In today’s world, where efficiency and safety are paramount, the choice of heating elements can significantly impact the performance and reliability of various systems. Among the numerous standards that govern these components, GOST R stands out as a crucial benchmark for quality and compliance. This article delves into the intricacies of GOST R heating elements, exploring their features, applications, and the assurance they bring to modern industries.

Introduction to GOST R Heating Elements

GOST R heating elements are a staple in the world of industrial heating solutions. These specialized components are designed to provide efficient and reliable heat for a wide range of applications, from commercial kitchens to industrial processes. At their core, GOST R heating elements are engineered to meet the stringent safety and quality standards set forth by the Russian state standard, GOST R.

Originating from the Soviet era, GOST R (Gosudarstvennyi Standart Rossii) is a comprehensive set of regulations that governs the production and certification of products within Russia. It ensures that products meet the necessary quality, safety, and performance criteria, making them suitable for use across various industries. When it comes to heating elements, GOST R certification is a mark of excellence that consumers and businesses alike can trust.

These heating elements are typically made from materials such as stainless steel, nickel-chromium alloys, or other high-temperature-resistant metals. They are designed to withstand extreme temperatures and harsh conditions, making them ideal for environments where heat is a critical factor. The design of a GOST R heating element often includes a robust sheath that protects the heating wire, ensuring longevity and safety.

One of the standout features of GOST R heating elements is their ability to provide precise temperature control. This is crucial in applications where maintaining a consistent heat level is essential, such as in food processing or material heating. The elements are often equipped with thermostats or temperature sensors that allow for accurate regulation, preventing overheating and potential damage to the equipment or products being heated.

In terms of energy efficiency, GOST R heating elements are designed to minimize heat loss. This not only helps in reducing energy consumption but also contributes to a more sustainable operation. The elements are engineered to distribute heat evenly, ensuring that the entire area requiring warmth receives the necessary thermal energy without any hotspots.

The versatility of GOST R heating elements is another reason for their popularity. They come in various shapes, sizes, and power ratings, making them suitable for a wide array of heating needs. Whether it’s a small domestic appliance or a large industrial machine, there’s a GOST R heating element that can meet the specific requirements of the application.

In the commercial kitchen industry, GOST R heating elements are commonly found in ovens, grills, and hot water tanks. Their ability to maintain consistent temperatures and their durability make them a preferred choice for chefs and kitchen managers who demand the best performance from their equipment.

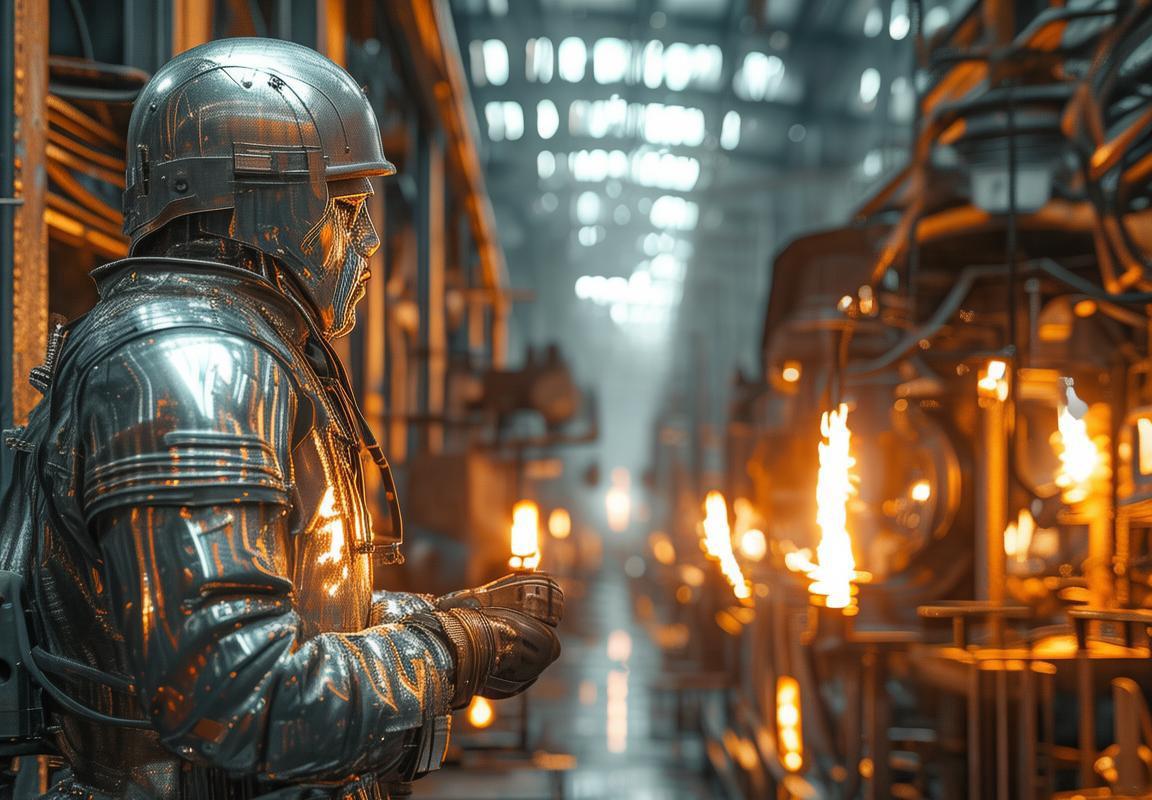

Similarly, in the industrial sector, GOST R heating elements are used in manufacturing processes that require precise heat control, such as heat treatment, soldering, and drying. The reliability and consistency of these elements ensure that the quality of the final product is not compromised.

Safety is paramount in the design of GOST R heating elements. The materials used are not only heat-resistant but also resistant to corrosion and electrical shock. The elements are often equipped with safety features like overheat protection and grounding, which further enhance their safety profile.

The manufacturing process of GOST R heating elements is rigorous and adheres to the strict guidelines set by the GOST R standard. This ensures that each element meets the required quality and performance standards. The production process includes several stages, such as material selection, winding, insulation, and testing, all of which are closely monitored to guarantee the final product’s excellence.

In conclusion, GOST R heating elements are a testament to the commitment to quality and safety that is ingrained in Russian industrial standards. Their versatility, efficiency, and reliability make them a preferred choice for a multitude of applications across various industries. Whether in a bustling kitchen or a high-tech manufacturing facility, GOST R heating elements are a reliable source of heat that businesses can count on.

Understanding the GOST R Standard

The GOST R standard, often referred to as the State Standard of the Russian Federation, is a comprehensive set of regulations and guidelines that govern the quality, safety, and performance of products within the country. Understanding this standard is crucial for anyone involved in the manufacturing, import, or export of goods in Russia.

GOST R is derived from the Soviet Union’s Gosstandart, which was established in 1925. Over the years, it has evolved to meet the changing needs of the Russian market and to align with international standards. Today, GOST R is recognized both domestically and internationally, ensuring that products meeting these standards are of high quality and safe for use.

One of the key aspects of the GOST R standard is its focus on product safety. This means that every product must undergo rigorous testing to ensure it does not pose any risk to consumers. This includes evaluating the product’s chemical composition, mechanical properties, and its ability to withstand various environmental conditions. For heating elements, this could mean testing for heat resistance, electrical conductivity, and the absence of harmful substances.

Another important element of the GOST R standard is the emphasis on quality control. Manufacturers are required to implement a quality management system that ensures consistent production of products that meet the specified requirements. This system must be documented and regularly audited to maintain compliance with the standard.

The GOST R standard is also known for its detailed technical specifications. These specifications outline the exact requirements for each product, from the materials used to the manufacturing process. For heating elements, this could include the thickness of the wire, the type of insulation, and the maximum operating temperature. These specifications are designed to ensure that all products are uniform in quality and performance.

In addition to safety and quality, the GOST R standard also addresses environmental concerns. Products must meet certain environmental requirements, such as being recyclable or not containing hazardous materials. This is particularly relevant for heating elements, which can have a significant impact on energy consumption and waste generation.

One of the unique features of the GOST R standard is its flexibility. While it provides a comprehensive framework for product development and manufacturing, it also allows for some variation in design and technology. This means that while all heating elements must meet certain fundamental requirements, there is room for innovation and improvement.

The standard is divided into various sections, each addressing different aspects of product development and manufacturing. For heating elements, these sections might include electrical engineering, thermal management, and material science. This division ensures that each aspect of the product is thoroughly evaluated and meets the necessary criteria.

Understanding the GOST R standard also involves recognizing its application across various industries. From industrial machinery to consumer electronics, the standard is used to ensure that products are reliable and safe. For heating elements, this means that they are not only suitable for industrial applications but also for household appliances and automotive systems.

The certification process for GOST R compliance is another critical aspect to understand. Manufacturers must apply for certification, which involves submitting detailed technical documentation and undergoing inspections. Once certified, the product can bear the GOST R mark, indicating its compliance with the standard.

It’s important to note that the GOST R standard is not static. It is regularly updated to reflect advancements in technology and changes in the market. This means that manufacturers must stay informed about the latest requirements to maintain compliance.

In conclusion, the GOST R standard is a complex and multifaceted set of regulations that covers safety, quality, and environmental considerations. For those dealing with heating elements, understanding these standards is essential for ensuring that their products meet the high standards expected in the Russian market and beyond. By adhering to GOST R, manufacturers can gain a competitive edge, expand their market reach, and build trust with consumers who value safety and reliability.

The Role of Heating Elements in Modern Applications

Heating elements play a pivotal role in modern applications across a vast array of industries. From industrial processes to household appliances, these components are essential for maintaining temperature control and ensuring the functionality of various systems. Here’s a closer look at the diverse roles heating elements fulfill in today’s world.

In the realm of industrial manufacturing, heating elements are indispensable. They are used in processes such as heat treatment, where metals are heated to specific temperatures to alter their physical and chemical properties. This can involve hardening, tempering, or annealing, all of which are critical steps in the production of high-quality steel and other metals.

Within the food industry, heating elements are crucial for ensuring food safety and quality. They are employed in ovens, fryers, and other cooking equipment to maintain consistent temperatures that prevent the growth of bacteria and preserve the freshness of products. This is particularly important in large-scale food processing plants where the integrity of the product line depends on precise temperature control.

In the medical field, heating elements are used in diagnostic equipment like MRI machines. These devices require a strong magnetic field, which is generated using superconducting coils. The coils are kept at extremely low temperatures, and heating elements are employed to maintain these temperatures, ensuring the accuracy of the imaging process.

The automotive industry relies on heating elements for a variety of purposes. They are used in seat warmers to provide comfort to drivers and passengers, especially in colder climates. Additionally, heating elements are integral to the defrosting systems in windshields, which help maintain visibility during adverse weather conditions.

Within the HVAC (Heating, Ventilation, and Air Conditioning) sector, heating elements are the backbone of heating systems. They are found in furnaces, heat pumps, and other heating equipment, providing the necessary warmth for residential and commercial spaces. The efficiency and reliability of these elements directly impact the comfort and energy consumption of buildings.

In the textile industry, heating elements are used in dyeing and finishing processes. They help to ensure that fabrics are evenly heated, allowing for consistent color and texture. This is particularly important for high-quality garments and home textiles.

The pharmaceutical industry also benefits from heating elements, which are used in the production of medication. They are crucial for maintaining the correct temperature during the mixing, drying, and packaging stages, which are critical to the efficacy and safety of the final product.

In the construction sector, heating elements are used in underfloor heating systems, which provide a comfortable and efficient way to warm homes. These systems are not only energy-efficient but also contribute to a healthier indoor environment by reducing the risk of mold and dust mites.

Heating elements are also fundamental in the production of various consumer goods. From toasters and kettles to ovens and clothes dryers, these elements are what make these appliances functional. They provide the heat necessary for cooking, boiling water, and drying laundry, all while ensuring safety and convenience.

In the world of renewable energy, heating elements are used in solar thermal systems to heat water and air. They are a key component in the conversion of solar energy into usable heat, which is particularly valuable in areas where traditional heating sources are scarce or expensive.

Lastly, heating elements are a part of the transportation sector, where they are used in electric vehicles to warm the cabin and defrost windows before the main propulsion system is activated. This not only enhances the driving experience but also contributes to the overall efficiency of the vehicle.

In summary, the role of heating elements in modern applications is multifaceted and essential. From the precision required in industrial manufacturing to the comfort provided in everyday life, these elements are a cornerstone of technology and convenience in the modern world.

Key Features of GOST R Heating Elements

GOST R heating elements are not just components; they are the heartbeat of numerous modern applications. Here are some of the key features that make these heating elements stand out:

Efficiency: The core feature of GOST R heating elements is their exceptional efficiency. Designed to convert electrical energy into heat with minimal energy loss, these elements ensure that the maximum amount of power is delivered to the intended application. This high efficiency translates to lower energy bills and a more sustainable operation.

Durability: GOST R standards are stringent, and this is reflected in the durability of the heating elements. Made from high-quality materials, these elements are built to withstand harsh conditions, including extreme temperatures, corrosive environments, and heavy loads. This durability means that they have a longer lifespan, reducing the need for frequent replacements.

Safety: Safety is paramount in heating applications, and GOST R heating elements are engineered with this in mind. They are designed with built-in safety features such as overheat protection, which automatically shuts off the element when temperatures exceed safe levels. This not only prevents damage to the equipment but also reduces the risk of fire and injury.

Precision: GOST R heating elements are known for their precision in temperature control. They can be precisely calibrated to maintain a consistent and accurate temperature, which is crucial in applications that require tight temperature control, such as in food processing, pharmaceuticals, and scientific research.

Versatility: These heating elements come in a variety of types, sizes, and shapes, making them suitable for a wide range of applications. From small household appliances to large industrial machinery, GOST R heating elements can be found in almost every sector that requires heating solutions. This versatility is a testament to their adaptability and the flexibility they offer to engineers and manufacturers.

Heat Distribution: One of the standout features of GOST R heating elements is their even heat distribution. They are designed to ensure that heat is evenly dispersed throughout the element, which is essential for applications that require uniform heating. This even distribution prevents hotspots and ensures that the entire surface of the heated object reaches the desired temperature.

Thermal Conductivity: The thermal conductivity of GOST R heating elements is another key feature. These elements are made from materials that excel in conducting heat, which means they can quickly and effectively transfer heat to the object they are designed to heat. This rapid thermal response is particularly important in applications where quick heating and cooling cycles are necessary.

Environmental Friendliness: In line with global trends towards sustainability, GOST R heating elements are designed to be environmentally friendly. They are made from recyclable materials and are designed to minimize waste throughout their lifecycle. This commitment to environmental responsibility is a significant factor for many consumers and businesses looking for greener solutions.

Customization: GOST R heating elements can often be customized to meet specific requirements. Whether it’s a unique shape, size, or material, these elements can be tailored to fit the exact needs of an application. This level of customization ensures that the heating element is not only efficient and safe but also perfectly suited to the task at hand.

Regulatory Compliance: As certified by the GOST R standard, these heating elements must meet rigorous safety and quality regulations. This compliance ensures that they are reliable and meet the highest industry standards, giving users peace of mind that they are using a product that has been thoroughly tested and approved.

In summary, the key features of GOST R heating elements encompass efficiency, durability, safety, precision, versatility, even heat distribution, high thermal conductivity, environmental friendliness, customization, and regulatory compliance. These features make them an invaluable component in countless modern applications, where reliable and effective heating solutions are essential.

Advantages of Using GOST R Certified Heating Elements

GOST R certified heating elements offer a range of advantages that make them a preferred choice in various industries. These benefits stem from the stringent quality standards and safety protocols enforced by the Russian state standard, GOST R. Here are some of the key advantages:

Endurance and LongevityGOST R heating elements are designed to withstand rigorous conditions over extended periods. The manufacturing process ensures that these elements are built with high-quality materials that can endure high temperatures and mechanical stress. This durability translates into a longer lifespan for the heating elements, reducing the frequency of replacements and maintenance costs.

Safety AssuranceSafety is paramount in any heating application, and GOST R certified heating elements are engineered with this in mind. They are tested to meet strict safety standards, which include resistance to overheating, electrical shock protection, and flame resistance. This means that using these elements reduces the risk of accidents and ensures a safer environment for both personnel and equipment.

Energy EfficiencyGOST R certified heating elements are known for their energy efficiency. They are designed to convert electrical energy into heat with minimal losses, which not only saves energy but also reduces operational costs. The advanced design and materials used in these elements contribute to their ability to maintain consistent temperatures, further optimizing energy use.

Wide Temperature RangeThe versatility of GOST R heating elements is highlighted by their wide operating temperature range. Whether it’s for industrial processes that require extreme heat or for more delicate applications that demand precise temperature control, these elements can adapt. This adaptability makes them suitable for a diverse array of industries, from food processing to chemical manufacturing.

Compliance with Russian and International StandardsGOST R certification ensures that these heating elements adhere to both Russian and international standards. This dual compliance is particularly beneficial for companies operating in the Russian market or looking to export their products to Russia. It simplifies the regulatory process and can be a significant competitive edge.

Customization and FlexibilityManufacturers of GOST R heating elements often offer customization services, allowing customers to tailor the elements to their specific needs. This flexibility can include adjustments in size, shape, and power output, ensuring that the heating elements perfectly match the requirements of the application. Customization can also involve the use of specialized materials that are resistant to certain chemicals or environments.

Quality Control and TraceabilityThe GOST R certification process includes rigorous quality control checks throughout the manufacturing cycle. This ensures that every heating element meets the highest standards of quality and performance. Additionally, the traceability of the certification allows for easy verification of the product’s compliance with standards, providing peace of mind to end-users.

Reduced Environmental ImpactIn today’s environmentally conscious world, the impact of products on the environment is a significant consideration. GOST R certified heating elements are designed with environmental concerns in mind. They are often made with materials that are recyclable or have a lower carbon footprint, contributing to a more sustainable approach to heating solutions.

Cost-Effective MaintenanceMaintaining heating elements is an essential aspect of their performance. GOST R certified elements are designed for ease of maintenance, which can lead to cost savings over time. The materials used are resistant to corrosion and wear, which means less frequent repairs and a longer lifespan, ultimately reducing maintenance costs.

Innovation and Technological AdvancementsThe certification process encourages manufacturers to innovate and improve their products. GOST R certified heating elements benefit from ongoing technological advancements, which means that users can expect cutting-edge solutions that offer improved performance and efficiency.

In summary, the advantages of using GOST R certified heating elements are multifaceted, offering a blend of safety, efficiency, durability, and compliance. These elements are not just heating devices; they are integral components of modern industrial processes, providing reliable and sustainable solutions for a wide range of applications.

Common Applications in Various Industries

Heating elements, whether they are part of GOST R-certified products or not, play a crucial role in a multitude of industries. These components are not just about generating heat; they are integral to the functionality, efficiency, and safety of various systems. Let’s delve into some of the common applications where heating elements are making a significant impact.

In the food industry, heating elements are essential for maintaining consistent temperatures during cooking and processing. They are used in ovens, grills, and other cooking appliances to ensure that food is cooked to perfection. Moreover, in food preservation, heating elements help in sterilizing equipment and packaging materials, extending the shelf life of products.

In the pharmaceutical sector, precise temperature control is vital for the production of medications and research. Heating elements are integrated into reactors, autoclaves, and drying chambers to facilitate chemical reactions and to maintain the required temperature ranges. This is particularly important in the production of heat-sensitive drugs and vaccines.

The automotive industry relies on heating elements for both comfort and performance. They are used in seat heaters, door panels, and dashboard components to provide warmth during colder months. Additionally, heating elements are employed in engine management systems to prevent cold starts and ensure efficient fuel combustion.

In the construction industry, heating elements are integral to heating, ventilation, and air conditioning (HVAC) systems. These elements help maintain comfortable indoor temperatures, especially in large commercial buildings and residential complexes. They are also used in radiant heating systems for both residential and commercial properties, offering an efficient and cost-effective way to distribute heat.

Agriculture benefits greatly from the use of heating elements, particularly in greenhouses and animal husbandry facilities. Greenhouses use heating elements to extend growing seasons and provide controlled environments for plants to thrive. In livestock operations, heating elements help regulate temperatures, ensuring the health and well-being of animals.

The chemical industry utilizes heating elements in reactors and processing equipment to facilitate chemical reactions at specific temperatures. These elements are often found in the form of immersion heaters or jacketed heaters, ensuring that the reaction vessels are kept at the precise temperature required for the process.

In the aerospace industry, heating elements are critical for maintaining structural integrity and functionality. They are used in aircraft de-icing systems to prevent ice buildup on wings and control surfaces, which could compromise flight safety. Additionally, heating elements help maintain hydraulic fluid temperatures in aerospace applications, ensuring that systems operate reliably.

The marine industry also relies on heating elements, particularly in shipboard systems. They are used to keep machinery rooms warm, preventing condensation and ensuring the proper functioning of engines and other mechanical equipment. In fishing vessels, heating elements can help preserve catches by maintaining cold storage temperatures.

The semiconductor industry is another area where heating elements are crucial. They are used in fabs to manage the temperature of wafers during the manufacturing process, ensuring that the materials are heated to the right temperatures for various processes like annealing and doping.

Lastly, in the waste management sector, heating elements are employed in incinerators to facilitate the combustion of waste materials. They provide the necessary heat to convert waste into ash, minimizing environmental impact.

Each of these industries, and many more, rely on heating elements for their specific needs. The versatility and dependability of these components make them a cornerstone of modern technology and industry. From keeping food safe to advancing scientific research, the role of heating elements is undeniable, and their presence in our everyday lives is often taken for granted. Yet, without these vital components, the operations and advancements in countless sectors would be severely hindered.

Ensuring Safety and Compliance with GOST R

In the realm of heating solutions, safety and compliance are paramount. Ensuring that heating elements meet the stringent standards set forth by the GOST R (State Committee for Standardization of the Russian Federation) is not just about adhering to regulations; it’s about providing users with reliable, efficient, and safe products. Here’s a closer look at how GOST R certification ensures safety and compliance:

The GOST R standard is a comprehensive set of requirements that cover everything from the design and manufacturing processes to the final product’s performance and safety. One of the key aspects of this certification is the rigorous testing that heating elements must undergo to prove their safety.

These tests include examining the materials used in the heating elements to ensure they are non-toxic and resistant to corrosion. The elements must also withstand high temperatures without warping or failing, which is crucial in environments where overheating can lead to fires or other hazards.

Moreover, GOST R certification demands that heating elements be designed with user safety in mind. This includes features like built-in thermostats that prevent overheating, insulation that minimizes the risk of electrical shocks, and casings that protect the elements from physical damage.

Safety is not just about preventing accidents; it’s also about protecting the environment. GOST R certified heating elements are required to meet environmental standards, which means they use materials that are sustainable and do not contribute to pollution or health risks.

Compliance with GOST R standards also involves quality control throughout the production process. Manufacturers must document every step, from the sourcing of raw materials to the final assembly, to ensure that the heating elements meet the required specifications. This documentation is crucial for traceability, allowing for quick identification and rectification of any issues that may arise.

In terms of performance, GOST R certified heating elements are designed to operate efficiently and effectively. They are engineered to provide consistent heat output, reducing energy consumption and lowering costs for consumers and businesses alike. This efficiency is a direct result of the stringent testing and design criteria set by GOST R.

Another important aspect of compliance is the compatibility of heating elements with different systems and applications. Whether it’s for residential, commercial, or industrial use, GOST R certified heating elements are designed to integrate seamlessly with various heating systems, ensuring that they can be used across a wide range of industries and environments.

For example, in the food industry, heating elements must be able to withstand the harsh conditions of commercial kitchens, including exposure to fats, oils, and high temperatures. GOST R certification ensures that these elements are not only safe but also durable and resistant to the elements they will be exposed to.

In the healthcare sector, heating elements used in medical equipment must meet specific safety standards to prevent harm to patients. GOST R certification plays a critical role in ensuring that these elements are reliable and can be used without posing a risk to human health.

In the construction industry, heating elements used in heating systems for buildings must comply with fire safety regulations. GOST R certification guarantees that these elements are designed to prevent fires and protect both the structure and the inhabitants.

The energy sector also benefits from GOST R certified heating elements, which are used in power plants and other facilities to provide heat for various processes. These elements are engineered to be energy-efficient and to last, reducing maintenance costs and the need for frequent replacements.

Ultimately, the GOST R certification process ensures that heating elements are not just safe and reliable but also contribute to the overall performance and longevity of the systems they are part of. By adhering to these standards, manufacturers and users can have confidence in the quality and safety of the heating elements they choose.

The Manufacturing Process of GOST R Heating Elements

The meticulous process of crafting GOST R heating elements involves several stages, each crucial to the final product’s quality and performance. From the selection of raw materials to the stringent quality control measures, here’s an insight into the intricate journey of manufacturing these heating elements.

Materials Selection and PurificationThe journey begins with the careful selection of materials, which are the backbone of any heating element. Materials such as nickel-chromium alloys, stainless steel, and other high-temperature-resistant metals are chosen for their ability to withstand extreme heat and maintain structural integrity. These materials are then purified to ensure there are no impurities that could compromise the heating element’s performance.

Design and EngineeringOnce the materials are selected and purified, the design phase commences. Engineers must consider the specific requirements of the heating element, including its intended application, operating temperature, and power output. Advanced computer-aided design (CAD) software is used to create detailed blueprints that guide the manufacturing process.

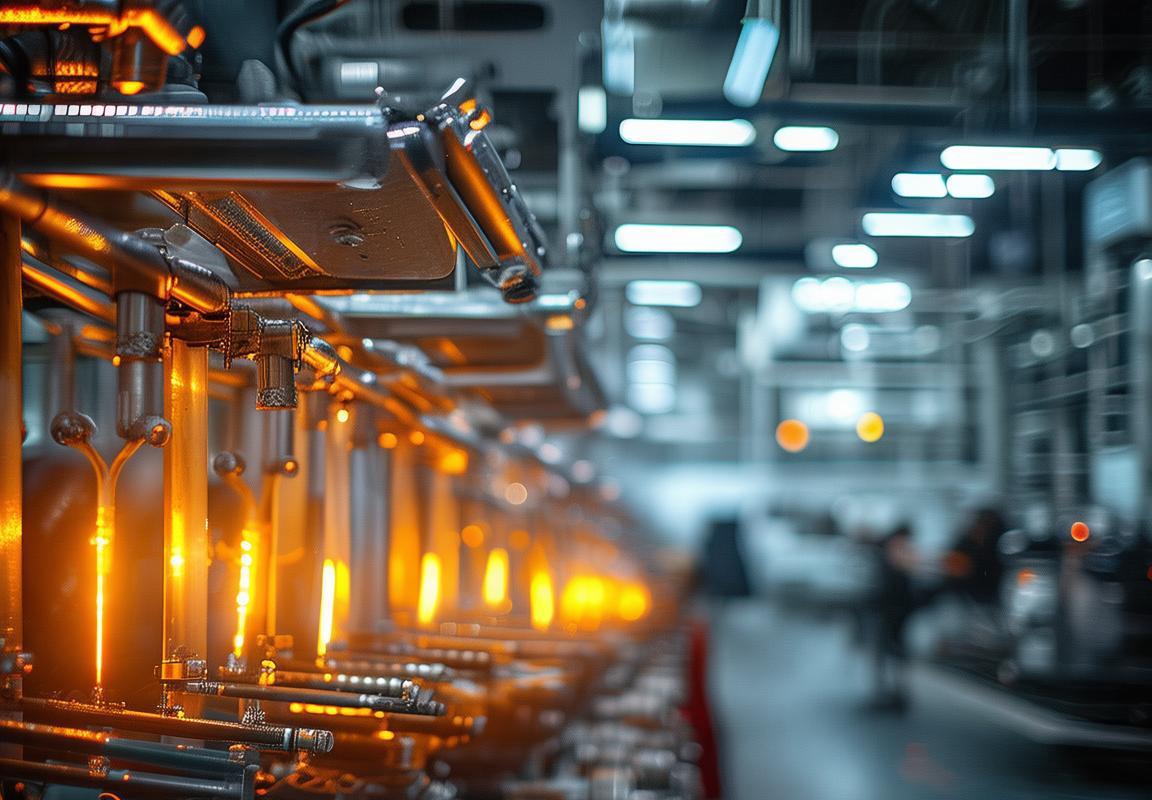

Winding and CoilingThe core of the heating element is typically made of resistance wire, which is wound around a ceramic or metal former. This process requires precision and care to ensure that the wire is evenly distributed and securely attached. The winding technique can vary depending on the element’s design, but the goal is always to maximize heat transfer and minimize electrical resistance.

Insulation and ProtectionAfter winding, the wire is insulated to prevent electrical short circuits and to enhance the element’s lifespan. High-quality insulation materials, such as glass fiber or mica, are used to create a protective barrier around the wire. This insulation also helps to maintain the element’s temperature distribution and prevent overheating.

Shaping and FormingThe next step involves shaping and forming the heating element into its final configuration. This may include bending, cutting, or shaping the element to fit specific equipment or spaces. The precision of this stage is critical, as any misalignment can affect the element’s performance and safety.

Testing and Quality ControlThroughout the manufacturing process, rigorous testing is conducted to ensure that each heating element meets the stringent requirements of the GOST R standard. These tests include electrical resistance measurements, temperature cycling, and mechanical strength assessments. Any deviations from the standard are flagged, and the element is either corrected or discarded.

Assembly and IntegrationOnce the individual heating elements pass all quality checks, they are assembled into larger units or integrated into the final product. This step requires careful handling to ensure that the elements are correctly positioned and that all connections are secure.

Packaging and DistributionAfter assembly, the heating elements are packaged to protect them during transit. Proper packaging not only prevents damage but also ensures that the elements remain safe and functional until they reach the end-user. Distribution protocols are followed to ensure that the products are delivered to the intended destinations efficiently.

Continuous ImprovementThe manufacturing process of GOST R heating elements is not static. Continuous improvement efforts are made to refine the process, enhance the quality of materials, and develop new technologies that can improve the performance and longevity of the heating elements. This includes investing in new machinery, adopting advanced manufacturing techniques, and staying abreast of industry standards and regulations.

In conclusion, the manufacturing process of GOST R heating elements is a complex and meticulous endeavor that demands precision, quality control, and adherence to strict standards. Each step, from material selection to final distribution, plays a vital role in ensuring that these heating elements are reliable, efficient, and safe for a wide range of applications.

The Future of GOST R Heating Technology

In the ever-evolving landscape of heating technology, GOST R heating elements are poised to play a pivotal role. As we look ahead, several trends and advancements are shaping the future of this technology, promising more efficient, sustainable, and innovative solutions.

The integration of smart technology is one such trend that is expected to revolutionize the heating industry. With the rise of the Internet of Things (IoT), heating elements are becoming smarter, capable of adapting to changing conditions and optimizing energy use. This not only enhances comfort but also significantly reduces utility bills.

Energy efficiency remains a cornerstone of GOST R heating technology. As environmental concerns grow, the demand for energy-saving solutions is increasing. GOST R heating elements are likely to incorporate advanced materials and design principles that minimize energy consumption while maintaining high performance. This includes the use of high-efficiency heat exchangers and improved insulation to retain heat more effectively.

Renewable energy sources are gaining traction, and GOST R heating technology is expected to integrate more closely with solar, wind, and geothermal energy systems. This synergy will allow for a more sustainable approach to heating, reducing reliance on fossil fuels and lowering greenhouse gas emissions.

The customization of heating solutions is another area where innovation is on the horizon. GOST R heating elements are likely to become more adaptable to specific applications and environments. This could involve modular designs that can be easily reconfigured or systems that learn from user behavior to provide personalized heating experiences.

Material science is advancing rapidly, and this progress is expected to have a direct impact on the future of GOST R heating technology. New materials with superior thermal conductivity and durability are being developed, which could lead to heating elements that are more robust and efficient than those currently available.

Safety is paramount in any heating technology, and the future of GOST R heating elements will likely see a focus on enhanced safety features. This could include built-in sensors to detect and prevent overheating, as well as materials that are inherently flame-retardant. These advancements will not only protect users but also comply with stringent safety standards.

The global market for heating elements is diverse, and GOST R heating technology is poised to expand its reach. As international trade continues to grow, the demand for high-quality, certified heating elements is likely to increase. This expansion will require GOST R to adapt its standards to meet the needs of different markets and regions.

Innovation in the field of nanotechnology is also likely to influence the future of GOST R heating elements. Nanomaterials could be used to create heating elements with unique properties, such as self-cleaning surfaces or elements that can adjust their thermal output based on environmental factors.

The importance of connectivity cannot be overstated. As heating systems become more integrated into smart homes and buildings, the ability to monitor and control heating elements remotely will become increasingly important. GOST R heating technology will need to embrace this trend to remain competitive.

Lastly, the future of GOST R heating technology will be driven by a commitment to continuous improvement. This means not only adhering to current standards but also proactively seeking out ways to exceed them. By staying at the forefront of research and development, GOST R heating elements will continue to be a leader in the industry, providing solutions that are both efficient and forward-thinking.

Conclusion: Why GOST R Heating Elements Are a Smart Choice

In today’s fast-paced world, the demand for efficient and reliable heating solutions is paramount. GOST R heating elements have emerged as a smart choice for a variety of reasons. From their robust construction to their compliance with stringent safety standards, these heating elements offer numerous benefits that make them a top pick for both residential and commercial applications. Here’s why GOST R heating elements stand out as a smart choice.

Their Durability and LongevityGOST R heating elements are renowned for their durability, which is a testament to the meticulous craftsmanship and high-quality materials used in their manufacturing. These elements are designed to withstand harsh conditions and prolonged use, making them a wise investment for any project. Whether it’s in a home or an industrial setting, their longevity ensures that they will continue to provide efficient heating for years to come.

Energy EfficiencyEnergy consumption is a critical concern for many businesses and homeowners. GOST R heating elements are engineered to maximize energy efficiency, reducing operational costs and minimizing environmental impact. With advanced heating technologies and optimal design, these elements convert electrical energy into heat more effectively, ensuring that your heating needs are met with minimal energy waste.

Compliance with Safety StandardsSafety is a top priority when it comes to heating systems. GOST R certified heating elements adhere to rigorous safety standards, ensuring that they meet or exceed industry regulations. This compliance means that users can trust that these elements are designed with their safety in mind, from the materials used to the manufacturing process and final product.

Versatility in DesignGOST R heating elements come in a wide range of designs, allowing them to be integrated into various applications. From small, compact units suitable for space heating in residential settings to larger, more robust systems for industrial processes, these elements offer versatility that caters to diverse needs. Their ability to adapt to different environments and requirements makes them a flexible choice for any project.

Easy Installation and MaintenanceInstalling and maintaining heating elements can be a challenge, but GOST R models are designed with ease of use in mind. The user-friendly design and straightforward installation process ensure that these elements can be easily integrated into existing systems or set up in new installations. Additionally, their maintenance requirements are minimal, with clear instructions and durable components that reduce the need for frequent repairs or replacements.

Cost-EffectivenessWhile GOST R heating elements may have a higher upfront cost compared to some other options, their overall cost-effectiveness is undeniable. The long lifespan, low maintenance needs, and high energy efficiency contribute to a lower total cost of ownership over time. This makes them an economical choice for businesses and homeowners looking to invest in a reliable heating solution without compromising on quality.

Innovation and Continuous ImprovementThe GOST R brand is committed to innovation and continuous improvement. This means that as technology advances, these heating elements are regularly updated to incorporate the latest advancements. By choosing GOST R heating elements, users are investing in a product that is not only reliable today but also primed to adapt to future technological developments.

Environmental ResponsibilityAs environmental concerns grow, so does the demand for sustainable heating solutions. GOST R heating elements are designed with environmental responsibility in mind, using materials that are environmentally friendly and reducing the carbon footprint of heating systems. By choosing these elements, users are contributing to a greener future.

Customer SatisfactionUltimately, the success of any product lies in its ability to meet or exceed customer expectations. GOST R heating elements have consistently delivered on this front, earning high ratings for customer satisfaction. From the initial purchase to the ongoing performance, users can expect a seamless experience that aligns with their heating needs.

In conclusion, GOST R heating elements offer a combination of durability, efficiency, safety, and versatility that makes them a smart choice for any heating application. Their compliance with GOST R standards, coupled with their commitment to innovation and customer satisfaction, positions them as a top-tier choice for those seeking reliable and effective heating solutions. With their proven track record and ongoing dedication to excellence, GOST R heating elements are set to remain a favorite among consumers for years to come.