In recent years, the heavy duty sandwich press industry has witnessed a surge in popularity, particularly in Western markets. This segment of the kitchen appliance sector has seen a blend of technological advancements, shifting consumer preferences, and evolving market dynamics. As we delve into the intricacies of this niche, it becomes evident that the industry is not just about pressing sandwiches but also about staying ahead in a competitive landscape. From innovations in design to the impact of global supply chains, the heavy duty sandwich press industry is poised for significant growth and transformation.

Introduction to Heavy Duty Sandwich Press Market Dynamics

The heavy duty sandwich press market has seen a significant surge in recent years, driven by changing consumer preferences and a growing demand for convenience in the kitchen. These robust sandwich makers have become a staple in both professional and home kitchens, offering a unique blend of functionality and ease of use. Let’s delve into the dynamic nature of this market and explore the factors that are shaping its growth.

The market for heavy duty sandwich presses is characterized by a competitive landscape, with numerous manufacturers vying for a share of the market. From small, family-owned businesses to large, international corporations, the industry encompasses a wide range of players, each bringing their own innovations and designs to the table.

Consumer demand for quick, delicious meals has played a pivotal role in the rise of the heavy duty sandwich press market. As busy lifestyles become the norm, individuals seek out appliances that can simplify meal preparation. The sandwich press offers a solution that is not only time-efficient but also customizable, allowing users to create their own signature sandwiches at home.

In the Western markets, particularly in Europe and the United States, the sandwich press has found a niche among health-conscious consumers. The popularity of fresh, whole-grain breads and the desire for healthier eating habits have contributed to the growth of the market. Moreover, the rise of gourmet food trends has also pushed the boundaries of what can be made in a sandwich press, leading to more complex and sophisticated recipes.

One of the key factors driving the heavy duty sandwich press market is the technological advancements in materials and design. Modern sandwich presses are often made with high-quality, heat-resistant materials that ensure durability and consistent performance. The introduction of non-stick surfaces and adjustable heating elements has made these appliances even more appealing to consumers looking for convenience and ease of cleaning.

The market is also segmented by different types of heavy duty sandwich presses, including flat-top, contact, and dual-pressure models. Each type caters to different cooking preferences and needs. For instance, flat-top presses are ideal for achieving a golden-brown crust on both sides of the sandwich, while contact presses are designed for a quick, even cook on one side.

The heavy duty sandwich press market is not without its challenges. Manufacturers must navigate various regulatory frameworks in the EU and the US, which include safety standards for electrical appliances and material requirements. Ensuring compliance with these regulations while maintaining competitive pricing is a delicate balance that manufacturers must carefully manage.

Moreover, the market is sensitive to economic fluctuations, as consumers may delay or reduce their spending on non-essential kitchen appliances during times of economic uncertainty. Despite these challenges, the long-term potential for growth remains strong, driven by the increasing number of single-person households and the ongoing trend towards healthier eating habits.

The global supply chain also plays a crucial role in the heavy duty sandwich press market. Many manufacturers source components from various countries, and any disruption in the supply chain can impact production timelines and costs. Despite these risks, the industry has shown resilience, with manufacturers often able to adapt to changing circumstances.

In conclusion, the heavy duty sandwich press market is a dynamic and evolving sector, shaped by consumer demand, technological innovation, and regulatory compliance. As the market continues to grow, manufacturers will need to stay attuned to emerging trends and consumer preferences to remain competitive. The future of the heavy duty sandwich press industry looks promising, with opportunities for expansion and innovation on the horizon.

The Rise of Sandwich Presses in the Western Markets

In recent years, the Western markets have witnessed a significant surge in the popularity of sandwich presses. This culinary gadget, once a niche item, has now become a staple in many kitchens across Europe and the United States. The reasons behind this rise are multifaceted, intertwining technological advancements, changing consumer habits, and the ever-evolving food culture.

The convenience factor plays a pivotal role in the growing demand for sandwich presses. These compact appliances allow users to prepare a hot, freshly toasted sandwich in mere minutes, perfect for busy individuals and families. The convenience extends beyond just saving time; it also offers the flexibility to customize sandwiches with various fillings and toppings according to personal preference.

Moreover, the health-conscious trend has spurred the popularity of sandwich presses. As people seek healthier alternatives to fast food and processed snacks, the ability to create a homemade, nutritious sandwich is highly appealing. The adjustable heat settings on these presses enable users to control the level of toasting and the cooking time, ensuring that the sandwich remains as healthy as possible.

The Western kitchen has long been a hub of culinary innovation, and sandwich presses are no exception. Manufacturers have leveraged this environment to introduce a variety of designs, from classic models with fixed plates to modern ones with adjustable pressure and temperature controls. The aesthetic appeal of these appliances has also been enhanced, with sleek, contemporary designs that blend seamlessly into modern kitchen decor.

The rise of gourmet and artisanal food movements has also contributed to the popularity of sandwich presses. As consumers become more interested in the quality of their food, they are increasingly turning to homemade sandwiches as a way to enjoy gourmet flavors without the high price tag. The ability to achieve a perfect, crispy texture on bread while keeping the fillings moist is a hallmark of a well-cooked sandwich, something that sandwich presses excel at.

The influence of food blogs, social media, and cooking shows cannot be overlooked. Chefs and home cooks alike have showcased the art of making a great sandwich, often using a high-quality sandwich press to achieve the desired results. This exposure has not only raised awareness about the appliance but has also inspired a generation of sandwich enthusiasts to invest in their own.

The versatility of sandwich presses extends beyond the traditional ham and cheese. They are now used to cook a variety of foods, from paninis and melts to stuffed peppers and vegetables. This versatility has broadened the appeal of sandwich presses, making them not just a kitchen tool but a culinary tool for those who enjoy experimenting with different flavors and textures.

The convenience, health benefits, innovation, and cultural trends have all played a part in the meteoric rise of sandwich presses in the Western markets. However, it’s not just the appliance itself that has changed; it’s the way we think about and enjoy our food. The sandwich press has become a symbol of the modern kitchen’s ability to cater to diverse tastes and lifestyles, from the quick breakfast on the go to a leisurely lunch with friends. As the market continues to grow, it’s clear that the sandwich press has become more than just a kitchen gadget; it’s a part of the fabric of modern Western dining.

Understanding the European and American Kitchen Appliance Markets

The European kitchen appliance market is a testament to the blend of culinary heritage and modern innovation. From Italy’s emphasis on high-quality, handcrafted appliances to Germany’s focus on efficiency and durability, each country brings its unique flavor to the sector. The market is characterized by a strong preference for brands that offer both style and substance, with a significant number of consumers opting for products that reflect their commitment to sustainability and energy efficiency.

In the United States, the kitchen appliance market is vast and diverse, reflecting the country’s varied demographics and lifestyle preferences. American consumers are known for their love of convenience and innovation, leading to a market that is rich in smart appliances and the latest technologies. The U.S. market is also heavily influenced by the trends in the foodservice industry, with many home appliances designed to mimic professional-grade equipment.

European consumers, particularly those in countries like France and the UK, have a penchant for classic designs and timeless aesthetics. The market is saturated with brands that offer a range of kitchen appliances that cater to both traditional and contemporary cooking styles. The emphasis on craftsmanship is evident in the prices, which often reflect the quality and longevity of the products.

American kitchen appliance markets, on the other hand, are more price-sensitive and trend-driven. The rise of the “home chef” culture has spurred the demand for high-end appliances that can handle complex recipes and offer precise control. This has led to a surge in the popularity of induction cooktops, smart refrigerators, and multipurpose appliances that can cater to a variety of cooking needs.

The European market is also marked by its strong emphasis on safety and regulatory compliance. European Union (EU) directives, such as the Energy Labeling Directive, have influenced the design and production of kitchen appliances, ensuring that they meet stringent energy efficiency and environmental standards. The American market, while less stringent in some aspects, also places a high value on safety, with rigorous testing and certification processes for all kitchen appliances.

In Europe, the kitchen appliance market is segmented into various categories, with each category having its own set of leading brands. For instance, in the area of dishwashers, Miele and Siemens are dominant players, known for their top-of-the-line performance and sleek designs. When it comes to ovens and ranges, brands like Gaggenau and BSH Hausgeräte stand out for their premium features and sophisticated engineering.

In the U.S., the market is similarly segmented, but with a different mix of brands. For example, KitchenAid and Whirlpool are household names in the appliance industry, offering a wide range of products that cater to different budgets and cooking preferences. The U.S. also sees a significant presence of import brands, such as Samsung and LG, which have gained popularity for their innovative features and competitive pricing.

Both the European and American markets have seen a shift towards healthier eating habits, which has influenced the types of kitchen appliances being purchased. For instance, the demand for air fryers and slow cookers has increased as consumers look for healthier alternatives to deep-frying and fast cooking methods. This trend has also spurred the development of smart appliances that can help monitor and control food preparation for better health outcomes.

In conclusion, the European and American kitchen appliance markets are distinct yet interconnected. They both offer a wide array of products that cater to different consumer needs and preferences, but they also face unique challenges and opportunities. The key to success in these markets lies in understanding the cultural nuances, regulatory landscapes, and evolving consumer behaviors that shape the industry.

Key Factors Driving Growth in the Heavy Duty Sandwich Press Industry

The heavy duty sandwich press industry has seen a remarkable surge in recent years, and several key factors have contributed to this growth. From evolving consumer preferences to technological advancements, let’s delve into the pivotal elements propelling this sector forward.

-

Consumer Demand for Convenience and QualityConsumers today are seeking convenience without compromising on quality. The demand for quick and easy meals has led to a rise in popularity for sandwich presses, which offer a fast and efficient way to prepare delicious sandwiches at home. As busy lifestyles become the norm, the convenience factor has become a significant driver for the heavy duty sandwich press market.

-

Health and Wellness TrendsWith a growing focus on health and wellness, many consumers are opting for homemade meals over processed ones. Sandwich presses allow for customization, enabling individuals to control the ingredients and cooking process, thereby aligning with health-conscious eating habits. This trend has spurred the demand for high-quality, heavy-duty sandwich presses that can handle various types of bread and fillings.

-

Innovative Design and FunctionalityThe industry has witnessed a wave of innovation in design and functionality. Modern heavy duty sandwich presses come with features like adjustable heat settings, non-stick surfaces, and even customizable press patterns. These innovations cater to a wide range of preferences and cooking styles, making them more appealing to a broader audience.

-

Cultural Diversity and Global InfluenceCultural diversity has played a crucial role in shaping the heavy duty sandwich press industry. As people from different cultures intermingle, new sandwich styles have emerged, and traditional sandwich presses have been adapted to accommodate these variations. Additionally, global influence through travel and media has introduced new flavors and ideas, further fueling the demand for specialized sandwich presses.

-

E-commerce and Online ShoppingThe rise of e-commerce has transformed the way consumers purchase kitchen appliances, including heavy duty sandwich presses. Online platforms provide a vast selection, competitive pricing, and the convenience of doorstep delivery. This accessibility has opened up the market to a wider demographic, including those who may not have access to brick-and-mortar stores.

-

Sustainability and Eco-Friendly ProductsSustainability is a growing concern among consumers. As a result, there is an increasing preference for eco-friendly kitchen appliances. Heavy duty sandwich presses made from sustainable materials and energy-efficient designs are gaining traction, as they align with the values of environmentally conscious consumers.

-

Marketing and Branding EffortsEffective marketing and branding strategies have also played a significant role in the growth of the heavy duty sandwich press industry. Companies have been successful in highlighting the benefits of their products through social media campaigns, influencer partnerships, and targeted advertising. These efforts have helped create awareness and drive sales.

-

Competitive Pricing and Value for MoneyCompetitive pricing has been a key factor in attracting customers. Manufacturers have been able to offer heavy duty sandwich presses at affordable prices without compromising on quality. This has made the product accessible to a broader market segment, further boosting sales.

-

Partnerships and CollaborationsCollaborations between sandwich press manufacturers and other kitchen appliance brands have opened up new opportunities. By integrating sandwich presses into larger kitchen appliance collections or offering bundled packages, companies have been able to cross-sell products and increase their market share.

-

Economic Growth and Increased Disposable IncomeEconomic growth and the subsequent increase in disposable income have also contributed to the growth of the heavy duty sandwich press industry. As people have more money to spend on home appliances, they are more likely to invest in high-quality products like heavy duty sandwich presses.

In conclusion, the heavy duty sandwich press industry’s growth is a result of a combination of factors, including evolving consumer preferences, technological advancements, and market dynamics. As these trends continue to shape the industry, it is expected that the demand for heavy duty sandwich presses will remain robust in the years to come.

Innovations and Technological Advancements in Sandwich Presses

The landscape of sandwich presses has evolved significantly over the years, with innovations and technological advancements playing a pivotal role in shaping the industry. From the classic flat-top presses to the latest electric models, here’s a look at how technology has transformed the way we make sandwiches at home.

Materials have always been a cornerstone of sandwich press innovation. Early models often used heavy-duty metals like cast iron for their robustness and even heat distribution. Today, materials science has introduced non-stick coatings, which make cleaning easier and prevent the dreaded burn marks on bread. Titanium-infused coatings are now becoming a sought-after feature, offering a combination of durability and non-stick properties.

Heat distribution is a critical factor in the success of a sandwich press. Traditional models relied on simple flat surfaces, which sometimes resulted in uneven cooking. Modern sandwich presses now come with advanced heating elements that ensure consistent temperatures across the entire surface. Some models even have temperature controls, allowing users to precisely regulate the heat for different types of bread and fillings.

In terms of design, sandwich presses have seen a shift from the classic two-sided design to multi-functional units. The original flat-top presses were simple and effective, but they lacked versatility. Today, you can find presses with adjustable plates, which can be flipped for pressing or flipped open to serve as a flat griddle. This dual-purpose design is particularly popular among those who like to cook more than just sandwiches.

One of the most significant technological advancements in sandwich presses is the introduction of electric models. These electric presses offer several advantages over their manual counterparts. They provide precise heat control, which is essential for achieving the perfect crispy exterior and tender interior. Moreover, electric presses often come with added features like timers, which alert users when the sandwich is done, ensuring that it’s cooked to perfection without overcooking.

The inclusion of safety features has also been a focus of innovation. Many modern sandwich presses are equipped with cool-touch handles and safety locks that prevent accidental closures. Some models even have automatic shut-off mechanisms to conserve energy and prevent burns. These safety features are particularly important in households with children, where the risk of injury is a concern.

Innovation isn’t just limited to the physical design and functionality of sandwich presses. Software and connectivity have also made their way into the kitchen appliance market. Some high-end models can be controlled via smartphone apps, allowing users to adjust settings and monitor cooking progress remotely. This level of connectivity is not only convenient but also demonstrates the growing trend of smart home technology in kitchen appliances.

Another area where technology has made a significant impact is in the materials used for the bread plates. Some presses now use ceramic-coated plates that not only heat up quickly but also maintain their heat longer, ensuring that the sandwich is cooked thoroughly without drying out. This is especially beneficial for those who enjoy a well-done sandwich with a crisp outer layer and a soft interior.

The design of the press has also evolved to accommodate a wider variety of sandwiches. For example, some models have deeper plates that can handle thick sandwiches, while others come with removable inserts for different shapes and sizes. This flexibility allows users to experiment with different types of bread, fillings, and cooking styles.

In the realm of energy efficiency, sandwich presses have also made strides. Modern models are designed to use less energy, which is not only better for the environment but also for users’ utility bills. Some presses even have eco-friendly settings that automatically reduce power consumption when not in use.

Finally, the customization of sandwich presses has expanded to include personalization. Some brands offer custom plates with unique designs, allowing users to express their individuality in their kitchen appliances. This level of personalization is a testament to how far sandwich presses have come in terms of both technology and consumer demand.

In conclusion, the heavy duty sandwich press industry has seen a remarkable transformation driven by innovations and technological advancements. From material improvements to smart features, these presses have become more efficient, versatile, and user-friendly. As the industry continues to evolve, we can expect even more exciting features and capabilities that will further enhance the enjoyment of home cooking.

Market Segmentation: Who’s Buying Heavy Duty Sandwich Presses?

The market for heavy-duty sandwich presses is diverse, with a wide range of consumers driving the demand. From professional chefs to passionate home cooks, the demographics are as varied as the types of sandwiches being pressed. Here’s a closer look at the segments that are fueling this industry:

Cafes and Quick Service Restaurants (QSRs)Cafes and QSRs are significant consumers of heavy-duty sandwich presses. These establishments require reliable and efficient equipment to handle high volumes of customers and quick service demands. The durability and performance of these presses are crucial for maintaining consistency in the quality of their sandwiches.

Home Chefs and Gourmet CooksThe rise of home cooking and gourmet culture has also contributed to the growth in heavy-duty sandwich press sales. As more people take pride in their culinary skills, they seek out high-quality appliances that can replicate the professional experience at home. This segment includes individuals who enjoy hosting dinner parties or simply appreciate the art of crafting a perfect grilled sandwich.

Commercial Bakers and CaterersCommercial bakers and caterers often use heavy-duty sandwich presses for their versatility. These appliances can be used to prepare not just sandwiches but also wraps, paninis, and other grilled foods. The ability to create a variety of menu items with a single piece of equipment makes them a valuable addition to any commercial kitchen.

Restaurants Specializing in Sandwiches and PaninisRestaurants that focus on sandwiches and paninis as their signature dish are heavy users of heavy-duty sandwich presses. These establishments often invest in high-end models that can produce a professional-looking finish and a perfect seal on their sandwiches, enhancing the visual appeal and taste.

Small Business Owners and Mobile VendorsSmall business owners and mobile vendors, such as food trucks and street food vendors, are also significant customers. These entrepreneurs rely on the portability and efficiency of heavy-duty sandwich presses to serve high-quality sandwiches on the go. The compact size and robust design of these presses make them ideal for mobile operations.

Health and Wellness EnthusiastsWith a growing trend towards health and wellness, many consumers are looking for ways to prepare their own meals with minimal processing. Heavy-duty sandwich presses allow individuals to create fresh, homemade sandwiches with minimal additives, aligning with their health-conscious lifestyle.

Gourmet Food Shops and DelisGourmet food shops and delis often use sandwich presses to offer a unique culinary experience to their customers. These businesses may offer a variety of high-quality meats, cheeses, and breads, and the presses help to create an attractive presentation that complements their gourmet offerings.

Educational Institutions and Catering ServicesEducational institutions, such as schools and colleges, and catering services often purchase heavy-duty sandwich presses for their meal services. These appliances can be used to prepare large quantities of sandwiches quickly and efficiently, ensuring that students and staff have access to a variety of food options.

Corporate Catering and Event PlannersCorporate catering and event planners are another segment that benefits from heavy-duty sandwich presses. These events often require a large volume of food, and the presses can be used to create a range of sandwiches that cater to different tastes and dietary preferences.

Eco-Conscious ConsumersLastly, there’s a growing segment of eco-conscious consumers who prefer to use reusable and sustainable materials for their meals. Heavy-duty sandwich presses that are made with eco-friendly materials or designed for longevity are increasingly popular among this demographic.

The diverse array of consumers in the heavy-duty sandwich press market reflects the appliance’s versatility and the evolving culinary landscape. From the bustling streets of city cafes to the serene comfort of home kitchens, these presses are a staple in many different settings, driving the industry’s growth and innovation.

Challenges and Opportunities for Heavy Duty Sandwich Press Manufacturers

In the competitive landscape of heavy-duty sandwich press manufacturing, several challenges and opportunities stand out as pivotal for the industry’s growth and sustainability.

The evolving consumer palate has introduced a surge in demand for gourmet and artisanal sandwiches, which in turn has pushed manufacturers to produce more sophisticated and durable presses. However, this shift also brings about challenges in terms of innovation and cost management.

One of the primary challenges faced by heavy-duty sandwich press manufacturers is the need to balance quality with affordability. As the market demands higher-quality products, the cost of materials and production processes can escalate, making it difficult to maintain competitive pricing. Additionally, the introduction of new features and technologies often requires significant investment, which can be a barrier for smaller manufacturers.

The rise of health consciousness among consumers has also presented a unique challenge. As people seek healthier options, manufacturers must now consider the health implications of their products, including the materials used in sandwich presses. This necessitates the exploration of non-toxic and eco-friendly materials, which can be more expensive and harder to source.

On the flip side, opportunities abound for those who can navigate these challenges effectively. The growing popularity of food trucks and pop-up restaurants has created a niche market for portable and robust sandwich presses. These establishments require durable, easy-to-use appliances that can withstand the rigors of frequent use and travel.

Similarly, the rise of home baking and cooking culture has opened up a new consumer segment. Many home chefs are looking for high-quality appliances that can replicate the professional experience, and heavy-duty sandwich presses fit this bill perfectly. This segment, though smaller, is growing rapidly and presents a significant opportunity for manufacturers to expand their customer base.

Moreover, the integration of smart technology into kitchen appliances has become a hot trend. Manufacturers who can incorporate features like digital temperature control, Bluetooth connectivity for remote operation, and programmable settings will find themselves in a prime position to capture the attention of tech-savvy consumers.

Another opportunity lies in the customization of sandwich presses. With the demand for personalized products on the rise, manufacturers can offer a variety of sizes, shapes, and materials to cater to different customer needs. This not only allows for higher profit margins but also fosters brand loyalty.

The global trend towards sustainability has also opened up new avenues for heavy-duty sandwich press manufacturers. There is a growing market for appliances made with sustainable materials and produced using eco-friendly processes. Companies that can align with these values and offer greener alternatives are likely to gain a competitive edge.

In the realm of international trade, the expansion into new markets, particularly in Asia and South America, offers a wealth of opportunities. These regions have a growing middle class with a penchant for convenience and gourmet foods, making them ideal targets for heavy-duty sandwich press manufacturers.

Moreover, the rise of e-commerce has made it easier for manufacturers to reach customers around the world. By leveraging online platforms, companies can reduce distribution costs and directly connect with end-users, leading to increased sales and market penetration.

Lastly, the challenge of meeting stringent safety standards and certifications presents an opportunity for manufacturers who can invest in quality control and compliance. By ensuring their products meet or exceed international safety regulations, manufacturers can build a reputation for reliability and trustworthiness.

In conclusion, while the heavy-duty sandwich press industry faces its fair share of challenges, the opportunities for growth and innovation are vast. By focusing on quality, affordability, technological advancements, customization, sustainability, and global market expansion, manufacturers can capitalize on these opportunities and secure a strong position in the ever-evolving kitchen appliance market.

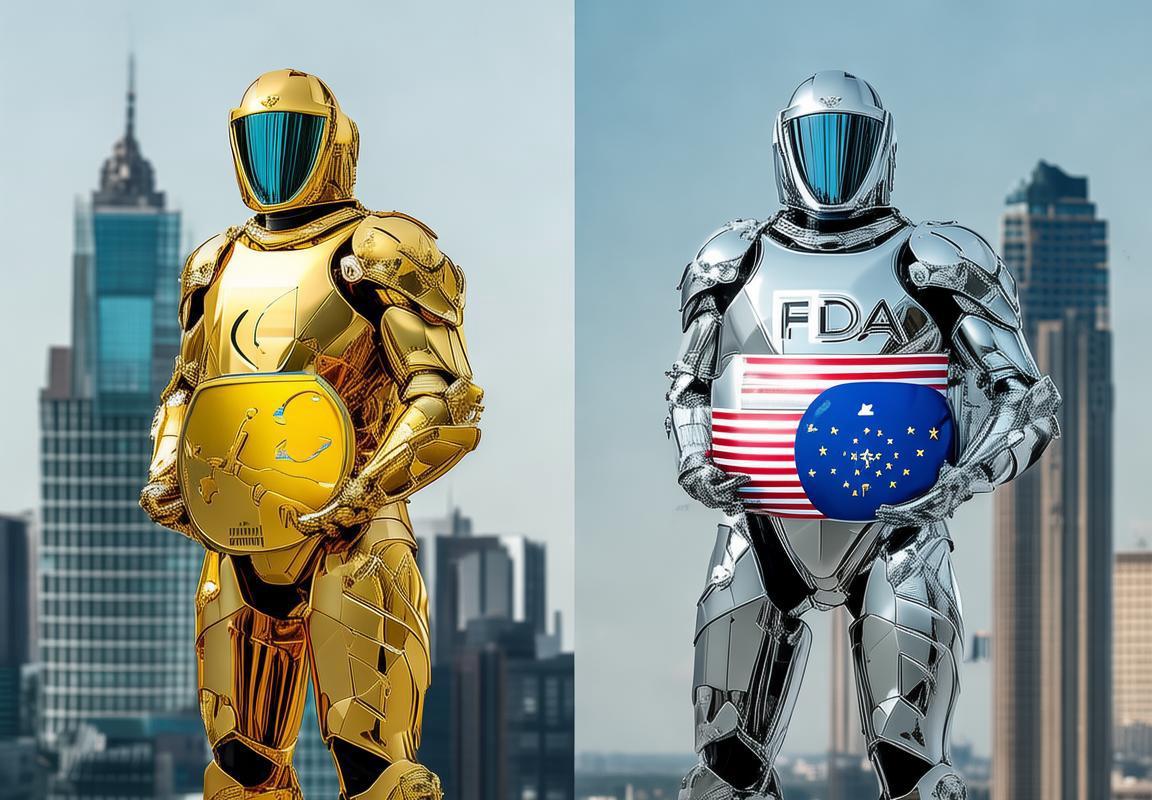

Regulatory Environment and Safety Standards in the EU and US

In the European Union (EU) and the United States (US), the regulatory environment for kitchen appliances, including heavy duty sandwich presses, is stringent to ensure consumer safety and compliance with environmental regulations. Here’s a breakdown of the key aspects that manufacturers must navigate:

-

EU Regulatory Framework: The EU has a comprehensive regulatory landscape that covers all aspects of product development, manufacturing, and distribution. The General Product Safety Directive (GPSD) sets out the basic requirements for the safety of all products placed on the market in the EU. This includes heavy duty sandwich presses, which must meet specific safety standards.

-

Safety Standards: In the EU, safety standards for kitchen appliances are governed by harmonized standards that are part of the New Approach to Technical Harmonization. These standards are designed to ensure that products are safe and do not pose a risk to health or the environment. For sandwich presses, this includes electrical safety, material safety, and mechanical safety.

-

CE Marking: A critical aspect of the EU regulatory environment is the CE marking, which signifies that a product complies with all applicable EU directives. For heavy duty sandwich presses, obtaining the CE mark involves conformity assessment procedures that ensure the product meets the necessary safety, health, and environmental protection requirements.

-

US Regulatory Landscape: In the US, the regulatory environment is similarly focused on safety and compliance. The Food and Drug Administration (FDA) and the Consumer Product Safety Commission (CPSC) are the primary regulatory bodies overseeing kitchen appliances.

-

FDA Regulations: The FDA regulates kitchen appliances that come into contact with food, ensuring they are safe and do not pose a risk to human health. For heavy duty sandwich presses, this means materials used must be FDA-approved and safe for food contact.

-

CPSC Regulations: The CPSC is responsible for protecting the public from unreasonable risks of serious injury or death from thousands of types of consumer products. For sandwich presses, this includes ensuring that the product design does not pose a risk of burns, electrical shock, or other hazards.

-

Energy Efficiency: Both the EU and the US have regulations that promote energy efficiency in appliances. In the EU, this is addressed through the Energy-Related Products (ErP) Directive, which requires appliances to meet certain energy consumption standards. In the US, the Energy Star program offers a voluntary labeling scheme that helps consumers identify energy-efficient products.

-

Environmental Regulations: The EU and the US also have regulations aimed at reducing the environmental impact of products. In the EU, this includes the Waste Electrical and Electronic Equipment (WEEE) Directive, which ensures the proper disposal of electrical and electronic equipment. In the US, the Electronic Waste Recycling Act (EERA) and state-specific e-waste recycling laws play a similar role.

-

Product Liability: Both regions have strict product liability laws that hold manufacturers accountable for any defects or failures that result in harm to consumers. This means that heavy duty sandwich press manufacturers must ensure their products are not only compliant with regulations but also free from design or manufacturing defects.

-

Continuous Monitoring and Compliance: Compliance with these regulations is not a one-time event; it requires ongoing monitoring and updating of products to keep pace with new standards and requirements. This includes regular audits and certifications to maintain the CE mark and any other applicable certifications.

-

Consumer Awareness and Expectations: The regulatory environment is also influenced by consumer awareness and expectations. Today’s consumers are more informed and more likely to demand products that are not only safe but also sustainable and environmentally friendly.

-

Global Harmonization Efforts: Despite the differences in regulations, both the EU and the US are part of global efforts to harmonize standards. This can create opportunities for manufacturers to streamline their production processes and reduce costs, as they can produce products that meet multiple markets’ requirements.

Understanding and navigating these regulatory environments is crucial for heavy duty sandwich press manufacturers. It not only ensures compliance but also helps build trust with consumers, who increasingly look for products that are safe, efficient, and environmentally responsible.

Consumer Trends and Preferences in Sandwich Cooking

In the ever-evolving world of culinary trends, sandwich cooking has seen a surge in popularity. From the classic ham and cheese to the exotic fusion varieties, the sandwich has become a staple in many diets. This shift in consumer behavior has influenced the market for heavy-duty sandwich presses, with specific trends and preferences shaping the industry. Here’s a closer look at what’s driving the sandwich revolution.

The demand for convenience and quick meals has skyrocketed, with busy lifestyles leaving little time for elaborate cooking. Sandwiches offer a perfect solution, combining simplicity with the ability to pack a nutritional punch. Consumers are gravitating towards portable, ready-to-eat options that can be enjoyed on the go, making sandwiches a convenient choice for breakfast, lunch, or even dinner.

Health-conscious consumers are increasingly seeking out options that align with their dietary preferences. This has led to a rise in gluten-free, vegan, and low-carb sandwiches, which are becoming staple offerings in many delis and fast-food chains. The popularity of these health-focused sandwiches is reflected in the types of heavy-duty sandwich presses that are being developed and marketed, with features that cater to specific dietary needs.

Customization is another key trend that’s shaping the sandwich market. Customers today enjoy the ability to tailor their meals to their personal tastes, and this extends to sandwiches as well. From selecting the type of bread, cheese, and fillings to adding gourmet toppings and spreads, the options are virtually limitless. Heavy-duty sandwich presses are being designed with this in mind, featuring non-stick surfaces and adjustable heat settings to accommodate a wide range of sandwich preferences.

The rise of gourmet and artisanal sandwiches has also had a significant impact on the market. These high-quality, handcrafted sandwiches are often made with premium ingredients and are becoming a favorite among food enthusiasts. The demand for these sandwiches has spurred the creation of specialty sandwich presses that can handle the delicate preparation required for such gourmet creations.

Another notable trend is the increasing importance of sustainability. Consumers are more aware of the environmental impact of their choices and are looking for products that align with eco-friendly practices. This extends to the kitchen appliances they purchase, including sandwich presses made from recycled materials or designed with energy efficiency in mind.

The preference for a perfect texture is also shaping the market. Many consumers are seeking sandwiches that are crispy on the outside yet soft and warm on the inside. Heavy-duty sandwich presses with precise temperature controls and non-stick surfaces are becoming a must-have for those who want to achieve that ideal sandwich texture at home.

Lastly, the rise of social media and influencer culture has played a role in the sandwich cooking trend. Influencers and chefs are showcasing their creative sandwich recipes, and the resulting buzz has sparked a wave of interest in homemade sandwiches. This has encouraged sandwich press manufacturers to focus on user-friendly features and designs that appeal to aspiring home chefs.

In conclusion, the trends in sandwich cooking are diverse and multifaceted, reflecting a blend of convenience, health, customization, and sustainability. These trends are not only shaping the market for heavy-duty sandwich presses but also influencing the way manufacturers design and market their products. As consumers continue to seek out unique and satisfying sandwich experiences, the industry will undoubtedly continue to evolve, bringing new innovations and preferences to the forefront.

Case Studies: Successful Heavy Duty Sandwich Press Factories

In the bustling world of foodservice and home cooking, heavy-duty sandwich presses have become a staple in many kitchens. Let’s delve into the stories of a few factories that have not only thrived but also set new standards in the industry.

The Factory in Chicago: A Culinary Innovation HubWith a reputation for pushing the boundaries of sandwich making, this Chicago-based factory has been a beacon of innovation. Their presses are known for their ability to achieve that perfect golden-brown crust on both sides of the sandwich, thanks to precise heat control technology. The factory’s success can be attributed to their relentless pursuit of customer feedback, which has led to constant improvements in their product design.

The Italian Craftsmanship of Florence’s FactoryNestled in the heart of Florence, Italy, this factory has mastered the art of blending old-world craftsmanship with modern technology. Their heavy-duty sandwich presses are a blend of traditional Italian design and advanced engineering. The factory’s attention to detail is evident in the precision of their presses, which are handcrafted by skilled artisans. Their commitment to quality has made them a favorite among gourmet sandwich shops across Europe.

The German Engineering Excellence in BerlinIn Berlin, a factory known for its engineering prowess has carved a niche in the sandwich press market. Their presses are renowned for their robust construction and durability. The factory’s engineering team has developed a unique heating element that ensures even heat distribution, resulting in consistently perfect sandwiches. Their innovative approach to manufacturing has helped them stand out in a competitive market.

The Asian Efficiency in Tokyo’s FactoryTokyo’s factory has managed to combine efficiency with quality, making it a leader in the Asian market. Their heavy-duty sandwich presses are not only durable but also energy-efficient. The factory’s focus on sustainability is reflected in their use of eco-friendly materials and energy-saving technologies. Their commitment to providing high-quality products at competitive prices has made them a go-to for businesses looking to expand their menu offerings.

The California Innovation LabOn the West Coast of the United States, a factory in California has embraced innovation with open arms. Their heavy-duty sandwich presses are a testament to the fusion of technology and culinary art. The factory has developed a range of presses that cater to different styles of sandwich cooking, from classic grilling to innovative air-frying methods. Their ability to adapt to the latest trends has helped them maintain a strong market presence.

The UK’s Focus on Health and WellnessA factory in the UK has recognized the growing demand for health-conscious options and has responded with a line of sandwich presses designed to cook healthier sandwiches. Their presses are equipped with adjustable temperature controls, allowing chefs to cook with less oil and fat. This focus on health and wellness has helped the factory carve out a loyal customer base among eco-friendly foodservice providers.

The Scandinavian SimplicityIn Scandinavia, a factory has taken a minimalist approach to sandwich press design, focusing on simplicity and functionality. Their presses are not only aesthetically pleasing but also highly efficient. The factory’s dedication to creating products that are easy to use and maintain has made them a favorite among busy cafes and delis.

The South American Market’s Rising StarsA factory in South America has emerged as a rising star in the heavy-duty sandwich press industry. Their presses are known for their affordability and reliability. The factory has managed to offer high-quality products without compromising on performance, making them a popular choice among small to medium-sized businesses looking to enhance their menu offerings.

These case studies highlight the diverse strategies that heavy-duty sandwich press factories have employed to achieve success. From innovation and craftsmanship to sustainability and health-conscious design, these factories have demonstrated that there is no one-size-fits-all approach to meeting the needs of the global market.

The Impact of Global Supply Chains on Factory Operations

In the modern era, the global supply chain has become an intricate web that intertwines the operations of factories worldwide. For heavy duty sandwich press manufacturers, the impact of this global network is both profound and multifaceted.

The complexity of the global supply chain has allowed these factories to source materials from various corners of the globe, leveraging the strengths and efficiencies of different regions. This diversity in sourcing can lead to cost savings, but it also brings its own set of challenges. Materials may arrive at different times, requiring factories to manage inventory meticulously to avoid disruptions in production.

Moreover, the reliance on international suppliers means that disruptions in the global supply chain can have a cascading effect on factory operations. For instance, a sudden halt in the supply of key components, such as springs or heating elements, can lead to production delays. These delays, in turn, can impact delivery schedules and customer satisfaction.

The globalization of the supply chain has also led to an increased focus on sustainability and ethical sourcing. Factories must navigate a landscape where consumers are increasingly aware and concerned about the environmental and social impact of their products. This means that manufacturers of heavy duty sandwich presses must ensure that their supply chain partners adhere to stringent environmental regulations and labor standards.

On the positive side, the global supply chain has opened up new markets for heavy duty sandwich press manufacturers. By sourcing components from different countries, factories can tailor their products to meet the specific needs and preferences of local markets. For example, a factory might source high-quality steel from Germany for durability and precision, while using advanced heating technology from Japan for consistent sandwich pressing.

The logistics of managing a global supply chain also necessitates sophisticated tracking and management systems. Factories must have real-time visibility into their supply chain to predict and mitigate risks. This often involves investing in technology that can provide insights into inventory levels, transportation routes, and potential bottlenecks.

In terms of labor, the global supply chain has enabled factories to tap into a global talent pool. This can lead to a more diverse workforce with a variety of skills and experiences. However, it also means that factories must navigate cultural differences and language barriers, which can affect communication and collaboration.

Another significant impact of the global supply chain on factory operations is the rise of just-in-time (JIT) production methods. JIT is a lean manufacturing approach that focuses on reducing inventory and waste by receiving materials and producing goods just in time for customer demand. This requires a high level of coordination and efficiency within the factory and with suppliers.

Furthermore, the global supply chain has increased the competition for heavy duty sandwich press manufacturers. With products and services being sourced from around the world, factories must constantly innovate to stay ahead. This can lead to a more dynamic and innovative environment, as factories seek to differentiate themselves through quality, design, and customer service.

The impact of global supply chains on factory operations is also evident in the area of intellectual property (IP) protection. As products move through various stages of production across multiple countries, factories must ensure that their IP is safeguarded against infringement. This involves navigating complex legal frameworks and establishing clear contracts with suppliers and partners.

In conclusion, the global supply chain has had a profound impact on the operations of heavy duty sandwich press factories. While it offers opportunities for cost savings, market expansion, and innovation, it also presents challenges related to supply chain disruptions, sustainability, and the need for advanced tracking and management systems. Factories must adapt to these dynamics to remain competitive and efficient in the ever-evolving landscape of global manufacturing.

Future Projections and Predictions for the Heavy Duty Sandwich Press Industry

The heavy duty sandwich press industry is poised for significant growth, influenced by a variety of factors. From evolving consumer tastes to technological advancements, the future looks promising for manufacturers in this niche market. Here are some key projections and predictions shaping the industry:

1. Market Expansion into Emerging MarketsEmerging markets, particularly in Asia and South America, are expected to see a surge in demand for heavy duty sandwich presses. As these regions experience economic growth and urbanization, the demand for convenience foods like sandwiches will likely rise, creating new opportunities for sandwich press manufacturers.

2. Technological IntegrationThe integration of smart technology into sandwich presses is anticipated to become more prevalent. Features such as programmable settings, Bluetooth connectivity for remote control, and even AI-driven recommendations for perfect sandwich preparation are on the horizon. This technological integration could appeal to tech-savvy consumers and open up new markets.

3. Health and Wellness TrendsWith a growing focus on health and wellness, there’s a prediction that sandwich presses will evolve to cater to these preferences. Manufacturers might see a rise in demand for models that can produce healthier sandwiches, such as those with reduced fat content or those that allow for the use of whole-grain breads and fresh ingredients.

4. Customization and PersonalizationThe ability to customize sandwiches to individual preferences is likely to become a key driver in the industry. This could lead to the development of sandwich presses that offer a variety of press plates for different types of bread and fillings, or even models that can be customized through 3D printing technology for unique shapes and sizes.

5. Sustainability FocusSustainability is a growing concern globally, and the heavy duty sandwich press industry is not immune. Predictions suggest that manufacturers will need to focus on eco-friendly materials and energy-efficient designs to meet the demands of environmentally conscious consumers.

6. Collaboration with Foodservice IndustryAs the demand for convenience grows, there’s an opportunity for heavy duty sandwich press manufacturers to collaborate with the foodservice industry. This could include developing commercial-grade presses for use in cafes, restaurants, and fast-food outlets, as well as creating solutions for mobile food vendors.

7. Increased Export OpportunitiesWith the expansion of global trade, the heavy duty sandwich press industry could see a boost in export opportunities. As countries become more open to international products, manufacturers may find new markets for their presses, especially in regions where the concept of a sandwich press is still relatively new.

8. Shift Towards Electric and Gas-Free ModelsGiven the environmental concerns, there’s a projection that manufacturers may shift towards electric and gas-free sandwich presses. These models would reduce emissions and align with the global push towards cleaner energy sources.

9. Niche Market FocusWhile the mainstream market continues to grow, there’s also an opportunity to tap into niche markets. This could include specialty presses for vegan, gluten-free, or keto diets, as well as presses designed for specific cultural or regional sandwich styles.

10. Regulatory ComplianceThe future of the heavy duty sandwich press industry will also be shaped by regulatory compliance. As standards for food safety and product quality continue to evolve, manufacturers will need to ensure their products meet the latest requirements to stay competitive.

11. Market Saturation and CompetitionIt’s important to note that as the market grows, so does competition. Manufacturers may need to differentiate their products through innovation, quality, and customer service to maintain a competitive edge.

12. Longevity and DurabilityConsumers are increasingly looking for durable and long-lasting appliances. The heavy duty sandwich press industry may see a trend towards products that offer greater longevity, ensuring that customers get the most out of their investment.

These projections and predictions offer a glimpse into the future of the heavy duty sandwich press industry, highlighting the potential for growth and innovation. As consumer preferences and market dynamics continue to change, manufacturers will need to stay agile and adapt to new trends to thrive in this dynamic sector.