some factories specialize in integrating technology such as Bluetooth connectivity, allowing users to control their grill remotely through a smartphone app. This not only adds convenience but also enhances the overall cooking experience by providing real-time temperature monitoring and precise cooking control.

The manufacturing process in a made-to-order factory is a complex and highly precise operation. It begins with the selection of high-quality materials, which are then cut and shaped to precise specifications. The components are assembled using advanced machinery, ensuring that each grill meets the exacting standards of the customer. Throughout the process, quality control measures are in place to inspect every aspect of the grill, from the heating elements to the hinges and handles.

Once the assembly is complete, the grills undergo rigorous testing to ensure they meet safety and performance standards. This testing can include everything from thermal shock tests to durability evaluations, all designed to guarantee that the final product is reliable and long-lasting. The result is a contact grill that not only looks and performs as intended but also stands up to the demands of everyday use.

In the world of contact grills, made-to-order factories are not just about customization; they are about innovation and excellence. By working closely with customers and manufacturers, these factories are able to push the boundaries of what is possible in contact grill design and functionality. This collaboration leads to the creation of unique products that not only meet the needs of consumers but also inspire new trends in the culinary world.

As the demand for high-quality, personalized kitchen appliances continues to grow, the role of made-to-order factories in the contact grill industry is more significant than ever. These factories are not just producing grills; they are crafting tools that bring joy and convenience to the cooking process, allowing enthusiasts and professionals alike to explore new flavors and techniques with ease.

In conclusion, the contact grill has evolved from a commercial staple to a beloved kitchen appliance, thanks in part to the advancements made by made-to-order factories. These factories have not only improved the functionality and durability of contact grills but have also expanded the possibilities for customization, ensuring that every grill is as unique as the person who cooks with it.

The Rise of Made-to-Order Cuisine

In recent years, the culinary landscape has witnessed a significant shift with the rise of made-to-order cuisine. This trend has transformed the way we think about dining, emphasizing personalization and customization over mass-produced meals. From gourmet coffee shops to high-end restaurants, the demand for tailored dishes has surged, reflecting a broader cultural shift towards individualism.

The roots of made-to-order cuisine can be traced back to the rise of food trucks and street food culture. These mobile food vendors offered a level of flexibility and freshness that was often lacking in traditional dining establishments. Customers could choose from a variety of ingredients, allowing them to create a meal that suited their tastes and dietary preferences. This concept quickly gained traction and inspired a new wave of eateries that embraced the idea of on-the-spot preparation and customer input.

Supermarkets and grocery stores have also jumped on the made-to-order bandwagon. Self-service salad bars, sushi counters, and custom sandwich shops have become commonplace, giving consumers the power to craft their own meals from a selection of fresh, high-quality ingredients. This shift towards self-assembly not only caters to individual preferences but also encourages mindful eating and a connection with the food’s origins.

The advent of technology has played a pivotal role in the growth of made-to-order cuisine. Online food ordering platforms and mobile apps have made it easier than ever for customers to specify their dietary restrictions, preferred cooking styles, and ingredient preferences. These digital tools have democratized the culinary experience, allowing even those without culinary expertise to create unique and personalized meals at home.

One of the key drivers behind the rise of made-to-order cuisine is the increasing awareness of food allergies and dietary restrictions. As more people seek to avoid certain ingredients due to health concerns or personal beliefs, the demand for customized meals has skyrocketed. Restaurants and foodservice providers have responded by offering a wider range of options, from gluten-free and vegan dishes to those catering to specific cultural cuisines.

Cultural exchange has also contributed to the popularity of made-to-order cuisine. With the globalization of food, diners are now exposed to an array of international flavors and cooking techniques. This has sparked a curiosity and desire to recreate these dishes at home or in a restaurant setting, leading to a surge in made-to-order options that allow customers to blend ingredients from different cultures.

In the realm of fast food, made-to-order cuisine has even started to challenge the traditional model. Fast-casual restaurants have emerged, offering a balance between the convenience of fast food and the quality and customization of sit-down dining. These establishments allow customers to choose their ingredients, cook their food to their desired level of doneness, and even select the type of sauce or dressing they prefer.

The rise of made-to-order cuisine has also had a significant impact on the food industry itself. Chefs and culinary professionals are now expected to be more adaptable and innovative, as they must cater to a diverse array of preferences and dietary needs. This has led to a more dynamic and creative approach to menu development and kitchen operations.

Moreover, the made-to-order trend has sparked a renewed interest in local and seasonal ingredients. As consumers demand more transparency in their food, they are increasingly interested in knowing where their food comes from and how it is prepared. This has encouraged restaurants and foodservice providers to source locally and offer menus that change with the seasons, providing fresh, sustainable, and healthful options.

In conclusion, the rise of made-to-order cuisine is a testament to the evolving food landscape. It reflects a consumer-driven market that values personalization, flexibility, and health. As this trend continues to grow, we can expect to see even more innovative dining experiences that cater to the unique tastes and needs of each individual.

The Role of the Made-to-Order Factory

In today’s fast-paced world, the demand for personalized experiences has never been higher, and this extends to the culinary realm as well. The rise of made-to-order cuisine has transformed the way we think about food, and at the heart of this transformation lies the made-to-order factory. These specialized facilities play a pivotal role in shaping the landscape of modern dining.

The made-to-order factory is a hub of precision and customization, where each dish is crafted with the individual preferences of the customer in mind. These factories are designed to cater to a diverse range of tastes and dietary requirements, ensuring that every meal is a unique and satisfying experience. They are not just about producing food; they are about creating stories through food.

One of the key functions of a made-to-order factory is to maintain consistency in quality. With a focus on freshness and hygiene, these factories adhere to stringent standards that guarantee each dish is not only delicious but also safe to consume. From the moment ingredients are sourced to the final plating, every step is meticulously controlled to ensure the highest level of quality.

In these factories, technology and innovation go hand in hand. Advanced machinery and software systems are used to streamline the production process, from inventory management to order processing. This not only enhances efficiency but also allows for real-time tracking of orders, ensuring that customers receive their meals promptly.

The made-to-order factory also serves as a testing ground for new and innovative food concepts. Chefs and culinary experts collaborate in these environments to develop unique recipes and flavor combinations that can be scaled up for mass production. This dynamic atmosphere fosters creativity and encourages the exploration of new culinary frontiers.

Customization is at the core of the made-to-order factory’s mission. Customers have the power to dictate exactly what they want in their meals, from the type of protein to the inclusion of specific spices or herbs. This level of personalization is not just a luxury; it’s a necessity for many who seek to align their dietary choices with their health and lifestyle goals.

Moreover, made-to-order factories often prioritize sustainability. They source locally and use organic, non-GMO ingredients, reducing the carbon footprint associated with long-distance transportation. This commitment to sustainability not only benefits the environment but also supports local farmers and businesses.

The made-to-order factory also plays a crucial role in the supply chain. By centralizing the production of made-to-order meals, these factories can serve multiple outlets, such as restaurants, cafes, and even hospitals and schools. This centralized approach minimizes waste and ensures that each location receives the same high-quality product.

Training and education are integral parts of the made-to-order factory’s operations. Employees are constantly trained on food safety, hygiene, and the latest culinary techniques. This investment in human capital ensures that the factory can adapt to changing trends and customer demands.

In addition to food production, made-to-order factories often offer value-added services. They may provide packaging solutions, meal prep services, and even catering for events. This versatility allows them to cater to a wide range of needs, from individual orders to large-scale events.

The made-to-order factory has also become a beacon for the foodservice industry, setting new standards for efficiency, quality, and customer satisfaction. By embracing technology, focusing on customization, and prioritizing sustainability, these factories are not just meeting the needs of today’s consumers but also preparing for the future.

In the world of made-to-order cuisine, the factory is the unsung hero. It’s where dreams are turned into dishes, and where the art of cooking meets the science of mass production. As the demand for personalized, high-quality food continues to grow, the role of the made-to-order factory is only set to become more significant, shaping the way we eat and the way we think about food.

Understanding Contact Grills in a Factory Setting

In a factory setting, contact grills play a pivotal role in the production of high-quality, customized cooking appliances. These grills, designed for both commercial and residential use, are crafted with precision and efficiency, reflecting the evolving demands of the culinary world.

The manufacturing process begins with the selection of durable materials, ensuring that the contact grills can withstand the rigors of consistent use. Aluminum and stainless steel are commonly used for their heat conductivity and longevity, making them ideal for grilling a variety of foods.

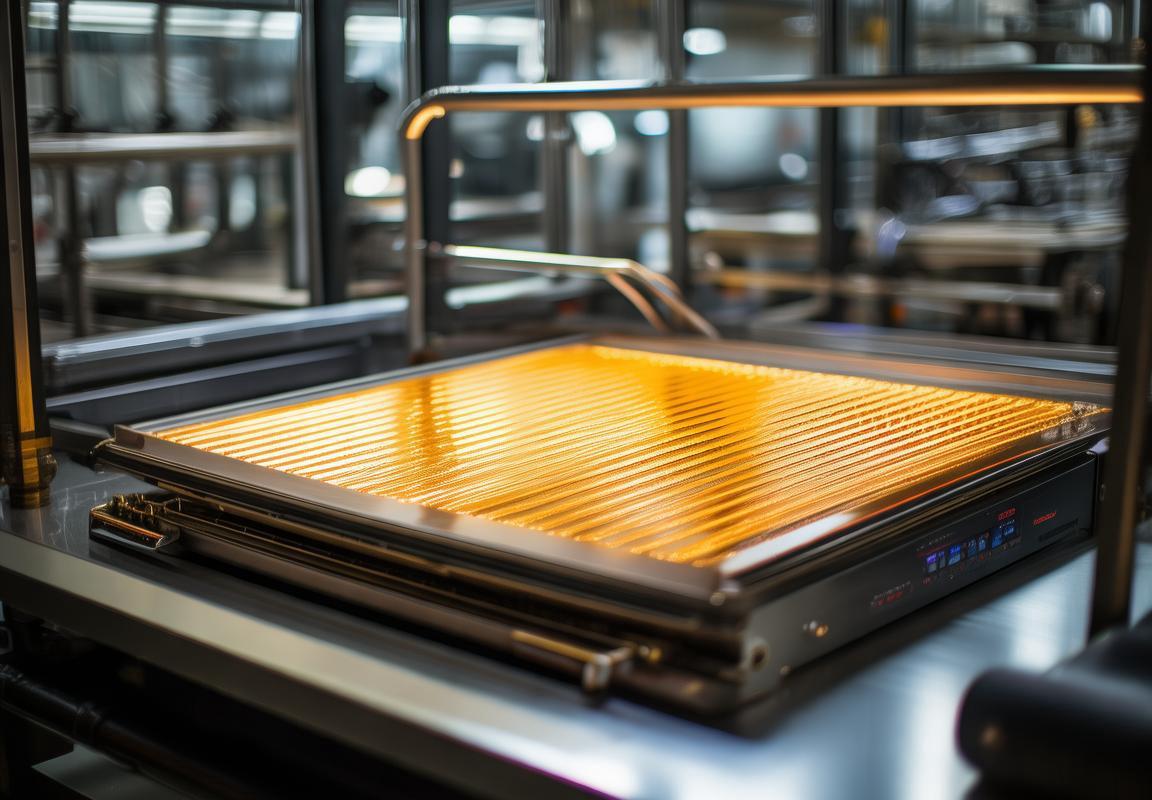

Once the materials are chosen, the components of the contact grill are meticulously assembled. This includes the heating elements, which are strategically placed to distribute heat evenly across the grill surface. The design of these elements is crucial, as they must maintain a consistent temperature to achieve the perfect sear on meats, vegetables, and other grillables.

In a factory setting, each step of the assembly process is carefully monitored. Workers, often trained in the art of grill construction, ensure that every part is correctly aligned and securely fastened. This attention to detail is what sets factory-made contact grills apart from those found in retail stores, where the quality control might not be as stringent.

The manufacturing environment is also equipped with state-of-the-art testing equipment. These tools allow for the assessment of the grill’s performance, including its heat distribution, temperature accuracy, and durability. For instance, thermal imaging cameras can detect any hotspots that might indicate an uneven heating issue, while stress tests can ensure the grill can handle prolonged use without failing.

In addition to the mechanical aspects, the aesthetics of the contact grill are also taken into account. The factory employs skilled painters and decorators who apply high-quality finishes to the grills, ensuring that they not only perform well but also look attractive. This is particularly important for commercial kitchens where the appearance of the equipment can impact the overall dining experience.

Safety is another critical factor in the factory setting. Contact grills are designed with safety features such as automatic shut-off mechanisms, which activate if the grill is left unattended for an extended period. This is a standard practice in industrial settings, where the potential for accidents is higher due to the continuous operation of machinery.

The factory also focuses on sustainability. Many contact grills are now made with eco-friendly materials and designed for energy efficiency. This not only benefits the environment but also reduces operating costs for consumers and businesses alike.

Customization is also a key aspect of contact grill production in a factory setting. Many customers have specific requirements, whether it’s a particular size, shape, or additional features like built-in thermometers or digital controls. Factories are equipped to handle these requests, often through a modular design that allows for easy swapping of parts or the addition of new components.

Lastly, the quality assurance team plays a crucial role in the factory. They inspect each grill at various stages of production, ensuring that all safety and performance standards are met. This rigorous quality control process guarantees that every contact grill leaving the factory is up to the highest industry standards.

In summary, the role of the made-to-order factory in contact grill production is multifaceted. It encompasses the careful selection of materials, precise assembly, rigorous testing, aesthetic design, safety compliance, sustainability considerations, customization capabilities, and thorough quality assurance. This comprehensive approach ensures that contact grills are not just reliable cooking tools but also a testament to the craftsmanship and innovation of modern manufacturing.

Benefits of Factory-Made Contact Grills

In a factory setting, contact grills have become a cornerstone of efficient and precise cooking technology. These versatile cooking appliances are designed to distribute heat evenly across their surfaces, ensuring that food is cooked to perfection. Let’s delve into the benefits that factory-made contact grills bring to the table.

Precision and ConsistencyFactory-made contact grills are engineered with precision, ensuring that every unit maintains consistent heat distribution. This uniformity is crucial for achieving consistent results, whether you’re grilling burgers, steaks, or vegetables. The meticulously calibrated heating elements guarantee that each piece of food receives the same level of heat, eliminating the guesswork that comes with traditional grilling methods.

Ease of UseOne of the standout benefits of factory-made contact grills is their user-friendliness. These appliances are designed with intuitive controls and features that make them accessible to both seasoned chefs and novices. The simple interface allows users to easily adjust the temperature, control the cooking time, and even lock in the perfect sear. This ease of use means that anyone can enjoy restaurant-quality grilling at home.

Durability and LongevityThe manufacturing process of contact grills is designed to produce a product that withstands the test of time. High-quality materials and robust construction ensure that these grills are built to last. From the stainless steel surfaces that resist corrosion to the durable hinges and hinges that withstand repeated use, factory-made contact grills are engineered to be a long-term investment. This durability not only saves money in the long run but also reduces the frequency of repairs or replacements.

Customization and VersatilityIn a factory setting, contact grills can be customized to meet specific needs. Whether it’s a smaller model for personal use or a larger one for commercial kitchens, the ability to tailor the grill to your requirements is a significant benefit. Additionally, many factory-made contact grills come with removable surfaces, allowing for easy cleaning and the option to switch between different cooking surfaces, such as cast iron, non-stick, or ceramic.

Efficiency and Energy SavingsContact grills are known for their efficiency. By cooking food quickly and evenly, these appliances reduce the amount of time and energy required to prepare a meal. Factory-made grills are designed to optimize heat transfer, which means less energy is wasted compared to traditional grilling methods. This efficiency not only saves on energy bills but also contributes to a more sustainable kitchen environment.

Safety FeaturesSafety is a top priority in factory-made contact grills. These appliances are equipped with various safety features, such as automatic shut-off functions that activate if the grill is left unattended for too long. Additionally, the non-slip feet and cool-to-the-touch handles ensure that the grill remains stable and safe to use. These safety features are especially important in busy commercial kitchens where accidents can happen.

Reduced Cleanup TimeCleaning up after grilling can be a daunting task, but factory-made contact grills simplify the process. Many models come with non-stick surfaces that make it easier to release food and reduce the need for excessive scraping. The flat surfaces of contact grills also make them easier to clean than traditional grills, which often have uneven surfaces that trap food particles. This reduction in cleanup time is a significant benefit for both home cooks and professional chefs.

Enhanced Cooking CapabilitiesContact grills offer a range of cooking capabilities that traditional grills cannot match. They can sear food to perfection, lock in flavors, and provide a consistent texture. The ability to grill, sauté, and even toast in one appliance is a game-changer for those looking to expand their culinary skills at home. Factory-made contact grills often come with adjustable temperature settings and features like adjustable grids, allowing for a variety of cooking techniques.

Innovation and Continuous ImprovementFactory-made contact grills benefit from continuous innovation. Manufacturers are constantly looking for ways to improve their products, whether it’s through new materials, more efficient heating elements, or additional features. This commitment to innovation ensures that users always have access to the latest technology and improvements in cooking appliances.

In conclusion, factory-made contact grills offer a multitude of benefits that enhance both the cooking experience and the efficiency of kitchen operations. From their precision and ease of use to their durability and safety features, these appliances are a testament to the power of modern manufacturing in creating tools that make life in the kitchen just a little bit easier and more enjoyable.

The Process of Manufacturing Contact Grills

The manufacturing process of contact grills involves several meticulous steps, each contributing to the creation of a high-quality, durable cooking appliance. From the initial design to the final assembly, here’s an intricate look at how these grills come to life.

Design and PrototypingThe journey begins with the creation of detailed designs for the contact grill. Engineers and designers collaborate to determine the grill’s size, shape, features, and materials. These designs are then translated into prototypes, often using 3D printing technology, to visualize and test the grill’s functionality before mass production.

Material SelectionOnce the design is finalized, the selection of materials is crucial. High-grade stainless steel is commonly used for its heat resistance and durability. Aluminum is often chosen for its lightweight properties. Other components, such as hinges, springs, and control panels, are selected for their specific functions and compatibility with the overall design.

Cutting and ShapingThe chosen materials are then cut to size using precision cutting machines. This step ensures that all parts are uniform and fit together correctly. The metal sheets are shaped into the grill’s body, lid, and cooking surfaces. Complex parts, like the hinges and handles, are also formed at this stage.

Welding and AssemblyAfter the parts are cut and shaped, they are (welded) together. Welding experts use various techniques, such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas), to join the metal pieces securely. The welding process must be precise to avoid weak spots or leaks.

Precision MachiningSome components require precision machining to ensure they fit perfectly within the grill’s framework. This includes the insertion of screws, bolts, and other fasteners. Specialized machines are used to bore holes, cut grooves, and create intricate designs that enhance the grill’s performance and aesthetics.

Surface FinishingOnce the structure is assembled, the surface finishing process begins. This can involve polishing, sanding, or applying a protective coating to the exterior. Polishing brings out the shine of the stainless steel, while protective coatings help prevent corrosion and extend the grill’s lifespan.

Electrical ComponentsContact grills often come with electrical elements such as heating elements, timers, and temperature controls. These components are carefully installed and connected within the grill’s casing. Electricians ensure that all wiring is secure and that the electrical system operates safely and efficiently.

Final AssemblyWith all the mechanical and electrical components in place, the final assembly of the contact grill begins. This involves placing the cooking surface, lid, and other parts into the casing and securing them. It’s a delicate process that requires precision to ensure the grill’s structural integrity and functionality.

Quality ControlThroughout the manufacturing process, quality control is paramount. Workers inspect each component and assembly to ensure they meet the specified standards. This includes checking for any defects, such as dents, scratches, or loose connections. Only once everything passes inspection does the grill move to the next stage.

Packaging and ShippingOnce the contact grill is fully assembled and passes all quality checks, it is prepared for packaging. This typically involves placing the grill in a protective foam-lined box, securing it with packaging tape, and affixing shipping labels. The grill is then transported to distribution centers or directly to retailers.

Customer DeliveryFinally, the contact grill is delivered to the customer. This could be through retail stores, online marketplaces, or direct-to-consumer shipping. The grill’s journey from raw materials to a fully functional cooking appliance is complete, and the consumer can now enjoy the benefits of a factory-made contact grill in their own kitchen.

Quality Control in Made-to-Order Factories

In a world where precision and consistency are paramount, the role of quality control in made-to-order factories is invaluable. Each stage of the production process is meticulously monitored to ensure that every product meets the highest standards. Here’s a glimpse into the intricate world of quality control within these specialized manufacturing environments.

The meticulous inspection of raw materials begins the journey. Suppliers must meet stringent criteria to be approved, and the incoming materials are thoroughly examined for any signs of defects or inconsistencies. This initial assessment sets the tone for the entire production cycle, ensuring that the foundation of every contact grill is strong and reliable.

Once the materials are deemed fit for use, they move to the assembly line. Skilled technicians handle each component with care, following detailed guidelines to ensure precise fitting and alignment. This hands-on approach to assembly is crucial, as it prevents errors that could compromise the performance or safety of the final product.

As the contact grill starts to take shape, automated inspection systems come into play. High-speed cameras and sensors are used to scan each part for any imperfections, such as burrs, scratches, or misalignments. These systems can detect issues that the human eye might miss, providing an extra layer of assurance that the product meets the factory’s high standards.

Throughout the manufacturing process, random samples are pulled for further testing. These samples are subjected to a range of stress tests, including heat resistance, durability, and safety checks. For example, the contact grill’s heating elements are tested to ensure they can maintain consistent temperatures without overheating or failing. These tests mimic real-world conditions to guarantee that the product can withstand the demands of everyday use.

One key aspect of quality control in made-to-order factories is the adherence to industry standards and certifications. Many factories must comply with various international regulations, such as those set by the Underwriters Laboratories (UL) or the European Union’s CE marking. These certifications require ongoing audits and assessments to maintain compliance, pushing the factory to continuously improve its processes.

In the realm of made-to-order factories, quality control also involves a deep understanding of customer expectations. Feedback from previous orders is used to refine production techniques and materials. If a particular batch of contact grills had a higher than usual return rate due to a specific issue, the factory would analyze the data to identify the root cause and implement corrective actions.

The importance of training cannot be overstated. Employees at made-to-order factories undergo rigorous training to understand the intricacies of the manufacturing process and the importance of quality control. This training includes not only technical skills but also a mindset that emphasizes attention to detail and a commitment to excellence.

Moreover, the implementation of a robust quality control system allows for quick response to any issues that arise. If a defect is detected, the process can be halted immediately, and the affected parts or products can be corrected or removed from the inventory. This proactive approach minimizes the risk of defective products reaching the consumer and maintains the factory’s reputation for reliability.

Another critical aspect of quality control is the traceability of products. Each contact grill is assigned a unique identification number that tracks its journey from raw materials to finished product. This traceability ensures that if a batch of grills were to fail a quality test, the entire batch could be quickly identified and addressed, preventing any potential issues from escalating.

As the contact grill approaches the final stages of production, it undergoes a series of functional tests. These tests are designed to simulate real-world cooking scenarios, ensuring that the grill operates as intended and meets the performance standards set by the manufacturer. Only once these tests are passed does the product move forward to packaging.

Finally, before shipping, each contact grill is packaged with care, using materials and methods that protect the product during transit. The packaging itself is also inspected to ensure it meets the required specifications and can withstand the rigors of shipping.

In summary, quality control in made-to-order factories is a multifaceted process that encompasses every stage of the manufacturing cycle. From the careful selection of raw materials to the final packaging, every step is scrutinized to ensure that the contact grill leaving the factory is not just a product, but a testament to the dedication to excellence in craftsmanship.

Customization Options for Contact Grills

In the realm of kitchen appliances, contact grills have become a staple for many households. These versatile cooking tools not only offer the convenience of quick and even heat distribution but also provide the unique char-grilled flavor that many home chefs crave. When it comes to these grills, the options for customization can be as diverse as the meals they prepare.

Manufacturers understand that not every kitchen is the same, and not every chef has the same taste or cooking style. This is where the ability to customize contact grills comes into play. Here are some of the ways in which these appliances can be tailored to suit individual preferences:

-

Size and ShapeThe size of a contact grill can make a significant difference in how much food it can cook at once. Whether you’re a solo cook or hosting a crowd, there are options to fit various needs. From compact models that can sit on a countertop to larger units that can accommodate a whole family’s meal, the size and shape of the grill can be chosen based on the space available and the quantity of food being prepared.

-

Material ChoicesThe materials used in the construction of a contact grill not only affect its durability but also its aesthetic appeal. From stainless steel to cast aluminum, there’s a range of materials that can be selected to match the kitchen decor or the cook’s preference for non-stick surfaces that reduce the need for grease and make cleaning easier.

-

Control FeaturesMany contact grills come with adjustable heat controls, allowing users to set the temperature to their desired level. Some models offer precise temperature settings, while others might have a simple on/off switch. The choice of control features can cater to those who prefer the simplicity of a single switch or the precision of a digital thermostat.

-

Plate DesignThe design of the grill plates is crucial for even cooking and the formation of those coveted grill marks. Some users might prefer flat plates for straightforward searing, while others might opt for grooved plates to add texture and promote more even heat distribution. Some models even offer reversible plates with different patterns to cater to various cooking techniques.

-

Additional FeaturesCustomization can also extend to additional features that enhance the cooking experience. These might include non-stick coatings that make cleanup a breeze, indicator lights that alert users when the grill is at the optimal temperature, or even built-in timers that help ensure food is cooked to perfection.

-

Safety and ConvenienceFor those who value safety and convenience, customization options can also include features like cool-touch handles to prevent accidental burns, safety interlocks to prevent operation with the lid open, and easy-to-use controls that can be adjusted with a simple turn or push of a button.

-

Style and DesignFinally, the style and design of a contact grill can be a reflection of the cook’s personality. With various colors, finishes, and even decorative trim, a contact grill can be a statement piece in the kitchen. Some brands even offer custom engravings or unique design elements that make their appliances stand out.

By offering these customization options, manufacturers ensure that contact grills can be as personal as the meals they are used to prepare. Whether it’s the size, material, control features, or additional conveniences, the ability to choose what best fits one’s needs and preferences is a testament to the evolving nature of kitchen appliances and the importance of catered solutions in modern homes.

The Impact on the Market and Consumers

In today’s fast-paced world, the demand for personalized and high-quality products has surged. The rise of made-to-order factories has significantly impacted the market and consumers, reshaping expectations and offering unparalleled convenience. Here’s a closer look at how this shift has influenced both sectors.

The market has witnessed a shift from mass production to customized solutions, with contact grills being at the forefront of this transformation. Consumers now have the power to choose the features, sizes, and specifications that best suit their needs, leading to a more diverse and tailored product range.

Manufacturers have responded by investing in advanced technology and skilled labor to cater to these diverse demands. The result is a market that’s more competitive, with brands constantly innovating to offer unique selling points. This competition has not only driven innovation but has also led to more affordable options for consumers.

For consumers, the impact has been profound. The ability to order contact grills according to personal preferences has enhanced their cooking experience. Whether it’s the size of the grill, the type of material, or the additional features like adjustable heat settings, consumers now have a say in the products they purchase.

The market has also seen an increase in eco-friendly options, with more consumers opting for sustainable materials and energy-efficient designs. This trend has not only benefited the environment but has also opened up new avenues for manufacturers to create greener products.

Moreover, the rise of made-to-order factories has led to a more transparent supply chain. Consumers can now trace the origin of their products, ensuring that they are getting quality items that align with their values. This transparency has also helped in reducing fraud and ensuring that consumers are getting what they pay for.

The convenience factor cannot be overstated. Made-to-order factories have made it possible for consumers to place orders online and have them delivered to their doorstep. This shift has saved time and effort, allowing people to focus on other aspects of their lives.

From a business perspective, made-to-order factories have helped companies reduce inventory costs. By producing items only when orders are placed, manufacturers can minimize the risk of overstocking and the subsequent waste of resources.

The impact on consumers is equally significant. With made-to-order contact grills, they now have the flexibility to experiment with different cooking styles and techniques. This has opened up a world of possibilities, from grilling vegetables with a specific type of grill to cooking delicate meats with precision controls.

Another effect on the market is the rise of niche markets. As consumers demand more specialized products, manufacturers have created tailored solutions for specific demographics. This has led to a more fragmented market, but it has also allowed for more focused marketing strategies.

In the realm of customer service, made-to-order factories have set new standards. With the ability to customize products, manufacturers are more likely to provide exceptional customer service to ensure customer satisfaction. This has led to a more customer-centric approach in the industry.

The market has also seen an increase in educational resources and tutorials. As consumers embrace the world of made-to-order contact grills, there’s a growing need for information on how to use these products effectively. This educational push has not only helped consumers but has also driven demand for higher-quality grills.

The rise of made-to-order factories has also had a positive impact on the economy. By creating jobs in manufacturing and logistics, these factories have contributed to economic growth. Additionally, the increased demand for customized products has spurred innovation in related industries, such as materials science and design.

In conclusion, the impact of made-to-order factories on the market and consumers is multifaceted. It has led to a more diverse and competitive market, offering consumers unparalleled convenience and choice. The shift towards customization has also brought about a more sustainable and transparent industry, benefiting both the planet and the people.

Conclusion: The Future of Contact Grill Manufacturing

The evolution of technology has significantly transformed the landscape of manufacturing, and contact grill production is no exception. As the demand for personalized and high-quality grilling solutions continues to grow, the role of made-to-order factories in shaping the future of contact grill manufacturing becomes increasingly pivotal. This concludes our exploration of the intricate process and its impact on the market and consumers, leading us to ponder the future trajectory of this industry.

The rise of made-to-order factories has allowed for a more tailored approach to manufacturing, where each contact grill is crafted to meet specific customer needs. This shift has not only enhanced the user experience but has also opened up new opportunities for innovation and efficiency in the production process. The market has responded positively, with consumers seeking out these customized grills for their unique features and superior performance.

One of the key benefits of made-to-order factories is the ability to cater to niche markets. By specializing in certain grill designs, materials, or functionalities, these factories can cater to a broader range of consumers, including those with specific dietary preferences or those living in areas with limited access to traditional grilling equipment. This niche focus can lead to higher customer satisfaction and loyalty, as well as the potential for increased market share.

The market impact of factory-made contact grills is profound. With the ability to produce grills that are both efficient and adaptable to various cooking styles, these products have become a staple in many households. The convenience and versatility of these grills have also contributed to a rise in outdoor cooking enthusiasts, leading to a surge in demand for quality grilling accessories and supplies.

Consumers, too, have seen a direct benefit from the made-to-order approach. With the ability to customize their grills, they can enjoy a more personalized cooking experience. Whether it’s the size, material, or even the specific features, such as temperature control or non-stick surfaces, the level of personalization has set new standards in the industry. This shift has not only improved user satisfaction but has also encouraged consumers to invest more in their outdoor cooking setups.

As for the future, it’s clear that the made-to-order factory model will continue to influence the direction of contact grill manufacturing. The integration of advanced technology, such as AI and robotics, could further streamline the production process, ensuring that each grill is not only customized but also produced with precision and efficiency.

Innovation in materials will also play a crucial role. As sustainability becomes a more pressing concern, factories may turn to eco-friendly and durable materials that can withstand the rigors of outdoor use. This could lead to a more sustainable approach to manufacturing, reducing waste and environmental impact.

Moreover, the rise of smart appliances has paved the way for contact grills that can be controlled remotely, offering users the convenience of monitoring and adjusting their cooking temperatures from the comfort of their homes. This integration of smart technology is likely to become more prevalent, enhancing the user experience and opening up new possibilities for grill design.

The competitive landscape is also set to evolve. As more factories embrace the made-to-order model, there will be a heightened focus on differentiation through quality, innovation, and customer service. This competition will drive further improvements in manufacturing processes and product offerings, ultimately benefiting both the market and consumers.

In conclusion, the future of contact grill manufacturing lies in a perfect blend of customization, technology, and sustainability. Made-to-order factories will continue to shape this industry, offering consumers a wide array of options that cater to their unique tastes and preferences. As the market adapts to these changes, we can expect to see a more dynamic and responsive grill manufacturing sector that not only meets the needs of today’s consumers but also prepares for the challenges and opportunities of tomorrow.