Beneath the storied skyline of St. Petersburg, a manufacturer known for its precision and innovation has been quietly shaping the future of industry. CIP St. Petersburg isn’t just a company; it’s a cornerstone of the local economy and a beacon of technological advancement. With a legacy that spans decades, CIP has become synonymous with excellence, and its journey is one that is as fascinating as it is inspiring.

Discovering CIP St Petersburg: A Hub of Manufacturing Excellence

CIP St Petersburg has long been recognized as a beacon of manufacturing excellence, a place where innovation meets tradition. Nestled in the heart of Saint Petersburg, this manufacturer has carved out a niche for itself in the global market, offering a wide array of high-quality products. As you delve into the world of CIP St Petersburg, you’ll find a story of dedication, precision, and relentless pursuit of perfection.

The city itself, renowned for its architectural wonders and cultural richness, serves as an inspiration for the company. Here, history and modernity blend seamlessly, much like the advanced techniques and age-old craftsmanship that CIP St Petersburg prides itself on. From the moment you step onto their premises, it’s clear that this is no ordinary manufacturing facility.

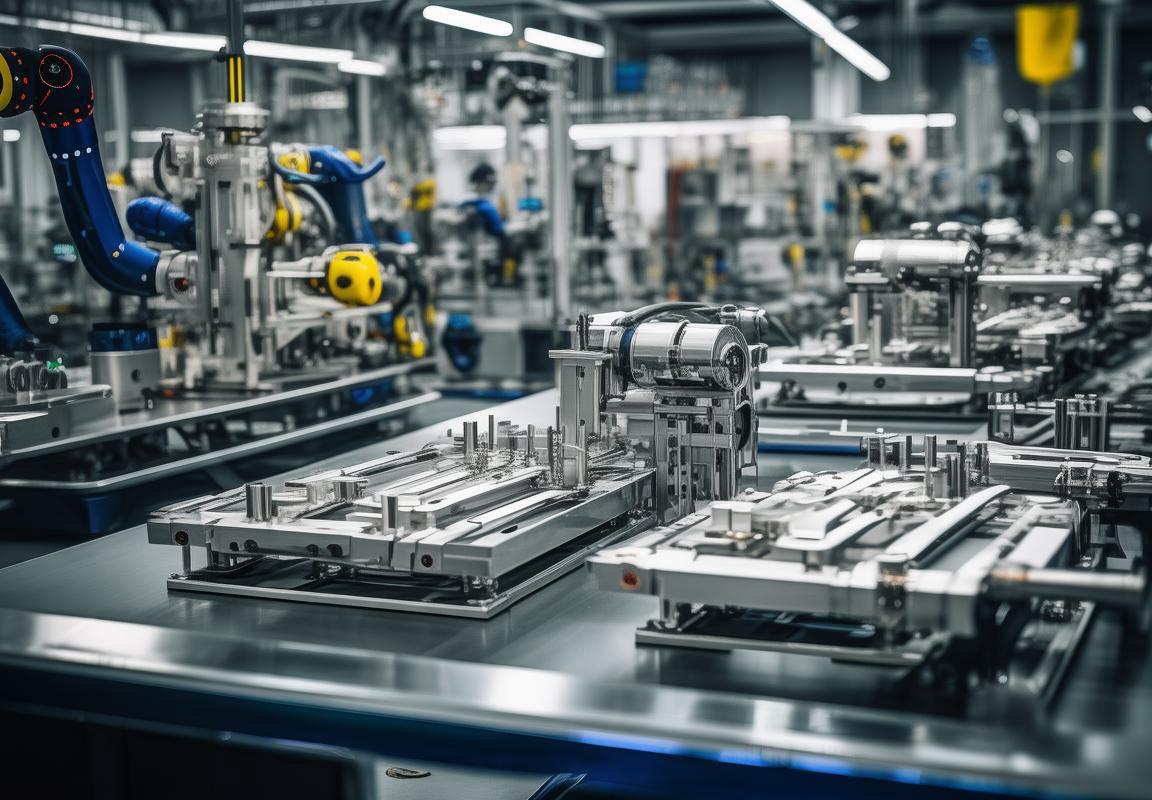

The company’s commitment to excellence starts with the raw materials they select. Each component is meticulously chosen for its quality and durability, ensuring that the final product is not only reliable but also stands the test of time. The factory floor is a testament to this philosophy, with state-of-the-art equipment working in harmony to transform raw materials into precision-engineered goods.

In the heart of the factory, the manufacturing process is a symphony of precision and coordination. Workers move with purpose, each step in the process a crucial part of the whole. Advanced machinery whirs and hums, guided by the expert hands of skilled technicians. It’s a scene that speaks volumes about the company’s investment in technology and the training of its workforce.

CIP St Petersburg’s product line is diverse, catering to a wide range of industries from automotive to aerospace. Their focus on innovation is evident in their design and development department, where engineers and designers collaborate to create cutting-edge solutions. The result is a product portfolio that is not only robust but also adaptable to the changing needs of the market.

The quality control at CIP St Petersburg is rigorous. Every product undergoes a series of checks and tests before it leaves the factory. This dedication to quality has earned the company a reputation for reliability, with clients returning time and again for their products and services.

The team at CIP St Petersburg is a blend of seasoned professionals and fresh talent. They come from various backgrounds, bringing with them a wealth of knowledge and experience. The company values this diversity, recognizing that it enriches their collective ability to tackle challenges and drive innovation.

Sustainability is another cornerstone of CIP St Petersburg’s operations. They are committed to minimizing their environmental footprint through the use of eco-friendly materials and energy-efficient processes. This approach not only reduces waste but also aligns with the global trend towards more sustainable manufacturing practices.

Client testimonials and case studies are a testament to the success of CIP St Petersburg’s products and services. Stories of how their solutions have improved efficiency, reduced costs, and enhanced performance in various applications are a testament to the company’s impact on the industry.

Collaborations and partnerships are integral to the company’s growth strategy. CIP St Petersburg actively seeks opportunities to work with other businesses, sharing resources and knowledge to create innovative solutions. These alliances have helped the company expand its reach and deepen its expertise.

Looking ahead, CIP St Petersburg is poised for continued growth. With plans to invest in new technologies and expand their production capabilities, the company is committed to staying at the forefront of the manufacturing industry. New projects are in the pipeline, promising to push the boundaries of what is possible.

In conclusion, CIP St Petersburg stands out not just for its products, but for its culture of excellence, innovation, and sustainability. It’s a place where the future of manufacturing is being shaped, and where the promise of quality and reliability is delivered daily.

The Rich History of CIP St Petersburg

Established in the late 19th century, CIP St Petersburg has a storied past that intertwines with the city’s own rich heritage. The roots of the company can be traced back to a time when craftsmanship and innovation were at the forefront of industrial development. Over the years, the company has evolved, reflecting the changing landscapes of technology and market demands.

The original founders, a group of visionaries with a passion for precision engineering, laid the groundwork for what would become a cornerstone of the St Petersburg manufacturing scene. Their dedication to quality and excellence has been a consistent thread through the company’s history, shaping its identity and reputation.

As the 20th century dawned, CIP St Petersburg expanded its operations, adapting to the era’s industrial revolution. The company’s expertise in metalworking and mechanical engineering became increasingly sought after, with a growing list of prestigious projects under their belt. The Soviet era brought about significant challenges, but also opportunities for growth, as the demand for high-quality manufacturing solutions surged.

During this time, CIP St Petersburg played a pivotal role in the development of various industries, including aerospace, defense, and heavy machinery. The company’s ability to innovate and adapt to new technologies was a testament to their resilience and foresight. The legacy of these early years is still evident in the company’s commitment to precision and the enduring craftsmanship that defines their products.

The fall of the Soviet Union marked a new chapter for CIP St Petersburg. The transition to a market economy brought about a period of restructuring and rebranding, but it also allowed the company to embrace international markets and collaborate with global partners. This era of globalization fostered a new wave of innovation, as the company began to incorporate advanced manufacturing techniques and state-of-the-art equipment into its production process.

Throughout the late 20th and early 21st centuries, CIP St Petersburg continued to evolve, diversifying its product range and expanding its capabilities. The company’s portfolio now includes a wide array of specialized components, equipment, and systems, catering to industries such as automotive, energy, and telecommunications.

One of the most significant milestones in the company’s history was the development of a proprietary technology that revolutionized the manufacturing process. This innovation not only increased efficiency but also set new standards for quality and reliability. The success of this technology has been a cornerstone of CIP St Petersburg’s growth and has positioned them as a leader in the field.

Despite the company’s expansion and technological advancements, the core values of CIP St Petersburg have remained steadfast. Integrity, customer focus, and a relentless pursuit of excellence are deeply embedded in their corporate culture. This commitment has not only helped the company survive through turbulent times but has also allowed it to thrive in an ever-changing market landscape.

In the face of modern challenges, such as the digital transformation and the rise of Industry 4.0, CIP St Petersburg has once again shown its adaptability. The company has embraced digital manufacturing and automation, investing in cutting-edge technologies that not only enhance productivity but also ensure that their products remain at the forefront of industry standards.

The history of CIP St Petersburg is a testament to the power of perseverance, innovation, and a dedication to quality. From its humble beginnings to its current status as a leading manufacturer, the company’s journey is a story of resilience and evolution. It’s a narrative that reflects the dynamic spirit of St Petersburg itself, a city that has always been at the forefront of progress and innovation.

A Glimpse into the Manufacturing Process

The manufacturing process at CIP St Petersburg is a testament to precision and innovation, a journey that begins with the selection of high-quality materials and culminates in the creation of top-tier products. Here’s an in-depth look at how it all comes together.

In the heart of the factory, raw materials are meticulously inspected to ensure they meet the stringent quality standards set by CIP. Metals, plastics, and other components are checked for purity, dimensions, and any defects that could compromise the final product.

The assembly line is where the magic happens, a symphony of mechanical precision and human ingenuity. Robots and automated systems work in tandem with skilled technicians, each step designed to minimize errors and maximize efficiency. The process starts with the placement of components onto a conveyor belt, where they are guided through various stations.

At the first station, a robot arm precisely positions the parts, ensuring they are aligned correctly. This is crucial, as any misalignment can lead to issues down the line. The second station involves the application of adhesives or other bonding agents, which are carefully measured to ensure they are applied evenly and in the right quantities.

The third station is dedicated to the welding process, where high-frequency currents fuse metal parts together. This step requires constant monitoring to avoid overheating or under-welding, both of which can weaken the structure. Skilled operators watch over the process, making adjustments as needed to achieve the perfect weld.

As the product moves through the assembly line, it undergoes a series of quality checks. These checks are not just superficial; they delve deep into the integrity of the product. Specialized machines measure the dimensions of parts, test the electrical connections, and even simulate real-world conditions to ensure the product can withstand the rigors of use.

One of the most fascinating aspects of the manufacturing process at CIP St Petersburg is the use of 3D printing technology. This cutting-edge method allows for the creation of complex shapes and prototypes that were once impossible to produce. The 3D printers use a layer-by-layer approach, building up the product from a digital design. This not only speeds up the development cycle but also allows for customization that was once unattainable.

After the assembly and initial quality checks, the product is subjected to rigorous testing. These tests can range from vibration tests to thermal shock tests, ensuring that the product is robust and reliable. The results of these tests are meticulously recorded and analyzed, feeding back into the manufacturing process to improve and refine the product further.

In the final stages of manufacturing, the product is painted, coated, or treated to enhance its appearance and durability. This is a delicate process that requires attention to detail, as the finish can significantly impact the product’s performance and lifespan. Skilled painters use advanced techniques to ensure a smooth, uniform finish that meets the highest aesthetic standards.

Once the finishing touches are applied, the product is prepared for packaging. Careful consideration is given to packaging materials and methods to ensure that the product arrives at its destination in perfect condition. This includes protective padding, secure packaging, and appropriate labeling to guide the product through distribution channels.

The manufacturing process at CIP St Petersburg is not just about producing goods; it’s about creating solutions. Every step is designed to ensure that the final product is not only functional but also durable, efficient, and user-friendly. The factory’s commitment to excellence is evident in the meticulous attention to detail and the relentless pursuit of perfection that characterize every aspect of their operations.

Innovative Products and Cutting-Edge Technology

In the heart of St Petersburg’s industrial landscape, CIP stands out as a beacon of innovation, offering a diverse range of products that push the boundaries of what’s possible. From state-of-the-art machinery to sophisticated solutions for various industries, here’s a closer look at some of the cutting-edge products and the technology that powers them.

Our product line begins with precision-engineered components, meticulously crafted to exacting standards. Each piece is designed with an eye for detail, ensuring durability and functionality that exceed industry norms. From bearings to gears, every component is a testament to the artistry and engineering prowess of our team.

At the forefront of our offerings is our range of automated machinery, designed to enhance efficiency and productivity. These systems are not just built; they are refined, with features that cater to the dynamic needs of modern manufacturing. With programmable logic controllers (PLCs) and advanced servo motors, our machinery offers seamless integration, reducing downtime and optimizing workflow.

The electronics division at CIP is a shining example of how technology and innovation go hand in hand. Our line of electronic controls is renowned for its robustness and reliability, making them the go-to choice for demanding applications. From sophisticated data acquisition systems to energy-efficient motor controls, each electronic device is a blend of advanced algorithms and physical computing prowess.

One cannot speak of CIP’s products without mentioning our specialized equipment for the pharmaceutical industry. Our machinery is designed to ensure compliance with the strictest safety and cleanliness standards. The use of stainless steel materials and high-tech sanitation features ensures that our pharmaceutical products contribute to the well-being of patients worldwide.

Our energy sector solutions are no less impressive. Our turbines and generators are crafted with the latest aerodynamic and thermodynamic principles, maximizing energy output while minimizing environmental impact. The integration of smart grid technologies allows for better energy management and grid stability, making our equipment essential for sustainable power generation.

In the aerospace and defense sectors, CIP’s products are synonymous with high performance and advanced engineering. Our lightweight, yet extremely strong materials and components are integral to aircraft construction and military equipment. The attention to material science and aerodynamics is unparalleled, offering solutions that meet the extreme demands of these industries.

Our line of robotics and automation systems is a marvel of modern technology. Equipped with advanced sensors and AI algorithms, these systems are capable of complex tasks with precision and consistency. They are not just tools but collaborators, working alongside human operators to achieve efficiency and accuracy that manual labor alone cannot match.

In the realm of industrial controls, CIP’s offerings are versatile and scalable. From small-scale control panels for small businesses to large, integrated systems for major industrial plants, our control solutions are tailored to fit any operational need. The integration of cloud-based data analytics allows for real-time monitoring and predictive maintenance, further enhancing reliability and reducing operational costs.

Our research and development department is always on the lookout for the next big breakthrough. By investing in cutting-edge technology such as 3D printing and additive manufacturing, we are able to prototype and produce complex parts that were once thought impossible. This commitment to innovation ensures that our products are not just meeting today’s needs but also anticipating future challenges.

Finally, our commitment to quality is evident in the meticulous testing and certification process each product undergoes. From material strength and endurance testing to environmental and safety compliance checks, every product is rigorously evaluated to ensure it meets the highest standards.

In essence, the products of CIP St Petersburg are not just items but innovations that drive progress across multiple industries. With a focus on cutting-edge technology and a dedication to continuous improvement, our offerings stand as a testament to what is possible when passion meets precision.

The Team Behind the Scenes

In the heart of CIP St Petersburg, a dedicated team of professionals works tirelessly to bring innovative solutions to life. This group of individuals, from engineers and designers to technicians and quality assurance experts, forms the backbone of the company’s success. Let’s take a closer look at the diverse roles and personalities that make up this exceptional team.

The engineers at CIP St Petersburg are the masterminds behind the company’s cutting-edge products. With degrees in various disciplines, they possess a deep understanding of both the theoretical and practical aspects of their field. They collaborate closely with the design team to translate complex concepts into feasible prototypes. Their meticulous attention to detail ensures that every component is optimized for performance and reliability.

The designers at CIP St Petersburg are the creative force behind the company’s product lineup. They draw inspiration from the latest market trends and customer needs, crafting innovative designs that not only look stunning but also function seamlessly. Their work often involves sketching out initial ideas, creating detailed 3D models, and iterating designs until they achieve perfection. The designers’ ability to think outside the box has led to several groundbreaking products that have set new standards in the industry.

The technicians at CIP St Petersburg are the hands-on experts who breathe life into the designs. They work in the factory, where they assemble, test, and fine-tune products to ensure they meet the highest quality standards. Their technical expertise is crucial in diagnosing and resolving any issues that arise during the manufacturing process. The technicians’ knowledge of various machinery and tools allows them to tackle complex challenges with ease, often finding solutions that others might overlook.

The quality assurance team at CIP St Petersburg plays a pivotal role in maintaining the company’s reputation for excellence. They meticulously inspect each product at various stages of the manufacturing process, from raw materials to the final assembly. Their attention to detail helps identify and rectify any defects before the product reaches the customer. The team’s rigorous testing protocols ensure that every item leaving the factory meets the strictest quality benchmarks.

The administrative staff at CIP St Petersburg are the unsung heroes who keep everything running smoothly. They handle orders, manage inventory, and coordinate with suppliers and distributors. Their organizational skills are essential in ensuring that materials and components are available when needed, minimizing downtime and keeping production on track. The administrative team also handles customer inquiries and resolves any issues promptly and efficiently.

The sales and marketing team at CIP St Petersburg are the face of the company. They work tirelessly to promote the company’s products and build strong relationships with clients. Their in-depth knowledge of the market and the company’s offerings allows them to effectively communicate the value proposition to potential customers. The sales team’s negotiation skills are crucial in closing deals and securing long-term partnerships.

The research and development team at CIP St Petersburg are the pioneers of new ideas and technologies. They are constantly seeking ways to improve existing products and explore new frontiers. This team collaborates with academic institutions and industry leaders to stay ahead of the curve and push the boundaries of what’s possible. Their innovative thinking has led to several patents and a competitive edge in the market.

The support staff, including human resources, finance, and IT, are the pillars that support the entire organization. They provide the necessary infrastructure and resources for the team to thrive. The HR department ensures that the company maintains a positive work environment and attracts top talent. The finance team manages the company’s budget and financial health, while the IT department keeps the company’s digital operations running smoothly.

Each member of the team at CIP St Petersburg brings their unique skills and perspectives to the table, contributing to the company’s collective success. Their dedication, creativity, and commitment to excellence are what set CIP St Petersburg apart from its competitors. It’s this diverse and dynamic team that makes the company a leader in its field, continuously pushing the boundaries of what’s achievable in manufacturing.

Sustainability and Quality Assurance at CIP St Petersburg

In the heart of St Petersburg, CIP stands not just as a manufacturer, but as a beacon of sustainability and quality assurance. Their commitment to both is woven into the very fabric of their operations, from the design phase to the final product delivery.

Our journey begins with the raw materials, meticulously selected to ensure they are not only of the highest quality but also environmentally friendly. CIP St Petersburg has implemented a stringent sourcing policy that prioritizes materials that are recyclable, biodegradable, or sourced from sustainable practices. This attention to detail is a testament to their dedication to reducing their ecological footprint.

The manufacturing floor buzzes with activity, but it’s the precision and care that truly set CIP apart. Advanced machinery, some of which is custom-built for the specific needs of their products, operates with a level of sophistication that is a testament to the company’s investment in technology. Employees, trained to the highest standards, work in harmony with these machines, ensuring that every component is crafted to perfection.

Quality assurance is not just a department at CIP; it’s an ethos that permeates every aspect of their work. A team of inspectors and quality control specialists monitors the production process at every stage, from the initial assembly to the final product inspection. Their keen eyes catch even the most subtle of defects, ensuring that only the best products leave the factory.

The company’s focus on sustainability extends beyond just materials and manufacturing. Energy efficiency is a cornerstone of their operations, with state-of-the-art systems in place to minimize waste and maximize energy recovery. Solar panels and wind turbines are integrated into the facility, providing a renewable energy source that reduces reliance on traditional grids.

Innovation is at the core of CIP St Petersburg’s DNA. They invest heavily in research and development, constantly seeking new ways to improve their products and processes. This drive for innovation has led to the creation of several groundbreaking products that have set new industry standards. From eco-friendly materials to energy-saving designs, these innovations reflect the company’s commitment to pushing boundaries.

The team at CIP St Petersburg is diverse and dynamic, reflecting the global nature of their business. Engineers, designers, and technicians collaborate closely, sharing ideas and expertise to solve complex problems. This collaborative environment fosters creativity and ensures that the best minds are working together to achieve common goals.

Training and development are key components of CIP’s employee culture. The company offers ongoing education and professional growth opportunities, ensuring that their workforce is always up to date with the latest industry trends and technologies. This investment in their team’s skills and knowledge pays off in the form of high-quality products and a satisfied customer base.

As we move through the factory, we see examples of CIP’s commitment to sustainability in action. Water recycling systems are in place to reduce waste, and the use of recycled materials is encouraged throughout the production process. Even the packaging is designed with sustainability in mind, using minimal materials and ensuring that it can be recycled or composted.

CIP St Petersburg’s dedication to quality assurance is evident in their certifications and accreditations. They hold several international standards, including ISO 9001 for quality management and ISO 14001 for environmental management, demonstrating their adherence to rigorous global standards.

In the end, it’s the people behind the scenes who make CIP St Petersburg what it is today. From the engineers who design the products to the logistics team who ensure they reach their destinations, each member of the team plays a crucial role in the company’s success. Their passion for excellence, combined with a deep sense of responsibility towards the environment, is what drives CIP to continue leading the way in sustainable manufacturing.

Customer Success Stories: Testimonials and Achievements

In the heart of CIP St Petersburg, stories of triumph and satisfaction resonate through the halls. These tales come from clients who have not only witnessed the transformation of their projects but also the commitment to excellence that defines the company. Let’s delve into a few of these success stories, sharing testimonials and achievements that highlight the impact of CIP St Petersburg’s work.

Our first story comes from a local architectural firm that was faced with a unique challenge. They needed a custom solution for a high-profile project, and CIP St Petersburg rose to the occasion. The firm’s lead architect, Maria Ivanova, shared, “The team at CIP was instrumental in helping us turn a complex design into a reality. Their attention to detail and their ability to innovate within the constraints of the project were truly remarkable.”

The project involved the design and installation of a custom glass facade that required both artistic flair and technical precision. CIP St Petersburg’s engineers worked closely with Maria’s team to ensure that the glass not only met the aesthetic requirements but also adhered to the highest safety standards. The end result was a stunning facade that has become a centerpiece of the city’s skyline.

Another testament to CIP St Petersburg’s dedication to customer satisfaction is the story of a global tech giant that sought to expand its operations in the region. The company needed a state-of-the-art data center, and CIP St Petersburg was tasked with the infrastructure design and construction. The project manager for the tech firm, Alexei Petrov, noted, “CIP St Petersburg delivered a facility that far exceeded our expectations. Their team was not only skilled in the technical aspects but also in understanding our business needs.”

The data center required a high level of energy efficiency and environmental sustainability. CIP St Petersburg’s experts designed a system that minimized energy consumption and waste, earning the facility a LEED certification. Alexei added, “The sustainability features were a crucial part of our strategy, and CIP St Petersburg made it happen without compromising on performance.”

Moving on to the healthcare sector, CIP St Petersburg’s involvement in a major hospital expansion project stands out as a shining example of their commitment to community. The hospital’s CEO, Elena Sergeeva, expressed her gratitude, “The team at CIP St Petersburg was not just a contractor but a partner in our mission to improve patient care. Their work on the expansion was meticulous, ensuring that every corner of the new facilities met the highest standards of cleanliness and functionality.”

The expansion included the construction of new operating rooms, intensive care units, and administrative offices. CIP St Petersburg’s engineers and architects worked in tandem with the hospital’s staff to create a layout that maximized efficiency and minimized patient wait times. Elena emphasized, “The result is a hospital that not only looks impressive but is also incredibly user-friendly for both patients and staff.”

One cannot overlook the impact of CIP St Petersburg’s work in the residential sector. A local developer, Ivan Kondratyev, turned to CIP St Petersburg to create a sustainable housing community. “The sustainability aspect was not just a marketing ploy,” Ivan said. “CIP St Petersburg’s team took it seriously and delivered a community that is both eco-friendly and luxurious.”

The housing development features energy-efficient homes, green spaces, and communal areas designed to foster a sense of community. Ivan continued, “CIP St Petersburg’s attention to detail in every aspect of the project, from the building materials to the landscaping, has set a new benchmark for sustainable living in our area.”

These stories, and many more, are a testament to the dedication and expertise of the team at CIP St Petersburg. From architecture to technology, healthcare to residential, their work is marked by a relentless pursuit of quality and innovation. As one satisfied client, Olga Dmitrieva, summed up, “When you work with CIP St Petersburg, you’re not just getting a service; you’re getting a partner in success.”

Collaborations and Partnerships

In the ever-evolving world of manufacturing, collaborations and partnerships play a pivotal role in driving innovation, expanding market reach, and ensuring the highest standards of quality. At CIP St Petersburg, these alliances are not just strategic moves but are deeply woven into the fabric of their business philosophy.

At CIP St Petersburg, one of the key strengths lies in the collaborative efforts with industry leaders. These partnerships often result in groundbreaking projects that push the boundaries of what’s possible in their field. By joining forces with top-tier companies, CIP St Petersburg is able to tap into a wealth of knowledge and expertise, creating a synergy that fuels their growth.

One notable collaboration involved a joint venture with a leading technology provider. This alliance allowed CIP St Petersburg to integrate advanced machinery and software into their production line, enhancing efficiency and precision. The outcome was not just a faster production process but also a significant reduction in waste and energy consumption, showcasing the power of innovation through collaboration.

CIP St Petersburg’s partnerships also extend to research and development. By collaborating with academic institutions, they have been able to leverage cutting-edge research and develop new products that address the evolving needs of their customers. This approach has led to the creation of several innovative solutions, each designed to offer superior performance and reliability.

Another key aspect of CIP St Petersburg’s collaboration strategy is their work with suppliers. These relationships are built on trust and mutual respect, ensuring a steady supply of high-quality materials that are essential for their manufacturing processes. This vertical integration not only ensures a consistent flow of materials but also allows for better control over the quality of the end products.

International collaborations have also been a cornerstone of CIP St Petersburg’s success. By partnering with companies from various parts of the world, they have been able to gain insights into different markets and customer preferences. This global perspective has helped them tailor their offerings to a wider audience, expanding their reach and influence.

The success of these partnerships can be seen in the testimonials from both customers and industry peers. Many have praised the company’s commitment to collaboration, noting how it has led to the development of products that exceed industry standards. These testimonials often highlight the shared values and common goals that drive these collaborations forward.

In the realm of sustainability, CIP St Petersburg has forged partnerships with environmental organizations. These alliances are not just about adhering to regulations but are about making a tangible impact on the environment. By working together, they have implemented green practices that not only reduce their carbon footprint but also set a new benchmark for sustainability in the manufacturing sector.

Furthermore, CIP St Petersburg has been instrumental in fostering industry-wide partnerships aimed at driving innovation and standards. These initiatives have led to the development of new industry protocols and certifications, ensuring that all participants in the supply chain maintain high levels of quality and safety.

One of the most impressive aspects of CIP St Petersburg’s collaborations is their ability to adapt to changing market dynamics. Whether it’s the adoption of new technologies, the expansion into new markets, or the need to respond to global supply chain disruptions, their partners have been able to rely on their flexibility and agility.

As the manufacturing landscape continues to evolve, CIP St Petersburg remains steadfast in its commitment to collaboration and partnerships. These alliances are not just a means to an end; they are the lifeblood of their operations, fueling their growth and innovation in a rapidly changing world.

These partnerships have not only brought about tangible benefits but have also fostered a culture of excellence within the company. The shared values and common goals have created a collaborative environment where ideas are freely exchanged, and the best practices are adopted. This collaborative spirit is evident in every aspect of their operations, from product design to customer service.

In conclusion, the collaborations and partnerships at CIP St Petersburg are a testament to their dedication to excellence, innovation, and sustainability. Through these alliances, they have been able to push the boundaries of what’s possible, deliver superior products, and leave a positive impact on the industry and the environment. As they continue to forge ahead, these collaborations are sure to play a pivotal role in shaping their future success.

Looking to the Future: Expansion and New Projects

Innovation is at the heart of CIP St Petersburg’s growth, and as the company continues to evolve, its expansion and new projects are poised to reshape the landscape of manufacturing. From groundbreaking research and development to strategic investments in cutting-edge technology, here’s a glimpse into the future endeavors of this innovative manufacturer.

Our commitment to pushing boundaries extends to our expansion plans, which are not just about increasing our footprint but also about enhancing our capabilities. We’re investing in new facilities that will not only accommodate our growing operations but also serve as hubs for innovation and collaboration.

One of the key projects on the horizon is the development of a state-of-the-art research and development center. This center will be a cornerstone of our future, designed to foster creativity and provide a platform for our engineers and scientists to work on groundbreaking solutions. It’s a place where the limits of what’s possible are constantly being redefined.

In addition to our R&D center, we’re looking at expanding our production lines to include new technologies that allow for higher efficiency and precision. This includes the integration of automated systems that can handle complex manufacturing tasks with unparalleled speed and accuracy. The goal is to ensure that every product we produce is not just of the highest quality but also reflects the latest advancements in manufacturing.

Another exciting aspect of our future is the exploration of new markets. We’re actively seeking opportunities to expand our reach into regions where our products can make a significant impact. This expansion is not just about increasing sales but also about sharing our expertise and contributing to the growth and development of these markets.

Collaborations are a cornerstone of our strategy. We’re forming strategic partnerships with leading universities, research institutions, and other companies to drive innovation forward. These collaborations are not just about sharing resources but also about combining diverse perspectives to create solutions that are both unique and practical.

One such partnership is with a renowned materials science firm, where we’re jointly developing new materials that can withstand extreme conditions. This collaboration is a testament to our belief in the power of collaboration to push the boundaries of what’s achievable.

We’re also investing in renewable energy initiatives, aiming to reduce our carbon footprint and contribute to a more sustainable future. Our new manufacturing facilities are being designed with energy efficiency in mind, featuring advanced systems for waste reduction and recycling.

In terms of new projects, we’re exploring the application of artificial intelligence in our manufacturing processes. AI has the potential to optimize production, predict maintenance issues, and even personalize products to meet individual customer needs. We’re looking at pilot programs to test these technologies and integrate them into our operations.

Our approach to expansion and new projects is guided by a deep sense of responsibility towards our employees, customers, and the environment. We’re committed to providing a safe and rewarding workplace, ensuring our products meet the highest standards of quality, and contributing positively to the communities in which we operate.

As we look to the future, we’re not just thinking about the next few years; we’re envisioning a future where technology, innovation, and sustainability go hand in hand. It’s a future where CIP St Petersburg continues to lead the way, setting new benchmarks in the manufacturing industry and beyond.

Conclusion: Why CIP St Petersburg Stands Out in the Industry

In the ever-evolving landscape of manufacturing, CIP St Petersburg has carved out a niche for itself with its unwavering commitment to excellence. The company’s reputation is not just built on the quality of its products but also on the innovative spirit that drives its workforce. Here’s a look at why CIP St Petersburg stands out in the industry.

The company’s legacy is a testament to its dedication to innovation and customer satisfaction. Over the years, it has embraced technological advancements and has become a beacon of progress in the sector. From the early days of handcrafted goods to the sophisticated machinery of today, CIP St Petersburg has continually pushed the boundaries of what is possible.

CIP St Petersburg’s workforce is a diverse and dynamic group of professionals who bring a wealth of experience and creativity to the table. They are not just employees; they are innovators, thinkers, and doers. Their passion for their work is evident in every detail, from the intricate designs to the meticulous quality checks.

The company’s focus on sustainability is another reason it stands out. CIP St Petersburg has implemented eco-friendly practices that not only reduce its environmental footprint but also enhance the quality of its products. By using sustainable materials and energy-efficient processes, the company ensures that its operations are both environmentally responsible and economically viable.

Customers who have worked with CIP St Petersburg often share success stories that highlight the company’s ability to deliver on its promises. From the initial consultation to the final delivery, the team at CIP St Petersburg is dedicated to understanding the unique needs of each client and providing tailored solutions. These testimonials speak volumes about the company’s commitment to excellence and customer service.

Collaborations and partnerships have been key to CIP St Petersburg’s growth and success. The company has forged strong alliances with industry leaders, academic institutions, and research organizations. These relationships have not only facilitated the development of new technologies but have also opened doors to new markets and opportunities.

The future of CIP St Petersburg is bright, and the company is actively seeking new ways to expand its capabilities. With plans to invest in state-of-the-art equipment and to develop new product lines, the company is poised to take its place among the industry leaders. The focus on research and development is unwavering, as CIP St Petersburg aims to stay ahead of the curve and offer solutions that are not just cutting-edge but also forward-thinking.

The company’s leadership understands that success is not just about what is done today but about the legacy that will be left behind. This forward-thinking approach is reflected in its approach to new projects. Whether it’s the development of a new material or the refinement of an existing product, every project is treated with the same level of care and attention to detail.

In an industry that is constantly changing, CIP St Petersburg’s adaptability is a significant factor in its continued success. The company’s ability to pivot and adjust to new challenges without compromising on quality or innovation is a testament to its resilience and foresight.

The company’s culture of continuous improvement is another reason it stands out. From the training programs that ensure employees are up-to-date with the latest industry standards to the regular feedback loops that allow for constant refinement, CIP St Petersburg is a place where excellence is not just a goal but a way of life.

As the company celebrates its achievements and looks forward to the future, it does so with a sense of pride and humility. The journey has been long and filled with milestones, but the path ahead is equally exciting. CIP St Petersburg is not just a manufacturer; it is a driving force for innovation and a symbol of what can be achieved through hard work, dedication, and a relentless pursuit of excellence.