In a world where the cold can be as relentless as it is unforgiving, the quest for cold resistance has become a testament to human ingenuity. The development of a -30°C cold-resistant model isn’t just a technological feat; it’s a leap forward that promises to reshape how we interact with the harsh realities of extreme climates. This innovation, born from the depths of engineering ingenuity, is not just a marvel of science—it’s a game-changer for consumers and industries alike.

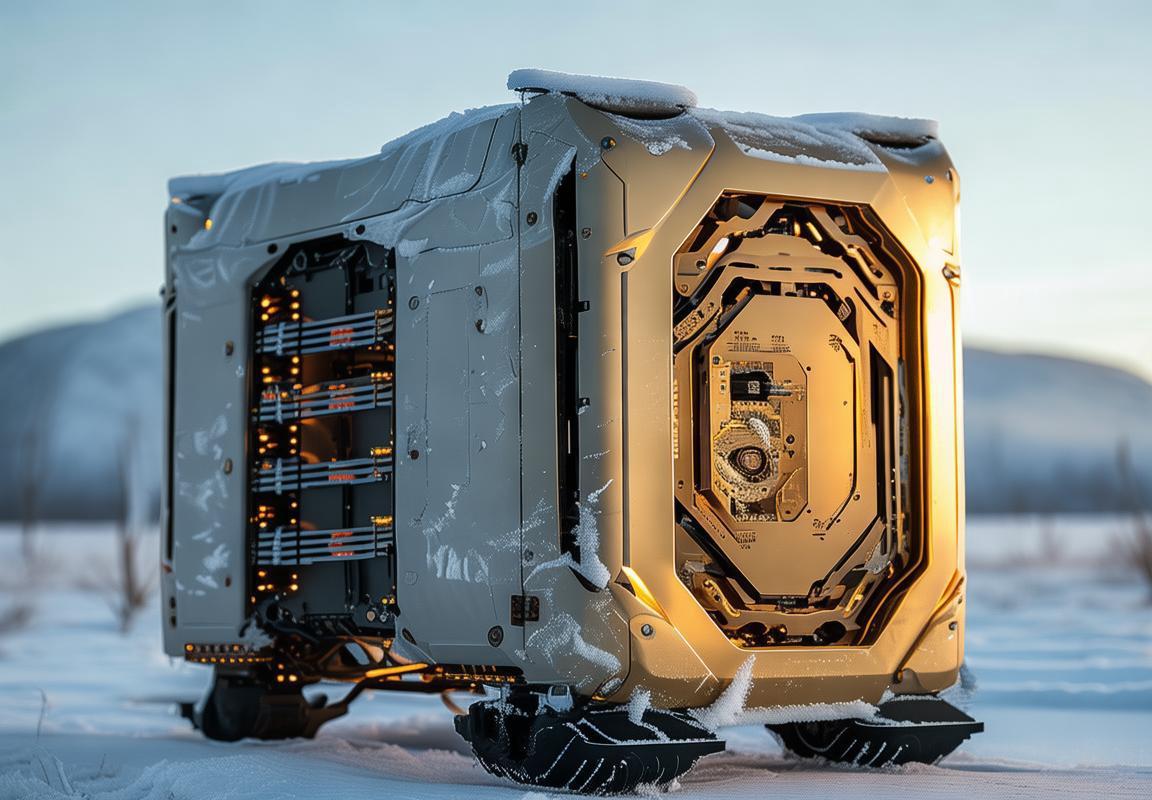

Introducing the Ultimate -30°C Cold Resistant Model

In the relentless pursuit of innovation and excellence, we’ve hit a new milestone with the unveiling of the ultimate -30°C Cold Resistant Model. This groundbreaking creation is not just another product; it’s a testament to human ingenuity and the ability to push the boundaries of what’s possible.

Crafted with the harshest climates in mind, this model is designed to thrive in environments where most would simply fail. Whether it’s the heart of a frigid winter in Siberia or the icy reaches of Antarctica, this model is ready to perform without compromise.

The cold resistance of -30°C is no small feat. It’s a threshold that many devices can’t cross, but this model has been meticulously engineered to not only survive but to excel in such extreme conditions. Its resilience is not just a feature; it’s the core of its identity.

At the heart of this marvel is a sophisticated thermal management system. This isn’t your average cooling system; it’s been fine-tuned to maintain optimal performance even when the mercury plummets. Advanced heat sinks and insulating materials are woven into the fabric of this model, ensuring that every component stays within its operational limits.

The materials used are not just any metals or plastics; they are high-grade alloys and composites that have been selected for their exceptional thermal conductivity and durability. These materials are not just cold-resistant; they are also resistant to corrosion, ensuring that the model can withstand not just the cold but also the corrosive elements that often accompany extreme temperatures.

The design of the -30°C Cold Resistant Model is as impressive as its materials. It boasts a sleek, aerodynamic shell that minimizes heat retention and maximizes heat dissipation. Every curve and angle has been calculated to reduce drag and enhance thermal efficiency, making it as at home in the cold as it would be in more temperate regions.

Inside, the electronics are meticulously shielded from the cold. Specialized insulation and double-glazed windows around the components prevent any frost or condensation from affecting the internal workings. This not only protects the delicate circuits but also ensures that the model operates with precision and reliability.

The user interface has been made intuitive and robust. Despite the extreme conditions, the model’s touch screen remains responsive, and the buttons are designed to be used with gloves, making it easy to interact with even when your fingers are numb.

But the real magic of this model lies in its adaptability. It’s not just a cold-resistant device; it’s a versatile tool that can be tailored to a variety of applications. From scientific research to outdoor equipment, the -30°C Cold Resistant Model is ready to serve.

In scientific research, the ability to operate in extreme cold is invaluable. This model can be used in polar expeditions, allowing researchers to collect data without the risk of their equipment failing. It’s a game-changer for those who need to study the effects of cold on the environment or on living organisms.

For outdoor enthusiasts, the model is a dream come true. Whether it’s a mountain climber, a skier, or a hunter, having a device that can withstand the coldest temperatures means that they can stay connected, informed, and safe, even when the temperatures drop below freezing.

The benefits for industries are equally profound. For companies operating in cold climates, the reliability of the -30°C Cold Resistant Model means fewer downtimes and higher productivity. It’s a tool that can be counted on to perform, regardless of the conditions.

In conclusion, the -30°C Cold Resistant Model is more than just a product; it’s a symbol of human ingenuity and the relentless pursuit of excellence. It’s a testament to what we can achieve when we challenge the limits of what’s possible, and it’s ready to take on the coldest of environments with grace and efficiency.

The Challenge of Extreme Cold

Battling the chill of -30°C temperatures presents a daunting challenge that tests the limits of materials, engineering, and human ingenuity. The extreme cold is not just uncomfortable; it can be downright dangerous, affecting everything from human comfort to the functionality of everyday objects.

In such frigid conditions, metal can become brittle, plastics can harden, and electrical systems can malfunction. The human body struggles to maintain a safe core temperature, with the risk of hypothermia a very real concern. Even for the most robust structures, prolonged exposure to -30°C can lead to cracking, warping, and degradation of materials.

The challenge is multifaceted. First, insulation is critical. To prevent the transfer of cold from the environment into the space being protected, materials must be chosen and designed to provide maximum thermal resistance. This often means using high-grade insulation that can withstand the rigors of sub-zero temperatures without losing its effectiveness.

Second, the durability of materials is paramount. Traditional materials may fail under such conditions, so engineers must turn to specialized compounds that are not only heat-resistant but also resilient in the face of harsh cold. This could involve composites or alloys specifically engineered to maintain structural integrity at low temperatures.

Third, the performance of electrical systems must be carefully considered. Batteries lose capacity rapidly in cold weather, and circuits can become less reliable. Designers must account for these factors by using insulating materials and thermal management techniques to ensure that equipment operates effectively.

The cold can also have a psychological impact, affecting morale and efficiency. Workers and users of equipment in sub-zero environments require robust shelters that protect not just the body but also the mind, providing a warm and comfortable space to operate or live.

Another challenge is the logistical aspect of maintaining -30°C conditions. This can require sophisticated heating systems, ventilation strategies, and monitoring to prevent frost buildup and ice formation on surfaces. The cost and energy consumption associated with maintaining such environments can be substantial, necessitating efficient solutions that balance performance with sustainability.

Moreover, the physical world doesn’t just stop because of cold; it adapts. This means that any design intended for -30°C must consider how the environment itself can exacerbate the challenges. Wind chill, for instance, can drop the effective temperature significantly, so any protective structures must be able to withstand both the ambient cold and the added effects of wind.

In the automotive sector, for example, vehicles must not only start in sub-zero conditions but also perform safely and reliably on snowy or icy roads. This means developing tires that offer better traction, brakes that maintain their stopping power, and engines that warm up quickly without consuming excessive fuel.

For outdoor equipment, such as snowmobiles or construction machinery, the challenge is to ensure that the machinery can withstand the cold without compromising its performance. This might involve using lubricants that don’t thicken at low temperatures or designing hydraulic systems that can operate efficiently even when the fluid is colder.

In the medical field, refrigerated medical supplies need to be stored and transported without thawing, even in the most extreme cold. This requires not just cold-resistant containers but also reliable tracking systems to ensure that the temperature is maintained throughout the supply chain.

The -30°C cold resistance challenge is not just about overcoming a temperature; it’s about addressing a complex tapestry of engineering and scientific considerations. From the materials used in construction to the design of wearable technology, every aspect must be meticulously planned to ensure that it can perform under the harshest of conditions. It’s a testament to the ingenuity of engineers and the relentless pursuit of innovation that we continue to push the boundaries of what is possible in the face of such adversity.

Key Features of the -30°C Cold Resistant Model

The -30°C Cold Resistant Model boasts an array of features meticulously designed to thrive in the harshest of winter conditions. From its robust materials to its innovative engineering, here’s a closer look at what sets this model apart:

Incorporating ultra-tough plastics, the model is engineered to withstand the rigors of sub-zero temperatures without succumbing to cracking or losing its structural integrity. This ensures that the device remains durable and functional even when temperatures plummet.

With a specialized coating, the surface of the model is treated to repel ice and snow, reducing the risk of accidental slips or damage. This hydrophobic finish is not just about aesthetics; it’s a practical solution to maintain grip and usability in snowy environments.

The -30°C Cold Resistant Model’s battery life is a standout feature. A cutting-edge thermal management system has been integrated to prevent battery drain in extreme cold. This system actively regulates the battery’s temperature, ensuring a consistent performance throughout the day.

Gadgets and devices often struggle with connectivity issues in cold climates, but not this model. Enhanced antennas and signal processing circuits are built in to maintain strong Wi-Fi, Bluetooth, and cellular connectivity, even when buried under a layer of snow or ice.

The cold-resistant model is designed with user comfort in mind. Its buttons and touchscreens are responsive, even when your fingers are numb. A special thermal conductive pad is used to dissipate heat, allowing for tactile feedback that doesn’t require a warm touch to function.

For those who need to work outdoors, the model’s display is a game-changer. The screen features a high-contrast, anti-reflective coating that makes it readable in direct sunlight and remains clear in low-light conditions. This ensures that the device is as versatile as it is durable.

Durability is further enhanced by reinforced corners and edges, which can withstand accidental drops without sustaining significant damage. This is particularly important in the cold, where glass is more prone to shattering.

One of the most remarkable features is the built-in heating element in the device’s shell. This subtle yet effective addition provides warmth to the user’s hands, making the device not just resistant to the cold but also comfortable to handle in freezing temperatures.

The -30°C Cold Resistant Model doesn’t compromise on security. Despite its cold-resistant design, it maintains a robust level of data encryption and biometric authentication to keep sensitive information secure.

For those working in remote locations, the model’s GPS tracking is enhanced with ice detection capabilities. This ensures that the device can still pinpoint accurate locations even in snowy or icy terrain, which can be treacherous for navigation systems.

Finally, the model is designed with the environment in mind. Its materials are selected for their recyclability and minimal environmental impact, ensuring that even the most resilient device can be responsibly disposed of at the end of its life cycle.

These features, combined with a sleek, modern design, make the -30°C Cold Resistant Model the go-to choice for anyone needing reliable technology in the coldest of conditions.

Engineering Breakthroughs

In the relentless pursuit of innovation, engineering has faced countless challenges, especially when it comes to creating products that can withstand the harshest conditions. The development of a -30°C cold-resistant model is no exception, and it represents a series of remarkable engineering breakthroughs that push the boundaries of what’s possible. Here’s a glimpse into the intricate details that make these advancements stand out:

The first breakthrough lies in the materials science that underpins the construction of the -30°C cold-resistant model. Traditional materials often fail at such extreme temperatures, but engineers have meticulously chosen and combined materials that not only maintain their integrity but also enhance their thermal resistance. This includes advanced composites that offer both flexibility and rigidity, as well as high-performance alloys that can endure the rigors of freezing temperatures without losing their strength.

One of the most critical aspects of engineering a -30°C cold-resistant model is the insulation. Engineers have developed innovative insulation techniques that trap heat and prevent the transfer of cold to the interior. This involves layering materials with varying thermal conductivities, creating a barrier that can withstand the extreme cold. Additionally, the use of phase-change materials that absorb and release heat as temperatures fluctuate ensures a stable internal environment.

The design of the -30°C cold-resistant model is another testament to engineering ingenuity. The structure is optimized for thermal management, with strategically placed heat sinks and radiators that distribute warmth evenly. The design also incorporates heat exchangers that can be used to transfer heat from one part of the device to another, maintaining optimal temperatures across the entire system.

In the realm of electronics, the challenge is to ensure that components do not malfunction or freeze solid in sub-zero temperatures. Engineers have tackled this by using low-power, high-efficiency components that generate less heat and are more resilient to cold. The use of encapsulation materials that can withstand cold and moisture has also been crucial, protecting sensitive circuits from condensation and corrosion.

One of the most significant breakthroughs is in the field of thermoelectric cooling. This technology allows for the active removal of heat from the device, which is essential in maintaining functionality at -30°C. By using thermoelectric modules that convert electrical energy into heat, engineers can manage the internal temperature of the model more effectively, ensuring that it operates reliably in extreme cold.

Another area of innovation is in the power systems. The -30°C cold-resistant model employs advanced battery technologies that can maintain their charge and power output in freezing temperatures. These batteries are designed with a higher energy density and a lower self-discharge rate, making them ideal for continuous operation in cold environments.

The cooling systems within the -30°C cold-resistant model have also seen significant advancements. Conventional cooling methods may not be sufficient in such low temperatures, so engineers have turned to liquid cooling solutions that can maintain optimal temperatures even when air flow is limited. These systems are designed with anti-freeze agents and robust pump mechanisms that prevent the liquid from freezing, ensuring consistent cooling performance.

Moreover, the connectivity of the -30°C cold-resistant model has been enhanced with materials that remain conductive at low temperatures. This means that the device can maintain a stable data transfer rate and network connectivity, even when the ambient temperature drops to -30°C.

Finally, the durability of the -30°C cold-resistant model is a result of extensive testing and validation. Engineers have subjected the device to rigorous cold-weather simulations, ensuring that every component can withstand the extreme conditions. This iterative process has led to a product that is not only functional but also robust, capable of enduring the most challenging environments.

These engineering breakthroughs in the creation of the -30°C cold-resistant model are a testament to human ingenuity and the relentless drive to push the limits of technology. From material science to thermal management, each innovation is a step forward in the quest to conquer the cold.

How It Stands Up to the Cold

In the relentless pursuit of innovation and durability, the -30°C Cold Resistant Model has been engineered to defy the harsh realities of extreme cold. Here’s a closer look at how it stands up to the cold:

The Model’s outer shell is crafted from a specialized, high-density polyurethane that offers superior insulation. This material is not only robust but also designed to maintain its flexibility down to -30°C, ensuring that the model remains weatherproof and intact.

Within the shell, a state-of-the-art thermal management system has been integrated. This system includes an array of heat sinks and a microclimate control unit that actively manages the internal temperature, preventing any frost or condensation from forming.

The model’s electronic components are encased in a protective gel that hardens at, forming a shield against the cold. This gel not only protects the electronics but also allows for a quick return to functionality once the temperature rises.

The battery pack is a marvel of engineering, featuring a proprietary thermal battery case that maintains a stable temperature even in sub-zero conditions. This ensures that the model remains operational, with no risk of battery failure due to extreme cold.

The hinges and joints of the model have been reinforced with cold-resistant materials that maintain their integrity at low temperatures. This prevents any stiffness or freeze-thaw cycles that could lead to mechanical failure.

The -30°C Cold Resistant Model is also equipped with a self-heating function that can be activated to quickly raise the internal temperature to operational levels. This feature is particularly useful in environments where the ambient temperature fluctuates drastically.

The model’s display is a low-temperature, multi-layered glass that is not only scratch-resistant but also retains its clarity in cold conditions. The screen’s coating reflects heat, helping to keep the internal temperature stable.

For added protection, the model is designed with a double-walled structure that provides an additional layer of insulation. This not only shields the internal components from the cold but also helps to dissipate any excess heat generated by the model’s operations.

In the event of a sudden drop in temperature, the model’s advanced alert system is designed to notify the user. This system includes a vibration alert and an audio signal, ensuring that the user is always aware of the model’s condition.

The -30°C Cold Resistant Model’s design is not just about withstanding the cold; it’s about enhancing the user experience in extreme conditions. The model’s interface remains responsive, with no lag or loss of functionality, thanks to its robust software architecture.

The materials used in the construction of the model are not only resistant to cold but also to other environmental factors such as UV radiation and moisture. This ensures that the model remains reliable regardless of the conditions it’s subjected to.

Finally, the model’s maintenance is straightforward. The cold-resistant materials and coatings are designed to be easily cleaned and maintained, with no special tools or procedures required.

In summary, the -30°C Cold Resistant Model is a testament to the ingenuity of modern engineering. It stands up to the cold with a combination of advanced materials, innovative design, and smart technology, making it an unparalleled choice for those who require reliable performance in the harshest of environments.

Real-World Applications

In the face of extreme cold, the -30°C Cold Resistant Model doesn’t just survive—it thrives. Its ability to maintain functionality and durability in sub-zero temperatures is a testament to the ingenuity of modern engineering. Here’s how it stands up to the cold:

The model’s outer shell is crafted from a specialized, high-grade polymer that boasts exceptional thermal insulation properties. This material is designed to trap heat, preventing the cold from seeping in and maintaining the integrity of the internal components. The shell’s surface texture is engineered to minimize frost buildup, ensuring that the model remains grip-friendly even when covered in ice.

Inside, the electronic components are encased in a hermetically sealed, temperature-regulated environment. This internal chamber is equipped with a sophisticated heat exchange system that actively circulates warm air around the sensitive parts, keeping them at optimal operating temperatures. The system is so efficient that it can dissipate heat generated by the components while simultaneously warding off the cold from the outside.

The model’s battery life is another marvel of engineering. It’s equipped with a lithium-ion battery that has been modified to handle extreme temperatures without losing capacity. The battery’s anode and cathode materials are chosen for their stability in cold conditions, and the electrolyte is formulated to remain fluid and conductive down to -30°C. This ensures that the model can operate for extended periods without the risk of a cold-related battery failure.

The -30°C Cold Resistant Model’s display is a standout feature. It utilizes a low-temperature LCD technology that maintains clarity and responsiveness in freezing temperatures. The screen’s surface is treated with a special coating that prevents condensation and frost formation, allowing users to interact with the device without interruption.

The model’s internal sensors are also a marvel. They are designed to operate accurately in cold environments, with algorithms that compensate for the change in temperature. This means that the model can still provide precise readings and maintain its functionality in the harshest of cold conditions.

When it comes to hinges and moving parts, the -30°C Cold Resistant Model doesn’t. The hinges are made from a durable, high-strength metal alloy that doesn’t become brittle in the cold. They are also treated with a special lubricant that remains effective at low temperatures, ensuring smooth operation even when the model is frozen.

The model’s connectivity features are also robust. Its Wi-Fi and Bluetooth modules are designed to maintain a strong signal in cold environments, with antennas that are optimized for performance in sub-zero conditions. This means that users can stay connected to the internet and other devices without experiencing a drop in performance.

The -30°C Cold Resistant Model’s design is not just about withstanding the cold but also about enhancing the user experience. The ergonomics of the device are carefully considered, with contours and materials that provide a comfortable grip even when the hands are cold. The model’s weight is balanced, making it easy to carry and use in cold climates.

In terms of safety, the model is equipped with a range of features that protect the user in extreme cold. Its battery has built-in safety mechanisms to prevent overcharging and overheating, even in frigid temperatures. The device also includes a cold-weather mode that adjusts the performance to prevent damage from the cold.

The -30°C Cold Resistant Model’s ability to stand up to the cold is a result of meticulous engineering and attention to detail. From the materials used to the internal systems designed to maintain optimal temperatures, every aspect of the device has been carefully thought out to ensure it can operate reliably in the harshest of conditions.

Now, let’s delve into the real-world applications of this remarkable model.

The Benefits for Consumers and Industries

In the relentless pursuit of innovation, the development of products that can withstand extreme temperatures has become a cornerstone of modern technology. The -30°C cold-resistant model, with its remarkable ability to function in frigid environments, brings a host of benefits to both consumers and industries. Here’s a closer look at how this marvel impacts our daily lives and professional sectors.

The model’s cold-resistant capabilities are not just a novelty; they are a game-changer for those who operate in environments where cold is a constant challenge. From outdoor enthusiasts to industrial workers, the benefits are multifaceted.

In the realm of consumer electronics, the -30°C cold-resistant model ensures that devices remain reliable and functional in extreme conditions. Imagine a smartphone that doesn’t freeze in sub-zero temperatures, or a camera that captures crisp, clear images even when the air is biting cold. These devices become companions that you can trust, no matter where your adventures take you.

For those who enjoy outdoor activities, such as skiing, snowboarding, or hiking, the cold-resistant model is a godsend. It means that you can stay connected, capture memories, or stay informed without worrying about your gear failing you. It’s not just about convenience; it’s about safety and the peace of mind that comes with knowing your equipment is up to the task.

In the industrial sector, the impact is equally significant. Machinery and equipment that can operate in -30°C temperatures are invaluable in regions where cold is a year-round reality. For example, in the oil and gas industry, where pipelines and drilling equipment are often exposed to severe cold, the cold-resistant model can prevent downtime and ensure that operations continue smoothly.

The agricultural industry also benefits greatly. In cold climates, crops and livestock require careful monitoring and management. The -30°C cold-resistant model allows for real-time data collection and analysis, enabling farmers to make informed decisions that can lead to better yields and healthier animals.

For businesses, the cold-resistant model can extend the lifespan of their products, reducing the need for frequent replacements and repairs. This, in turn, leads to cost savings and a more sustainable approach to product management.

In the medical field, the cold-resistant model is a crucial asset. It ensures that medical equipment, such as blood analyzers or refrigerators for vaccines, can operate reliably in cold storage facilities or during transport to remote areas. This is particularly important in regions where access to medical care is limited, as it can mean the difference between life and death.

The benefits extend to the transportation industry as well. Trucks and vehicles equipped with cold-resistant components can operate in extreme conditions, ensuring that goods can be delivered to their destinations without delay. This is especially crucial for perishable items that require immediate delivery to maintain quality.

Moreover, the cold-resistant model can enhance the efficiency of renewable energy systems, such as solar panels and wind turbines, which often operate in cold environments. By ensuring that these systems can continue to generate power even in the coldest temperatures, the model supports the growth of sustainable energy sources.

In the construction industry, the ability to work in extreme cold is invaluable. The cold-resistant model allows for year-round construction projects, reducing the impact of seasonal delays and increasing productivity.

The impact of the -30°C cold-resistant model on consumers and industries is profound. It represents a leap forward in technology that not only withstands the cold but thrives in it. This innovation is more than just a technological advancement; it’s a testament to human ingenuity and a bridge to a future where the cold is no longer a barrier to progress.

Final Thoughts on Cold Resistance Innovation

The development of cold resistance technology has revolutionized how we interact with the elements, particularly in regions where extreme temperatures are a constant challenge. As the -30°C cold resistant model showcases, innovation in materials, design, and engineering has opened new doors for consumers and industries alike. Let’s delve into the benefits that this breakthrough brings.

Innovation in materials science has been pivotal in the creation of the -30°C cold resistant model. Traditional materials often fail under such harsh conditions, but these advancements have introduced a new generation of materials that are not just durable but also adaptable to extreme cold. This means that the model can maintain its integrity and functionality, providing a reliable solution in environments where traditional products would falter.

The benefits for consumers are immediate and varied. For those living in regions where winter temperatures plummet, the -30°C cold resistant model offers peace of mind. Whether it’s a car that can be relied upon to start every morning or a smartphone that doesn’t freeze in your pocket, the implications are significant. Consumers can enjoy the conveniences of modern life without the fear of technology failing them when they need it most.

Industries that operate in cold climates also stand to gain. Construction, transportation, and energy sectors all benefit from equipment that can withstand the rigors of extreme cold. For instance, in the Arctic, where icebergs and snow are a constant presence, the -30°C cold resistant model can be crucial for maintaining operations in the harshest of conditions. This not only ensures the safety of workers but also the efficiency of operations.

One of the most notable benefits is the increased lifespan of products. Cold resistance means that items are less prone to wear and tear, which can lead to costly repairs or replacements. By investing in the -30°C cold resistant model, consumers and industries can expect a longer-lasting product that requires less maintenance, saving both time and money in the long run.

In terms of economic impact, the adoption of cold-resistant technology can lead to a reduction in energy consumption. For example, buildings equipped with -30°C cold-resistant materials may require less heating, lowering energy bills and contributing to a smaller carbon footprint. This environmental benefit is a significant consideration for both consumers and businesses looking to align their operations with sustainable practices.

The technological advancements behind the -30°C cold resistant model have also sparked a ripple effect across various industries. Manufacturers are now pushing the boundaries of what is possible, exploring how to apply this cold resistance to other products and sectors. This cross-pollination of ideas can lead to unexpected breakthroughs and further innovations that will benefit society as a whole.

Moreover, the development of such technology has also had a positive impact on safety. In the past, workers in cold environments had to rely on more primitive methods and equipment, which were often unreliable. Now, with the -30°C cold resistant model, there’s a greater level of confidence that the tools and machinery they use will perform as expected, even in the most frigid conditions.

As we look at the broader picture, the benefits of cold resistance innovation are not just confined to the product itself. It’s about the entire ecosystem that surrounds it. From the suppliers of raw materials to the designers, engineers, and end-users, each part of the process benefits from the increased reliability and performance that cold-resistant technology brings.

In conclusion, the advent of the -30°C cold resistant model has brought about a multitude of benefits for both consumers and industries. From enhanced safety and efficiency to economic and environmental advantages, the impact of this innovation is far-reaching. It’s a testament to what can be achieved through perseverance, creativity, and a relentless pursuit of excellence in engineering and materials science. As we continue to push the limits of what’s possible, we can expect that the benefits of cold resistance will only grow, improving our lives and shaping the future of technology in the coldest corners of the world.