In the bustling world of food production, the waffle iron plant stands as a testament to the art of consistency and efficiency. These specialized facilities are the unsung heroes behind the perfect waffle, ensuring that from farm to table, every bite is a delightful experience. Today, we delve into the intricacies of continuous operation waffle iron plants, exploring how they shape the future of this beloved breakfast staple.

The Joy of Continuous Operation: A Waffle Iron Plant Unveiled

The relentless rhythm of the machinery echoes through the vast factory floor. Here, in the heart of the waffle iron plant, the joy of continuous operation is palpable. Imagine a world where waffles are produced not in batches, but in a seamless, uninterrupted stream. This is the reality of a continuous operation waffle iron plant, a marvel of modern food manufacturing that brings a smile to the faces of both producers and consumers alike.

The plant is a symphony of precision, with each machine working in harmony to create the perfect waffle. The waffle irons are arranged in a long, linear row, each one a testament to engineering excellence. They are heated to a consistent temperature, ensuring that every waffle that comes off the line is as golden and crisp as the last.

The process begins with the dough, a mixture of flour, water, yeast, and sugar, which is gently mixed in a large hopper. This dough is then piped into the molds of the waffle irons at a steady pace, thanks to a sophisticated conveyance system. The dough is spread evenly across the surface of the iron, which is already at the optimal temperature for waffle-making.

As the dough hits the hot surface, it begins to bubble and steam, the scent of fresh-baked waffles filling the air. The iron’s surface is coated with a non-stick material, allowing the waffle to release smoothly and without sticking. The waffle irons are designed to cook each waffle in a matter of seconds, ensuring that the product remains hot and crisp until it reaches the packaging area.

The joy of continuous operation is evident in the efficiency of the system. Unlike traditional methods that require frequent stops for cleaning and maintenance, this plant operates 24⁄7, producing thousands of waffles every hour. The streamlined process minimizes waste and maximizes output, a win-win situation for the company and the consumer.

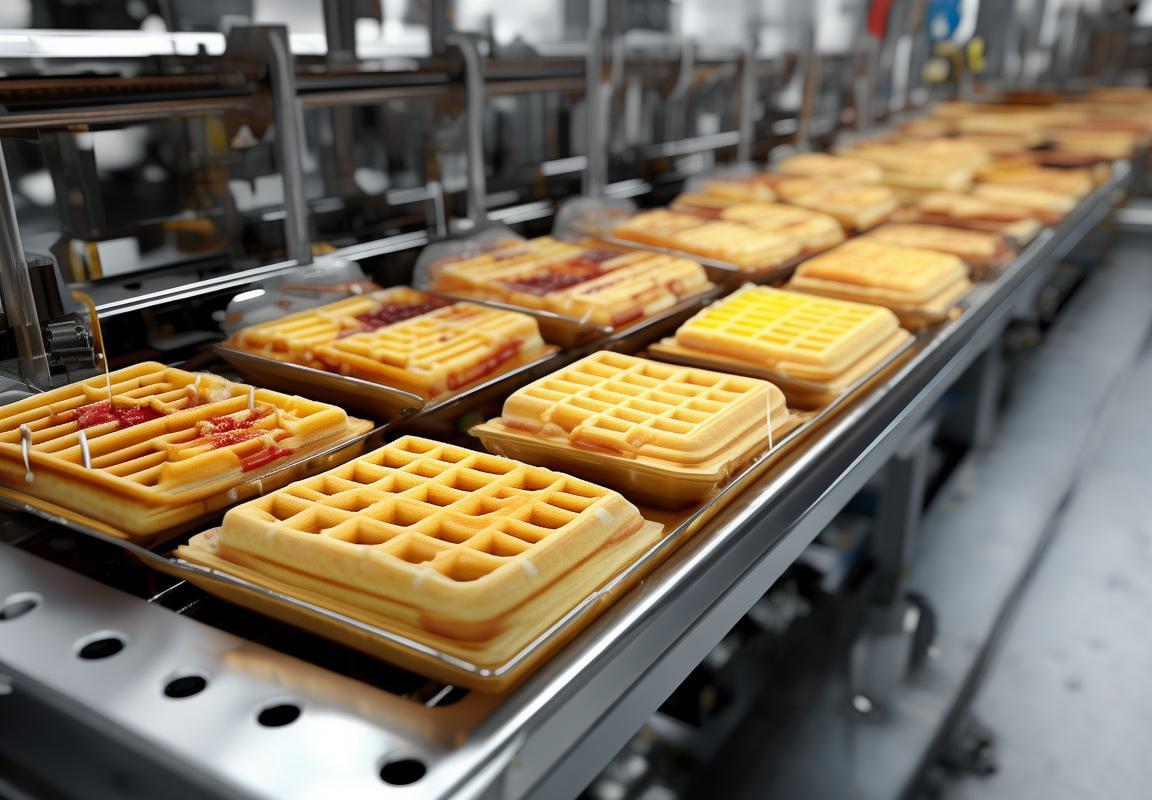

The conveyance system is a marvel in itself. It moves the freshly cooked waffles from the iron to the cooling conveyor, where they are allowed to cool slightly before being packaged. This cooling process is crucial, as it prevents the waffles from becoming soggy and ensures they maintain their structural integrity.

The packaging area is equally impressive. The waffles are placed into airtight bags, which are then sealed with heat to prevent spoilage. The packaging process is automated, with each bag being checked for quality before being placed on a pallet. This high level of automation not only speeds up the process but also reduces the potential for human error.

One of the key advantages of a continuous operation waffle iron plant is the consistency of the product. Each waffle is identical to the last, thanks to the precision engineering of the plant. This consistency is important for brand image and customer satisfaction, as consumers can rely on the same quality every time they purchase a product from this plant.

In addition to efficiency and consistency, the plant also prioritizes safety. The machinery is equipped with advanced safety features, such as emergency stop buttons and safety guards, to prevent accidents. The plant is also regularly inspected to ensure compliance with health and safety regulations.

The joy of continuous operation extends beyond the factory floor. For the company, it means increased productivity and profitability. For the consumer, it means a steady supply of high-quality waffles, available at their local store or whenever they desire.

The continuous operation waffle iron plant is a testament to human ingenuity and the relentless pursuit of perfection. It’s a place where the joy of producing a perfect waffle meets the satisfaction of meeting a growing demand. As the world becomes more fast-paced, the need for efficient, reliable, and high-quality food production becomes ever more critical. And in this pursuit, the continuous operation waffle iron plant stands as a shining example of what can be achieved when technology, engineering, and dedication come together.

The Heart of the Waffle: How a Continuous Operation Waffle Iron Plant Works

In the heart of a modern waffle iron plant, the essence of continuous operation lies in the seamless flow of production. The machinery is designed to operate 24⁄7, ensuring a steady supply of fresh, golden waffles. The process begins with the selection and preparation of high-quality ingredients, each meticulously measured and mixed to achieve the perfect consistency.

The batter is then pumped into the waffle iron, where it is spread evenly across the heated plates. These plates are designed with intricate patterns that define the classic waffle shape. As the batter hits the hot surface, steam rises, causing it to expand and rise within the grooves. The steam pressure is carefully controlled to ensure that the waffles achieve the desired crispness without becoming too tough.

The waffle iron is equipped with sensors that monitor the temperature and timing, guaranteeing consistency in every batch. Once the waffle reaches the perfect level of browning, the iron opens automatically, allowing the freshly cooked waffle to drop onto a conveyor belt. This belt moves through the cooling area, where the waffles are cooled to room temperature to maintain their texture and flavor.

The cooled waffles are then sorted and packaged, with automated systems ensuring that each product is sealed in its protective packaging. The packaging process is designed to protect the waffles from moisture and to maintain their freshness. It’s a delicate balance of temperature, pressure, and time that ensures the waffles remain delicious until they reach the consumer.

In the heart of the plant, the waffle irons are the stars of the show. They are built with precision engineering to handle the demands of continuous operation. The irons are constructed from durable materials that can withstand the heat and stress of constant use. They are also designed to be easily cleaned and maintained, which is crucial for the plant’s efficiency.

The waffle irons are often equipped with programmable controls that allow for adjustments in the cooking process. This flexibility is important for catering to different types of waffle recipes, from the traditional Belgian style to the more contemporary American version. The ability to tweak the settings means that the plant can cater to a variety of customer preferences and dietary needs.

The plant’s infrastructure is designed to support this level of continuous operation. The walls are insulated to maintain a consistent temperature, and the air is kept clean and dry to prevent any contamination of the waffles. The plant also has a sophisticated ventilation system to manage the heat generated by the cooking process, ensuring that the working environment remains comfortable for the staff.

The staff themselves are an integral part of the continuous operation. They are trained to operate the machinery with precision and to monitor the production line for any potential issues. The plant’s management team keeps a close eye on key performance indicators, such as the number of waffles produced per hour, the efficiency of the packaging process, and the overall quality of the product.

One of the key advantages of a continuous operation waffle iron plant is its scalability. The plant can easily increase or decrease production based on market demand. This is achieved through the use of modular systems that can be expanded or reconfigured as needed. Whether the plant is producing a few thousand waffles a day or tens of thousands, the machinery and processes are designed to maintain the same high level of quality and consistency.

The continuous operation also means that the plant can implement just-in-time inventory management. This approach minimizes waste and reduces costs by ensuring that ingredients and packaging materials are ordered only as needed. The plant’s logistics team works closely with suppliers to maintain a steady supply of raw materials, ensuring that the production line never stops.

In the end, the heart of the continuous operation waffle iron plant beats with the rhythm of efficiency and quality. From the moment the batter is mixed to the moment the waffles are packaged and shipped, every step is carefully controlled and monitored. The plant’s commitment to continuous operation ensures that consumers around the world can enjoy the joy of fresh, delicious waffles, delivered right to their tables.

Consistent Quality: The Benefits of a Waffle Iron Plant in Continuous Mode

In the realm of waffle production, consistency is king. A continuous operation waffle iron plant is designed to uphold the highest standards of quality, ensuring that every waffle that rolls off the line is a delight to the palate. Here’s how it achieves this:

The precision of the machinery is unparalleled. These plants are equipped with advanced technology that guarantees each waffle receives the same treatment throughout the production process. From the dough being evenly spread across the waffle iron to the precise timing of cooking, every detail is controlled with surgical precision.

One of the most significant benefits of operating in continuous mode is the elimination of batch variations. Traditional waffle production methods often see batches of waffles with slight differences in texture and appearance due to variations in the dough’s mixing, resting, and cooking times. In contrast, a continuous operation plant maintains a steady, uniform output, making it easier to maintain a consistent product.

Quality control is ingrained in the design of these plants. Sensors and automated systems constantly monitor the waffle iron’s temperature, the consistency of the batter, and the cooking time. This real-time monitoring ensures that any deviation from the set standards is quickly detected and corrected, ensuring that the end product meets the stringent quality criteria.

The use of high-quality ingredients is a non-negotiable in a continuous operation waffle iron plant. The plant is designed to handle a variety of ingredients, from traditional flour blends to gluten-free options, and it ensures that these ingredients are fresh and measured with precision. This commitment to quality is reflected in every waffle that is produced.

The even distribution of batter across the waffle iron is a key factor in consistent quality. These plants often employ a dosing system that precisely measures and dispenses the batter, ensuring that each waffle receives the right amount of liquid. This consistency is crucial for the waffle’s texture and prevents any undercooked or overcooked spots.

Another benefit is the ability to maintain consistent temperature throughout the production cycle. Fluctuations in temperature can greatly affect the final product, causing some waffles to be too hard while others are too soft. Continuous operation waffle iron plants are engineered to maintain a constant temperature, resulting in waffles with the perfect crispness.

The continuous nature of the plant also means that there is a consistent supply of fresh, hot waffles ready for consumption. Whether it’s for a breakfast buffet, a festival, or a busy café, this steady stream of quality waffles keeps customers satisfied and ensures that no one is left waiting for their treat.

In terms of appearance, the consistency is striking. Every waffle emerges from the iron with the same pattern, the same color, and the same overall presentation. This uniformity is not just aesthetically pleasing but also gives consumers a sense of trust in the product’s quality.

The efficiency of a continuous operation waffle iron plant also contributes to its ability to maintain quality. By reducing downtime and optimizing the production line, the plant can produce a higher volume of waffles with minimal waste. This efficiency means that the plant can quickly respond to fluctuations in demand, ensuring that quality is never compromised.

Lastly, the durability of the waffle irons themselves plays a role in consistency. These irons are built to withstand constant use, with materials that won’t degrade over time. This durability ensures that the waffle pattern remains consistent, and the iron performs as it should day in and day out.

In summary, the benefits of a continuous operation waffle iron plant in maintaining consistent quality are vast. From precise machinery and automated quality control to the use of high-quality ingredients and the ability to produce a steady stream of uniformly delicious waffles, these plants set the gold standard for waffle production. Whether for commercial use or for a home baker seeking to perfect their craft, the continuous operation waffle iron plant is the epitome of quality and reliability.

Efficiency at Its Best: Why Continuous Operation is Key for Waffle Iron Plants

Continuous operation in a waffle iron plant is not just a buzzword; it’s the backbone of a smooth, high-volume production process. Here’s why this non-stop mode is pivotal for such plants:

In a continuous operation waffle iron plant, the flow of production never stalls. The machinery is designed to run around the clock, ensuring a steady stream of waffles being made. This unyielding consistency in output is the first benefit that stands out.

The efficiency of a continuous operation is undeniable. By running non-stop, the plant minimizes downtime, which is crucial for maintaining a high output rate. Every second the machines are idle is a second that could have been spent producing waffles.

Maintaining a consistent flow in production also means that the plant can handle fluctuations in demand with ease. Whether there’s a surge in sales or a slower period, the continuous operation ensures that the production line can keep pace without interruption.

One of the most significant advantages of continuous operation is the reduction in labor costs. With machines running continuously, the need for constant human oversight is reduced. This allows the plant to optimize its workforce, focusing on maintenance and quality control tasks rather than the actual production process.

Another key aspect of continuous operation is the predictability it brings to inventory management. With a steady output, the plant can forecast its inventory needs more accurately, reducing waste and ensuring that raw materials are used efficiently.

Quality control in a continuous operation waffle iron plant is a breeze. The consistent flow of production allows for easier monitoring and adjustment of the process. Any deviations can be quickly identified and corrected, ensuring that every waffle meets the highest standards.

The continuous operation also fosters a culture of reliability and dependability. Customers can count on a steady supply of waffles, which builds trust and loyalty. Consistency in product quality and availability is a powerful tool in the competitive world of food manufacturing.

Energy efficiency is another area where continuous operation shines. By keeping the machinery running at a steady pace, the plant can take advantage of economies of scale in energy consumption. This often results in lower energy costs compared to plants that operate in batches.

Moreover, the continuous nature of the operation means that the machinery can be designed for long-term durability. High-quality components and maintenance schedules are tailored to handle the constant stress of production, leading to a longer lifespan for the equipment.

The automation involved in a continuous operation waffle iron plant also contributes to its efficiency. Automated systems can perform complex tasks with precision, reducing the margin for error and ensuring that every waffle is crafted to perfection.

Furthermore, the plant can integrate advanced technologies, such as IoT (Internet of Things) sensors, to monitor and optimize the production process in real-time. These sensors can detect issues before they become major problems, leading to even greater efficiency.

In the realm of sustainability, continuous operation waffle iron plants have a leg up. By minimizing waste and using resources efficiently, these plants are better positioned to reduce their environmental footprint. This is a crucial factor for businesses looking to align their practices with eco-friendly values.

Lastly, the scalability of a continuous operation waffle iron plant is unmatched. As the market grows, the plant can easily expand its production capacity without a significant overhaul of its infrastructure. This flexibility is essential for staying competitive in a rapidly evolving industry.

In conclusion, the continuous operation of a waffle iron plant is a game-changer. It brings efficiency, predictability, and quality to the production process, all while reducing costs and minimizing environmental impact. For any business looking to excel in the waffle market, embracing continuous operation is a strategic move that pays dividends in the long run.

Keeping Up with Demand: How a Continuous Operation Waffle Iron Plant Scales

In the bustling world of waffle production, the ability to keep up with demand is paramount. A continuous operation waffle iron plant is designed to do just that, scaling its output to meet the insatiable appetites of consumers. Here’s how it manages to maintain such a pace without compromising quality.

The heart of a continuous operation waffle iron plant lies in its ability to churn out waffles at a relentless pace. The machines are engineered to run 24⁄7, often with minimal downtime, ensuring that the production line never stops. This non-stop operation is possible due to several key factors that allow the plant to handle high volumes efficiently.

One of the most significant advantages is the streamlined process. Unlike batch production, where each batch of waffles is completed before the next begins, a continuous operation plant starts a new batch almost immediately after the previous one finishes. This seamless transition means there’s no lag time between production cycles, allowing for a steady flow of waffles.

The use of high-capacity machinery is another cornerstone of this efficiency. These machines are not just larger but also more robust, designed to handle the rigors of continuous use. They can produce multiple waffles at once, often in a synchronized pattern that maximizes output without overwhelming the plant’s resources.

Energy management is critical in such a setting. Continuous operation waffle iron plants are equipped with sophisticated systems that monitor and adjust energy consumption in real-time. This not only ensures that the plant operates within its energy budget but also reduces waste and lowers the carbon footprint.

Scalability is a defining feature of these plants. As demand for waffles grows, the plant can easily expand its production capacity. This scalability is achieved through modular design, allowing for additional units to be added without a complete overhaul of the existing system. It’s a cost-effective solution that keeps the plant flexible and responsive to market changes.

Moreover, the plant’s layout is meticulously planned to minimize bottlenecks. The flow of raw materials, the cooking process, and the cooling stages are all optimized to ensure that each waffle is produced as efficiently as possible. This includes automated systems for ingredient delivery, precise temperature control, and efficient cooling mechanisms that prevent overcooking.

The quality control in a continuous operation waffle iron plant is as rigorous as the production process itself. Quality assurance teams monitor the entire process, from the arrival of ingredients to the packaging of the final product. Advanced sensors and automated checks ensure that every waffle meets the highest standards of consistency and taste.

In the realm of labor, these plants are often staffed with skilled operators who are trained to manage the complex machinery. Their expertise is crucial in maintaining the plant’s efficiency. Additionally, the use of robotics and automation reduces the need for manual labor, freeing up human resources for more strategic tasks.

The continuous operation of a waffle iron plant also offers significant cost benefits. By minimizing downtime and maximizing production, the plant can achieve economies of scale that reduce the cost per unit. This cost-effectiveness is passed on to consumers, making high-quality waffles more accessible.

Furthermore, the flexibility of a continuous operation plant allows for the production of various waffle styles and flavors. The plant can quickly switch between different recipes and designs, catering to market trends and consumer preferences without interrupting the production line.

Lastly, the environmental impact of a continuous operation waffle iron plant is less pronounced compared to traditional methods. The efficient use of resources, combined with the plant’s ability to handle large volumes, means that the environmental footprint is spread out over a wider scale of production.

In summary, the scalability of a continuous operation waffle iron plant is a game-changer in the industry. It allows for the production of a vast number of waffles while maintaining consistent quality, all while being cost-effective, flexible, and environmentally friendly. As the world’s demand for waffles continues to rise, these plants are well-equipped to meet the challenge.

The Tech Behind the Scenes: Innovative Features of Modern Waffle Iron Plants

In the bustling heart of a modern waffle iron plant, technology plays a pivotal role in ensuring that every batch of waffles is as perfect as the last. From automated systems to precision controls, here’s a look at some of the innovative features that make these facilities tick.

The Automation RevolutionAutomation has transformed the waffle-making process, eliminating the need for manual labor and reducing the potential for human error. Modern plants are equipped with robotic arms and conveyors that move waffles through the production line with precision. These systems can work tirelessly around the clock, ensuring a consistent flow of products.

Precision ControlsOne of the key features of modern waffle iron plants is the use of advanced control systems. These systems monitor and adjust various aspects of the waffle-making process, from temperature to pressure, to guarantee the perfect waffle every time. Sensors and algorithms work in tandem to maintain the ideal conditions for waffle batter to be poured, cooked, and cooled efficiently.

Smart SensorsInside the heart of a waffle iron plant, smart sensors are everywhere. These devices monitor the performance of the equipment, alerting operators to any deviations from the desired specifications. Whether it’s the temperature of the waffle iron or the consistency of the batter, these sensors ensure that every waffle meets the highest quality standards.

Customizable RecipesEach waffle iron plant has the capability to store and recall a variety of recipes. This means that the same equipment can be used to produce different types of waffles, from classic Belgian to sweet and savory varieties. The technology allows for quick and easy adjustments, ensuring that the plant can meet diverse market demands without a lengthy downtime for retooling.

Energy EfficiencyEnergy consumption is a significant concern in any manufacturing setting, and waffle iron plants are no exception. Modern plants are designed with energy efficiency in mind, incorporating features like LED lighting, energy-saving motors, and intelligent heating systems. These technologies not only reduce operational costs but also minimize the plant’s environmental footprint.

Maintenance MonitoringRegular maintenance is crucial for the longevity and efficiency of waffle iron equipment. Advanced plants use predictive maintenance systems that analyze data from the machines to predict when maintenance is needed. This proactive approach prevents costly breakdowns and keeps the plant running smoothly.

User-Friendly InterfacesEven with all the high-tech gadgets, the operators of a waffle iron plant need to be able to manage the systems with ease. Modern plants are equipped with user-friendly interfaces that allow operators to monitor and control the production process without the need for extensive technical knowledge. These interfaces are designed to be intuitive, reducing the learning curve and increasing efficiency.

Customization and FlexibilityThe ability to customize and adapt to different product specifications is a hallmark of modern waffle iron plants. Whether it’s altering the shape, size, or texture of the waffles, these plants can do it all. The technology behind these facilities allows for rapid changes in production, making it possible to respond swiftly to market trends and customer preferences.

Quality AssuranceThroughout the production process, quality assurance is paramount. Modern waffle iron plants employ high-resolution cameras and advanced imaging systems to inspect each waffle for defects. These systems can identify issues like uneven cooking or missing patterns, ensuring that only the highest-quality products leave the facility.

Integration with Supply ChainTo keep up with demand, waffle iron plants must be integrated with a robust supply chain. Modern technology allows for real-time data sharing with suppliers, ensuring that raw materials are always available when needed. This integration also helps in managing inventory levels and reducing waste.

In conclusion, the technology behind modern waffle iron plants is a marvel of innovation. From automation and precision controls to energy efficiency and smart sensors, these plants are designed to produce high-quality waffles at a scale that can meet the demands of today’s market. The key to their success lies in their ability to adapt, respond quickly to changes, and maintain the highest standards of quality and efficiency.

From Farm to Table: The Role of Continuous Operation in the Waffle Industry

In the bustling world of the waffle industry, the journey from farm to table is a story of efficiency, innovation, and the relentless pursuit of quality. Continuous operation waffle iron plants play a pivotal role in this narrative, ensuring that every waffle that hits the consumer’s plate is a testament to the industry’s commitment to excellence.

The heart of a waffle iron plant, especially one that operates continuously, is its ability to churn out waffles at a steady, reliable pace. These facilities are equipped with advanced technology that not only maintains a consistent output but also ensures that each waffle is a uniform size and shape. This uniformity is crucial for brands looking to establish a recognizable product that stands out on the shelves.

Automated systems within these plants manage the entire process, from the mixing of batter to the baking of the waffles. High-speed mixers ensure that the batter is perfectly blended, with no lumps or inconsistencies. From there, the batter is piped onto the hot waffle iron plates, which are designed to bake the waffles quickly and evenly. The use of precision heating elements means that the waffles are golden brown and crispy on the outside, yet tender on the inside, every single time.

One of the most significant advantages of continuous operation is the scalability. As demand for waffles increases, these plants can easily adapt and expand their production lines. The modular design allows for additional units to be added without disrupting the existing workflow. This flexibility means that whether the market is in high gear or experiencing a lull, waffle iron plants can keep up with the rhythm of demand.

Moreover, the efficiency of continuous operation plants is not just about volume; it’s also about the quality control they maintain. By automating the process, these plants can enforce strict quality checks at every stage. Sensors and automated inspection systems can detect any irregularities in the waffles as they move through the production line, ensuring that only the highest quality products reach the consumer.

The role of continuous operation in the waffle industry also extends to sustainability. By optimizing the production process, these plants use less energy and reduce waste. The precise control over the cooking time means that the waffles are baked to perfection without any overcooking, which would otherwise lead to energy waste and a decrease in product shelf life.

From the farm, where high-quality wheat is harvested to produce the flour, to the table where consumers enjoy their waffles, every step is connected. Continuous operation waffle iron plants act as the bridge that connects these two ends of the supply chain. They source their ingredients from reliable suppliers who can provide consistent supplies of quality wheat, ensuring that the flour used is of the highest grade.

Once the flour is received, the plant’s systems are designed to handle large volumes with precision. The dough is then formed into waffles, which are then baked, cooled, and packaged. The packaging itself is a part of the continuous operation process, with automated systems that seal, label, and box the waffles at high speeds, ready for distribution.

The industry’s reliance on continuous operation waffle iron plants is also a reflection of the changing consumer landscape. Today’s consumers demand convenience and consistency, and these plants deliver. They can produce a vast array of waffle varieties, from classic Belgian to gourmet flavors, all within the same production line. This variety is a testament to the versatility of these plants, which can quickly adapt to new trends and market demands.

As the waffle industry continues to grow, so too does the importance of continuous operation plants. They are the backbone of the industry, providing the stability and reliability needed to meet the ever-increasing demand. Their role is not just in producing waffles but in shaping the future of the industry itself, ensuring that every waffle that crosses the threshold of a consumer’s home is a delicious reminder of the industry’s commitment to quality and innovation.

Safety First: Ensuring Reliable and Safe Continuous Operation

In the realm of waffle production, safety is paramount, and a reliable continuous operation is the cornerstone of a successful waffle iron plant. Ensuring that every aspect of the process is secure and efficient is not just about compliance with regulations; it’s about fostering a culture of safety that protects employees, products, and the reputation of the brand. Here’s a closer look at how continuous operation waffle iron plants prioritize safety:

The meticulous planning that underpins a continuous operation starts with the selection of the right equipment. Modern waffle iron plants are equipped with state-of-the-art machinery that is designed to minimize the risk of accidents. The machinery is built to withstand the rigors of constant use, with robust construction and high-quality materials that can endure years of production without compromising on safety.

Regular maintenance is a non-negotiable part of the continuous operation. The plant’s engineers and technicians perform routine checks on all equipment to ensure that they are in optimal working condition. This includes inspecting the electrical systems for any potential hazards, verifying the integrity of the waffle irons, and ensuring that all safety features are functioning correctly. By catching and addressing issues before they become problems, the plant avoids costly downtime and maintains a safe working environment.

Safety protocols are woven into the fabric of the continuous operation. Employees are trained on the latest safety procedures, from the correct use of personal protective equipment (PPE) to emergency response protocols. This training is not a one-time event but an ongoing process, with refresher courses and drills to keep everyone’s knowledge and readiness sharp. In the event of a malfunction or emergency, these protocols ensure that everyone knows exactly what to do to keep themselves and their colleagues safe.

The layout of a continuous operation waffle iron plant is designed with safety in mind. Wide aisles and clear signage facilitate the smooth flow of personnel and materials, reducing the likelihood of collisions. The placement of emergency exits and fire extinguishers is strategic, ensuring that they are easily accessible in case of an emergency. Additionally, the plant’s ventilation system is carefully designed to remove any harmful fumes or particles, maintaining a healthy air quality that supports the well-being of workers.

The integration of automation into the continuous operation of a waffle iron plant has also greatly enhanced safety. By automating repetitive tasks, the plant reduces the risk of human error, which can lead to accidents. Sensors and control systems monitor the production line, detecting anomalies and stopping the process before any damage can occur. This proactive approach to safety means that the plant can quickly identify and rectify issues, preventing potential hazards from escalating.

In the realm of continuous operation, the importance of safety cannot be overstated. The plant’s management recognizes that a safe workplace is not just about avoiding accidents; it’s about creating a culture where employees feel valued and secure. This culture is reflected in the attention to detail in every aspect of the plant’s operations.

Safety audits and compliance checks are conducted regularly to ensure that the plant adheres to the highest safety standards. These audits often involve third-party experts who provide an unbiased assessment of the plant’s safety measures. Any identified gaps are addressed promptly, reinforcing the plant’s commitment to safety.

In the waffle industry, the continuous operation is not just about production volume; it’s about producing those volumes with peace of mind. A waffle iron plant that prioritizes safety understands that reliable and safe operation go hand in hand. It’s a testament to the plant’s dedication to excellence, as it knows that a safe environment is the foundation for its success.

The role of management in ensuring continuous operation safety is pivotal. They set the tone for the entire organization, emphasizing that safety is everyone’s responsibility. This leadership is evident in the allocation of resources, the implementation of safety initiatives, and the communication of safety policies throughout the plant.

The continuous operation of a waffle iron plant is a complex process that requires a meticulous approach to safety. From the selection of equipment to the implementation of safety protocols, every step is carefully considered to protect both the workers and the product. In an industry where quality is king, a focus on safety is not just a legal requirement; it’s a commitment to excellence that resonates throughout the entire operation.

The Future of Waffles: What Continuous Operation Waffle Iron Plants Mean for Consumers

In the world of waffles, the introduction of continuous operation waffle iron plants has brought about a revolution, reshaping the way these beloved breakfast treats are produced and consumed. These state-of-the-art facilities not only streamline the manufacturing process but also hold the promise of a bright future for the waffle industry. Here’s a glimpse into what this shift means for consumers.

Continuous operation waffle iron plants are designed to run non-stop, producing waffles in a continuous stream. This mode of operation is a game-changer because it allows for consistent output, which is crucial in meeting the increasing demand for waffles. Consumers benefit from this in several ways:

-

Consistent Availability: With continuous operation, waffle irons can churn out waffles at a steady pace, ensuring that retailers and foodservice establishments can stock their shelves and menus with fresh, hot waffles at all times. This means that even during peak demand periods, consumers can find their favorite waffles whenever they desire.

-

Enhanced Quality Control: These plants are equipped with advanced quality control systems that monitor every stage of the waffle-making process. From the mixing of ingredients to the cooking of the waffles, each step is carefully managed to maintain the highest standards. This level of oversight ensures that every waffle that reaches the consumer meets the exacting quality standards expected.

-

Increased Variety: The efficiency of continuous operation allows manufacturers to experiment with different waffle recipes and designs more easily. Consumers can expect a wider variety of waffles, from classic Belgian to modern twists like chocolate chip, banana, or even savory flavors. This diversity caters to a broader range of tastes and preferences.

-

Reduced Costs: The automation and continuous flow of production in these plants lead to significant cost savings. By reducing labor and minimizing waste, these facilities can offer waffles at competitive prices. Consumers benefit from the affordability of this versatile breakfast staple.

-

Environmental Responsibility: Continuous operation waffle iron plants are designed with sustainability in mind. By using energy-efficient equipment and optimizing the use of resources, these plants help reduce the carbon footprint associated with waffle production. Consumers who are environmentally conscious can feel good about choosing waffles from these facilities.

-

Longevity and Durability: The high-tech machinery in these plants is built to last, ensuring that the production process remains reliable over the long term. This means that the waffles are not only consistent in quality but also in availability, as there is less downtime for maintenance or repairs.

-

Innovation in Packaging: As these plants scale up production, there is also an opportunity for innovation in packaging. New materials and designs that protect the waffles better and reduce waste are being developed. Consumers can look forward to convenient and eco-friendly packaging solutions.

-

Enhanced Flavor Profiles: The precision of continuous operation allows for better control over the cooking process, which can lead to more nuanced flavor profiles in the waffles. Consumers can enjoy waffles that are perfectly crisp on the outside and tender on the inside, with the full flavor of the ingredients shining through.

-

Global Reach: With the ability to produce large quantities of waffles, continuous operation plants can supply markets all over the world. This means that consumers in countries that may not have traditionally enjoyed waffles can now easily incorporate this delightful breakfast treat into their diets.

-

Personalization: The efficiency of continuous operation waffle iron plants also opens the door for personalization. Consumers could potentially have waffles made to their specific recipe and dietary preferences, right at the point of sale, thanks to on-site production capabilities.

The continuous operation of waffle iron plants represents a leap forward in the waffle industry, offering consumers a range of benefits from enhanced quality and variety to affordability and environmental responsibility. As these plants evolve, we can expect to see even more innovations that will shape the future of waffles and how we enjoy them.

The Bottom Line: Why Investing in a Continuous Operation Waffle Iron Plant Pays Off

Continuous operation waffle iron plants represent a significant leap forward in the production of those beloved breakfast treats. The benefits of such a system extend far beyond the mere output of waffles; they reshape the entire industry, offering a host of advantages that can be felt all the way from the factory floor to the consumer’s kitchen. Let’s delve into why this kind of investment is not just smart, but potentially revolutionary.

For starters, the very essence of a continuous operation waffle iron plant lies in its ability to churn out waffles at a pace that far outstrips traditional batch methods. This relentless, uninterrupted flow ensures a consistent supply of fresh, hot waffles, a must-have for businesses that aim to meet consumer demand without missing a beat. The scalability of such a plant is unparalleled; as demand grows, the plant can effortlessly increase production, maintaining quality and efficiency.

In the heart of these plants, the machinery is the silent workhorse. High-speed waffle irons are the backbone, capable of producing waffles in rapid succession. Advanced sensors and control systems manage the precise timing and temperature, ensuring that each waffle emerges with the perfect consistency in texture and color. This level of automation means that the human touch is reduced to the initial setup and occasional maintenance, freeing up labor for other tasks and minimizing the risk of human error.

One of the most compelling reasons to invest in a continuous operation waffle iron plant is the dramatic reduction in waste. Batch production often leads to overproduction and subsequent waste, as not all waffles can be sold within a short time frame. Continuous operation minimizes this issue, as the plant is tailored to produce the exact amount needed to fulfill orders, thereby cutting down on waste and reducing the environmental impact.

The quality of the waffles is another critical aspect. A continuous operation plant can maintain the same high standards throughout its production cycle. The consistency in temperature and pressure guarantees that each waffle will have the same delicious taste and appealing look, which is vital for brands looking to establish a reputation for excellence. This uniformity also means that customers can expect the same level of quality every time they purchase a waffle from a brand that uses such a plant.

Energy efficiency is a cornerstone of continuous operation waffle iron plants. By running the equipment non-stop, plants can optimize their energy usage, ensuring that waffles are produced using the least amount of energy possible. This not only cuts down on operational costs but also aligns with the growing trend of sustainability and corporate social responsibility.

In the waffle industry, the ability to adapt to market trends is crucial. Continuous operation plants are highly flexible, allowing manufacturers to quickly shift production lines to accommodate new flavors, sizes, and designs. This agility is particularly important in a market that loves variety and innovation, as it ensures that manufacturers can keep up with consumer demands and preferences without the delays associated with traditional production methods.

From a consumer standpoint, the benefits are clear. With continuous operation plants, there’s a more reliable supply of fresh waffles, which means they’re available when customers want them. Whether it’s a busy weekend or a last-minute breakfast idea, these plants ensure that waffles are just a short trip away. Additionally, the high efficiency of these plants often translates to lower prices for consumers, as the cost savings can be passed down the supply chain.

Moreover, the uniformity of waffles produced by continuous operation plants can lead to increased brand loyalty. When consumers know they can count on the same quality every time, they are more likely to return and recommend the product to others. This consistency is a powerful marketing tool in a world where brand trust is hard-earned and fiercely protected.

The future of waffles looks bright for consumers, thanks to the advancements made possible by continuous operation waffle iron plants. As technology continues to evolve, we can expect even more innovations that will further enhance the consumer experience. Imagine a world where your favorite waffle is just a click away, delivered fresh and ready to eat, thanks to the efficiency and reliability of these modern plants.

In conclusion, investing in a continuous operation waffle iron plant is a strategic move for any business looking to thrive in the waffle industry. The benefits of scalability, reduced waste, consistent quality, energy efficiency, and the ability to meet consumer demands are just a few reasons why this type of plant pays off in the long run. As the industry continues to evolve, it’s clear that these plants will play a pivotal role in shaping the future of breakfast, one waffle at a time.